ToolsTalk MT (9.4.0)

Software

General Data Protection Regulation (GDPR)

This product offers the possibility to process personal identifiable information such as system user name, role and IP-address. The purpose of this processing capability could be to enhance quality control through traceability and proper access management.

If you decide to process personal data you need to be aware of and comply with relevant personal data protection rules, including, in the EU the GDPR as well as other applicable laws, directives and regulations. Atlas Copco can in no way be held liable for any use made by you of the product.

Liability

Many events in the operating environment may affect the tightening process and shall require a validation of results. In compliance with applicable standards and/or regulations, we hereby require you to check the installed torque and rotational direction after any event that can influence the tightening result. Examples of such events include but are not limited to:

initial installation of the tooling system

change of part batch, bolt, screw batch, tool, software, configuration or environment

change of air- or electrical connections

change in line ergonomics, process, quality procedures or practices

changing of operator

any other change that influences the result of the tightening process

The check should:

Ensure that the joint conditions have not changed due to events of influence.

Be done after initial installation, maintenance or repair of the equipment.

Occur at least once per shift or at another suitable frequency.

Configuration overview

Introduction to ToolsTalk MT

The MicroTorque system is the Atlas Copco screw driving range for low torque applications.

ToolsTalk MT is a PC software package that offers easy and user friendly programming and real time monitoring of MicroTorque controllers, including:

-

Multistep screw fastening procedure with torque and angle control.

-

Flexible programmable screw fastening step sequences.

-

Precise tightening torque, angle control and multistep process data documentation.

-

Multipoint communication via USB for parameter settings, graphical readout and process data communication.

ToolsTalk MT Password protection

You need administrative rights on the PC to enable or disable the Tools Talk MT password protection. Administrative rights are not needed to change the password once the authentication is enabled.

When you start ToolsTalk MT with password protection enabled, you are in Read only mode.

Find and right-click ToolsTalk MT in the Start menu and select Run as administrator.

Select Yes in the User Account Control window.

In ToolsTalk MT select the User icon

.

.In User settings select Password protect ToolsTalk MT and select SET PASSWORD.

In Authentication settings enter a password (minimum 4 characters), and then select OK.

In User settings select OK. You are now signed-in in Editing mode.

Go to EDITING and then select Sign Out to go back to Read Only mode.

Pset

The tightening programs in ToolsTalk MT are called Psets. A Pset can consist of different steps. All steps have precise speed control and many options of angle and torque monitoring.

Verification Program

A verification program is a unique type of tightening program that is used to verify the tool when doing torque checks.

Batch sequence

Batch sequence is a way of grouping and adding control over the tightening work flow. A batch sequence can be a list of batches, events or information steps that will be executed by the controller in sequential order. The batch sequence can interact with the operator in terms of screen instructions and with the use of external equipment, for example PLC or scanners.

Batch

A batch is defined as how many times a specific Pset should run.

Event

An event is a way of controlling the surroundings, setting output, waiting for input, monitoring the level of an input, setting a delay or collecting data from scanners.

Information

The information step can be used to inform and guide the operator.

Work selection (Select source)

The system can select work, that is Psets and batch sequences, in four different ways:

Protocol (Tools Talk MT + Atlas Copco Open Protocol)

Digital I/O

Scanner (Barcode/RFID)

Controller

Fieldbus

Result handling

After each tightening and measurement, result data is generated and stored on the controller memory. Up to 100.000 results and 1000 graphs can be stored on the tightening controller, and up to 10 000 results and graphs can be stored on the measurement controller.

When the maximum number of results have been reached the newest result will overwrite the oldest result.

It is possible to collect serial numbers and production data via scanners and storing it with the results for increased traceability and continuous improvement.

The result can be exported from the controller over the communication network (Ethernet or USB) or by manual extraction with a USB flash drive.

For increased traceability and production monitoring, the MTF 6000 can connect to ToolsNet 8.

User interface

The figure below shows the main window when connected to a controller. The icons can vary depending on different IAMs connected.

A | Manage connections |

B | Pset and Verification program |

C | Batch sequence |

D | Identifiers and generation of station barcode |

E | Configurations |

F | Analysis |

G | Step results/Results/Events |

H | Tool settings |

I | Controller settings |

J | Digital I/O and password settings |

K | Fieldbus |

L | Transducer settings |

M | Undo all changes |

N | Save changes to controller. In offline mode changes are saved to a file. |

O | Select how to display the open windows: tile, cascade or one single window. |

P | User settings. |

Q | Help |

R | ToolsTalk MT software version |

S | TN displays if the controller is connected to ToolsNet 8. |

T | Warning/information if a new ToolsTalk MT is available for download |

U | Hint message |

V | Type of active event |

W | Active event text |

Getting started

Start the controller

Connect the PSU to the controller and check that it is powered on. If you are using a QA or Tightening station, start the unit by pressing the button on the battery.

Start ToolsTalk MT

Start ToolsTalk MT using the icon on the PC desktop or the shortcut in the program menu.

Manage connections menu

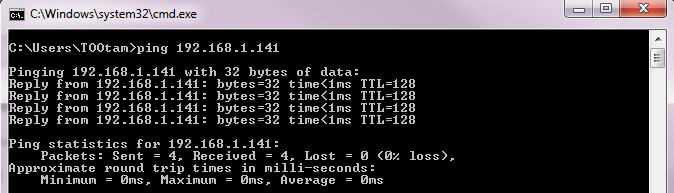

It is possible to connect to a controller in different ways:

USB

Serial (Only available for MTF 400 and G4)

Ethernet (Only available for MTF 6000 and ACTA MT4)

Controllers connected via Ethernet can be saved as favorites.

Offline

In offline mode ToolsTalk MT is connected to a virtual device. All features have the same functionality as when connected to a real controller.

It is possible to export and import offline files from controller via usb flash drive or through ToolsTalk MT.

Save all changes done while working in offline mode by clicking the Save-button.

It is not possible to virtually connect to a QA controller, only tightening.

Network update

With Network Update it will be possible to update firmware and configurations (Pset, Batch sequence and identifiers) to several controllers across the network in one go. There will no longer be a need to update each controller one by one as long as they are connected to the network. This feature is only supported with the IAM Smart Automation.

When using Network update the new configuration will remove and overwrite all existing Psets, Batch Sequences and Identifiers.

Settings

Pset and Verification Program

The tightening programs in ToolsTalk MT are called Psets.

A Pset is set to the tool that is connected to the controller when the Pset is created. If another tool is connected when the Pset is active a prompt will be show that explains that the Pset will not work.

Introduction to the Pset list

Each line represents one Pset. The columns contain the following information:

Check box to select the Pset

Number

Name, a user defined name

Step no.

Last change

Tool model, the tool model that the Pset will work with.

Tuning

Active

It is possible to sort the list by clicking the header of each column.

Adding a Pset/Verification program

To add a Pset, perform the following steps:

Click the Pset icon the Menu bar. The workspace area shows a list of all the current Psets.

Click the Add button. The Create Pset window opens.

Enter Pset number and name.

Click the OK button.

A new Pset is added and the list is updated.

Deleting a Pset

To delete one or several Psets, perform the following steps:

-

Click the Pset icon in the Menu bar. The workspace area shows a list of all the current Psets.

-

For each Pset to be deleted, mark the check box in the leftmost column in the workspace area.

-

Click the Delete button.

-

Confirm the deletion in the Confirm window.

The selected Pset(s) are removed and the list is updated.

Copy Pset

To copy a Pset, perform the following steps:

-

Right-click on the Pset you want to copy from.

-

Select Copy.

-

Right-click on the Pset you want to copy to.

-

To confirm, press the Yes button in the Confirm window.

Set up a new Pset

The basic workflow when programming a Pset in ToolsTalk MT consists of the following steps:

-

Open the Psets window.

-

Click the Add button.

-

Select a Pset number and a Pset name.

Click the OK button.

The Pset will appear in the Pset list.

-

Doubleclick on the Pset to open the Pset window or mark and click Open.

-

Enter general settings.

-

Add the Pset steps. This is the most common setup for a standard screw tightening application:

-

Thread engagement step

-

Angle step

-

Torque step.

-

-

Press the Expand all button or doubleclick on a step.

-

Set step type for each step and set the step parameters.

-

Click the Save button to save the settings to the controller.

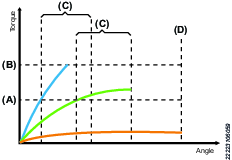

Example, three-step tightening strategy

-

Finding the thread.

-

Run down until the screw head touches the work piece.

-

Clamping the joint.

