STpalm (07.04x)

Data collector

General Data Protection Regulation (GDPR)

This product offers the possibility to process personal identifiable information such as system user name, role and IP-address. The purpose of this processing capability could be to enhance quality control through traceability and proper access management.

If you decide to process personal data you need to be aware of and comply with relevant personal data protection rules, including, in the EU the GDPR as well as other applicable laws, directives and regulations. Atlas Copco can in no way be held liable for any use made by you of the product.

Introduction

About Configuration Manual

The Configuration Manual contains information on how to set up and configure the device. This manual is not intended to replace the training and expertise of the end-user.

Before beginning the installation or configuration process make sure to inspect all components and accessories. Contact Atlas Copco Customer Center if there are any missing or damaged items.

Revision history

Software version | Change |

|---|---|

07.04x | - |

07.03x | - |

07.02x | - |

07.01x | - |

07.00x |

|

06.03x |

|

06.02x |

|

06.01x |

|

6.00x |

|

04.05x |

|

04.04x |

|

04.03x |

|

04.02x |

|

04.01x |

|

04.00x |

|

03.01x |

|

03.00x |

|

Getting started

Starting

After switching on the device, the following is displayed:

A | Language icon | B | Login dialog box |

C | Reference firmware version |

Starting the device

In the Username box, type the username.

In the Password box, type the password.

Tap Login.

Selecting the language

Tap Language icon. The following options are available:

German.

English.

French.

Italian.

Swedish.

Czech.

Spanish.

Hungarian.

Chinese.

Japanese.

Polish.

Portuguese.

Rumanian.

Slovak.

Tap the necessary language.

Shutting down the STpalm

From the Login page:

In the Login page, tap Exit.

In the Exit STpalm window, tap OK.

From a page of the application:

In the Toolbar, tap the Menu icon (

). Then select Logout.

). Then select Logout.In the User logout window, tap OK.

In the Login page, tap Exit.

In the Exit STpalm window, tap OK.

Features

Home

After starting STpalm, the following Home page is displayed:

A | Header | B | Toolbar |

C | Barcode button |

Date and time (

): it is associated to the date and time of the operating system.

): it is associated to the date and time of the operating system.STwrench connection icon (

): it is displayed when the STpalm is connected to the STwrench.

): it is displayed when the STpalm is connected to the STwrench.

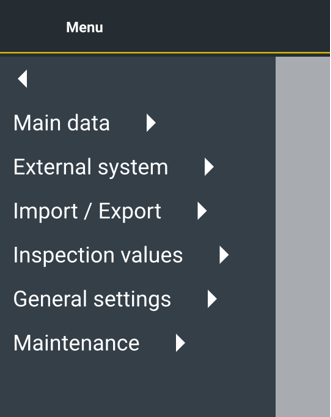

The toolbar provides the following functionality:

Menu icon (

): it lists all of the available features of STpalm. The menu icon is always available on the toolbar, regardless of the selected feature.

): it lists all of the available features of STpalm. The menu icon is always available on the toolbar, regardless of the selected feature.Barcode button (

): allows to scan a barcode to search the corresponding inspection(s) (Tool, Joint or Part inspections) on the measuring device. If the search finds a single inspection, it is automatically run; if the search finds multiple inspections with the same barcode identifier, run the inspection of interest from the list.

): allows to scan a barcode to search the corresponding inspection(s) (Tool, Joint or Part inspections) on the measuring device. If the search finds a single inspection, it is automatically run; if the search finds multiple inspections with the same barcode identifier, run the inspection of interest from the list.

The barcode button is displayed only if enabled external software.

Below the Menu items are listed:

Home: it allows to get back to the Home page (for more information, see “Home”).

Route: it allows to open the Route page (for more information, see “Route”).

Results: it allows to open the Results page (for more information, see “Results").

Joints: it allows to open the Joints page (for more information, see “Joints”).

Measuring devices: it allows to open the Measuring devices page (for more information, see “Measuring devices”).

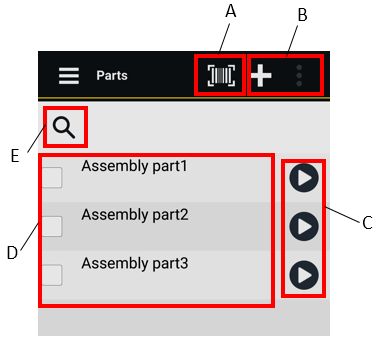

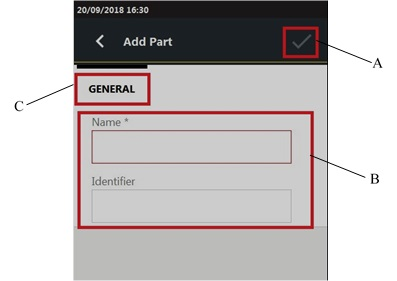

Parts: it allows to open the Parts page (for more information, see “Parts”).

