Joint check testing

The quality control strategies are used to check tightening operations already performed, by executing the residual torque check operation.

In the following a description of different strategies.

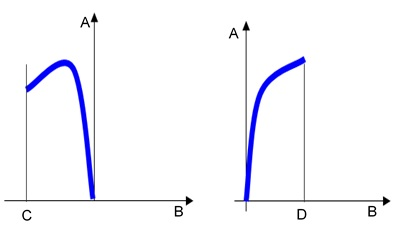

Residual Torque/Angle

This strategy evaluates the residual torque on a joint, looking for the residual point of the Torque / Angle trace.

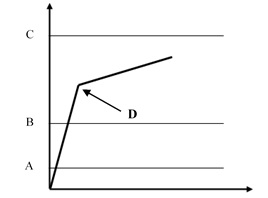

A | Cycle start | B | Minimum torque |

C | Maximum torque | D | Breakaway = Residual |

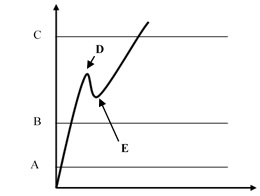

A | Cycle start | B | Minimum torque |

C | Maximum torque | D | Breakaway |

E | Residual |

Define the torque limits such that the residual point is OK in the result.

The Final angle monitoring torque, which must be greater than the Cycle start, defines the point from which the device algorithm starts analyzing the torque/angle trace. This is useful to filter all the noise that may occur at low torque value, and that could be detected as a false residual point.

Torque result:

If the residual point is detected, the result is associated with the residual point; the test is OK if the residual falls within the limits.

If the residual is not detected or the torque goes over the maximum torque, the torque result is the maximum value. Therefore, if the maximum value falls within the limits, the torque result is still OK, but the overall result is marked as Not OK.

If the torque goes over the Change Screw value, the residual is no longer detected and the torque result is the maximum torque.

In the configuration of the residual torque/angle strategy, there are two advanced parameters:

Breakaway angle threshold: it specifies the maximum angle for the residual torque (measured from the Final angle monitoring torque).

Residual angle threshold: it specifies the maximum angle (measured from the Final angle monitoring torque) for the residual torque when a the residual torque is lower than the breakaway point.

If the residual point precedes the Residual angle threshold, the residual torque is detected. this is the normal condition for a residual torque test.

If the residual point is over the Residual angle threshold, the breakaway point is the result of the test. In this case, the Residual angle threshold should be increased to detect the proper residual point.

If the breakaway point is over the Breakaway angle threshold, the residual point is not detected even if the residual point precedes the Residual angle threshold

Residual Torque/Peak

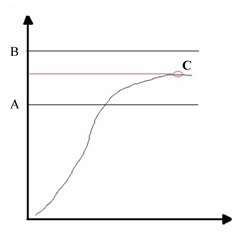

This strategy evaluates the residual torque on a joint as the peak torque necessary to rotate the screw further.

With this strategy, the breakaway point is not detected automatically. Therefore, this is a less objective method of evaluating residual torque. It may be used when the residual torque/time or torque/angle methods cannot be performed.

A | Minimum torque | B | Maximum torque |

C | Torque peak |

Specify the torque limits in order to get a result “OK”.

If the Target Angle is not specified, the angle result is marked as Not Applicable.

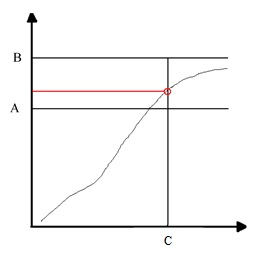

If a Target Angle value is specified, the residual torque result is measured at the specified angle (starting from the Final angle monitoring torque) instead of the peak torque:

A | Minimum torque | B | Maximum torque |

C | Target angle |

Loose and tightening

The Loose and Tightening strategy is available only with STa 6000.

The purpose of this strategy is to evaluate the residual torque on a joint by loosening the bolt up to the target angle and by tightening it back to its original position.

The strategy is composed of two phases: in the first phase (loose), the operator unscrews the bolt for a few degrees; in the second phase (tightening), the operator screws the bolt until the original position is reached.

A | Torque | B | Angle |

C | Target angle | D | Original position target angle |

Specify the torque limits and set the Target angle to a few degrees, so that the torque during the loosening phase does not go under the Cycle start value.

The result of the test is OK when the bolt is tightened back to its position and within the specified torque limits.