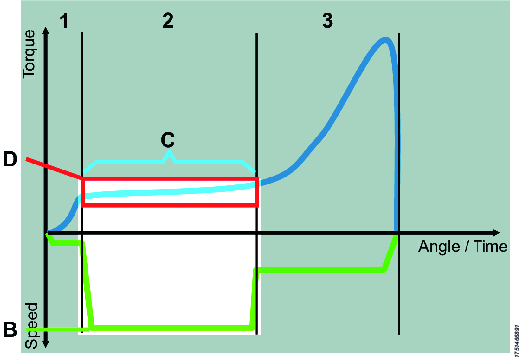

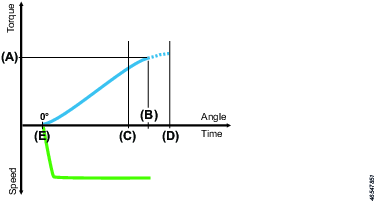

Step 1: Finding the thread

First use the thread engagement step to find the thread.

|

B - Slow speed, 100-150 rpm. C - Transition to next step on raised torque when the screw enters the thread |

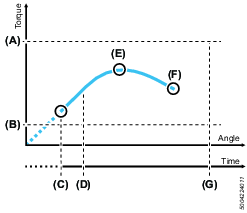

Step 2: Run down

Use the angle step to run down the screw.

| B - High speed C - Transition to next step on angle, corresponding to the thread length before the screw head touches the work piece D - Torque window to supervise the run down and alert on faults, e.g. damaged thread It is important that the angle step stops before the screw head touches the work piece, if not it can lead to unwanted overshoots since the tool might not be able to break in time. |

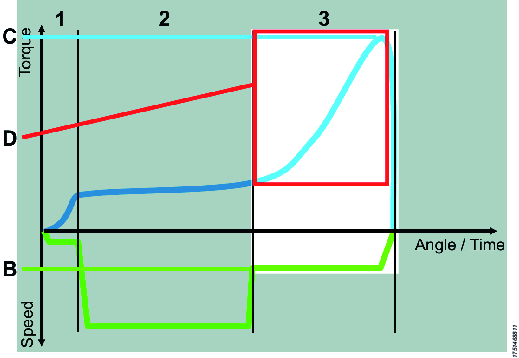

Step 3: Clamping the joint

Use the torque step to clamp the joint.

|

B - The speed the tool has been configured with C - The joint is finished when the target torque is reached D - Angle window from torque level to supervise the clamping and alert on faults, e.g. broken work piece or missing washer |

Add Pset with Quick programming on controller

It is possible to add a Pset or Verification program using the controller, see MTF 6000 Configuration guide.

Pset window

|

GUI object |

Description |

|

Change tool type |

Only available in offline mode. |

|

Test button |

Opens a window that enables you to start, stop and reset the active Pset |

|

Activate button |

Sets the current Pset to the active Pset on the controller. The Selected source must be set to Protocol/ToolsTalk MT. |

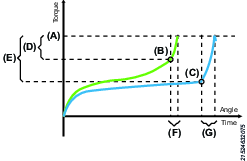

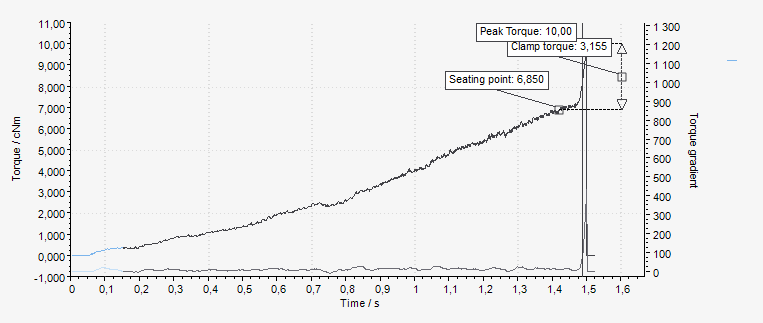

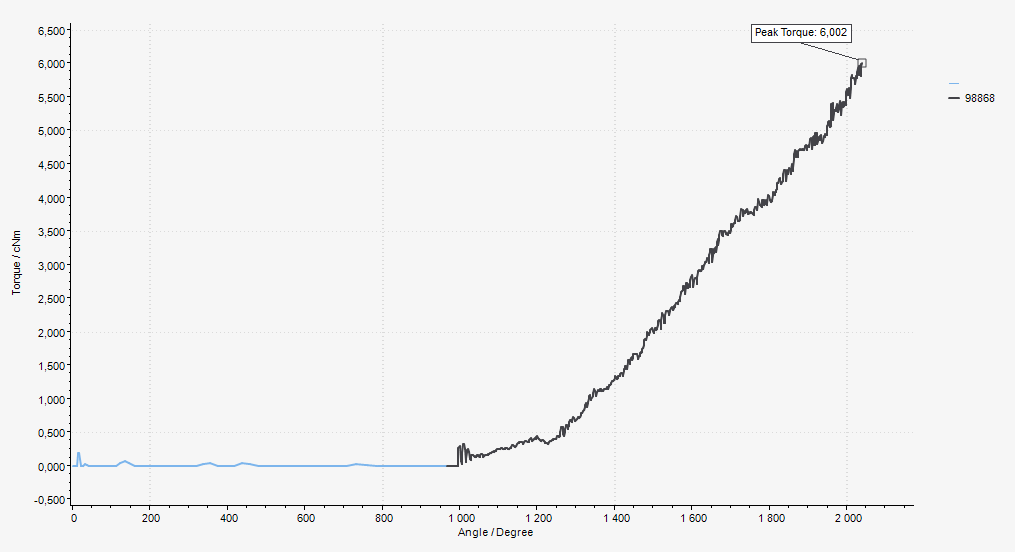

Key tightening definitions

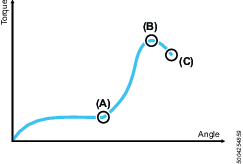

The screw is run down until the screw head touches the work piece at the seating point (A). The screw is then tightened until the final torque (C) is reached, this is often also the peak torque (B), but in some cases the final torque is lower.

The clamp angle (D) and clamp torque (E) is measured between the seating point and the peak torque.

A | Seating point |

B | Peak torque |

C | Final torque |

D | Clamp angle |

E | Clamp torque |

General settings

Parameter | Description |

Pset name | Is shown in Pset list. The Pset name is stored with the result and will be displayed in the controller result view. |

Pset revision | Revision number of the Pset. |

Pset created | The date when the Pset was created. |

Pset modified | The date when the Pset was last modified. |

Configured tool name | The tool type the Pset was linked to (model type in text). |

Min. total time | Minimum time a tightening must run to pass as a tightening. |

Max. total time | Maximum time a tightening can run to pass as a tightening. |

Min. total angle | Minimum number of degrees the tool must turn during a tightening. |

Max. total angle | Maximum number of degrees the tool is allowed to turn during a tightening. |

Trigger lost torque | An error will be sent if the tool button is released after the Trigger lost torque value have been passed but before the tightening is completed. |

Graph start step | The number of the step from which the graph is started. |

Torque tuning | Adjust torque calibration for this Pset. The controller multiplies measured torque with the factor “(1.0 – Torque tuning)”. So a positive Torque tuning increases the applied torque. Torque tuning can be +/-0.1 |

Angle range start step | Defines from which step the result angle will start measuring. |

Angle range stop step | Defines from which step the result angle will stop measuring at. |

Min. angle range | Minimum number of degrees the tool must turn between angle range start and stop step. |

Max. angle range | Maximum number of degrees the tool is allowed to turn between angle range start and stop step. |

Requested Bit | Disables tool if requested bit is not picked from Accessory Bus bit selector. If no Accessory Bus bit selector is connected the tool will still be disabled. If set to None, parameter is not active. |

Final report step | Defines which tightening step in a Pset should report the final torque in the result. It is usually the last step in a Pset but can sometimes be another step. |

Final report torque | Decides if the final report step should report the peak, clamp or final torque. |

Final report angle | Decides if the final report step should report the step, clamp or tightening angle. |

Final seating point angle start step | Determines from what step the Final seating point angle result parameter should be calculated from. |

Bit slip detection | (Licenced feature) Bit slip is a function to detect when the bit slips out of the joint. It is a sign that the bit or the screw head is damaged. If bit slip occurs during a Seating Control Step or a Torque Seating Monitoring and bit slip is disabled, a seating can falsely be detected. |

Damaged thread detection | (Licenced feature) Will detect if the screw's threads have been damaged. |

Tool rehit | Pset defined rehit parameter that can override the global controller settings for rehit.

|

Configure Pset

The configuration pane includes the steps in the Pset.

Add step

There are two ways to add steps:

To add a single step, click the Add button.

To add several steps, right-click on the Add button and select the number of steps you want to add.

Delete step

To delete one or several steps, perform the following steps:

Mark the check box in front of the steps you want to delete.

Click the Delete button.

Click the Yes button in the Confirm window.

Thread engagement step

The thread engagement step is used to facilitate screw engagement, normally at low RPM (100-150 rpm). This step is finished by either reaching transition torque or transition angle. If the transition angle is set to infinite, the step can be finished only by reaching the transition torque or it will be aborted when the max. step time has been reached.

