QA Supervisor (08.00x)

Software

General Data Protection Regulation (GDPR)

This product offers the possibility to process personal identifiable information such as system user name, role and IP-address. The purpose of this processing capability could be to enhance quality control through traceability and proper access management.

If you decide to process personal data you need to be aware of and comply with relevant personal data protection rules, including, in the EU the GDPR as well as other applicable laws, directives and regulations. Atlas Copco can in no way be held liable for any use made by you of the product.

Introduction

Target group

This user guide is intended for personnel using QA Supervisor for example:

Operator

Product function

Error reporting

Troubleshooting

Production technician

General function

Communication

System input/output

Quality engineer

Results / statistics

Data backup

IT/System maintenance

System capability

System monitoring

Data input style.

The objects in this documentation marked with " " or < > are variable values or data text field. The objects are highlighted and used together with the System data style. Insert the value between the characters " " and replace the < xxxxxx > as shown in the example.

Example:

<add name="SQL_Server"....User ID=User; Password=<Password>==;<add name="Tools_Server"....User ID=User; Password=UserPassword==;

Conventions

To enhance user understanding, certain formatting conventions are used throughout this document. The formatting conventions used are listed below.

Element | Notation | Description | Output |

|---|---|---|---|

General emphasis | In the Program workspace. | To make certain text elements stand out, or to highlight. | Text in Bold |

Graphical User Interface (GUI) items | Select the Function button. | Any reference to items found on screen in the GUI (for example, command buttons, icon names and field names). | Text in Bold |

Graphical User Interface (GUI) Path > | Generally, on the top of the GUI. | Navigation aid which keeps track of the location in the GUI. | For example: Controller > Program > Edit |

User input | Enter a Description for the program. | Any text input by the user. | Text in Bold |

File names | Enter a File Name for the export. | Files either exported from, or imported into the system. | Text in Bold Italic |

Variable and parameter names | Enter a Name for the export. | Variable and parameter names (not values). | Text in Italic |

Variable and parameter values | Enter a VALUE for the export. | Variable and parameter values. | Text in BOLD CAPS |

System output | Client.Domain.Models.ExportImportConfiguration | Any text output by the system. | Text in Monospace |

External links | Links to external sites that have information connected to the document or subject content. These could include:

| Selectable text to external sites | |

Internal documentation links |

If available, these links will be presented below the text. | Selectable text to internal content |

About the manual

The configuration manual is divided into the following sections:

Introduction: it explains the structure of the manual and the conventions used to explain the configuration.

Getting Started: it explains how to start the system and the main functions the operator can perform.

Features: the main bulk of the manual describes the various settings and configurations that can be performed by the operator.

The settings are divided into three categories:

Concept: it provides information about the settings or parameters.

Task: it provides instructions how to do the configuration.

Reference: it provides tables and listings of the parameter names descriptions and default values.

References: it gives the sources of the information related to the method of the inspections.

Third party licenses: if third party intellectual property is used in the product, it is described in this section.

The Features chapter follows the user interface structure. The various icons are explained and instruction procedures explain how configurations are created and edited.

Revision history

Software version | Change |

|---|---|

08.00x |

|

07.05x |

|

07.04x |

|

07.03x |

|

07.02x | - |

07.01x |

|

07.00x |

|

06.03x |

|

06.02x |

|

06.01x |

|

06.00x |

|

04.05x |

|

04.04x |

|

04.03x |

|

04.02x |

|

04.01x |

|

04.00x |

|

03.01x |

|

03.00x |

|

02.00x |

|

01.03x |

|

01.02x |

|

01.01x |

|

Getting started

Prerequisites

Many events in the operating environment may affect the tightening process and shall require a validation of results. In compliance with applicable standards and/or regulations, we hereby require to check the installed torque after any event that can influence the tightening result. Examples of such events include but are not limited to:

initial installation of the tooling system

change of part batch, bolt, screw batch, tool, software, configuration or environment

change of air- or electrical connections

change in line ergonomics, process, quality procedures or practices

changing of operator

any other change that influences the result of the tightening process

The check should:

ensure that the joint conditions have not changed due to events of influence

be done after initial installation, maintenance or repair of the equipment

occur at least once per shift or at another suitable frequency

Anyone interested in learning more can benefit from reading this manual and other QA Supervisor documentation.

Before starting the application ensure that:

the QA Supervisor server application is installed

controllers are configured to communicate with the QA Supervisor server application

Browser requirements

Google Chrome 112

Microsoft Edge 112 (chromium)

Mozilla Firefox 112

The browser zoom must always be set to 100% while using the application.

TLS versions prior to 1.2 are no longer supported.

Default ports

Port number | Function | Direction |

|---|---|---|

1883 | MQTT | Out |

4711 | QA Station MT/Open Protocol | In |

7102 | NotificationService | Out |

7110 | ACDC | Out |

8080 | QA Supervisor http port | In |

8443 | QA Supervisor https port | In |

9990 | QA Supervisor http management port | In |

9993 | QA Supervisor https management port | In |

60005 | STpad/STpalm/STbench | Out |

60101 | JSB (QA Supervisor Agent) | Out |

60102 | STa6000 (QA Supervisor Agent) | Out |

Starting the QA Supervisor

In a web browser, enter the URL http://<IP address or hostname>:8080/qasupervisor or https://<IP address or hostname>:8443/qasupervisor.

<IP Address> is the IP Address of the QA Supervisor Application Server.

<hostname> is the hostname of the QA Supervisor Application Server.

To make a safe connection, it is necessary to install a certificate. Contact the Atlas Copco Service Personnel for the installation of the certificate.

In the Username box and in the Password box, type the user name and the password, respectively.

Then, click Login.

After five failed logins, the user is disabled. To enable the user again, login the application as admin and edit the user configuration by changing the Status.

After five failed logins as Admin, the Admin user is disabled. To enable the user again, contact the Atlas Copco Service Personnel.

Features

Settings

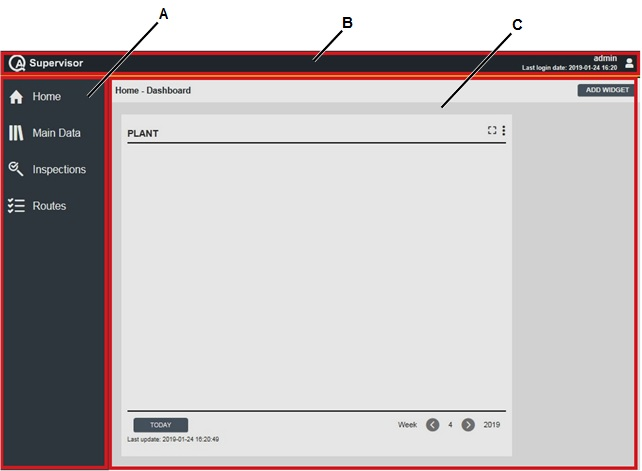

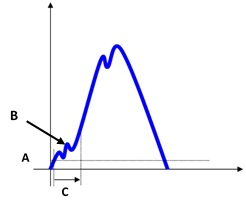

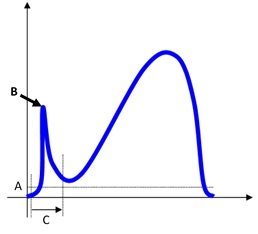

After a successful start of QA Supervisor, the following is displayed:

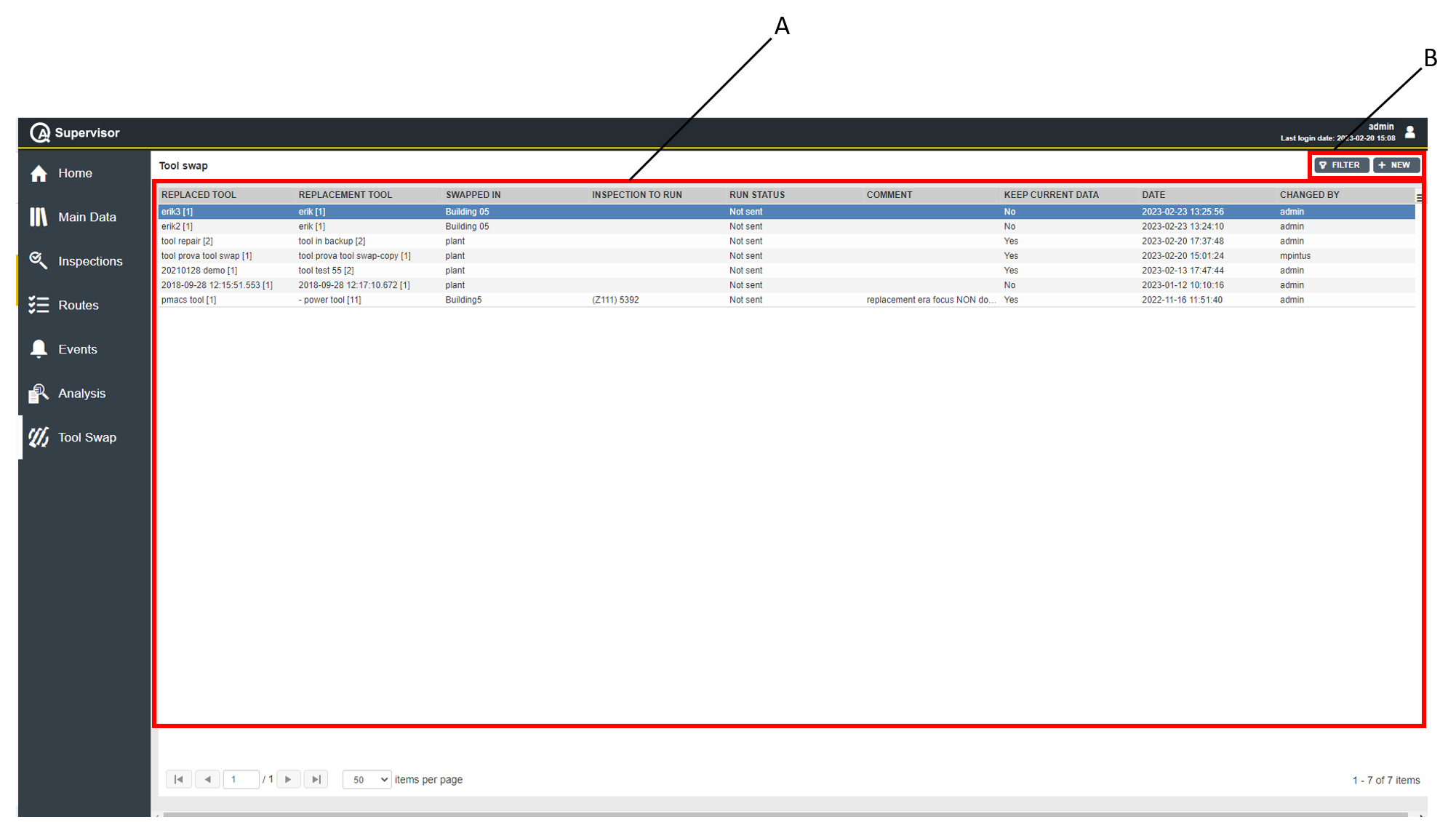

A | Left-side menu bar | B | QA Supervisor menu bar |

C | QA Supervisor workspace | ||

QA Supervisor workspace area displays different content and depends on the selected menu.

Navigate the left-side menu bar to view or edit any configuration parameters (for more information, see Main Data, Inspections, and Routes).

QA Supervisor menu bar is always on the top of the software page.

On the right side, the user name with the related user picture and the last login date are displayed.

Click the user name/user picture to open the following:

Application settings

Application custom fields

Personal settings

Notifications

Change password

Logout

Viewing/editing application settings

Each page of QA Supervisor software complies with the Application settings parameters selected in the Application settings page for all the users configured in the application.

On the right side of the QA Supervisor menu bar, click the user name/user picture. Then, click Application Settings.