Controllers: it allows to open the Controllers page (for more information, see “Controllers”).

Configuration: it allows to open the Configuration page (for more information, see “Configuration”).

Links: it allows to open the Links page (for more information, see "Links").

Logout: it allows to shut down the application (for more information, see "Shutting down the STpalm").

Route

The route is a set of tests to run.

The device can store up to 100 routes into its memory. Each route can include up to 500 Inspections.

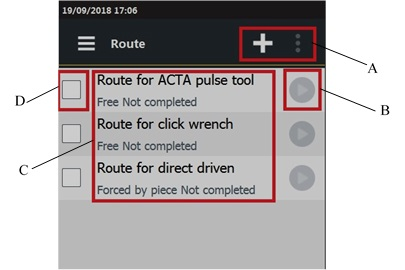

Tap the Menu icon ( ) in the Home page. Then, select Route from the Menu list.

) in the Home page. Then, select Route from the Menu list.

The following is displayed:

A | Command buttons | B | Play button |

C | List of Routes | D | Route check box |

In each row, the following information are shown:

Name: it is assigned when the route is created. For more information about how to edit the Route name, see “Editing the Route name".

Sequence: it can be either "Free" or "Forced by piece", depending on the way the inspections configured in the Route are run.

Status: it can be either “Completed” or “Not completed” depending on the status of the route.

Play: icon to run the inspection. If the icon is unavailable, no inspection is available.

Scanning a barcode

In the Route page, tap the More options icon ( ). Then, select Scan.

). Then, select Scan.

The SCAN button allows to scan a barcode to find the corresponding inspection(s) (Tool, Joint or Part inspections) remotely.

If the remote search finds a single inspection, a Route with the name of the barcode identifier is created and the inspection is automatically run.

If the remote search finds multiple inspections with the same barcode identifier, a Route with the name of the barcode identifier is created and the inspection of interest can be run from the list.

The measuring device stores only the latest Route created scanning a barcode identifier, the previous one is deleted from the device memory.

During the synchronization with an external software, a popup message informing of the ongoing synchronization might be displayed.

Deleting a Route

In the Route page, select a check box near the name of the route to delete.

In the upper-right corner of the Toolbar, tap the More options icon (

). Then, select Delete.

). Then, select Delete.In the Confirmation required window, tap OK.

Resetting a Route

In the Route page, select a check box near the name of the route to delete.

In the upper-right corner of the Toolbar, tap the More options icon (

). Then, select Reset.

). Then, select Reset.In the Confirmation required window, tap OK.

By resetting a route, the status of the route becomes "Not completed" and it is possible to run it again.

The results saved before the reset are not deleted.

Editing a Route

From the Route page, tap an existing route.

The following is displayed:

A

Barcode button

B

Command button

C

Categories

D

Play button

E

Inspections

F

Search button

In the Edit route page, edit the Route parameters according to customer needs.

In the General category are displayed the parameters of the route.

In the Inspections category, it is possible to delete the inspections linked to the route.On the upper-right corner of the Edit route page, tap the Save icon (

).

).

The Save icon is available after one item has been edited.

When enabled by external software, the Barcode button (

) allows to scan a barcode to search the corresponding inspection(s) inside the Route. If the search finds a single inspection, it is automatically run; if the search finds multiple inspections with the same barcode identifier, run the inspection of interest from the list.

) allows to scan a barcode to search the corresponding inspection(s) inside the Route. If the search finds a single inspection, it is automatically run; if the search finds multiple inspections with the same barcode identifier, run the inspection of interest from the list.

The Barcode button is available only for Free routes.

Running a free Route

Connect the device to the necessary measuring device (for more information, see “Measuring devices”).

Tap the route name or the Run icon to run the route.

In the Edit Route page - Inspection category, tap Play in correspondence of the inspection to be run (for more information, see “Inspections”).

If necessary, in the Edit Route page - General category, edit the route parameters according to customer needs (for more information, see “Editing a Route”).

The status of all the inspections, except ISO 5393, can be: To do, Partial, OK, or NOK.

The status of the inspections ISO 5393 can be: To do, Partial, or Completed.

Running a force by piece Route

Connect the device to the necessary measuring device (for more information, see “Measuring devices”).