Parameter | Description |

Speed | The tool speed is programmable within the valid range. |

Transition torque (A) | The step is considered done when the step torque reaches the transition torque. |

Transition angel (B) | The step is considered done when the step angle reaches the transition angle. |

Direction | Direction of the tightening, clockwise or counterclockwise. Use clockwise setting for normal tightening. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Fast speed change | Makes it possible to shift fast between fast and slow speed. When enabled it will be possible to get a more accurate torque estimation for current controlled tools over a longer time frame. This applies in the transition of the current step and the next step. |

Step start delay (E) | Delay from trigger to tool start. |

Min. step time (C) | Setting a minimum time for the step. If not reached the controller will display an error message. |

Max. step time (D) | Setting a maximum time for the step. If exceeded, the controller will display an error message. |

Angle step

The angle step is used to run the screw down for a certain number of revolutions, most of the time at high RPM. The angle step is finished when the angle target is reached.

A | Max. torque |

B | Min. torque |

C | Step start |

D | Min. step time |

E | Peak torque |

F | Target angle / Final torque |

G | Max. step time |

Parameter | Description |

Speed | The tool speed is programmable within the valid range. |

Target angle (F) | The angle that shall be reached to successfully complete the step. |

Direction | Use clockwise setting for normal tightening. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Fast speed change | Makes it possible to shift fast between fast and slow speed. When enabled it will be possible to get a more accurate torque estimation for current controlled tools over a longer time frame. This applies in the transition of the current step and the next step. |

Min. torque (B) | The torque must not be below the set min. torque during the step. If the torque drops below the minimum torque the driver will stop and the controller will display an error message. If min. Torque is set above 0 cNm, add a step before the angle step to reach the set torque before the angle step starts. |

Max. torque (A) | The maximum torque value must not be exceeded during the step. If the maximum torque is reached, the driver will stop and the controller will display an error message. |

Step start delay | Delay from trigger to tool start. |

Min. step time (D) | Setting a minimum time for the step. If not reached the controller will display an error message. |

Max. step time (G) | Setting a maximum time for the step. If exceeded, the controller will display an error message. |

Torque step

The torque step is used for final tightening of the screw and to ensure that the correct torque is reached.

A | Max. torque |

B | Target torque |

C | Min. torque |

D | Rescinding torque limit |

E | Tightening angle trigger |

F | Tightening angle |

G | Min. angle |

H | Max. angle |

Parameter | Description |

Speed | The tool speed is programmable within the valid range. |

Target torque (B) | The target torque of the joint. This is also the final and peak torque of the step. |

Direction | Use clockwise setting for normal tightening. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Min. torque (C) | If the minimum torque value is not reached, the controller will display an error message. |

Max. torque (A) | The maximum torque value must not be exceeded during this step. If the maximum torque is reached, the tool will stop and the controller will display an error message. |

Rescinding torque limit (D) | This monitor parameter sets a lower limit for the torque in this step. If the torque, at any time, drops below this limit the tightening will stop with an error message. |

Min. angle (G) | Angle that must have been reached when the step is finished. |

Max. angle (H) | Angle that must not be exceeded prior to reaching target torque. |

Step start delay | Delay from trigger to tool start. |

Min. step time | Minimum time for the step. If not reached, the controller will display an error message. |

Max. step time | Maximum time for the step. If exceeded, the controller will display an error message. |

Tightening angle trigger (E) | Once the tightening angle trigger value is reached, angle counting begins for this step. |

Min. tightening angle | The tightening angle must exceed the min. tightening angle for the tightening to pass. |

Max. tightening angle (G) | The maximum tightening angle (E) value must not be exceeded during this step. If the maximum tightening angle is reached, the tool will stop and the controller will display an error message. |

Torque seating monitoring step

This step is a torque step with additional seating monitoring. When a seating isn't found a tightening error will be triggered. It is also possible to collect clamp torque and clamp angle data. The torque seating monitoring step has a given target torque and includes a seating detection.

Parameter | Description |

Speed | The tool speed is programmable within the valid range. |

Target torque | The target torque of the joint. |

Seating angle displacement | Angle window for calculating the seating point from the gradient trigger point. |

Gradient trigger point | The torque level when the tool detects that the screw head has touched the work piece. This is the end point of the Seating angle displacement. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Min. torque | If the total torque is below minimum torque, an error message will be displayed. |

Max. torque | The maximum torque value must not be exceeded during this step. If the maximum torque is reached, the driver will stop and the controller will display an error message. |

Rescinding torque limit | This monitor parameter sets a lower limit for the torque in this step. If the torque, at any time, drops below this limit, the tightening will stop with an error message. |

Min. angle | Angle that must have been reached when the step is finished. If not reached, the controller will display an error message. |

Max. angle | Angle that must be exceed when the step is finished. If exceeded, the controller will display an error message. |

Min. clamp torque | The min. clamp torque can be used to detect joint anomalies. |

Max. clamp torque | The max. clamp torque can be used to detect joint anomalies. |

Min. clamp angle | The min. clamp angle can be used to detect joint anomalies. |

Max. clamp angle | The max. clamp angle can be used to detect joint anomalies. |

Step start delay | Delay from trigger to tool start. |

Min. step time | Minimum time for the step. If not reached, the controller will display an error message. |

Max. step time | Maximum time for the step. If exceeded, the controller will display an error message. |

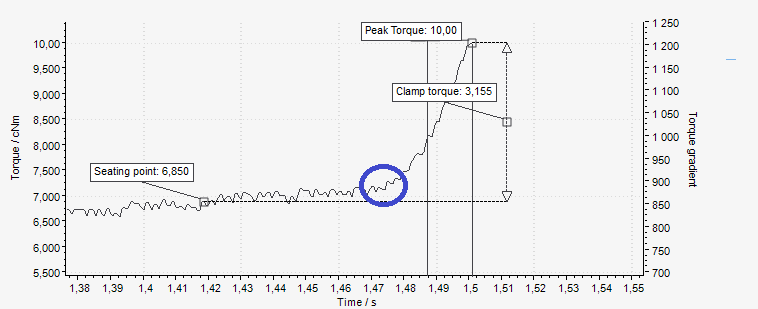

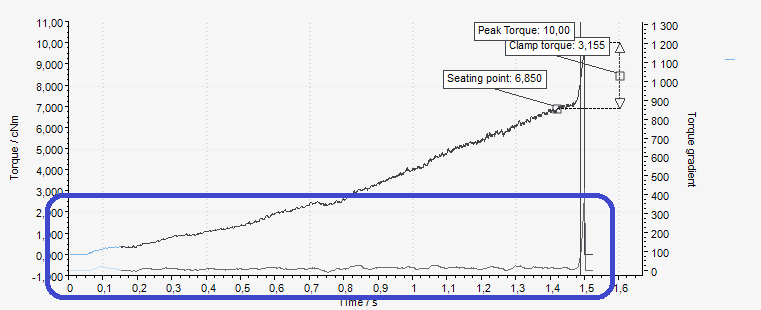

Seating control step

This step is specialized for joints with increased rundown friction, such as thread cutting, thread forming screws or joints with sideloads from misaligned parts.

In this type of applications it is common with variations from joint to joint. The main goal of this step is to eliminate floating screws and apply the same clamp torque or clamp angle to all joints even though the joints vary. The step monitors the gradient of the clamp torque over clamp angle and can detect when the screw is seated, that is when the screw head is in contact with the joint surface. From the seating point, the configured torque or angle is applied. The total torque or angle may differ from tightening to tightening but the same amount of clamp torque is used to compress the joint.

The method works as follows:

A torque level, the gradient trigger point, is set for detection of the point where the screw head is touching the work piece.

When the torque gradient exceeds the gradient trigger point, the seating point is detected. The torque gradient can be displayed in the tightening graph in the analysis window.

From this point, where the torque curve starts rising, the Seating point is calculated. This is done by calculating the mean torque from the gradient trigger point and looking back the amount of degrees from seating angle displacement.

This step type allows lower target torque and higher speeds than what the tool is calibrated for. This means that you may sometimes not get the desired results. If this happens, try to change the speed in order to get a more desired clamp value.

