Peak strategy

This strategy is applicable to a peak wrench, defined as indicating torque tools (type I by standard ISO 6789).

The peak wrench test provides the maximum torque measured during the test.

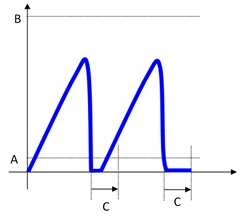

The parameters that characterize the peak point detections are:

End cycle time: it defines the end of the test. When the torque goes and remains below the transducer minimum load (usually 5% of the transducer full scale) for the given timeout, the test ends.

If torque goes over transducer minimum load before the timeout, the test continues. The test ends when torque remains under the transducer minimum load for the timeout.

Torque vs time A

Transducer min load

B

Transducer full scale

C

End cycle time

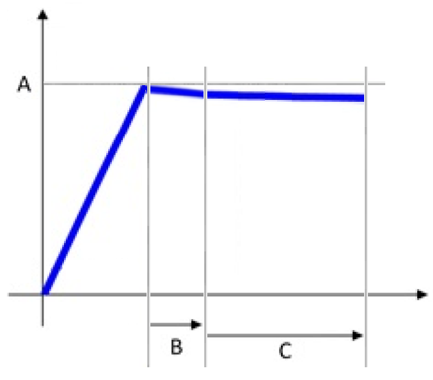

Relaxation time + End cycle time: due to the mechanical relaxation of the wrench, the torque peak detected by the wrench slightly decreases after a short time interval. The relaxation time allows to adjust the peak detection in case of wrenches that do not save the torque peak, thus reducing discrepancies between the transducer and the wrench torque peak detections. If Relaxation time > 0, the End cycle time starts when the Relaxation time expires.

Torque vs time A

Torque peak

B

Relaxation time

C

End cycle time