Configure the available parameters.

Click on Save.

Application settings parameters

Application version: current version of the application.

General parameters

Background picture: click on the Add icon (

) to upload a new picture, or click on the Delete icon (

) to upload a new picture, or click on the Delete icon ( ) to restore the default Atlas Copco background picture.

) to restore the default Atlas Copco background picture.Date format: from the drop-down list, select the date format to use in the application.

Language: from the drop-down list select the language of the application.

Report format: from the drop-down list, select between DOCX and PDF.

Report logo: click on the Add icon (

) to upload a new picture and customize the logo displayed in the reports, or click on the Delete icon (

) to upload a new picture and customize the logo displayed in the reports, or click on the Delete icon ( ) to restore the default Atlas Copco logo.

) to restore the default Atlas Copco logo.Online interval check: from the drop-down list, select between 30 s or 60 s.

Torque measurement unit: from the drop-down list, select the measurement unit to use in the application.

Status for replaced tool: from the drop-down list, select the default status for the tool to replace in a tool swap operation.

OP devices: retrieve old results: by default enabled; when an Open Protocol measuring device is connected for the first time, all the results stored in the device are transferred to QA Supervisor.

Once the measuring device is connected, this setting cannot be changed for the single device: if the switch is enabled, the old results are always retrieved; if the switch is disabled, the old results can no longer be retrieved.

If this option is disabled, at least one measurement must be stored in the device before connecting it to QA Supervisor.

If the new measuring device is created manually, it is possible to override this setting during the configuration of the Measuring Device parameters.

Deleted measurements

In the Deleted measurements section, select the Deleted measurements options to display the deleted results of the tests made by STbench/ STpad/STpalm.

Click on the switches to enable/disable the following options:

Display in pages and export: by enabling this option, it is possible to display the deleted results in the Data details card and in the exported excel files.

Display in reports: by enabling this option, it is possible to display the deleted measurements in the tests reports.

Not detected measurements

In the Not detected measurements section, select the Not detected measurements options to display the measurements not detected by STbench/STpad/STpalm.

Click on the switches to enable/disable the following options:

Display in pages and export: by enabling this option, it is possible to display the not detected measurements in the Data details card and in the exported excel files.

Display in reports: by enabling this option, it is possible to display the not detected measurements in the tests reports.

Traces

Display traces in application: by enabling this option, the Traces menu and the traces linked to the joints are displayed in the application.

Custom URLS

In the Custom URLS section, it is possible to add up to four URLS that will be available for navigation on STbench/ STpad/STpalm.

For each URL, type the name of the label. The labels will be displayed on STbench/ STpad/STpalm.

The web browser navigation bar will not be present on the devices: navigation is limited to the configured URLs and some basic browser functionality are inhibited (such as: next, back, refresh, right-click, etc.).

Due to screen size, QA Supervisor is not available for navigation on STpalm.

Additional status (for not in use tools)

In the Additional status (for not in use tools) section, define the condition of the tools that are not in use.

Assign a customized name to each status by typing the name in the Status text box.

Then, enable/disable one or more statuses by clicking on the status switch.

Status text boxes must always have a name.

The maximum number of characters for the Status name is 50.

It is not allowed to configure two statuses with the same name.

API communication

API are a set of commands that allow to integrate QA Supervisor with other systems.

In the API communication section, click on the switch to enable/disable API communication.

By default, the API enable switch is disabled.

Default values

In the Common section of the Default values, configure the parameters common to all inspections.

In the Default values section, configure the default values for Tool check, Joint check, Visual check, and Dimension inspections.

For the SPC inspections of each type, it is possible to enable a custom set of rules to be used by STpad.

In the Default value, click the value of the Enabled rules.

In the SPC Enabled rules page, enable or disable the rules to use and click Apply.

ToolsNet 8 Settings

Connectivity

In the Connectivity section, type the IP address/hostname and port of the following ToolsNet 8 services:

Data communication service: the default port is 7110.

Notification service: the default port is 7102

MQTT server: the port is optional; the connection must be open without credentials.

Click on the Check button placed next to each service to check the connection between QA Supervisor and ToolsNet 8 services. A popup message with the status of the connection is shown, and the following details are displayed in the ToolsNet 8 Parameters section: application name; application version; API version.

If an older version of ToolsNet 8 is used, additional information on QA Supervisor features not supported by the ToolsNet 8 version in use are displayed.

Refer to the ToolsNet 8 manuals for more information about these services.

Automatic Tool Import

In the automatic tool import sections, it is possible to set up the parameters used for the tool synchronization.

Enable automatic tool import: by enabling this option, the tool synchronization will be activated.

Do not enable automatic tool import unless the parameters below have been checked. Imported tools can’t be deleted.

The below fields are disabled if the enable automatic tool import is not enabled.

Tools used in the last ... months: only tools that have performed a tightening in the specified time frame are synchronized from ToolsNet.

Default location: select the location where the imported tools are placed.

Default status: select the status that is assigned to the imported tools.

Default manufacturer: select the manufacturer that is set for the imported tool model.

During the tool synchronization several scenarios could occur:

Scenario 1: the part code is sent from ToolsNet 8 and a tool model with the same part code is already defined. In this case, the new tool is created with the already defined tool model.

Scenario 2: the part code is sent from ToolsNet 8 but a tool model with the same part code is not defined. In this case, the new tool is created with a brand new tool model with a generic type

Scenario 3: the part code is not sent from ToolsNet 8. In this case, the tool is created without a model.

For scenarios 2 and 3, a manual user action is needed complete the data. It is not possible to create inspections on tools that don’t have a tool model or tools with a generic tool model.

Viewing/editing the application custom fields

In order to enable the custom fields on STbench/STpad/STpalm it is mandatory to configure and save the Application custom fields.

On the right side of the QA Supervisor menu bar, click the user name/user picture. Then, click on Application Custom fields.

In the Route custom fields section, add/select/remove the custom fields that will be used as filters for the routes on STpad/STpalm/STbench.

Click on Save.

The custom fields configured in the Application custom fields are automatically added in each new route created.

Application custom fields parameters

Custom field 1-5: add/select/remove the custom field.

Do one of the following:

Click Add icon (

) to add a new custom field.

) to add a new custom field. In the Add Selectable card, configure the available parameters related to the new custom field.

Then, click Save.

Click Search icon (

) to select a custom field already configured.

) to select a custom field already configured.In the Selectables card, select a custom field from the list.

Then, click Apply.

Click Delete icon (

) to remove the custom field.

) to remove the custom field.

For more information on how to create Selectables, refer to the paragraph Selectables.

Reports settings

The customizable analysis reports are: CmCmk/CpCpk trend, Capability, Gage R&R.

The customizable inspection results reports are: CmCmk, SPC (tool), Tool calibration.

To customize the template of a report:

On the right side of the QA Supervisor menu bar, click the user name/user picture. Then, click Reports settings.

On the left side of the Reports settings workspace, click on the report of interest to open the configuration card.

Download the Standard template and make adjustments as needed.

In the Custom template section, click on the Select button to upload the edited template.

Once uploaded, the switch placed next to the report selected changes from Standard to Custom.On the upper-right corner of the Reports settings page, click Save.

To restore the standard template of a report:

On the right side of the QA Supervisor menu bar, click the user name/user picture. Then, click Reports settings.

On the left side of the Reports settings workspace, click on the report of interest to open the configuration card.

In the Custom template section, click on the Delete button to remove the custom template.

Once deleted, the switch placed next to the report selected changes from Custom to Standard.On the upper-right corner of the Reports settings page, click Save.

Viewing/editing personal settings

On the right side of the QA Supervisor menu bar, click the user name/user picture. Then, click Personal settings.

On the left side of the Personal settings page, enter the Personal details.

On the left side of the Personal settings page, below the Personal details, enter the Company contacts information.

On the right side of the Personal settings page, select the Preferences.

On the right side of the Personal settings page, below the Preferences, select the Measurement unit.

Each page of QA Supervisor software agrees with the Preferences and the Measurement unit selected in the Personal settings page.

On the upper-right corner of the Personal settings page, click Save.

Viewing/editing notifications

On the right side of the QA Supervisor menu bar, click on the user name/user picture. Then, click Notifications.

On the left side of the Notifications workspace, click on the switches to enable/disable the following event notifications:

Inspection NOK: if enabled, a notification is sent when an inspection result is NOK.

Inspection expired: if enabled, a notification is sent when an inspection is expired.

Inspection expiring: if enabled, a notification is sent before an inspection expires.

Certificate expired: if enabled, a notification is sent when the certificate of a transducer or measuring device is expired.

Tightening program changed: if enabled, a notification is sent when a Tightening program that belongs to an inspection is changed.

Tool import (from ToolsNet 8): if enabled, a notification is sent when a Tool is imported from ToolsNet 8.

Tool model import (from ToolsNet 8): if enabled, a notification is sent when a Tool Model is imported from ToolsNet 8.

Tool Swap: if enabled, a notification is sent when a Tool Swap operation is performed.

On the left side of the Notifications workspace, click on each notification to open the configuration card.

For each notification, configure the available parameters.

Notifications parameters

Location (*): select the area of the plant where to send the event notification. By default it is set to the is the location of the user.

To change the default location:

Click Location icon (

).

).In the Location dialog box, select the area of the plant.

Then, click Apply.

Inspection Type

Tool check: click on switch to enable/disable the notification event for Tool check inspections.

Joint check: click on switch to enable/disable the notification event for Joint check inspections.

Visual check: click on switch to enable/disable the notification event for Visual check inspections.

Dimension: click on switch to enable/disable the notification event for Dimensional inspections.

By part grouping: click on switch to enable/disable the notification event for By part grouping inspections.

Expiring filters

The following parameters are displayed only for the Inspection expiring notification.

If the Inspection expiring notification is enabled, at least one of the following Expiring filters must be set. The Expiring filters can be combined together.

Expiry period %: by setting a percentage value from 50 to 99, a notification is sent when the inspection expiry period reaches the defined percentage value.

Remaining days: by setting a number of days from 1 to 364, a notification is sent when the defined remaining days before expiration are reached.

Remaining hours: by setting a number of hours from 1 to 72, a notification is sent when the defined remaining hours before expiration are reached.

Expiry date: from the drop-down list, select between:

Today: by selecting this value, a notification is sent the day of the inspection expiration date.

Tomorrow: by selecting this value, a notification is sent the day before the inspection expiration date.

This month: by selecting this value, a notification is sent for the inspections expiring in the current month.

Next month: by selecting this value, a notification is sent for the inspections expiring during the next month.

Notification channels

Online: click on the switch to enable/disable the notifications online.

To receive notifications of the events, the Online switch must be enabled.

Email: click on the switch to enable/disable the notifications by emails.

To enable the reception of notifications by email, contact Atlas Copco Service Personnel.

The notification emails are sent to the email address set in the Personal settings. To set or change the email address, refer to the paragraph Viewing/editing personal settings.

Changing the password

On the right side of the QA Supervisor menu bar, click the user name/user picture. Then, click Change password.

In the Password box, type the old password.

In the New password box, type the new password.

In the Confirm new password box, type the new password again.

On the lower-right corner of the Change password dialog box, click Save.

In the upper-right corner of the Change password dialog box, click Close button to exit the Change password dialog box without saving any change.

Follow these requirements for the New password:

The New password must be 8 to 25 characters long.

The New password must have one upper case character (at least).

The New password must have one lower case character (at least).

The New password must have one number (at least).

Empty spaces are permitted.

Upper/lower case characters with accent are not upper/lower case characters.

CODE 39 character set is permitted.

Home page

On the left-side menu bar, click Home.

The Home page displays a widget that lists all the scheduled inspections to be done during each day of the selected week. Within the selected week, the inspections are ordered according to date and time.