Parameter | Description |

Speed | The tool speed is programmable within the valid range. |

Final tightening method | Decides if the tightening should use clamp torque or clamp angle. |

Clamp torque (A) / Clamp angle (B) | Sets the value for the clamp torque or the clamp angle. |

Seating angle displacement (G) | Angle window for calculating the seating point from the gradient trigger point. |

Gradient trigger point (H) | The torque level when the tool detects that the screw head has touched the work piece. This is the end point of the Seating angle displacement. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Min. torque (L) | If the total torque for a seating control step is below minimum torque, an error message will be displayed. |

Max. torque (D) | The Maximum torque value must not be exceeded during this step. If the Maximum torque is reached, the driver will stop and the controller will display an error message. |

Min. angle (F) | Angle that must have been reached when the step is finished. If not reached, the controller will display an error message. |

Max. angle (E) | Angle that must not be exceeded prior to reaching target torque. If exceeded, the controller will display an error message. |

Min. clamp torque | The min. clamp torque can be used to detect joint anomalies. |

Max. clamp torque | The max. clamp torque can be used to detect joint anomalies. |

Min. clamp angle | The min. clamp angle can be used to detect joint anomalies. If below, the controller will display an error message. |

Max. clamp angle | The max. clamp angle can be used to detect joint anomalies. If exceeded, the controller will display an error message and the tool will stop. |

Step start delay (M) | Delay from trigger to tool start. |

Min. step time (J) | Minimum time for the step. If not reached, the controller will display an error message. |

Max. step time (K) | Maximum time for the step. If exceeded, the controller will display an error message. |

Seating angle displacement (G) | Angle window for calculating the seating point from the gradient trigger point. |

Gradient trigger point (H) | The torque level when the tool detects that the screw head has touched the work piece. This is the end point of the Seating angle displacement. |

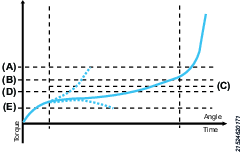

Friction Control Step

The friction control step is a smarter version of the angle step that can measure the average torque (friction) during the rundown phase. The step is finished when the target friction control angle is reached. The step will fail if the average torque is not within the average torque limits. Tightening will still be aborted if torque goes above/below the max/min torque limits.

A | Max. torque |

B | Max. average torque |

C | Average torque |

D | Min. average torque |

E | Min. torque |

Parameter | Description |

Speed | The tool speed is programmable within the valid range. |

Friction control angle | The angle that shall be reached to successfully complete the step. |

Direction | Direction of the tightening, clockwise or counterclockwise. Use clockwise setting for normal tightening. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Fast speed change | Makes it possible to shift fast between fast and slow speed. When enabled it will be possible to get a more accurate torque estimation for current controlled tools over a longer time frame. This applies in the transition of the current step and the next step. |

Min. torque (E) | The torque must not be below the set minimum torque during the step. If the torque drops below the min. torque the driver will stop and the controller will display an error message. |

Max. torque (A) | The maximum torque value must not be exceeded during this step. If the maximum torque is reached, the tool will stop and the controller will display an error message. |

Min. average torque (D) | Minimum average torque value the step shall have at the end of the step. If min. average torque is not reached at the end of the step the tightening will be aborted with a NOK result. |

Max. average torque (B) | Maximum average torque value the step shall have at the end of the step. If max. average torque is exceeded at the end of the step the tightening will be aborted with a NOK result. |

Step start delay | Delay from trigger to tool start. |

Min. step time | Setting a minimum time for the step. If not reached the controller will display an error message. |

Max. step time | Setting a maximum time for the step. If exceeded, the controller will display an error message. |

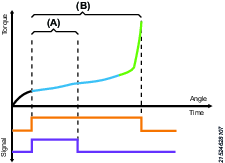

Digital Input Step

The digital input step will pause the ongoing tightening until a specific signal has been received by the controller.

This is not a hold step. Tool will pause the tightening and will not hold the torque.

A | Pause tightening and wait for signal |

B | Resume tightening |

C | Signal high |

D | Signal low |

Parameter | Description |

Input signal | External monitored 1-8 |

Signal flank |

|

Max. step time | Setting a maximum time for the step. If exceeded, the controller will display an error message. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Digital Output Step

The digital output step will set a specific signal high/low. The signal can be set until a tightening or a specific duration have been completed.

A | Signal set HIGH for a specific duration |

B | Signal set HIGH until tightening is completed |

Parameter | Description |

Output signal | External monitored 1-10 |

Signal mode |

Output signal will always be reset at the end of the tightening, regardless of mode. |

Signal level |

|

Signal duration | Decides how long the output will be active. |

Smart Engagement Step

Smart engagement is used to facilitate screw engagement, normally at low RPM (100-150 rpm). Smart engagement first reaches an engagement torque and then has to stay below Max. torque and over the engagement torque during a set validation angle. By monitoring the torque during the validation angle and the tightening step angle, the step can instantly detect tilted and missing screws.

When reaching the set engagement torque a possible engagement is triggered. After reaching the engagement torque the controller will monitor the torque for a set validation angle to make sure that the screw is correctly engaged. If the tightening reaches max. torque or max. angle a retry action is triggered. A retry action can either consists of a retry or an abort. The user can define how the tightening should act according to the different errors. If the retry action is triggered due to max. torque it is most likely caused by a tilted screw and therefor retry is advised as a retry action.

If the retry action is triggered due to max. angle it is likely that the error was triggered by a missing screw and therefor abort is advised as a retry action.

Speed | The tool speed is programmable within the valid range. |

Engagement torque (A) | Activates validation angle after reaching the engagement torque. |

Validation angle (C) | Monitors the torque for a specified angle to make sure that the torque is above the engagement torque and below the max torque. Step is completed when these requirements are fulfilled. |

Retry action |

|

Loosening angle method |

|

Loosening angle | User defined angle used for retries. |

Loosening torque | Max. torque while loosening. |

Loosening speed | The speed set for loosening if a retry has been triggered. |

Direction | Direction of the tightening, clockwise or counterclockwise. Use clockwise setting for normal tightening |

Retry Signal | Defines what Externally Monitored Input should activate if the tool is currently loosening during a retry. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Fast speed change | Makes it possible to shift fast between fast and slow speed. When enabled it will be possible to get a more accurate torque estimation for current controlled tools over a longer time frame. This applies in the transition of the current step and the next step. |

Max. torque (B) | If max torque is reached a retry action will be triggered. |

Max. angle (D) | If max angle is reached a retry action will be triggered. |

Retry limit | Number of times the tightening will try to retighten the screw after a retry action has been met. |

Step start delay | Delay from trigger to tool start. |

Min. step time | Minimum time for the step. If not reached, the controller will display an error message |

Max. step time | Maximum time for the step. If exceeded, the controller will display an error message. |

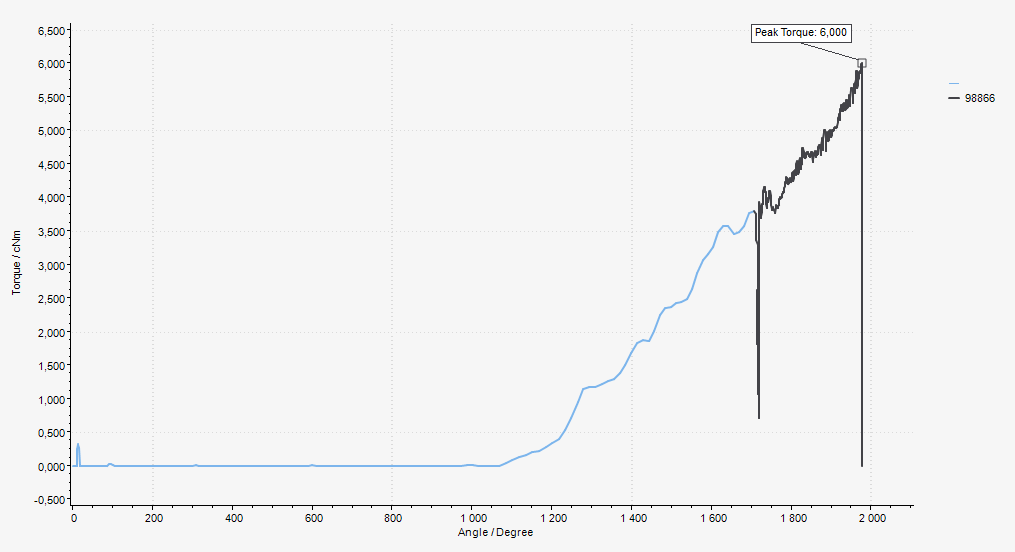

Smart Torque Seating Monitoring (Smart TSM)

The smart torque seating monitoring step is a smarter version of the torque step, with a brand-new seating detection algorithm. The smart TSM will tighten the screw to a desired target torque and will also monitor if the screw has found seating or not. If not, it will report a NOK Seating was not detected if the screw is floating. The controller needs to know an estimated clamp torque and clamp angle to calculate the seating detection. A detected seating point can be rejected if the torque gradient falls too low during the tightening. It will then be regarded as a false seating point and will continue to search for another seating point.