In the Route page, tap Play in correspondence of the enabled inspection.

Navigating a forced by piece Route

From the measurement screen, it possible to navigate the inspections of a forced by piece route.

On the upper-right corner of the Instruction page tap the More options icon (

).

).Tap on Next or Back to switch to the next or previous inspection; tap on Resume to return to the current inspection run.

To skip a measure (when enabled by external software):

tap on the More options icon (

) and then on Skip.

) and then on Skip.from the Inspection category of the Edit route pag, tap on the More options icon (

) and then on Skip.

) and then on Skip.

If a measure of a forced by piece route is skipped, it is not possible to run it later.

Running a forced by inspection route

Connect the device to the necessary measuring device (for more information, see “Measuring devices”).

In the Route page, tap Play in correspondence of the enabled inspection.

Navigating a forced by inspection route

From the measurement screen, it possible to navigate the inspections of a forced by inspection route.

On the upper-right corner of the Instruction page tap the More options icon (

).

).Tap on Next or Back to switch to the next or previous inspection; tap on Resume to return to the current inspection run.

To skip a measure (when enabled by external software):

tap on the More options icon (

) and then on Skip.

) and then on Skip.from the Inspection category of the Edit route pag, tap on the More options icon (

) and then on Skip.

) and then on Skip.

If an inspection of a forced by inspection route is skipped, it is not possible to run it later.

Searching a Route

From the Menu, select Routes.

Above the list of Routes, tap the Search icon (

).

).In Search text box, type the string to search.

Partial matching is supported: routes whose name, sequence or status match the text string are shown.

To reset the typed string, tap the Reset icon ( ).

).

To exit the search function, tap the Left arrow icon ( ).

).

Searching in a route

From the Menu, select Routes.

Tap on a Route from the list of Routes.

Above the list of Inspections of the Route, tap the Search icon (

).

).In Search text box, type the string to search.

Partial matching is supported: inspections whose status, inspection name, type, location, tool ID, part/joint name, part/joint identifier or tool serial number match the text string are shown.

To reset the typed string, tap the Reset icon ( ).

).

To exit the search function, tap the Left arrow icon ( ).

).

Filtering the routes using the custom fields

The list of routes can be filtered using the custom fields only if the enabled by external software.

From the Home page, tap on Route.

In the upper right corner of the Route page, tap on the More option icon (

) and then on the Filter button.

) and then on the Filter button.In the Custom filter dialog box, select the values to filter from the drop-down list of each object.

By selecting a value, the values displayed for the other objects change accordingly.

Tap on the OK button to apply the route filter.

Filtering the inspections in a route

From the Route page, tap on an existing route.

In the upper right corner of the Inspections category, tap on the More option icon (

) and then on the Filter button.

) and then on the Filter button.In the Inspection filter dialog-box, select/unselect the following Inspection status check boxes:

To do: select the checkbox to display all the inspections of the route marked with the status To do .

Partial: select the checkbox to display all the inspections of the route marked with the status Partial.

Completed: select the checkbox to display all the inspections of the route marked with the status Completed.

By default, all the Inspection status are selected.

Tap on the OK button to apply the Inspection filter.

By exiting the Edit route page, the Inspection filter is restored to the default.

Results

Results section lists the results of the inspections done. The results list is organized by date: then, the last inspection done is the first item of the list.

In the Home page, tap the Menu icon ( ). Then select Results between the available features.

). Then select Results between the available features.

For each result, the following information are shown:

Inspection name

Date and time of the test

Status of the inspection. Each inspection has one of the following status:

Partial: in case the number of samples is not completed or equal to 0.

Completed: in case the number of samples is completed.

Abandoned: in case the inspection/tool/joint is deleted or if the parameters that reset the statistics, change.

The device saves up to 50000 single results. If this amount is exceeded, the oldest results are overwritten with the new ones.

Viewing the details of the inspection results

In the Results page, click the inspection to view. The Result details page opens.

The General category lists the parameters of the selected inspection. The parameters change depending on the inspection selected into the Results page.

The General category is a read-only page.

The Results category lists the single results done during the inspection. If a result is NOK, the related value is highlighted with a red colored bar.

If during the test run a measurement is deleted or is not detected, it is deleted from the Measure page, but it is displayed in the Results category.

Not detected measurements are marked with a dash.

Deleted measurements are grayed out.

Measurements not detected and deleted are marked with a dash and are grayed out.

Tap a single value to open the Measure page, where the general information of the test are displayed.

In the Trace category, the acquired trace is shown.