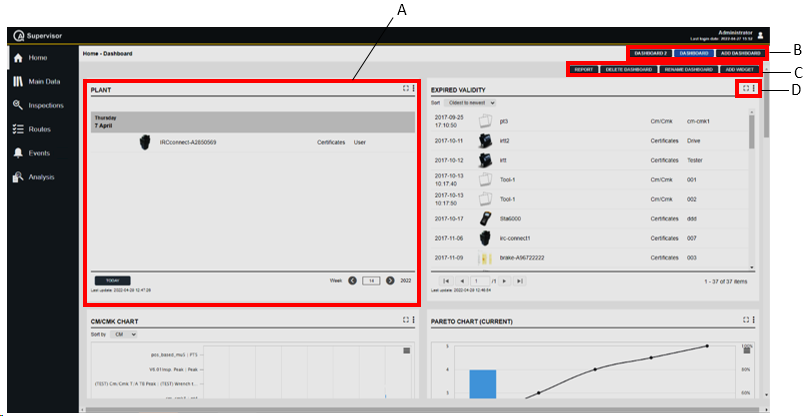

If the Dashboard license is activated, it is possible to configure other types of widgets and to create multiple dashboards:

A | Example of a widget | B | Navigate dashboards / Add dashboard |

C | Dashboard command buttons | D | Widget icons |

In the Home - Dashboard workspace, configure the following widgets:

Calendar: widget that shows the due date of Measuring device and Transducer calibration certificates and scheduled inspections.

Cm/Cmk: widget that shows the worst values of Cm and Cmk for each pair tool – executed inspection.

Pareto: widget that shows the Pareto chart of the NOK results related to a tool.

Expirations: widget that lists all the expired Measuring device and Transducer calibration certificates and scheduled inspections.

Cp/Cpk: widget that shows the worst values of Cp and Cpk for each pair joint – executed inspection.

Sent routes: widget that shows the status and the scheduling of each Route sent to the measuring devices.

If the Dashboard license is not active, only the Calendar widget is displayed in the dashboard.

Calendar widget

The Calendar widget shows for each day the scheduled inspections to be done and the expired calibration certificates of measuring devices and transducers.

On the upper-right corner of the Calendar widget, the following icons are shown:

Full screen: click to enlarge and show only the widget.

Menu: click to change the configuration of the widget (for more information, see “Adding Calendar widget(s)”).

On the lower-left corner of the calendar page, click Today: the current week is displayed and the current day is yellow highlighted in case of scheduled inspection(s).

On the lower-right corner of the calendar page, click the arrow keys to browse all of the scheduled inspections, week by week.

Cm/Cmk widget

The Cm/Cmk widget shows the worst values of the Cm and related Cmk for each pairs of executed inspection – tool ordered by increasing Cm or Cmk values.

On the upper-right corner of the Cm/Cmk widget, the following icons are shown:

Full screen: click to enlarge and show only the widget.

Menu: click to change the configuration of the widget (for more information, see “Adding a Cm/Cmk widget”).

Above the Cm/Cmk graph, the Sort by filter is displayed. Select one of the available options to give an order to the data depending on Cm or Cmk.

On the upper-right corner of the graph, a menu to print and download the chart as image is displayed. Select one of the options.

Pareto widget

The Pareto widget shows the histogram of the NOK results of an ispection of type: Tool check, Joint check, Visual check, and Dimensional check.

On the upper-right corner of the Pareto widget, the following icons are shown:

Full screen: click to enlarge and show only the widget.

Menu: click to change the configuration the widget (for more information, see “Adding a Pareto widget”).

On the upper-right corner of the graph, a menu to print and download the chart as image is displayed. Select one of the options.

Expirations widget

The Expirations widget shows for each day the expired inspections and calibration certificates of measuring devices and transducers.

On the upper-right corner of the Expirations widget, the following icons are shown:

Full screen: click to enlarge and show only the widget.

Menu: click to change the configuration of the widget (for more information, see “Adding Expirations widget”).

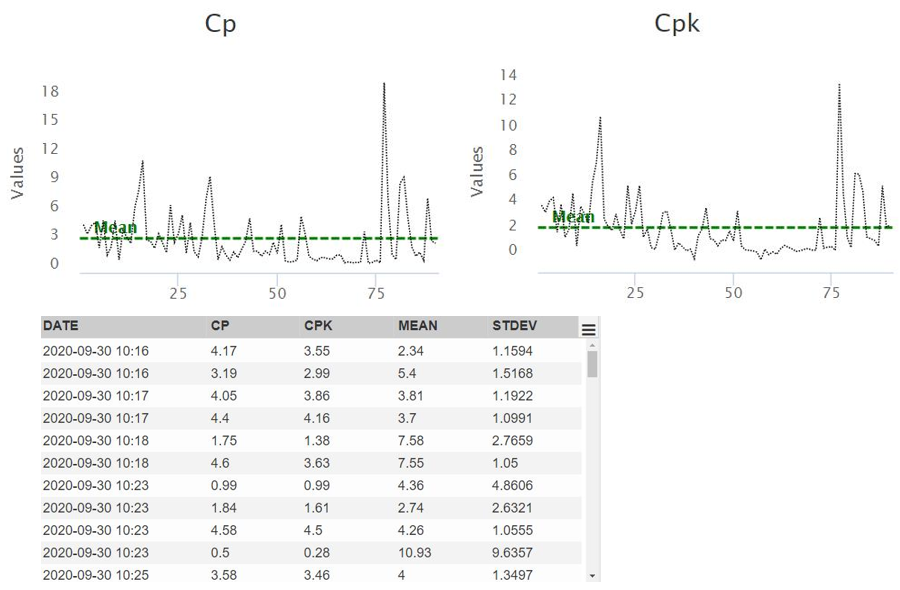

Cp/Cpk widget

The Cp/Cpk widget shows the worst values of the Cp and related Cpk for each pairs of executed inspection – tool ordered by increasing Cp or Cpk values.

On the upper-right corner of the Cp/Cpk widget, the following icons are shown:

Full screen: click to enlarge and show only the widget.

Menu: click to change the configuration of the widget (for more information, see “Adding a Cp/Cpk widget”).

Above the Cp/Cpk graph, the ”Sort by” filter is displayed. Select one of the available options to give an order to the data depending on Cp or Cpk.

On the upper-right corner of the graph, a menu to print and download the chart as image is displayed. Select one of the options.

Sent routes widget

The Sent routes widget shows the status and the scheduling of each route sent to the measuring devices.

On the upper-right corner of the Sent routes widget, the following icons are shown:

Full screen: click to enlarge and show only the widget.

Menu: click to change the configuration of the widget (for more information, see “Adding Calendar widget(s)”).

Adding a widget

On the upper-right corner of the Dashboard workspace, click Add widget.

In the Add widget dialog box, select le widget type to add.

On the lower-right corner of the Add widget dialog box, click OK.

On the upper-right corner of the Widget, click Menu icon to select one of the following options:

Resize: select Resize to decrease the widget size to half.

Move down: select Move down to move the widget to the next position, if more than one widget is configured.

Move up: select Move up to move the widget to the previous position, if more than one widget is configured.

Configure: set the options to filter the widget data.

Delete: select Delete to delete the widget.

On the lower-right corner of the Widget, click OK.

Calendar widget configuration

Location: select an element of the factory structure tree.

Title: type the name of the widget in the Title text box or type the mark up listed below the title text box.

Due date: select one of the following due date: Inspection expiring or Calibration certificate expiring.

Type: select inspection type. The available types are: Tool check or Joint check. The Type filter is available only if Inspection expiring is selected as due date.

Method: select the inspection method. It depends on the selected inspection type. The Method filter is available only if Inspection expiring is selected as due date.

Refresh: select the time to refresh automatically the widget. The available value are: None, Every minute, Every 5 minutes, Every 15 minutes.

Cm/Cmk widget configuration

Location: select an element of the factory structure tree.

Title: type the name of the widget in the Title text box or type the mark up listed below the title text box.

Controlled variable: select the variable to control. The available options are: Angle and Torque.

Number of object: select the number of value to display. The available values are: 5, 10, 20, and 50.

Refresh: select the time to refresh automatically the widget. The available value are: None, Every minute, Every 5 minutes, Every 15 minutes.

Pareto widget configuration

Location: select an element of the factory structure tree.

Date range: filter the date range. Do one of the following:

From - to: click the box to open a calendar. Select the date from the calendar. Then, click Delete icon (

) to delete a date already configured.

) to delete a date already configured.Range: in the Range drop-down list, select a specific time interval.

Title: type the name of the widget in the Title text box or type the mark up listed below the title text box.

Type: select inspection type. The available types are: Tool check, Joint check, Visual check or Dimensional check.

Method: select the inspection method. It depends on the selected inspection type.

Refresh: select the time to refresh automatically the widget. The available value are: None, Every minute, Every 5 minutes, Every 15 minutes.

Expirations widget configuration

Location: select an element of the factory structure tree.

Title: type the name of the widget in the Title text box or type the mark up listed below the title text box.

Due date: select one of the following due date: Inspection expiring or Calibration certificate expiring.

Type: select inspection type. The available types are: Tool check or Joint check. The Type filter is available only if Inspection expiring is selected as due date.

Method: select the inspection method. It depends on the selected inspection type. The Method filter is available only if Inspection expiring is selected as due date.

Refresh: select the time to refresh automatically the widget. The available value are: None, Every minute, Every 5 minutes, Every 15 minutes.

Cp/Cpk widget configuration

Location: select an element of the factory structure tree.

Title: type the name of the widget in the Title text box or type the mark up listed below the text box.

Controlled variable: select the variable to control. The available options are: torque (default value), area, force, pressure, length, volume.

Number of object to show: select the number of value to display. The available values are: 5, 10, 20.

Refresh: select the time to refresh automatically the widget. The available value are: None, Every minute, Every 5 minutes, Every 15 minutes.

Sent routes widget configuration

Title: type the name of the widget in the Title text box.

Status: select one or more statuses. The available statuses are: Pending, Sent, Got results, Not sent.

Route name: type the name of the route(s) to display.

Refresh: select the time to refresh automatically the widget. The available values are: None, Every minute, Every 5 minutes, Every 15 minutes.

Adding a Dashboard

If the Dashboard license is active, it is possible to create up to 10 different dashboards.

On the upper-right corner of the Home - Dashboard workspace, click Add dashboard.

On the upper-right corner of the Home - Dashboard workspace, using the command buttons it is possible to:

Report: create a report to export the information of the widget(s) contained in the selected dashboard. The widgets exported are: Pareto widget, Cm/Cmk widget, Cp/Cpk widget.

Delete dashboard: delete the selected dashboard.

Rename dashboard: rename the selected dashboard.

Add widget: add one or more widget types.