A | Target torque |

B | Seating point |

C | Seating point |

D | Clamp torque |

E | Clamp torque |

F | Clamp angle |

G | Clamp angle |

Speed | The tool speed is programmable within the valid range. |

Target torque | The target torque of the joint. |

Clamp torque | Expected clamp torque for the tightening. |

Clamp angle | Expected clamp angle for the tightening. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Min. torque | If the minimum torque has not been reached when the step is finished, an error message will be displayed. |

Max. torque | If the maximum torque is reached before the step is finished, the tool will stop and the controller will display an error message. |

Rescinding torque limit | This monitor parameter sets a lower limit for the torque in this step. If the torque, at any time, drops below this limit, the tightening will stop with an error message. Setting this parameter to 0 will disable the rescinding torque monitoring. |

Min. angle | If the minimum angle has not been reached when the step is finished, an error message will be displayed. |

Max. angle | If the maximum angle is reached before the step is finished, the tool will stop and controller will display an error message. |

Min. clamp torque | The minimum clamp torque can be used to detect joint anomalies. If below, the controller will display an error message. |

Max. clamp torque | The maximum clamp torque can be used to detect joint anomalies. If exceeded, the tool will stop and the controller will display an error message. |

Min. clamp angle | The minimum clamp angle can be used to detect joint anomalies. If below, the controller will display an error message. |

Max. clamp angle | The maximum clamp angle can be used to detect joint anomalies. If exceeded, the tool will stop and the controller will display an error message. |

Step start delay | Delay from trigger to tool start. |

Min. step time | Minimum time for the step. If not reached, the controller will display an error message. |

Max. step time | Maximum time for the step. If exceeded, the controller will display an error message. |

Smart Seating Control Step (Smart SCS)

This step is specialized for joints with increased rundown friction, such as thread cutting, thread forming screws or joints with sideloads from misaligned parts. In these types of applications, it is common with variations from joint to joint. The main goal of this step is to eliminate floating screws and apply the same clamp torque or clamp angle to all joints even though the joints deviate. The step monitors the gradient of the clamp torque over clamp angle and can detect when the screw is seated, that is when the screw head is in contact with the joint surface. From the seating point, the configured clamp torque or clamp angle is applied. The total torque or angle may differ from tightening to tightening but the same amount of clamp torque, or clamp angle, is used to compress the joint. The clamp torque and clamp angle are set to tell the controller what it should expect after detecting a seating. (The seating detection is calculated based on these values.) A detected seating point can be rejected if the torque gradient falls too low during the tightening. It will then be regarded as a false seating point and will continue to search for another seating point.

This step type allows lower target torque and higher speeds than what the tool is calibrated for. This means that you may sometimes not get the desired results. If this happens, try to change the speed in order to get a more desired clamp value.

A | Peak torque |

B | Peak torque |

C | Seating point |

D | Seating point |

E | Clamp torque |

F | Clamp torque |

G | Clamp angle |

H | Clamp angle |

Speed | The tool speed is programmable within the valid range. |

Final tightening method | Decides if the tightening should use clamp torque or clamp angle as target. |

Clamp torque | Expected clamp torque for the tightening. |

Clamp angle | Expected clamp angle for the tightening. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Min. torque | If the minimum torque has not been reached when the step is finished, an error message will be displayed. |

Max. torque | If the maximum torque is reached before the step is finished, the tool will stop and the controller will display an error message. |

Min. angle | If the minimum angle has not been reached when the step is finished, an error message will be displayed. |

Max. angle | If the maximum angle is reached before the step is finished, the tool will stop and controller will display an error message. |

Min. clamp torque | The minimum clamp torque can be used to detect joint anomalies. If below, the controller will display an error message. |

Max. clamp torque | The maximum clamp torque can be used to detect joint anomalies. If exceeded, the tool will stop and the controller will display an error message. |

Min. clamp angle | The minimum clamp angle can be used to detect joint anomalies. If below, the controller will display an error message. |

Max. clamp angle | The maximum clamp angle can be used to detect joint anomalies. If exceeded, the tool will stop and the controller will display an error message. |

Step start delay | Delay from trigger to tool start. |

Min. step time | Minimum time for the step. If not reached, the controller will display an error message. |

Max. step time | Maximum time for the step. If exceeded, the controller will display an error message. |

Loosening

The loosening step is used to loosen or unscrew a screw.

Parameter | Description |

Loosening torque | Maximum torque allowed for a loosening. |

Loosening angle | Maximum angle allowed for a loosening. |

Loosening speed | Speed for loosening. |

Loosening max time | Maximum time for a loosening. If exceeded, the controller will display an error message. |

Loosening vacuum pump | Digital output to switch on an external vacuum pump. |

Loosening start delay | Delay from trigger to tool start. |

Force loosening on NOK | Forces the user to conduct a loosening before another tightening can be done. This feature is disabled when run from a Batch Sequence. |

Screw pickup

Screw pickup helps the operator to pick up a screw before starting the tightening. The first start signal will trigger the screw pickup function and the second start signal will trigger the tightening. Meaning that the start signal must be pressed/triggered twice to activate the tightening procedure.

Tightening procedure when Screw pickup is enabled:

Activate start signal to pick up screw.

Place the screw in the correct position.

Activate the start signal again to trigger the tightening.

Parameter | Description |

|---|---|

Not aligned limit | Vacuum level required to acknowledge that a screw has been picked up. |

Aligned limit | Vacuum level required to acknowledge that the screw is aligned. |

Screw pickup | Indicates if the function is enabled. |

Screw pickup can be used both for handheld and automatic operations. The parameters Not aligned limit and Aligned limit requires the use of Vacuum Pump MT, which is only compatible with a controller with MTF6000 revision C or later.

If screw pickup is enabled, the following parameters can be configured:

Parameter | Description |

|---|---|

Vacuum pump | Starts vacuum pump upon activating screw pickup function |

Rotate bit on pickup | Bit rotates slowly CCW to help attach the bit to the screw. |

Timeout | Timeout is used to set an interval how long the pickup should take. If the time is exceeded the controller will leave the busy state and go back to idle. |

Guiding light | Activates the MT tool guiding light upon activating screw pickup function. |

Pickup guide

Vacuum pickup guide is available with Vacuum pump MT (8432 0854 00) and a controller with MTF6000 revision C or later. Click PICKUP GUIDE to open the wizard. The vacuum starts automatically if the vacuum pump MT is connected.

On the wizard page, you can set the limits by moving the limit indicators up and down. A two-step setup guide is also available by clicking SETUP GUIDE:

Follow the instructions on the screen to set the value when the screw is picked up but not aligned.

Follow the instructions on the screen to set the value when the screw is picked up and aligned.

You can always manually update the values afterwards.

Custom View

The custom view makes it possible to customize the last view on the controller. The selected information will only be displayed during the selected Pset. If no Pset is selected the screen will be blank.

The screen can be configured to show one to four fields. For each field it is possible to display general or step information.

The first field have a white background, the following have grey background. This is to give a focal point and have no other intended meaning.

General data

Parameter | Description |

|---|---|

Final torque | Shows the final torque of the tightening. Final torque can be configured in the general settings of the Pset. |

Peak torque | Shows the maximum achieved torque in the tightening. |

Tracking torque | Follows the torque during the tightening. |

Final angle | Shows the final angle of the tightening. Final angle can be configured in the general settings of the Pset. |

Total angle | Shows the total angle of the tightening. |

Tracking angle | Follows the angle during the tightening. |

Tightening error | Shows the current error message, blank if no current error. |

Pset name and number | Shows Pset number and name. |

Controller date | Controller date. |

Controller name | Controller name (configured under Controller settings). |

Station name | Station name (configured under Controller settings). |

Line name | Line name (configured under Controller settings). |

Logged in user | Displays if any user level is logged in (L1-L3) or "-" if no user is logged in. |

Tightening duration | The time in seconds of the last tightening. |

Tool serial number | The serial number of the connected tool. |

Tool type | The type of the connected tool. |

Calibration date | Date of last calibration. |

Tool statistics | Tool statistics, displays the OK and NOK tightenings since last calibration. |

Select source | Displays the source of Pset and batch sequence selections. |

Controller time | Controller time. |

Tool temp | Current temperature of tool. |

Vacuum pressure | Displays real time vacuum pressure in kPa. |

Step data

Parameter | Description |

|---|---|

Step number | Selects from which step the parameter "Step data" shall get its values from. |

Step peak torque | Shows the maximum achieved torque in the selected step. |

Step clamp torque | Shows the achieved clamp torque in the selected step. |

Step transition torque | Shows the maximum last measured torque in the selected step. |