If the trace has not been acquired, the Trace category is not displayed.

In the Photo category the photo saved during test run are shown.

In the Traceability tag category, the used traceability tags, the assignable causes, the corrective actions and the comments added during the test run are shown.

Filtering the results

On the upper-right corner of the Results page, click the Filter icon (

).

).In the Result filter dialog box, select the check box of the options to enable:

Start date

End date

Number of results

Set the values of the selected options.

On the lower-right corner of the Result filter dialog box, tap Update to apply the selected filters.

Searching a result

From the Menu, select Results.

Above the list of Results, tap the Search icon (

).

).In Search text box, type the string to search.

Partial matching is supported: results whose inspection name, inspected object, date, status, result, part/joint identifier or tool serial number match the text string are shown.

To reset the typed string, tap the Reset icon ( ).

).

To exit the search function, tap the Left arrow icon ( ).

).

Exporting the results

On the upper right corner of the Results page, tap the More option icon (

).

).Tap on the Export button to export all the Inspection results displayed in the results page.

If a filter is applied in the Results page, only the inspections results filtered are exported.

The file export-results/yyyymmdd-hhmmss.txt is automatically created in the File manager > Internal Storage > Download folder of the device.

Connect the device to the PC via USB cable, bluetooth, or by means of the cradle.

In the Autoplay dialog box, select Open the device to see the files > Internal storage > Download. Then, copy the export-results/yyyymmdd-hhmmss.txt file on the PC.

If the Export result file is not displayed in the Download folder, press F5 on the PC keyboard to refresh the folder content.

Tools

Tools section describes how to setup the parameters (Tools and Inspections) necessary to do a test.

The device can store up to 10000 tools into its own memory. The Inspection gives the test type; the maximum number of Inspections per Tool is equal to 60.

Tap the Menu icon ( ) in the Home page. Then select Tools.

) in the Home page. Then select Tools.

The following is displayed:

A | Barcode button | B | Command button |

C | Play button | D | List of Tools |

E | Search button |

In each row, the following information about the tool are shown:

Name

Serial number

Tool type. The type is one of the following: click wrench, power tool, peak, pulse tool.

Torque range.

When enabled by external software, the Barcode button ( ) allows to scan a barcode to search the corresponding Tool inspection(s) on the measuring device. If the search finds a single Tool inspection, it is automatically run; if the search finds multiple Tool inspections with the same barcode identifier, run the inspection of interest from the list.

) allows to scan a barcode to search the corresponding Tool inspection(s) on the measuring device. If the search finds a single Tool inspection, it is automatically run; if the search finds multiple Tool inspections with the same barcode identifier, run the inspection of interest from the list.

Play ( ) gets active only after adding Inspection(s) to the Tool. If enabled, tap Play to run the test.

) gets active only after adding Inspection(s) to the Tool. If enabled, tap Play to run the test.

Adding a tool

In the Home page, tap the Menu icon (

). Then, select Tools.

). Then, select Tools.On the upper-right corner of the Tools page, tap Add icon (

).

).In General category of the Add tool page, configure the tool parameters.

In the upper part of the Add tool page, tap Controller. This category is available only if Tool type is set to Power tool.

In the Controller category of the Add tool page, tap the search icon on the right of the controller box. The Controllers page opens, where the already configured controllers are listed. If necessary, add a new controller according to customer needs.

To link the controller to the tool, tap the check mark on the right of the controller name.

For more information about how to configure a new controller, see Controllers.

On the upper-right corner of the Add tool page, tap Save (

).

).

Deleting a tool

In the Tools page, select the check box near the tool to delete.

On the upper-right corner of the Tools page, tap the More option icon (

). Then select Delete.

). Then select Delete.On the Confirmation required message, tap OK.

Editing a tool

From the Tools page, tap an existing joint.

In the categories (General, Controller, Inspections) of the Edit tool page, edit the necessary parameter(s) according to customer needs.

The Controller category is available only if the Tool type is set to Power tool.

On the upper-right corner of the Edit tool page, tap the Save icon (

).

).

The Save icon is available after one item has been edited.

Searching a Tool

From the Menu, select Tools.

Above the list of Tools, tap the Search icon (

).

).In Search text box, type the string to search.

Partial matching is supported: tools whose name, serial number, model name, tool type or range match the text string are shown.

To reset the typed string, tap the Reset icon ( ).

).

To exit the search function, tap the Left arrow icon ( ).

).

Tool inspections

It is possible to save two inspection with the same name and the same target objet. A warning message is displayed to advise the operator an inspection with the same name already exists.