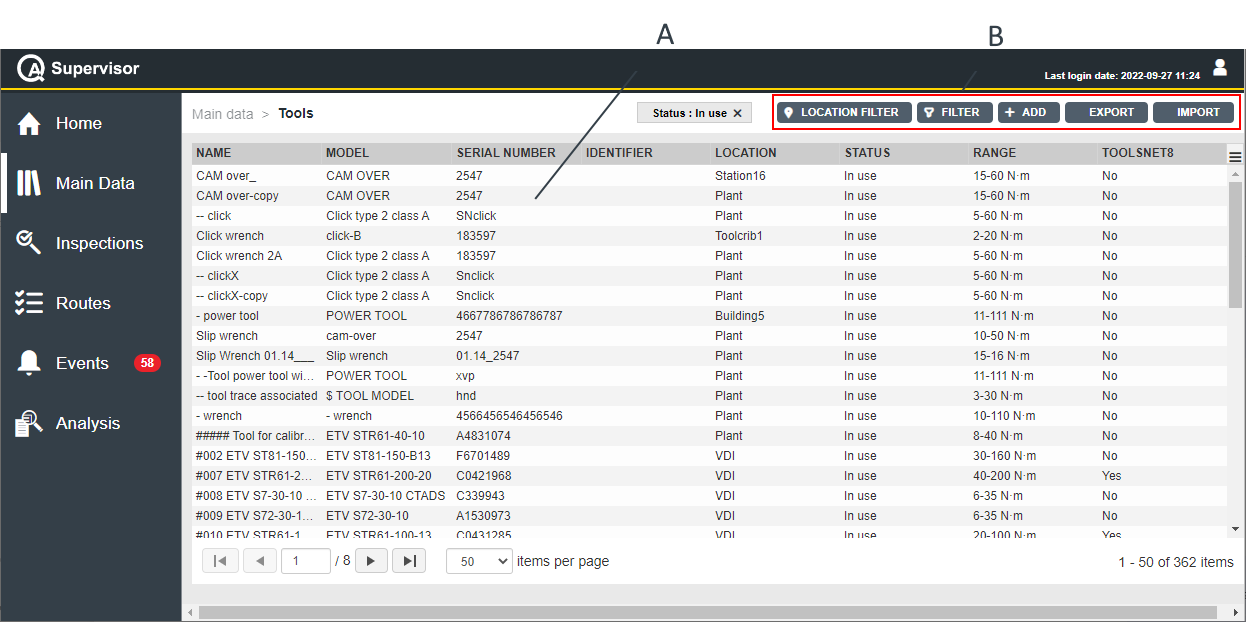

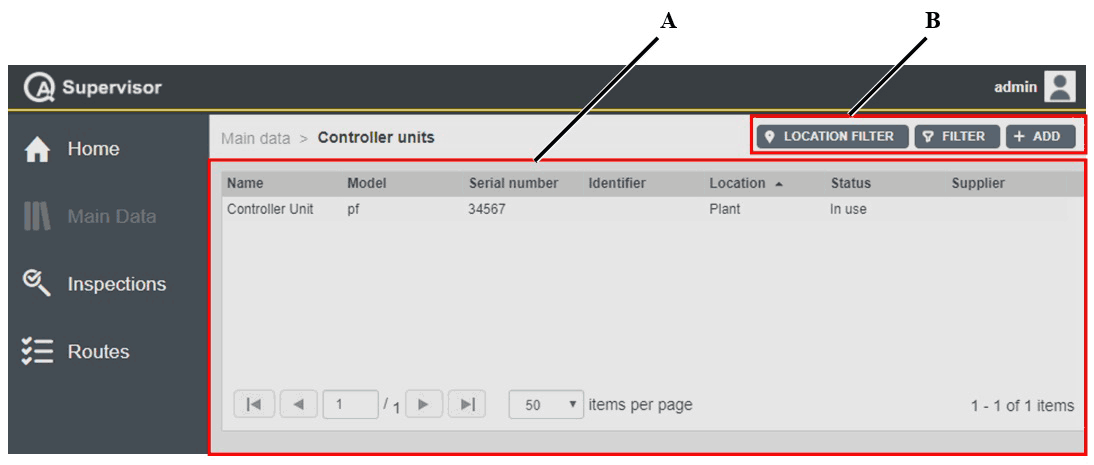

Main Data menu

On the left-side menu bar, click Main Data to configure the following items:

Measuring devices

Transducers

Joints

Tools

Controller units

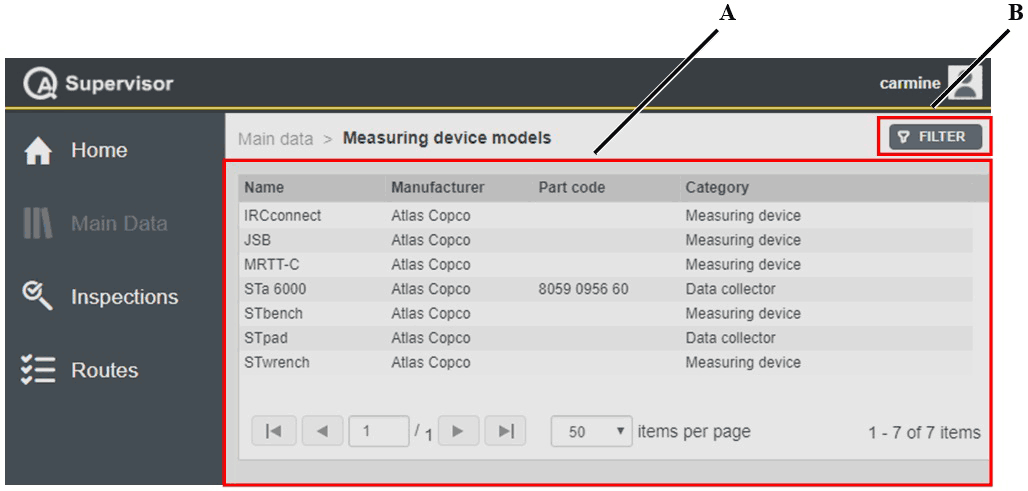

Measuring devices models

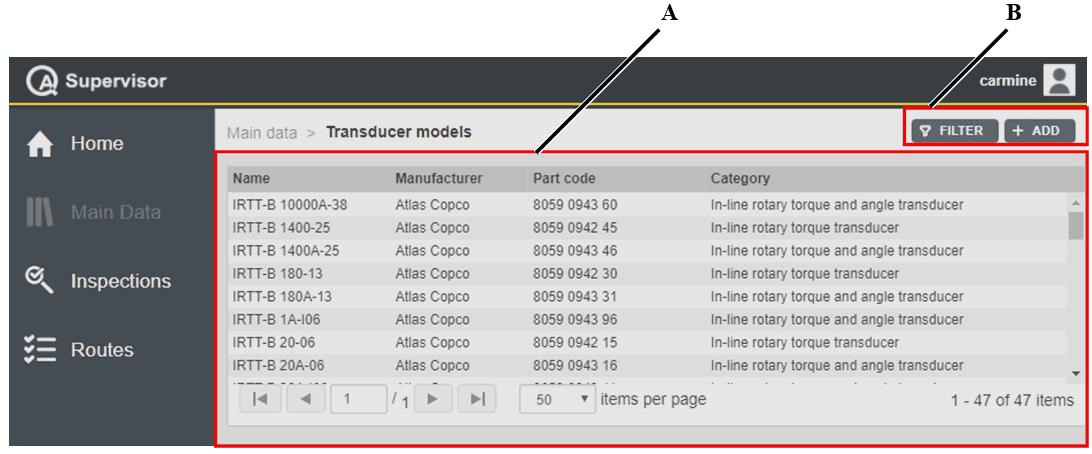

Transducer models

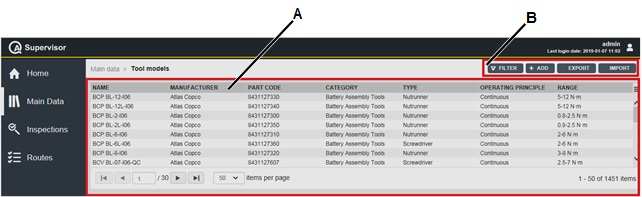

Tools models

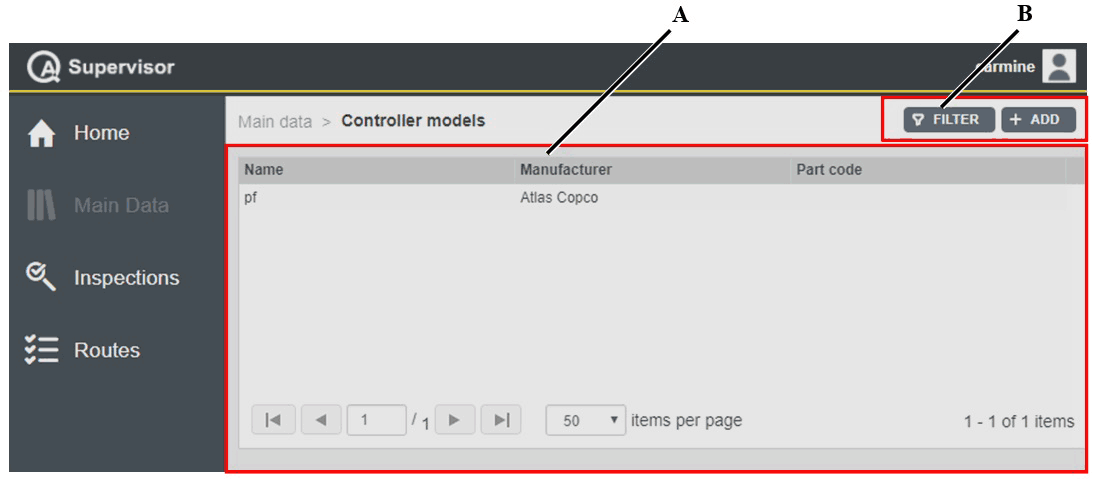

Controller models

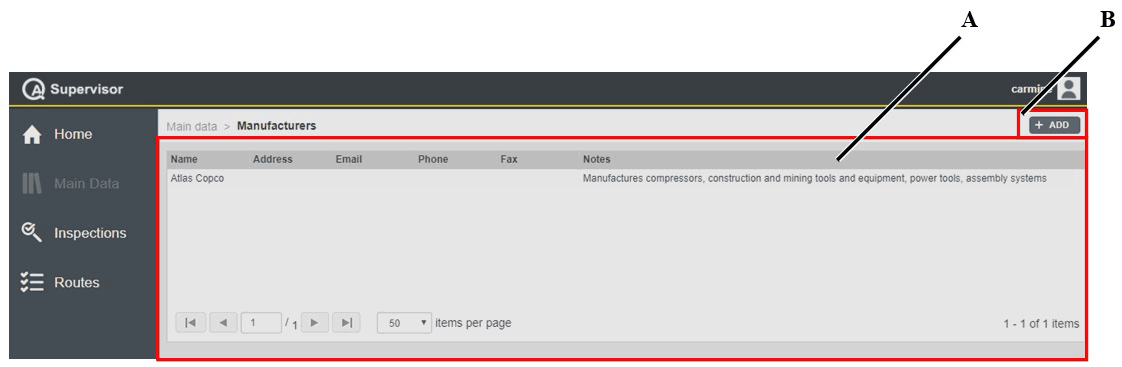

Manufacturers

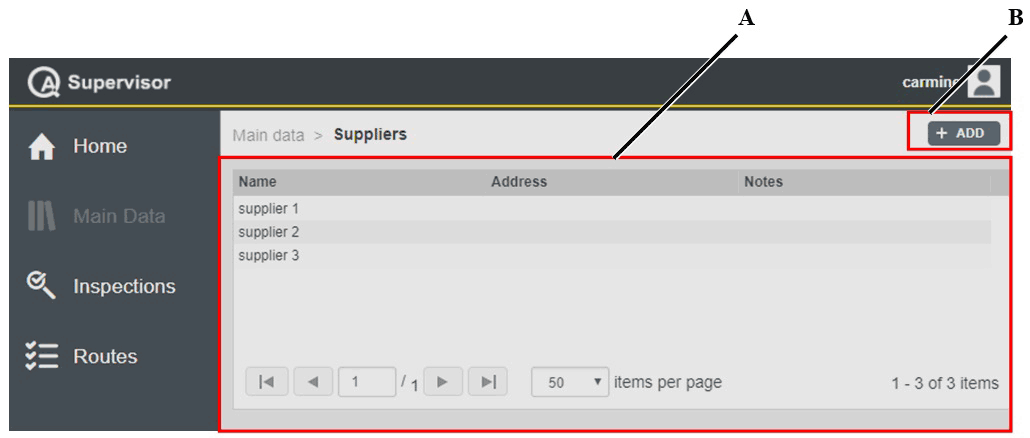

Suppliers

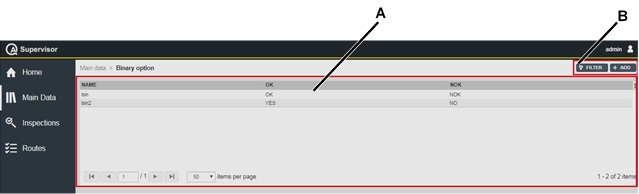

Binary options

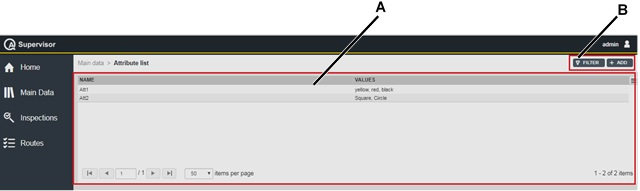

Attribute lists

Selectable

Users

Roles

Factory structure

Measuring devices

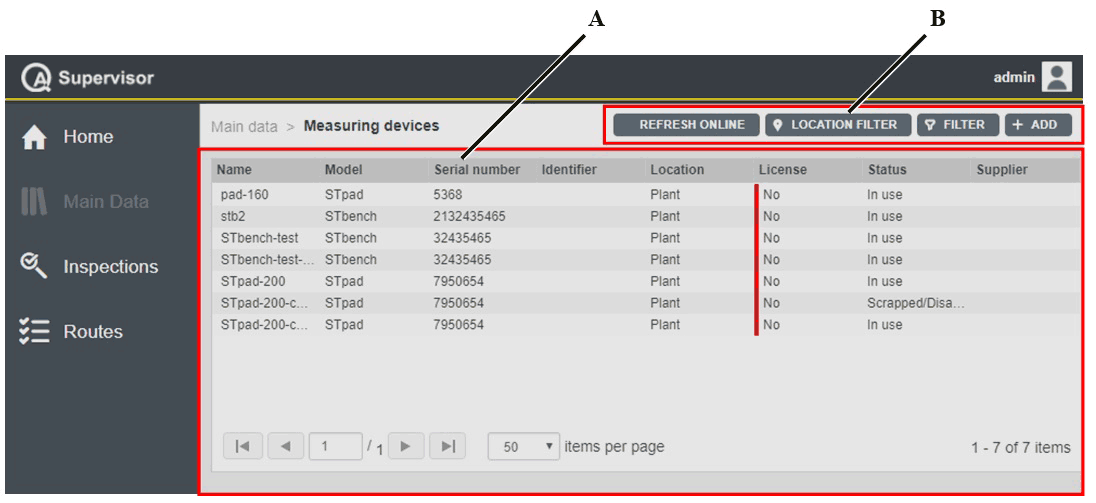

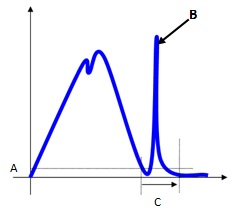

On the left-side menu bar, click Main Data > Measuring devices.

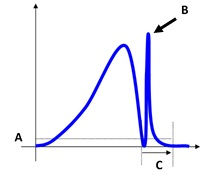

A | Measuring devices workspace | B | Command buttons |

The Measuring devices workspace is divided into the following columns:

Name: name of the measuring device.

Model: model of the measuring device.

Serial number: serial number of the measuring device.

Identifier: custom identification code linked to the current measuring device.

Location: area of the plant where using the measuring device.

License: below are the license options, depending on the status of the license of the measuring device:

Yes: measuring device with license.

No: measuring device without license.

N/A: measuring devices without network connectivity (MRTT-C, IRC-Connect, and STwrench).

Status: below are the available options, depending on the status of the measuring device:

In use: the measuring device is ready to work on the production applications.

Service/Repair: the measuring device cannot be used on the assembly line before maintenance is complete. The capability of the measuring device is verified according to customer’s procedures.

Scrapped/Disabled: the measuring device is out of order. Do not use it on the assembly line.

Supplier: supplier of the measuring device.

In the Measuring devices workspace, click a measuring device to display the related Measuring Device Details card.

On the upper-right corner of the Measuring Device Details card, click the Close button to exit the Measuring Device Details card.

At the end of the Measuring Device Details card, the following items record all of the changes made for the selected measuring device:

Version: version of the measuring device configuration.

In the Edit Measuring Device dialog box, change one of the following items to make a new version: Serial number, Identifier, Location, and Status.

Changed by: name of the operator who has made a change to the measuring device configuration.

History: the history table records all of the changes made for the selected measuring device.

The first line of the history table summarizes the latest version of the measuring device configuration. Click a previous line: the related Measuring Device Details card opens on the left of the Measuring Device Details card related to the latest version. The differences between the two Measuring Device Details cards are yellow highlighted.

On the upper-right corner of the oldest Measuring Device Details card, click Restore: the previous version of the measuring device configuration becomes the latest one.

On the upper-right corner of the Measuring devices workspace, there are the following command buttons:

Add: click to add a new measuring device into the Measuring devices page.

Filter: click to give filters and list only the necessary measuring device(s).

Location Filter: click to filter the measuring device(s) depending on its location in the factory structure.

Refresh Online: click to refresh the Measuring devices page and to verify if the enlisted measuring device(s) with In use status are online or not.

Adding a measuring device

On the left-side menu bar, click Main Data > Measuring devices.

On the upper-right corner of the Measuring devices workspace, click Add.

In the Add Measuring Device dialog box, configure the measuring device parameters.

On the upper-right corner of the Add Measuring Device dialog box, click Save.

Editing a Measuring Device Details card

On the upper-right corner of the Measuring Device Details card, click Edit.

In the Edit Measuring Device dialog box, make the necessary changes.

On the upper-right corner of the Edit Measuring Device dialog box, click Save.

Measuring device parameters

Name (*): type the name of the measuring device.

Description: type a description of the measuring device.

Model (*): select a model. The available measuring devices models are:

IRC-Connect

JSB

MRTT-C

QA Station MT

Open Protocol

STa 6000

STbench

STpad

STpad Cable Adapter

STpalm

STwrench

STRwrench

The QA Station MT/Open Protocol can be created automatically by entering the QA Supervisor hostname and port (port number 4711) in the measuring device.

The Add Measuring Device dialog box changes depending on the model selected.

Serial number (*): type the serial number of the measuring device.

Identifier: type the identification code linked to the measuring device.

Location (*): select the area of the plant where using the new measuring device model. By default it is set to the is the location of the user.

Do as follows:

Click Location icon (

).

).

In the Location dialog box, select the area of the plant where using the new measuring device model.

Then, click Apply.Status (*): select one of the following options, depending on the status of the measuring device:

In use: the measuring device is ready to work on the production applications.

Service/Repair: the measuring device cannot be used on the assembly line before maintenance is complete. The capability of the measuring device is verified according to customer’s procedures.

Scrapped/Disabled: the measuring device is out of order. Do not use it on the assembly line.

By default, the status is set to In use

Barcode configuration (*): select one of the following options:

Online & offline: it enables the search of inspections both locally and on QA Supervisor when a barcode is scanned on the measuring device.

Only online: it enables the search of inspections on QA Supervisor when a barcode is scanned on the measuring device.

Only offline: it enables the local search of inspections when a barcode is scanned on the measuring device.

None: it disables the search of inspections by scanning a barcode on the measuring device.

This field is available only for STpad, STpalm and STbench.

Automatic clean up: click on the switch to enable/disable the deletion of the data sent by QA Supervisor before a new route is sent to the measuring device.

By enabling this switch, the results of the inspections are not deleted.

This field is available only for STpad, STpalm and STbench.Enable delete measures: click on the switch to enable/disable the deletion of measures while running an inspection.

This field is available only for STpad, STpalm and STbench.Enable custom Web links: click on the switch to enable/disable the possibility to navigate the URLs configured in the Application Settings.

This field is available only for STpad, STpalm and STbench.Enable trace processing: click on the switch to enable/disable the possibility to view and process traces on the measuring device.

This field is available only for STpad and STbench.Retrieve old results: click on the switch to enable/disable the automatic acquisition of the results stored in the measuring device when connected to QA Supervisor.

This field is available only for QA Station MT/Open Protocol.If this option is disabled, at least one measurement must be stored in the device before connecting it to QA Supervisor.

License: the license switch is displayed depending on the model of the measuring device selected. The measuring devices without network connectivity (MRTT-C, IRC-Connect, and STwrench) do not show the license switch.Click the License switch to enable the license (the switch becomes blue colored).

The counter on the right of the License switch displays the available license(s) with the total number of enabled license(s) (for example, if the counter is x/y, x is the number of the available license(s) and y is the total number of the enabled license(s)).

The License switch is disabled and the counter is 0/0, if there are no available license(s).

The License switch (and the counter) is not displayed, in case of Unlimited License.

JSB license: the JSB license switch is displayed only if the model JSB is selected.

Click the License switch to enable the license (the switch becomes blue colored).

The counter on the right of the License switch displays the available license(s) with the total number of enabled license(s) (for example, if the counter is x/y, x is the number of the available license(s) and y is the total number of the enabled license(s)).

Connectivity

Host: type the host address of the measuring device.

Port: type the port number to communicate with the measuring device.

Supplier: click the arrow to open the supplier list and select the necessary supplier.

To add a new supplier, click Add icon ( ).

).

In the Add Supplier dialog box, enter the details related to new supplier.

Then, click Save.Purchase date: click the box and select the purchase date.

To delete a purchase date previously configured, click Delete icon ( ).

).Calibration certificates: in the Calibration certificates box, select the necessary calibration certificate.

To add a new calibration certificate, click Add icon ( ).

).

In the Add Calibration Certificate dialog box, enter the following details related to new calibration certificate:Calibration procedure (*): type the name of the Calibration procedure used to calibrate the measuring device.

Calibration system: calibration system of the current calibration certificate. It is the traceability information for the selected measuring device with a known accuracy, higher than the expected device under calibration and certificated according the same standard for which the calibration certification is claimed for the device under test.

Calibration system S/N: type the serial number of the system used to calibrate the measuring device.

Reference transducer: traceability information for the transducer device used to calibrate a measuring device under test, where the sensitivity and the precision is proved and certified so that its output can be used as reference values for the comparisons in the calibration procedure.

Reference transducer S/N: type the serial number of the reference transducer used.

Certificate number: type the number of the calibration certificate.

Certificate link (attachment): attachment box for any document related to the calibration certificate.

Certificate date: enter the date of the emission of the certificate.

Certification expiry date (*): enter the expiry date of the calibration certificate.

Laboratory: name of the laboratory where the calibration certificate was done.

Laboratory accreditation ID: type the accreditation identification number of the laboratory where the calibration certificate was done.

Accreditation body: type the name of the accreditation body. The Accreditation body is the independent body that assessed the laboratory for the conformity to the reference standard.

Then, click Save.

To edit a calibration certificate already configured, in the Calibration certificates box, select it.

Click Edit icon ( ).

).

In the Edit Calibration Certificate dialog box, edit the calibration certificate details.

Then, click Save.

To delete a calibration certificate already configured, in the Calibration certificates box, select it.

Then, click Delete icon ( ).

).Connected measuring devices: in the Connected measuring devices box, select the measuring device to be connected.

To add a new measuring device, click Add icon ( ).

).

In the Add Measuring Device dialog box, enter the details related to new measuring device.

Then, click Save.

To select a measuring device already configured, click Search icon ( ).

).

In the Measuring Devices workspace, select the necessary measuring device.

Then, click Apply.

To delete a measuring device already configured, in the Measuring devices box, select it.

Then, click Delete icon ( ).

).Connected transducers: in the Connected transducers box, select the transducer to be connected with the measuring device.

To add a new transducer, click Add icon ( ).

).

In the Add Transducer dialog box, enter the details related to new transducer.

Then, click Save.

To select a transducer already configured, click Search icon ( ).