Step angle | Shows the achieved angle for the selected step. |

Step clamp angle | Shows the achieved clamp angle in the selected step. |

Seating point | Shows the seating torque of the step. |

Tightening angle | Shows the tightening angle for the selected step |

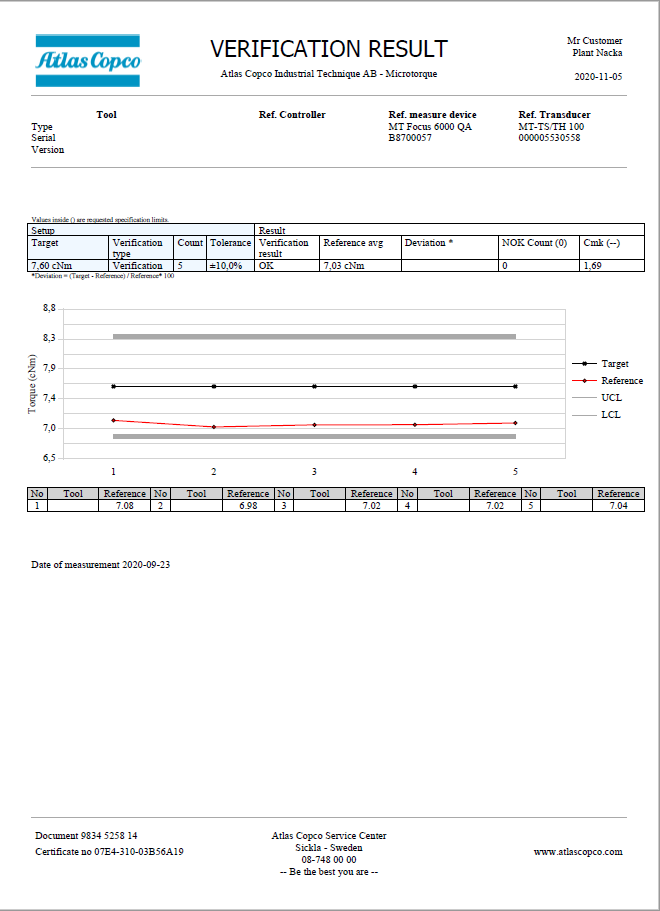

Verification Program

The Verification program is a specific form of Psets that can be used to verify the tool accuracy together with an IAM QA controller.

A Verification program is a form of torque step with limited parameter input. The window limits will not be set on the tightening itself but can be sent to the IAM QA controller to set limits on the measured torque.

General data

Parameter | Description |

Name | Is shown in Verification program list. The Verification program name is stored with the result and will be displayed in the controller result view. |

Revision | Revision number of the Verification program. |

Created | The date when the Verification program was created. |

Modified | The date when the Verification program was last modified. |

Configured tool name | The tool type the Verification program was linked to (model type in text). |

Control limit | How much the reference value can deviate from:

|

Verification size | Number of tightenings to perform for the testing of the tool |

Verification mode | Decides what the verification result should trigger on.

|

Measurement Evaluation mode | The measurement will compare the Target or Tool peak value against the QA reference and the control limit to see if a measurement should be OK or NOK. Current controlled tools are locked to Target vs Reference. (read only parameter) Transducerised tools are editable and has the possibility to select between:

|

Minimum CMK | Minimum allowed CMK value (disable chef if set to 0). |

On Verification complete | Decides what shall happen after the verification program is completed.

|

Operator ID required |

|

Step data

Parameter | Description |

|---|---|

Speed | The speed to tool will run at during the test. |

Target torque | The target torque the test shall be performed on. |

Vacuum enabled | If enabled, the vacuum is activated during the test. |

Step start delay | Set a start delay of the tightening |

Batch sequence

This function provides the possibility to control a sequence of screw joints with different tightening strategies related to the assembly of one workpiece.

Batch

To set-up a batch a pre-defined Pset and a batch size is needed, that is the number of tightenings to be performed.

It is possible to define a repair Pset and a repair limit. If a tightening fails, the repair limit is incremented. If the repair attempts exceed the repair counter the whole batch sequence is failed.

It is possible to set two timeout values, from start and from tightening. If a batch takes longer time than the set value, the batch is failed and aborted.

Event

The event step can be used to interact with the workstation and control the flow of the tightening process.

Input

The input step will wait for the Batch Sequence DI1-12 signal to be in a desired state, set by the Signal flank parameter. Signal flank defines if the input step should react on changes from low to high (positive flank), high to low (negative flank), just being high/low or react to any signal changes (any).

Output

The output step will set a Batch Sequence DO1-8 signal in a desired state, set by the Output signal level parameter.

Output signal level defines if the signal should be set high (one) or low (zero). The output mode defines if the signal should be permanently set to the output signal level or be pulsed (duration). In the case of duration, the time for the pulse must be selected. The max time for the pulse is three seconds, if a longer step is needed it is possible to use two output steps in set mode with a delay step in-between.

Delay

It is possible to delay the sequence for a given time between 0.01 and 30 seconds.

Advanced scan

This step forces the user to scan a barcode or read a RFID-tag. The data can be stored with the tightening result data for traceability.

Configuring this step requires one or more pre-defined identifiers. An identifier is a rule that is used to verify if the scanned string is correct.

This step can house up to four identifiers, this is to manage variations in product serial numbers. For example it can be that the scan will store the serial number of a module in the product. The module can come from two different suppliers and have different serial numbers. Then serial numbers of both types should be accepted as correct.

Simple scan

This step forces the user to scan a barcode or read a RFID-tag. The data can be stored with the tightening result data for traceability.

The information is saved to a custom ID. No validation is made.

Input monitor step

The input monitor step can be used to monitor the level of a digital input during the batch sequence. When triggered, the batch sequence will be aborted and the sequence is restarted.

Bit selector

The bit selector step can be used to force the operator to change bit before continuing.

Introduction to the batch sequence list

Each line represents one batch sequence. The columns contain the following information:

Check box to select the batch sequence

Number

Name, a user defined name

Number of

Active

Last change

It is possible to sort the list by clicking the header of each column.

Adding a batch sequence

To add a batch sequence, perform the following steps:

-

Click the Batch sequence icon in the Menu bar. The workspace area shows a list of all the current batch sequences.

-

Click the Add button. The Create batch sequence window opens.

-

Enter batch sequence number and name.

-

Click the OK button.

A new batch sequence is added at the place of select number and the list is updated.

Deleting a batch sequence

To delete a batch sequence, perform the following step:

-

For each batch sequence to be deleted, mark the check box in the left most column in the workspace area.

-

Click the DELETE button.

-

Confirm the deletion in The Confirm window.

The selected batch sequence(s) are removed and the list is updated.

Copy batch sequence

To copy a batch sequence, perform the following steps:

-

Right-click on the batch sequence you want to copy.

-

Select Copy.

-

Right-click on the batch sequence you want to copy to.

-

Select Paste.

-

To confirm, press the Yes button in the Confirm window.

General settings

Parameter | Description |

Batch sequence name | Is shown in the batch sequence list. Will be displayed on the result screen on the controller. Will be saved together with all tightening results made in the batch sequence. |

Batch sequence revision | Revision of the batch sequence. |

Batch sequence created | The date when the batch sequence was created. |

Batch sequence modified | The date when the batch sequence was last modified. |

Beep on error | When enabled, the controller will beep if a batch sequence has failed. |

Abort time | If a batch sequence takes longer time than this, the batch sequence is failed and aborted with an error message. |

Reset idetifier on batch sequence complete | When enabled, the controller will clear the contents of Custom ID 1-4 upon the completion of a batch sequence. |

Configuration

The configuration pane includes the batch, events or information steps in the batch sequence.

Add batch, event or information step

There are two ways to add steps:

-

To add a single step, click the Add button.

-

To add several steps, right-click on the Add button and select the number of steps you want to add.

-

Click the Add button.

Delete batch, event or information step

To delete a batch, event or information step perform the following steps:

-

Mark the check box in front of the batch, event or information step you want to delete.

-

Click the Delete button.

-

Click the Yes button in the Confirm window.

Batch parameters

A batch is a series of tightenings with one defined Pset.

Parameter | Description |

Pset number | Number of the Pset to use. |

Batch size | The number of tightenings with the selected Pset. |

Repair mode | Enabled/Disabled. If enabled the loosening trigger will automatically be disabled until a tightening error. When the loosening trigger is enabled the tool trigger is disabled. After a loosening, the repair Pset mode is enabled. |

Increment batch counter on | OK or OK/NOK. Should the batch counter increase on OK tightenings only or on OK and Not OK tightenings. |

Fail on NOK no. | The maximum number of allowed failed tightenings during a batch. |

Repair Pset | Select a repair Pset. |

Repair limit | If a tightening fails, the repair limit is incremented. If the repair attempts exceed the repair counter the whole batch sequence is failed. |

From start | The maximum execution time for the batch step. If the batch step takes longer time than this, the batch sequence is failed and aborted with an error message. |

From tightening | The maximum execution time for a batch step counting from the start of the first tightening. If the batch step takes longer time than this, the batch sequence is failed and aborted with an error message. |

Event parameters

Parameter | Description |

Event type | Advanced scan, input, output, delay, simple scan, input monitor or bit selector. |

Advanced scan

Parameter | Description |

Identifier source | Protocol, scanner, any |

Identifier rule 1-4 | Up to four identifier rules to parse incoming identification strings. |

Information text | User defined text to be displayed on the screen during the advanced scan step. |

Timeout | If an Advanced scan takes longer time than this, the batch sequence is failed or aborted. |

Input

Parameter | Description |

Input signal | Decides which Batch Sequence DI1-12 signal to wait for. |

Signal flank | Decides if the step should react to positive/negative/any flank or positive/negative level. |

Timeout | If an Input step takes longer time than this, the batch sequence is failed or aborted. |

Information text | User defined text to be displayed on the screen during the step. |

Output

Parameter | Description |

Output signal | Decides which Batch Sequence DO1-8 to set. |

Output signal mode | Decides if the signal should be permanently set or for a set time. |

Output signal level | Decides if the output should be set high or low. |

Output signal duration | Appears if signal mode is set to duration and decides for how long the output should be active. |

Delay

Parameter | Description |

Delay time | Decides for how long the event will stay active. Can be set from 0.01-30 s. |

Simple scan

Parameter | Description |

Identifier source | Protocol, scanner, any |

Save destination | Save to one Custom ID. |

Information text | User defined text to be displayed on the screen during the simple scan step. |

Timeout | If a simple scan takes longer time than this, the batch sequence is failed and aborted with an error message. |

Key | Static text defined by user and saved with data in custom ID. |

Input monitor

The input monitor step can be used to monitor the level of a digital input during the batch sequence. When enabling an input monitor it will be active until end of the batch sequence or until it is disabled.

