Smart Torque Seating Monitoring (Smart TSM)

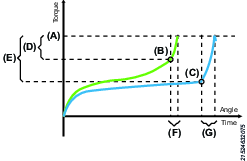

The smart torque seating monitoring step is a smarter version of the torque step, with a brand-new seating detection algorithm. The smart TSM will tighten the screw to a desired target torque and will also monitor if the screw has found seating or not. If not, it will report a NOK Seating was not detected if the screw is floating. The controller needs to know an estimated clamp torque and clamp angle to calculate the seating detection. A detected seating point can be rejected if the torque gradient falls too low during the tightening. It will then be regarded as a false seating point and will continue to search for another seating point.

A | Target torque |

B | Seating point |

C | Seating point |

D | Clamp torque |

E | Clamp torque |

F | Clamp angle |

G | Clamp angle |

Speed | The tool speed is programmable within the valid range. |

Target torque | The target torque of the joint. |

Clamp torque | Expected clamp torque for the tightening. |

Clamp angle | Expected clamp angle for the tightening. |

Vacuum enabled | Digital output to switch on an external vacuum pump. |

Min. torque | If the minimum torque has not been reached when the step is finished, an error message will be displayed. |

Max. torque | If the maximum torque is reached before the step is finished, the tool will stop and the controller will display an error message. |

Rescinding torque limit | This monitor parameter sets a lower limit for the torque in this step. If the torque, at any time, drops below this limit, the tightening will stop with an error message. Setting this parameter to 0 will disable the rescinding torque monitoring. |

Min. angle | If the minimum angle has not been reached when the step is finished, an error message will be displayed. |

Max. angle | If the maximum angle is reached before the step is finished, the tool will stop and controller will display an error message. |

Min. clamp torque | The minimum clamp torque can be used to detect joint anomalies. If below, the controller will display an error message. |

Max. clamp torque | The maximum clamp torque can be used to detect joint anomalies. If exceeded, the tool will stop and the controller will display an error message. |

Min. clamp angle | The minimum clamp angle can be used to detect joint anomalies. If below, the controller will display an error message. |

Max. clamp angle | The maximum clamp angle can be used to detect joint anomalies. If exceeded, the tool will stop and the controller will display an error message. |

Step start delay | Delay from trigger to tool start. |

Min. step time | Minimum time for the step. If not reached, the controller will display an error message. |

Max. step time | Maximum time for the step. If exceeded, the controller will display an error message. |