).

In the Transducers workspace, select the necessary transducer.

Then, click Apply.

To delete a transducer already configured, in the Connected transducers box, select it.

Then, click Delete icon ( ).

).Notes: if necessary, type a note.

Items marked with an asterisk (*) are required.

Cloning a Measuring Device Details card

On the upper-right corner of the Measuring Device Details card, click Clone.

The Add Measuring Device dialog box automatically opens with all the items configured as in the Measuring Device Details card cloned.

If necessary, in the Add Measuring Device dialog box, make the necessary changes.

On the upper-right corner of the Add Measuring Device dialog box, click Save.

Getting results from the measuring device with QA Supervisor

If a measuring device has a license and it is online, on the upper-right corner of the Measuring Device Details card, click on Get results to retrieve results from the measuring device with QA Supervisor.

To get results from STa 6000, the device must be in the Home page of the application. Otherwise, an Information message is displayed on the device.

When online, results from STbench/STpad/STpalm are automatically synchronized with QA Supervisor each time an inspection is completed.

In case of "Forced by piece route", results are automatically synchronized with QA Supervisor when the operator exits the measurement screen on the device.

A green notification message is displayed when the synchronization is successfully complete.

After the results are got from the measuring devices, the Measuring devices details card is updated with the following items:

Last online date: date of the last time the measuring device has been online.

Firmware version: version of the firmware of the STpad or STbench.

Cleaning up a Measuring device

On the upper-right corner of the Measuring Device Details card, click Clean up.

The data sent by QA Supervisor to the measuring device are deleted from the device memory.

Setting the measuring device filter

On the left-side menu bar, click Main Data > Measuring devices.

On the upper-right corner of the Measuring devices workspace, click Filter.

In the Measuring Devices Filter dialog box, set the filter criteria (depending on the customer needs) (part 1):

On the upper-right corner of the Measuring Devices Filter dialog box, click Apply.

Measuring device filter criteria

Name: type the name of the measuring device to be filtered.

Serial number: type the serial number of the measuring device to be filtered.

Identifier: type the identification code linked to the measuring device to be filtered.

Status: select one of the following options, depending on the status of the measuring device to be filtered:

In use: select the measuring device ready to work on the production applications.

Service/Repair: the measuring device cannot be used on the assembly line before maintenance is complete. The capability of the measuring device is verified according to customer’s procedures.

Scrapped/Disabled: select the measuring device out of order. Do not use it on the assembly line.

License: select one of the following options:

Yes: select the measuring device(s) with license.

No: select the measuring device(s) without license.

Both: select both the measuring device(s) with license and the measuring device(s) without license.

If the measuring device does not have any license, a red line is displayed in the License column of the Measuring devices workspace, on the left of the license option of the measuring device.

Calibration certificate: select one of the following options:

At least one valid: select the measuring device(s) with at least one valid calibration certificate.

None valid: select the measuring device(s) without valid calibration certificate.

Online: select one of the following options:

Yes: select the measuring device(s) online.

No: select the measuring device(s) offline.

If the measuring device is online, a blue line is displayed in the Name column of the Measuring devices workspace, on the left of the name of the measuring device.

Models: in the Models box, select the measuring device model to be filtered.

To select a measuring device model, click Search icon (

).

).In the Tool Models workspace, select the necessary measuring device model.

Then, click Apply.

To delete a measuring device model, in the Models box, select it.

Then, click Delete icon (

).

).Connected Measuring devices: in the Connected measuring devices box, select the necessary measuring device.

To select a measuring device, click Search icon (

).

).In the Measuring Devices workspace, select the necessary measuring device.

Then, click Apply.

To delete a measuring device, in the Measuring devices box, select it.

Then, click Delete icon (

).

).Connected transducers: in the Connected transducers box, select the necessary transducer.

To select a transducer, click Search icon (

).

).In the Transducers workspace, select the necessary transducer.

Then, click Apply.

To delete a transducer, in the Connected transducers box, select it.

Then, click Delete icon (

).

).Selected filter: from the drop-down list, select one of the saved customized filter.

For more information on how to manage customized filters, refer to Filters customization.

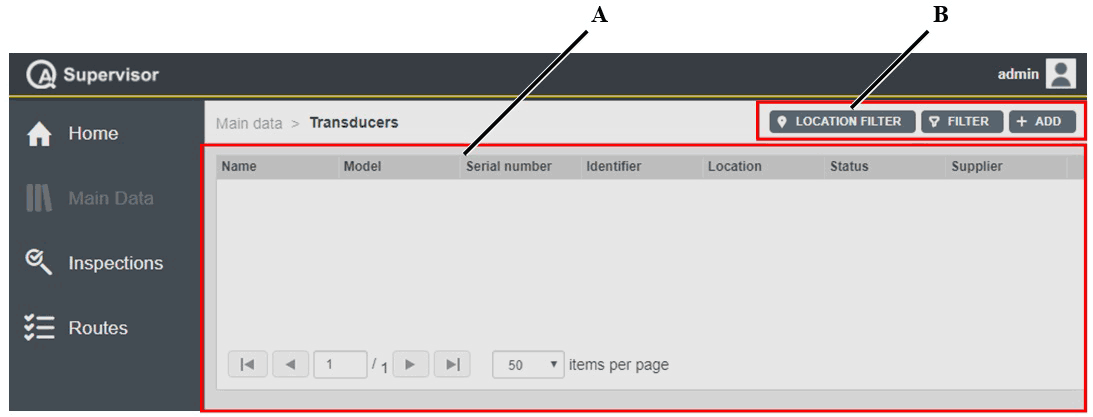

Transducers

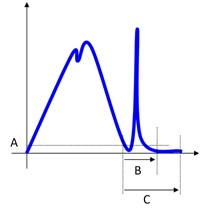

On the left-side menu bar, click Main Data > Transducers.

A | Transducers workspace | B | Command buttons |

The Transducers workspace is divided into the following columns:

Name: name of the transducer.

Model: model of the transducer.

Serial number: serial number of the transducer.

Identifier: custom identification code linked to the current transducer.

Location: area of the plant where using the transducer.

Status: below are the available options, depending on the status of the transducer:

In use: the transducer is ready to work on the production applications.

Service/Repair: the transducer cannot be used on the assembly line before maintenance is complete. The capability of the transducer is verified according to customer’s procedures.

Scrapped/Disabled: the transducer is out of order. Do not use it on the assembly line.

Supplier: supplier of the transducer.

In the Transducers workspace, click a transducer to display the related Transducer Details card.

On the upper-right corner of the Transducer Details card, click the Close button to exit the Transducer Details card (without saving any change).

At the end of the Transducer Details card, the following items record all of the changes made for the selected transducer:

Version: version of the transducer configuration.

In the Edit Transducer dialog box, change one of the following items to make a new version: Serial number, Identifier, Location, Location history, Status, Sensitivity, Min Load, and Full scale.

Changed by: name of the operator who has made a change to the transducer configuration.

History: the history table records all of the changes made for the selected transducer.

The first line of the history table summarizes the latest version of the transducer configuration. Click a previous line: the related Transducer Details card opens on the left of the Transducer Details card related to the latest version. The differences between the two Transducer Details cards are yellow highlighted.

On the upper-right corner of the oldest Transducer Details card, click Restore: the previous version of the transducer configuration becomes the latest one.

On the upper-right corner of the Transducers workspace, there are the following command buttons:

Add: click to add a new transducer into the Transducers workspace.

Filter: click to give filters and list only the necessary transducer(s).

Location Filter: click to filter the transducer(s) depending on its location in the factory structure.

Adding a transducer

On the left-side menu bar, click Main Data > Transducers.

On the upper-right corner of the Transducers workspace, click Add.

In the Add Transducer dialog box, configure the tranducer parameters.

On the upper-right corner of the Add Transducer dialog box, click Save.

Editing a Transducer Details card

On the upper-right corner of the Transducer Details card, click Edit.

In the Edit Transducer dialog box, make the necessary changes.

On the upper-right corner of the Edit Transducer dialog box, click Save.

Transducer parameters

Name (*): type the name of the transducer.

Description: type a description of the transducer.

Model (*): add/select the transducer model.

Do one of the following:

Click Add icon (

) to add a new transducer model.

) to add a new transducer model. In the Add Transducer Model dialog box, enter the details related to new transducer.

Then, click Save.

Click Search icon (

) to select a transducer model already configured.

) to select a transducer model already configured.In the Transducer Model workspace, select the necessary transducer model.

Then, click Apply.

Serial number (*): type the serial number of the transducer.

Identifier: type the identification code linked to the transducer.

Location (*): select the area of the plant where using the new transducer model. By default it is set to the is the location of the user.

Do as follows:

Click Location icon (

).

).In the Location dialog box, select the area of the plant where using the new transducer model.

Then, click Apply.

Status (*): select one of the following options, depending on the status of the transducer:

In use: the transducer is ready to work on the production applications.

Service/Repair: the transducer cannot be used on the assembly line before maintenance is complete. The capability of the transducer is verified according to customer’s procedures.

Scrapped/Disabled: the transducer is out of order. Do not use it on the assembly line.

By default, the status is set to In use.

Sensitivity: type the sensitivity of the transducer.

Measurement unit: select the measurement unit to define the torque parameters of the transducer. The default measurement unit is defined both in the Application settings and in the Personal settings.

Min load: type the minimum load of the transducer.

Full scale: type the full scale of the transducer.

Supplier: click the arrow to open the supplier list and select the necessary supplier.

To add a new supplier, click Add icon (

).

).In the Add Supplier dialog box, enter the details related to new supplier.

Then, click Save.

Purchase date: click the box and select the purchase date.

To delete a purchase date previously configured, click Delete icon (

).

).Calibration certificates: in the Calibration certificates box, select the necessary calibration certificate.

To add a new calibration certificate, click Add icon (

).

).In the Add Calibration Certificate dialog box, enter the following details related to new calibration certificate:

Calibration procedure (*): type the name of the Calibration procedure used to calibrate the transducer.

Calibration system: calibration system of the current calibration certificate. It is the traceability information for the selected transducer with a known accuracy, higher than the expected device under calibration and certificated according the same standard for which the calibration certification is claimed for the device under test.

Calibration system S/N: type the serial number of the system used to calibrate the transducer.

Reference transducer: traceability information for the transducer device used to calibrate a measuring device under test, where the sensitivity and the precision is proved and certified so that its output can be used as reference values for the comparisons in the calibration procedure.

Reference transducer S/N: type the serial number of the reference transducer used.

Certificate number: type the number of the calibration certificate.

Certificate link (attachment): attachment box for any document related to the calibration certificate.

Certificate date: enter the date of the emission of the certificate.

Certification expiry date (*): enter the expiry date of the calibration certificate.

Laboratory: name of the laboratory where the calibration certificate was done.

Laboratory accreditation ID: type the accreditation identification number of the laboratory where the calibration certificate was done.

Accreditation body: type the name of the accreditation body. The Accreditation body is the independent body that assessed the laboratory for the conformity to the reference standard.

Then, click Save.

To edit a calibration certificate already configured, in the Calibration certificates box, select it.

Click Edit icon (

).

).In the Edit Calibration Certificate dialog box, edit the calibration certificate.

Then, click Save.

To delete a calibration certificate already configured, in the Calibration certificates box, select it.

Then, click Delete icon (

).

).Measuring devices: in the Measuring devices box, select the necessary measuring device.

To add a new measuring device, click Add icon (

).

).In the Add Measuring Device dialog box, enter the details related to new measuring device.

To select a measuring device already configured, click Search icon (

).

).Then, click Save.

In the Measuring devices workspace, select the necessary measuring device.

Then, click Apply.

To delete a measuring device already configured, in the Measuring devices box, select it.

Then, click Delete icon (

).

).Notes: if necessary, type a note.

Items marked with an asterisk (*) are required.