If the monitor error is triggered, it will activate a batch sequence error and the sequence will be aborted.

Parameter | Description |

Monitor mode | Enable or disables the input monitor. If enabled the input monitor will be active until the end of the batch sequence or until disabled. |

Input signal | Select the batch sequence input signal that should be monitored. The input signal must be assigned to an actual input in the I/O configuration. |

Trigger error on | If the signal assumed the error trigger state, high or low, the batch sequence will be aborted and a batch sequence error will be active. |

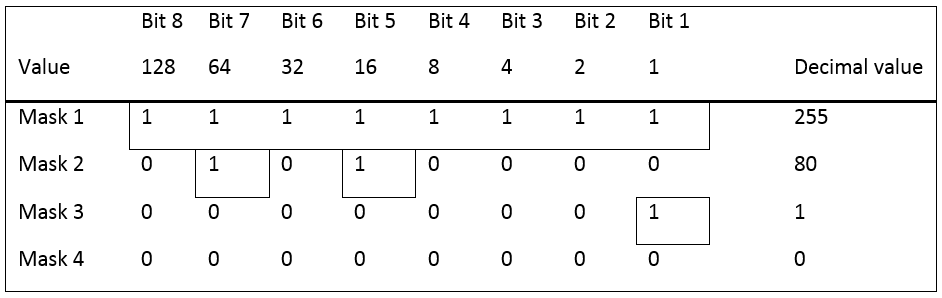

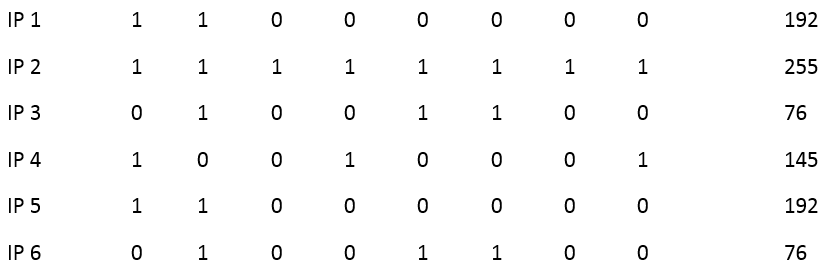

Bit selector

The bit selector step will force the user to pick up a specific bit in order to complete the step.

Digital I/O bit selector

Digital input function "Select bit 0-3" must be linked in order to detect if a bit is selected. The bit selector event will always set digital output function "Unlock bit 0-3" to identify which bit that should be selected to an external device.

"Unlock bit" and "Select bit" are both calculated binary.

Select Bit 0 weight = 1

Select Bit 1 weight = 2

Select Bit 2 weight = 4

Select Bit 3 weight = 8

Example: If Event is set to take Bit #7 then Select Bit 0, 1 and 2 should be high in order to complete the event step. (1 + 2 + 4 = 7)

Accessory Bus bit selector

The Accessory Bus uses its own protocol and has nothing to do with the digital I/Os. There is no need to link any "Select bit" to make the accessory bus bit selector work.

Example: If event is set to take Bit#7 then the selector indicator LEDs will show which bit to pick, which is the bit located at position number 7.

Parameter | Description |

Requested Bit | Select which bit the operator shall pick in order to continue on with the step. It is possible to select up to 8 different bits. (These bits are independent of the settings in configuration and will not execute any other command if picked.) |

Identifier source | Select from which source the signal shall come from Digital I/O or Accessory Bus. |

Information parameters

|

Parameter |

Description |

|

Information text |

User defined text to be displayed on screen during the information step. |

|

Information transition mode |

This parameter defines how the information step is finished. It can transition to the next step after a given time or after a press of the OK button. |

|

Information transition time |

If transition mode is selected, a time can be entered. |

|

Buzzer frequency |

The frequency of the buzzer. |

|

Buzzer duration |

The duration of the buzzer - set to zero if no buffer wanted. |

Identifiers

Identifiers are used to both store valuable information, such as operator ID and serial numbers in each result and also to select the next task for the controller.

Identification strings can be inserted into the controller either via Open protocol, Fieldbus or a Scanner.

The inserted/scanned value is validated according to the predefined identifiers and if the controller finds a match it will perform the action of that identifier.

There are several different ways of using inserted/scanned data:

Traceability and production monitoring (Operator ID, Store in Custom ID and Save ID)

Work control (Select Pset, Verification program and Batch sequence)

User access control (Login).

To configure how inserted/scanned values are used, the user needs to setup identifier rules. These rules first tries to validate an incoming identification string (scanner input). If the identification string is validated by the rule, it will issue an action to the system.

Scanner

A scanner can be connected to a USB or a serial port on the controller.

The USB-scanners must have:

USB HID interface (Keyboard)

English-US keyboard interface

MTF6000 offers the possibility of connecting scanners via USB HID (as keyboard) and RS232. It is possible to use any type of scanner that uses any of these interfaces. The system will accept text strings of up to 512 characters.

Creating station barcode

For traceability between the tightening and measuring controller it is possible to generate a station barcode containing information regarding tool, torque, controller ID, and so on. This station barcode is automatically generated inside the MTF6000 if a verification program is selected and shown on the controller display. If the controller is out of range for the quality operator it is possible to manually generate a station barcode in ToolsTalk MT that can be printed and placed next to the station so the barcode can be scanned by the IAM QA controller. The values in the station barcode is stored together with the measurement result to gain traceability between the tightening and measurement result.

In the identifier list view, click Barcode to create a station barcode. Since the station barcode is entered manually in ToolsTalk MT, it is possible to enter any values, which means that the tightening can be made with a non MTF6000 controller and the IAM QA controller will store the information regardless.

Adding an identifier

To add a identifier perform the following steps:

-

Click the Identifier icon in the Menu bar. The workspace area shows a list of all the current identifiers.

-

Click the Add button. The Create window opens.

-

Enter identifier number and name.

-

Click the OK button.

A new identifier is added at the place of select number and the list is updated.

Deleting an identifier

To delete a identifier, perform the following step:

-

For each identifier to be deleted, mark the check box in the left most column in the workspace area.

-

Click the DELETE button.

-

Confirm the deletion in The Confirm window.

The selected identifier(s) are removed and the list is updated.

Copy identifier

To copy an identifier, perform the following steps:

-

Right-click on the identifier you want to copy.

-

Select Copy.

-

Right-click on the identifier you want to copy to.

-

Select Paste.

-

To confirm, press the Yes button in the Confirm window.

General settings

|

Parameter |

Description |

|

Name |

Name of the identifier. |

|

Identification string |

The set string. The Enter/Scan button can be used to manually enter a barcode. |

Validation

The validation settings are used to verify if the rule applies to the incoming identification string. If the rule applies, the controller will execute the actions attached to the rule.

It is possible to select anything from 1 to 64 characters in the string to match against a given text.

Example:

Match part-> 1-3, 9-10

Match string->SNPDL

String 1-> SNP12345DL -> Match (bit 1-3 is SNP and bit 9-10 is DL)

String 2-> SNPDL1234 -> No match (bit 1-3 SNP but bit 9-10 is 34)

For firmware version 1.15.0 and later it is possible to add an Accept anything validation. Set the Length to 0 and leave the Match Part and Match Text empty. Do not create more than one accept anything validation on the same controller.

Parameter | Description |

Identification string length | Length of identification string. Set automatically when the Enter/scan button and then the OK button is clicked. |

Match part | Positions in the indentification string. The selection is done in a separate window. |

Match string | Characters that will match the string according to the match part. |

Configuration

In all identifier actions except login it is possible to save up to 100 characters in each custom ID. This string will then be attached to the result data from the tightening.

There are four custom ID slots that the user can fill with text. Each custom ID has two fields, key and format. The key value is a static text that can be entered when configuring the identifier. The value field will be filled when the scan happens. The value format setting decides what data is entered into the field, it will define the number and order of bits to select.

