Direct driven strategy

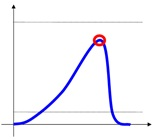

For power tool test, the torque result is the peak value measured during the test.

In case of multiple peaks, the result is the highest peak.

Testing the tool with a torque/angle transducer makes possible to define a torque/angle window in which the result is OK.

The parameter that characterize the peak point detections are:

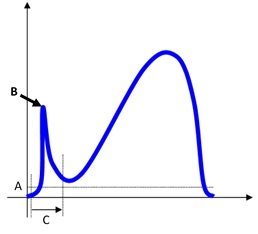

Measure delay time: this timeout is used to filter the possible spikes or noise at the beginning of the test. When the torque reaches the Cycle Start value, the timer starts. During this time the torque trace is not considered.

Torque vs time A

Cycle start

B

Ignored point

C

Measure delay time

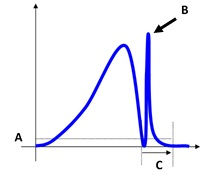

Reset time: this timeout is used to filter the possible spikes/bounces after the tool clutch release the torque. When the torque goes below the cycle complete value, the timer starts. During this time the torque trace is not considered.

Torque vs time A

Cycle start

B

Ignored point

C

Reset time

This timeout can be used in those cases where the power tool produces such spikes-bounces at the end of the test.

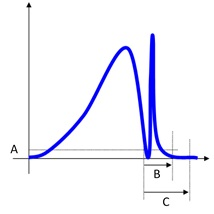

End cycle time: this timeout defines the end of the test. When the torque goes and remains below the Cycle Complete for the given timeout, the test ends.

Torque vs time A

Cycle complete

B

Reset time

C

End cycle time

The Cycle Complete must be equal or less than the Cycle Start. The value of the End cycle time must be equal or greater than the Reset time value.