Cloning a Transducer Details card

On the upper-right corner of the Transducer Details card, click Clone.

The Add Transducer dialog box automatically opens with all the items configured as in the Transducer Details card cloned.

If necessary, in the Add Transducer dialog box, make the necessary changes.

On the upper-right corner of the Add Transducer dialog box, click Save.

Setting the transducer filter

On the left-side menu bar, click Main Data > Transducers.

On the upper-right corner of the Transducers workspace, click Filter.

In the Transducer Filter dialog box, set the transducer filter criteria (depending on the customer needs).

On the upper-right corner of the Transducer Filter dialog box, click Apply.

Transducer filter criteria

Name: type the name of the transducer to be filtered.

Serial number: type the serial number of the transducer to be filtered.

Identifier: type the identification code linked to the transducer to be filtered.

Status: select one of the following options, depending on the status of the transducer to be filtered:

In use: select the transducer ready to work on the production applications.

Service/Repair: the transducer cannot be used on the assembly line before maintenance is complete. The capability of the transducer is verified according to customer’s procedures.

Scrapped/Disabled: select the transducer out of order. Do not use it on the assembly line.

Models: in the Models box, select the transducer model to be filtered.

To select a transducer model, click Search icon (

).

).In the Transducer Models workspace, select the necessary transducer model.

Then, click Apply.

To delete a transducer model, in the Models box, select it.

Then, click Delete icon (

).

).Measuring devices: in the Measuring devices box, select the necessary measuring device.

To select a measuring device, click Search icon (

).

).In the Measuring Devices workspace, select the necessary measuring device.

Then, click Apply.

To delete a measuring device, in the Measuring devices box, select it.

Then, click Delete icon (

).

).Selected filter: from the drop-down list, select one of the saved customized filter.

For more information on how to manage customized filters, refer to Filters customization.

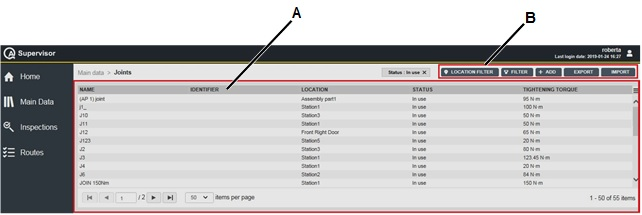

Joints

On the left-side menu bar, click Main Data > Joints.

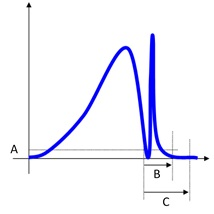

A | Joints workspace | B | Command buttons |

The Joint workspace is divided into the following columns:

Name: name of the joint.

Identifier: custom identification code linked to the current joint.

Location: area of the plant where using the joint.

Status: below are the available options, depending on the status of the joint:

In use: the joint is in working condition.

Scrapped/Disabled: the joint is out of order.

Tightening torque: target torque defined in the production process to tighten the joint.

In the Joint workspace, click a joint to display the related Joint Details card.

On the upper-right corner of the Joint Details card, click the Close button to exit the Joint Details card (without saving any change).

At the end of the Joint Details card, the following items record all of the changes made for the selected joint:

History: the history table records all of the changes made for the selected joint.

The first line of the history table summarizes the latest version of the joint configuration.

Click a previous line: the related Joint Details card opens on the left of the Joint Details card related to the latest version. The differences between the two Joint Details cards are yellow highlighted.

On the upper-right corner of the oldest Joint Details card, click Restore: the previous version of the joint configuration becomes the latest one.

Version: version of the joint configuration.

In the Edit Joint dialog box, change one of the following items to make a new version: Identifier , Location, Status, Risk/Function class, Geometry, Material surface, Lubricant, Bolt type, Size, Strength grade, Friction coefficient, Assembly pre-load, Yield point stress, Tightening torque, Torque tolerance limits, Torsion angle, Angle tolerance limits, and Final angle monitoring torque.

Changed by: name of the operator who has made a change to the joint configuration.

Changed on: optional field, it appears only if the change was made by an operator on a device.

On the upper-right corner of the Joint workspace, there are the following command buttons:

Import: click to import joints into the Joints workspace

Export: click to export t he joint configured in the application

Add: click to add a new transducer into the Joint workspace.

Filter: click to give filters and list only the necessary joint(s).

Location Filter: click to filter the joint(s) depending on its location in the factory structure.

The Import and Export button are available only if the roles for importing and exporting data are enabled. Refer to the Roles paragraph for more information.

Adding a joint

On the left-side menu bar, click Main Data > Joint.

On the upper-right corner of the Joint workspace, click Add.

In the Add Joint dialog box, configure the Joint parameters.

On the upper-right corner of the Add Joint dialog box, click Save.

Editing a Joint Details card

On the upper-right corner of the Joint Details card, click Edit.

In the Edit Joint dialog box, make the necessary changes.

In the upper-right corner of the Edit Joint dialog box, click Save.

Joint parameters

Joint image: upload the image of the joint model.

Name (*): type the name of the joint.

Description: type a description of the joint.

Identifier: type the identification code linked to the joint.

Location (*): select the area of the plant where using the new joint.

Do as follows:

Click Location icon (

).

).In the Location dialog box, select the area of the plant where using the new joint.

Then, click Apply.

Status (*): select one of the following options, depending on the status of the joint:

In use: the joint is ready to work on the production applications.

Scrapped/Disabled: the joint is out of order.

By default, the status is set to In use

Risk/Function class: select one of the following options:

A: direct or indirect danger to body and life.

B: breakdown.

C: customer’s nerves.

Measurement unit: select the measurement unit to define the torque parameters of the joint.

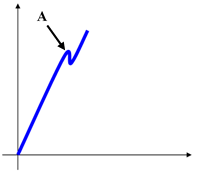

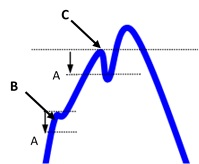

Trace

Trace: add/select a trace to be linked to the joint.

Do one of the following:Click Add icon (

) to add a new trace.

) to add a new trace.

In the Add Trace card, enter the details related to the trace and import the traces.

Then, click Save. The trace added is displayed in the chart.Click Search icon (

) to select a trace already configured.

) to select a trace already configured.

In the Trace Title card, select the necessary trace.

Then, click Apply. The trace selected is displayed in the chart.Click Delete icon (

) to delete the selected trace.

) to delete the selected trace.

Tightening

Torque (*): type the tightening torque of the joint.

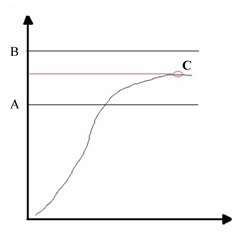

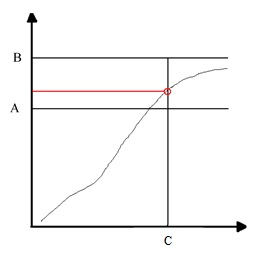

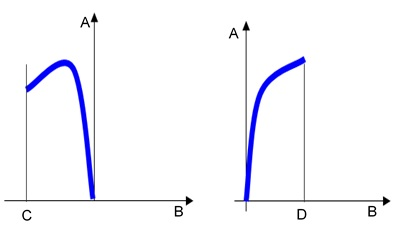

The torque value can be given as follows:

Torque target and torque tolerance.

Lower limit (LSL) and upper limit (USL).

Torque tolerance (*): type the percentage of the torque tolerance limits.

Tightening direction (*): select one of the following options:

CW: clockwise.

CCW: counter-clockwise.

Torsion angle (*): type the target torsion angle of the joint.

Even if the tightening in production is only torque, indication of the target angle is used to define the joint characteristics.The torsion angle can be given as follows:

Torsion angle and torsion angle tolerance (by default 270° and 90° respectively).

Lower limit (LSL) and upper limit (USL) (by default 180° and 360° respectively).

Final angle monitoring torque (*): the final angle monitoring torque specifies the torque value from which the angle measurement starts.

For older products, this item is indicated as Start final angle.Assembly pre-load: bolt clamp force applied on the joint.

Tools: in the Tools box, select the necessary tool.

To add a new tool, click Add icon (

).

).In the Add Tool dialog box, enter the details related to new tool. Then, click Save.

To select a tool already configured, click Search icon (

).

).In the Tools workspace, select the necessary tool. Then, click Apply.

To delete a tool already configured, in the Tool box, select it. Then, click Delete icon (

).

).To view the Tool Details card of a tool already configured, in the Tool box, select it. Then, click View icon (

).

).

Bolt

Geometry: in the items list, select the geometry of the bolt.

Configure the items list in the Selectables submenu.

Material and surface: in the items list, select the material and surface of the bolt.

Configure the items list in the Selectables submenu.

Lubricant: in the items list, select the lubricant of the bolt.

Configure the items list in the Selectables submenu.

Bolt type: in the items list, select the bolt type.

Configure the items list in the Selectables submenu.

Size: in the items list, select the size of the bolt.

Configure the items list in the Selectables submenu.

Strength grade: in the items list, select the strength grade of the bolt.

Configure the items list in the Selectables submenu.

Friction coefficient, µ: in the items list, select the friction coefficient of the bolt.

Configure the items list in the Selectables submenu.

Yield stress point: in the items list, select the yield stress point of the bolt.

Configure the items list in the Selectables submenu.

Utilization factor, v: this item shows the ratio between Tightening torque and Yield stress point.

Configure the items list in the Selectables submenu.

Notes: if necessary, type a note.

Items marked with an asterisk (*) are required.

Cloning a Joint Details card

On the upper-right corner of the Joint Details card, click Clone.

The Add Joint dialog box automatically opens with all the items configured as in the Joint Details card cloned.

If necessary, in the Add Joint dialog box, make the necessary changes.

On the upper-right corner of the Add Joint dialog box, click Save.

Setting the joint filter

On the left-side menu bar, click Main Data > Joints.

On the upper-right corner of the Joints workspace, click Filter.

In the Joint Filter dialog box, set the joint filter criteria (depending on the customer needs):

On the upper-right corner of the Joints Filter dialog box, click Apply.

Adding a Joint inspection

On the upper-right corner of the Joint details card, click on the Inspections button.

On the upper-right corner of the Inspection Definition card, click on the Add button.

In the Add inspection definition dialog box, configure the inspection parameters.

On the upper-right corner of the Add inspection definition dialog box, click on the Save button.

Running a Joint inspection

On the upper-right corner of the Joint details card, click on the Inspections button.

In the Inspection Definition card, click on an Inspection from the list.

In the Inspection Definition Details card, click on the Run button to send the selected inspection to the measuring device configured in the Personal settings.

If no measuring device is configured in the Personal settings, the Run button is disabled.

To configure a measuring device, please refer to the paragraph "Viewing/editing personal settings".

If the inspection is correctly sent to the measuring device, a green notification message is displayed.

If the inspection is not sent to the measuring device, an error message alerts the user about the problem that occurred.

This functionality sends the inspection to the measuring device and runs it, the success of the running operation has to be verified on the measuring device.

Joint filter criteria

Name: type the name of the joint to be filtered.

Identifier: type the identification code linked to the joint to be filtered.

Status: select one of the following options, depending on the status of the joint to be filtered:

In use: select the joint ready to work on the production applications.

Scrapped/Disabled: select the joint out of order. Do not use it on the assembly line.

Tools: in the Tools box, select the tool to be filtered.

To select a tool, click Search icon (

).

).In the Tools workspace, select the necessary tool.

Then, click Apply.

To delete a tool selected previously, in the Tools box, select it.

Then, click Delete icon (

).

).Selected filter: from the drop-down list, select one of the saved customized filter.

For more information on how to manage customized filters, refer to Filters customization.

Exporting data

On the upper-right corner of the page, click Export.

An Excel file is created with all the configured data.

If some filters are applied to the list, only the filtered items are exported.