Parameter | Description |

Action type | Save ID

Select VProg |

Keep until replaced |

|

Save ID

The Save ID action can only be used inside a batch sequence.

This action is used to save data from the scanned tag with the result data. By adding a static key the data will be searchable in a database. It is possible to set up to four save strings. The scanner input can save 100 key characters and 100 scanned characters, that is, 200 in total.

Parameter | Description |

Key 1-4 | Static text defined by user saved with scanner data. |

Format 1-4 | The part of incoming string that will be saved in the custom ID. |

Save destination 1-4 | None |

Select Pset

This action can only be executed if the selected source is set to scanner. This is set in Controller settings > Configuration > Select source.

This action will select a Pset.

Parameter | Description |

Pset | Select from available Psets. |

Key 1-4 | Static text defined by user saved with scanner data. |

Format 1-4 | The part of incoming string that will be saved in the custom ID. |

Save destination 1-4 | None |

Select batch sequence

This action can only be executed if the selected source is set to scanner. This is set in Controller settings > Configuration > Select source.

This action will select a batch sequence.

Parameter | Description |

Batch sequence | Select from available batch sequences. |

Batch sequence restart mode | Decide whether the batch sequence should wait for a new scan or start automatically when it finishes. |

Key 1-4 | Static text defined by user saved with scanner data. |

Format 1-4 | The part of incoming string that will be saved in the custom ID. |

Save destination 1-4 | None |

Store in custom ID

Store in custom ID can be used to save a scanned value without any dependencies to other functions.

Parameter | Description |

Key 1-4 | Static text defined by user saved with scanner data. |

Format 1-4 | The part of incoming string that will be saved in the custom ID. |

Save destination 1-4 | None |

Operator ID

Stored in the QA controller to link an operator with a measurement result.

Parameter | Description |

|---|---|

Operator ID format | The part of incoming string that will be saved as the Operator ID. |

Open IDENTIFIERS.

Press ADD.

Open identifier.

Setup validation.

Setup operator ID format.

Go back to IDENTIFIERS.

Press OPERATORS.

Press ADD.

Enter Key (value that must match the format that was setup under operator id format).

Enter Name (Name of operator).

Example

Setup identifier

Parameter

Value

Identification string length

6

Match part

{1-3}

Match string

ABC

Operator ID format

{4-6}

Setup operators

Operator

Parameter

Value

1

Key

001

Name

Atlas

2

Key

002

Name

Copco

Result

Barcode

Operator

ABC001

Atlas

ABC002

Copco

ABC003

N/A

ABC0010

N/A

Select Vprog

This action can only be executed if the selected source is set to scanner. This is set in Controller settings > Configuration > Select source.

This action will select a Verification program.

Parameter | Description |

VProg reference | Select from available Psets. |

Vprog restart mode | Decide whether the verification program should wait for a new scan or start automatically when it finishes. |

Key 1-4 | Static text defined by user saved with scanner data. |

Format 1-4 | The part of incoming string that will be saved in the custom ID. |

Save destination 1-4 | None |

Login

This action enables a user to log in to a user level. The user level is set in I/O and Password settings > Password > Controller.

Scanning the code while logged in will automatically log out the user.

|

Parameter |

Description |

|

Level |

Select level 1 to 3. |

Station barcode

The station barcode can be manually entered to create a QR code containing information about the tool and controller which can be sent to the IAM QA controller via a scanner.

Parameter | Description |

|---|---|

Tool serial number | Serial number of the tightening tool. |

Controller serial | Serial number of the tightening controller. |

Controller ID | Controller ID of the tightening controller. |

Station ID | Station ID of the tightening controller. |

Line ID | Line ID of the tightening controller. |

Verification program instance no | Tightening program number. |

Tool type | Type of tool that will perform the tightening. |

Calibration date | Date of tool calibration. Expressed in YYYY-MM-DD. |

Target torque | The amount of torque the controller will tighten to and the measurement target. |

Control limit | Max allowed deviation from target/tool and used to calculate the CMK. |

Verification size | Number of tightenings to perform for the testing of the tool. |

Minimum CMK | Minimum value CMK can have to report a verification OK (if CMK is below min value the verification will report NOK). If parameter is empty or set to 0 then the verification will evaluate the result according to the measurement results. |

Operator ID required |

|

Save

Saves the QR code and all parameters as a picture in .jpg or .bmp format on your computer.

Export

Saves the parameters in an .xml file on your computer which can be imported and re-edited at a later time.

Import

Imports an existing .xml file containing all the parameters and their values.

Print

Prints the QR code and all parameters in a nice format that is ready to be placed next to the tightening station.

Load parameters

Load active controller parameters into the appropriate fields. Parameters that will be loaded into the station barcode are:

Tool serial number

Controller serial number

Controller ID

Station ID

Line ID

Tool type

Configurations

This function provides the possibility to control the bit selector behavior, stacklight behavior, the transducers and the tool functions, such as buttons and LED lights.

Configurations list

Each line represents the configurations for a specific tool/transducer family or accessory. The columns contain the following information:

Check box to select configuration

Name, a user defined name

Last change

Configuration type

ETD M

ETD M + PTS (push to start)

ETD MC/MT

ETD MC/MT + PTS (push to start)

QMC/QMT

MT TS/TH/TRA

Bit Selector

Stacklight

Active

Adding a configuration

When connecting a tool or a transducer with the controller, the controller will automatically add a configuration for that tool family or transducer type.

Select Add to open the Configuration window.

Enter Name and select a tool family or transducer type, then select OK.

A new Configuration is added and the list is updated.

Select Add to open the Configuration window.

Select the accessory in the list.

Deleting a configuration

To delete one or several configurations:

Select the check box of the configurations that you want to delete and then click Delete.

Active Configurations cannot be deleted.

Click Confirm in the dialogue box.

The configurations are removed and the list is updated.

General settings

Parameter | Description |

|---|---|

Name | User defined name which is shown in the configurations list. |

Configuration revision | Revision of the configuration. |

Created | Creation date of the configuration. |

Modified | Latest modification date of the configuration. |

Configurations

The configuration options vary depending on transducer or tool types. For tools, the tool trigger, lights and tactile feedback can be configured.

The controller will automatically create a configuration if a new tool/transducer type is connected to the controller.

It is not possible to create several configurations for the same tool/transducer type.

Parameter | Description |

|---|---|

Configuration type | Tool/Transducer configuration |

Tool family | Name of current tool family (only valid for tool configuration) |

ETD M / ETD M + PTS

Parameter | Description |

|---|---|

Tool start trigger |

|

Tool loosening trigger |

|

Trigger Push-To-Start |

|

ETD MC/MT / ETD MC/MT + PTS

Parameter | Description |

|---|---|

Tool start trigger |

|

Trigger start function | Only available if Tool start trigger is set to Disabled.

|

Trigger start input function | Only available if Tool start function is set to Input function. See also Digital I/O |

Trigger Push-To-Start |

|

Config single function |

|

Config single input function | Only available if Config single function is set to Input function. See also Digital I/O |

Config single output function | Only available if Config single function is set to Toggle output function or Pulse output function. |

Config double function |

|

Config double input function | Only available if Config double function is set to Input function. See also Digital I/O |

Config double output function | Only available if Config double function is set to Toggle output function or Pulse output function. |

Config hold function | Configurations will take effect approximately one second after pressing the button.

|

Config hold input function | Only available if Config hold function is set to Input function. See also Digital I/O |

Config hold output function | Only available if Config hold function is set to Toggle output function or Pulse output function. |

Led intensity | Sets the brightness for the LED of green, blue and red. Scale is from 1-5. |

Led timeout | Sets for how many seconds the LED will be on after activating green, blue or red. Timeout can be set to 0-300 where 0 is infinity. |

Led OK |

|

Led NOK |

|

Led batch OK |

|

Led batch OK color | Only available if Led batch OK is set to enabled.

|

Led guiding intensity | Sets the brightness for the LED of guiding light. Scale is from 1-5. |

Led guiding timeout | Sets for how many seconds the LED will be on after activating guiding light. Timeout can be set to 0-300 where 0 is infinity. |

Tactile on NOK |

|

QMC / QMT

Parameter | Description |

|---|---|

Led intensity | Sets the brightness for the LED of green, blue and red. Scale is from 1-5. |

Led timeout | Sets for how many seconds the LED will be on after activating green, blue or red. Timeout can be set to 0-300 where 0 is infinity. |

Led busy |

|

Led OK |

|

Led NOK |

|

Led batch OK |

|

Led batch OK color | Only available if Led batch OK is set to enabled.

|

Transducer

Parameter | Description |

|---|---|

Type | Type of transducer. For example, MT-TS |

Name | Transducer name. |

Max torque | Highest torque the transducer can measure. |

Torque threshold | Start/Stops measurement after reaching threshold. |

Torque target | What the measurement aims to reach. |

Control limit | How much the measurement in % can deviate from the target/tool torque. Is also used to calculate the CMK. |