Pulse strategy

To calculate the tool frequency, the Pulse Tool strategy uses a configurable threshold to identify a peak.

The parameter that characterize the peak point detections are:

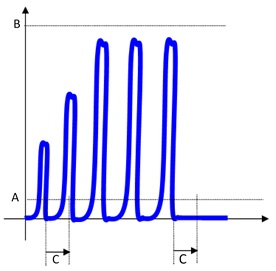

End cycle time: when the torque goes and remains below the transducer minimum load (which is normally the 5% of the transducer full scale) for the given time, the test ends.

Timeout can be set from 0.1 s up to 5 s. The default value is 0.4 s.

Torque vs time A

Transducer min load

B

Transducer full scale

C

End cycle time

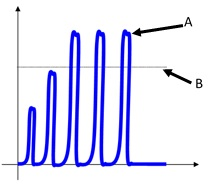

Torque coefficient: Pulse tools do not provide a continuous torque output, but they generate single high energy pulses of very short duration (» 1ms). This series of pulses results in the tightening of a joint. Due to the physics of the tool the final torque reached cannot be measured directly as for real torque tools. The reason for this is that pulse tools provide a very high torque for such a short time that only a part of these peaks translates into the tightening of the joint (generating more clamping force). This depends on many factors such as the bolt mass, friction, the stiffness of the joint, etc... The torque coefficient can be used to align the torque measured by the transducer with the real torque produced on the joint. The torque produced on the real joint will be always smaller (ideally equal) than the peak torque measured on the transducer. Therefore, this coefficient can be set to values between 0.1 and 10.

Torque vs time A

Peak value measured on the torque transducer

B

Actual torque measured on the joint

The only way to evaluate the actual torque is to make a residual torque check on the real joint (for instance, by using a STwrench). The relation between the peak torque measured on the transducer and the actual torque on the joint is affected by all the components: The pulse tool, the adapters, the transducer and the joint itself. If any of these components is changed, the relation peak torque – actual torque should be recalculated.

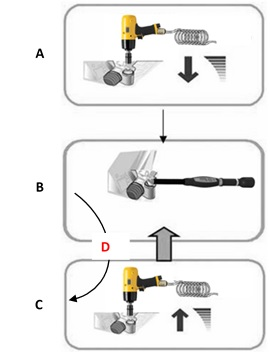

The following process should be used to adjust the pulse tool in order to provide the desired torque on the real joint and to calculate the proper coefficient K:

A

Set a value torque

B

Check the residual torque

C

Slightly increase torque

D

Too low

For instance, assume a target torque for the joint of 100 Nm, and after the tool regulation the residual torque check gives 100 Nm; if the torque measured on the transducer is 120 Nm, in that case the coefficient is 100/120 = 0.83.

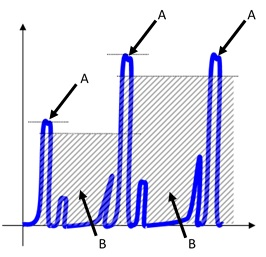

Threshold: it is used to filter the trace for proper peak detection for the frequency calculation. After each peak is detected, all the values under the threshold are discarded. This filters all the bounces always present in a pulse tightening.

The threshold can be set from 1 to 99 %. The default value is 80%.

Torque vs time A

Peak

B

Bounce