All the saved information are exported, except the pictures.

Importing data

On the upper-right corner of the page, click Export. An Excel file is created.

If the page is empty, the export file is created with all the fields empty.

Save the Excel file created by the application.

Open the Excel file and add/edit the items of interest following the rules listed at the end of the procedure.

Save the edited file.

On the upper-right corner of the page, click Import. Then select the file to import from the upload window and click Open.

If some errors occurred during the import, a yellow message is displayed and an Excel file with all the not imported rows is created.

The description on the error occurred for each rows is displayed at the last columns on the right of the Excel file.

Open the excel file with the list of error and correct them following the rules listed below.

Save the edit file.

On the upper-right corner of the page, click Import. Then select the file to import from the upload window and click Open.

Repeat the step from 7 to 9 until all the errors are corrected.

The “Internal ID” column determines if the data is new or an update of existing ones. If set to empty, it is new data, if left with exported value, it is an update.

To edit the export file:

Do not delete or edit the header of the columns.

Do not change the order of the columns of the exported file.

Do not add other sheet to the exported file.

Do not change the name of the sheet of the exported file.

Do not change the file format.

To delete an entire row of the exported file: select the row, right-click it and select Delete.

It is allowed to change the file name.

The columns of the exported file are independent. If a unit of measurement is changed, the related numerical value is not converted.

Joint report

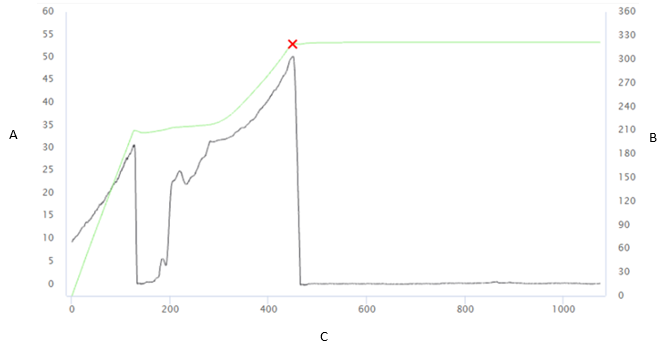

The Joint report can combine data coming from different applications: Tool Check, Joint Check and, optionally, Production readings coming from ToolsNet 8

This report is available only if the Joint report license is activated.

Setting the Joint report filter

On the left-side menu, select Main data > Joints.

In the Joints page, select a joint linked to a tool.

If the Joint is not linked to any tool, the joint report function is not available.

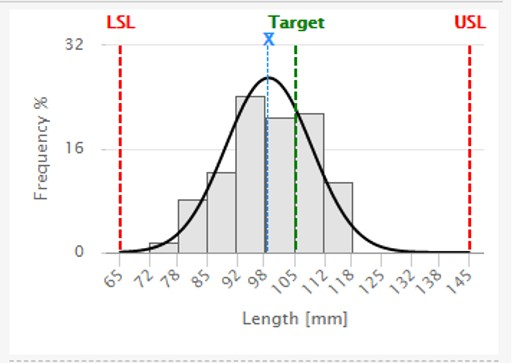

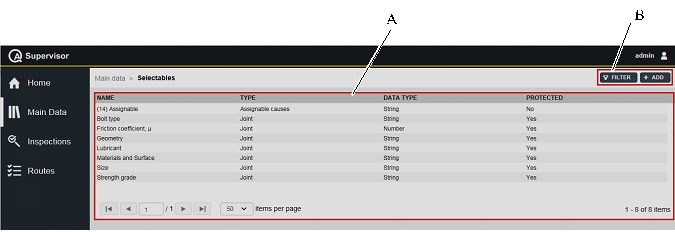

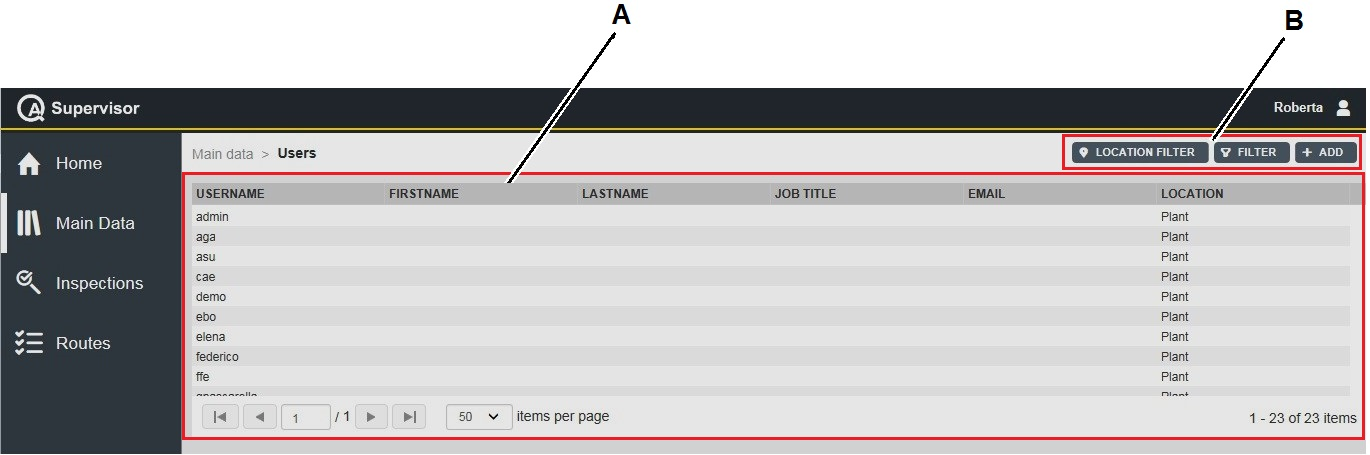

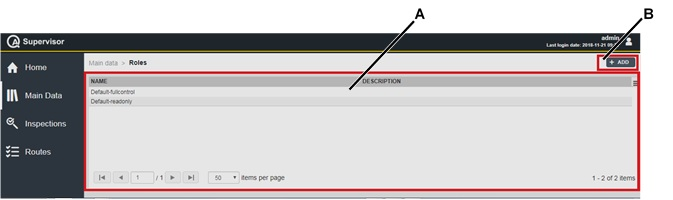

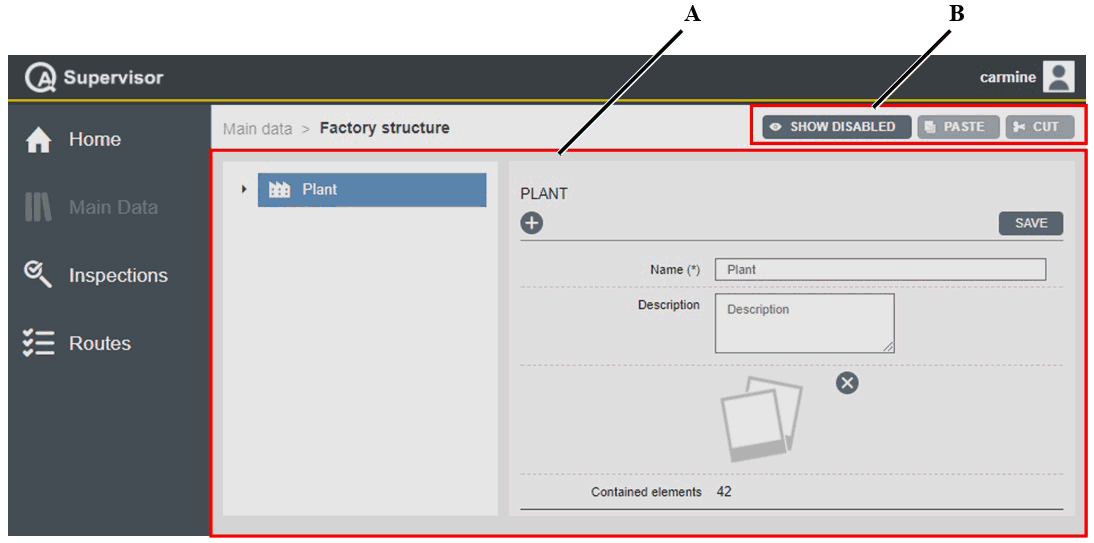

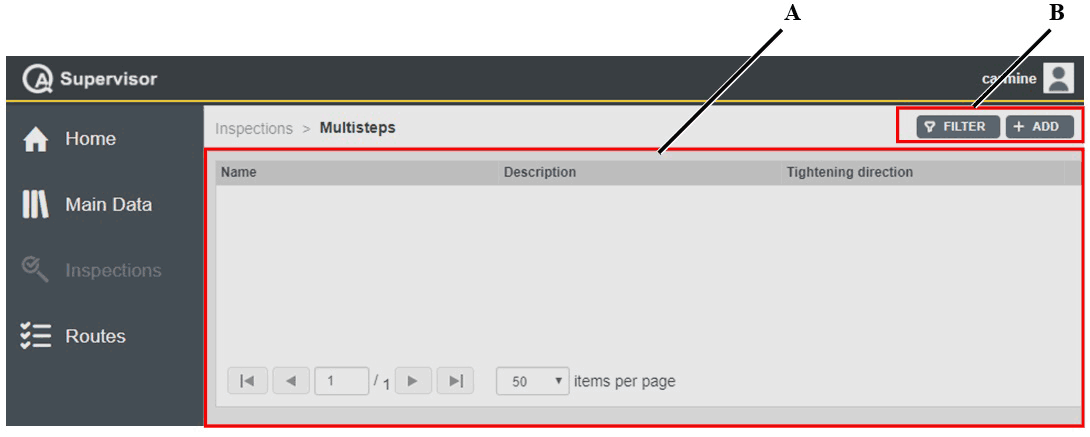

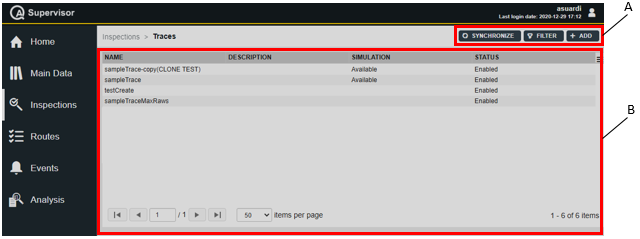

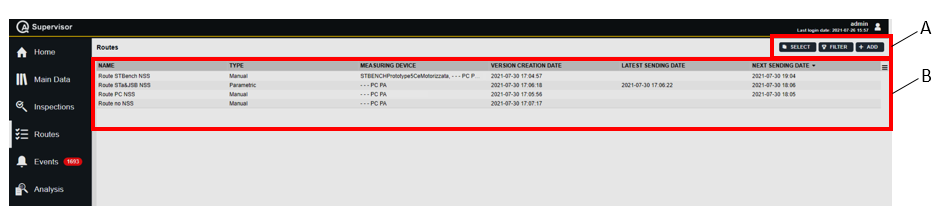

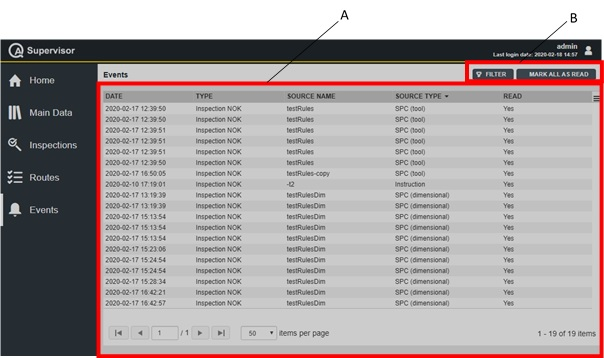

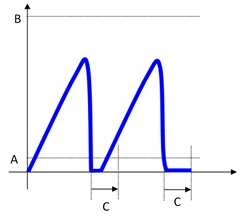

In the Joint details card, click the Joint report button.