Definitions

On the left-side menu bar, click Inspections > Definitions.

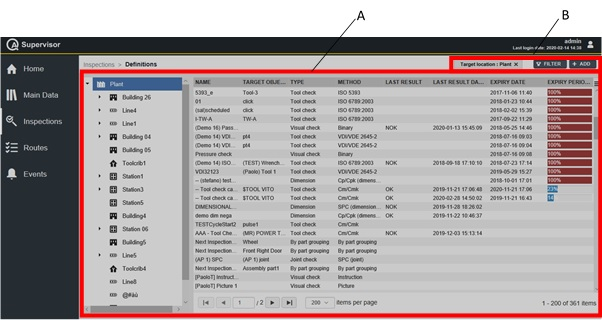

A | Definitions workspace | B | Command buttons |

On the left side of the Definitions workspace, the tree view shows the hierarchical structure of the plant. Click the arrow on the left of the element of the factory structure to show the related sub-element(s).

By selecting an item of the factory structure, the inspection definitions are filtered.

On the right side of the Definitions workspace, all of the inspections of a selected element of the plant (see the left side of the Definitions workspace) are displayed.

The right side of the Definitions workspace is divided into the following columns:

Name: name of the inspection.

Target object: name of the tool under control.

Type: type of the inspection.

Method: method of the quality control (Cm/Cmk, SPC, ISO 6789, and ISO 5393).

Last result: result of the last inspection (OK and NOK).

Last result date: date of the result of the last inspection.

Expiry date: after scheduling a specific inspection, the expiry period shows the date and time on which an inspection can be used (starting from the related last result date).

Expiry period: due date for a planned inspection activity. After the due date, if a new inspection is not performed, the previous one is no more valid. Then, the process is no more under control.

In the Definitions workspace, click an inspection to display the related Inspection Definition Details card.

On the upper-right corner of the Inspection Definition Details card, click the Close button to exit the Inspection Definition Details card (without saving any change).

If the message “Toolcheck feature not licensed” is displayed on the top of the Inspection Details card, it is only possible to add a new inspection or edit, clone and display the inspection executions already configured.

At the bottom of the Inspection Definition Details card, the following items record all the changes made for the selected inspection:

History: the history table records all the changes made for the selected inspection.

The first line of the history table summarizes the latest version of the inspection configuration. Click a previous line: the related Inspection Definition Details card opens on the left of the Inspection Definition Details card related to the latest version. The differences between the two Inspection Definition Details cards are highlighted in yellow.

On the upper-right corner of the oldest Inspection Definition Details card, click Restore: the previous version of the inspection configuration becomes the latest one.

Version: version of the inspection configuration.

In the Inspection Edit dialog box, change one of the following items to make a new version: Inspection, Scheduling, Name, Inspection method, Tool, Joint, and Status.

Changed by: name of the operator who has made a change to the inspection configuration.

Changed on: optional field, it appears only if the change has made by an operator on a device.

The restored inspection is linked to the scheduling and tool(s) of the latest version in use.

On the upper-right corner of the Definitions workspace, there are the following command buttons:

Add: click to add a new inspection into the Definitions workspace.

It is possible to create new tool check inspections only for tool whose status is either In use, Backup or Toolcrib.

It is possible to create new joint check inspections only for joints whose status is In use.

Filter: click to give filters and list only the necessary inspection(s).

It is possible to save two inspection with the same name and the same target objet. A warning message is displayed to inform the operator that an inspection with the same name already exists.

Select Yes to save the inspection.

Select No to discard the inspection.

- Adding an inspection

- Editing an Inspection Definition Details card

- Running an inspection

- Tool check inspection

- Joint check inspection

- Visual check inspection

- Dimensional check inspection

- By part grouping inspection

- Cloning an Inspection Definition Details card

- Displaying the Inspection Results

- Setting the inspection filter

- Inspection filter criteria