Select Yes to save the inspection.

Select No not to save the inspection.

Adding a Tool inspection

In the Tools page, select a Tool already configure.

On the upper part of the Edit tool page, tap Inspections.

On the upper-right corner of the Inspections page, tap the Add icon (

).

).In the Test type window, select a inspection type.

In the General category of the Add Cm/Cmk inspection page, configure the general parameters of the inspection:

On the upper part of the Add inspection page, tap Torque

In the Torque category, configure the torque parameters of the inspection.

On the upper part of the Add inspection page, tap Angle .

For the Pulse tool, this category is replaced by the Pulse category. Refer to step 12 of this procedure for the Pulse category configuration.

In the Angle category, configure the angle parameters of the inspection.

On the upper part of the Add inspection, tap More option icon (

). Then, select Time.

). Then, select Time.In the Time category, configure the time parameters of the inspection.

In the upper part of the Add inspection, tap More option icon (

). Then, select Pulse.

). Then, select Pulse.

This category is displayed only for the Pulse tools.

In the Pulse category, configure the pulse parameters of the inspection.

In the upper part of the Add inspection, tap the More options icon (

). Then, select Picture.

). Then, select Picture.In the Picture category, it is possible to:

Add an image/video: connect the STpalm to a PC. In the Download folder of the STpalm add a new folder named media_items and save in this folder the image/video to upload. In the Picture category of the Add inspection page, tap the Add icon (

) and select the media to upload.

) and select the media to upload.The maximum size of images is 5 MB, the maximum size of videos is 10 MB.

Remove an image/video: on the upper part of the Picture category, tap the Remove icon (

).

).

In the upper part of the Add inspection, tap the More options icon (

). Then, select Traceability.

). Then, select Traceability.In the Traceability category, configure the following parameters

Verification code: type the verification code that must be entered or scanned when the inspection is run. This field is case-sensitive.

Verification code description: to guide the operator, type the description of the verification code dialog box that is displayed when the inspection is run.

Assignable causes: it is possible to:

List:

select an assignable causes list: tap the Search icon (

) and then select an already configured item in the Assignable causes list page.

) and then select an already configured item in the Assignable causes list page.add a new assignable causes list: tap the Search icon (

); on the upper-right corner of the Assignable causes list page, tap Add to configure a new item.

); on the upper-right corner of the Assignable causes list page, tap Add to configure a new item.delete the link to the assignable causes list: tap the Delete icon (

).

).

Mandatory: if the check box is selected, the operator must select/type an assignable cause to continue the test.

Force selection from list: select between:

No: the operator can type the assignable cause, without selecting it from the list.

Yes: the operator can only select the assignable cause from the list.

Inherit: the selection from list can be forced or not forced, depending on the definition of this parameter in the Assignable causes list page.

Corrective actions: it is possible to:

List:

select a corrective actions list: tap the Search icon (

) and then select an already configured item in the Corrective actions list page.

) and then select an already configured item in the Corrective actions list page.add a new corrective actions list: tap the Search icon (

); on the upper-right corner of the Corrective actions list page, tap Add to configure a new item.

); on the upper-right corner of the Corrective actions list page, tap Add to configure a new item.delete the link to the corrective actions list: tap the Delete icon (

).

).

Mandatory: if the check box is selected, the operator must select/type a corrective action to continue the test.

Force selection from list: select between:

No: the operator can type the corrective action, without selecting it from the list.

Yes: the operator can only select the corrective action from the list.

Inherit: the selection from list can be forced or not forced, depending on the definition of this parameter in the Corrective actions list page.

On the upper-right corner of the Add inspection page, tap Save.

Cm/Cmk ISO parameters

General category

Name: type the name of the inspection.

Barcode identifier: it identifies the inspection. If left blank, the identifier corresponds to the inspection name.

Strategy: select the tool strategy to use. The available strategies for each tool type are:

Click, Cam-over for click wrenches.

Direct driven for power tools.

Peak for peak tools.

Pulse tool, ACTA pulse tool for pulse tools.

Check type: select the check type from the drop down list. The available check types are:

Torque and angle.

Only torque.

Only angle.

Angle and torque.

Two steps: select the check box to enable the dual step strategy of the tool.

This parameter is available only for Direct driven strategy.

Joint: it is possible:

to select a joint: near the joint box, tap the Search icon (

) and then select an already configured joint in the Joints page.

) and then select an already configured joint in the Joints page.to add a new joint: near the joint box, tap the Search icon (

). On the upper-right corner of the Joints page, tap Add to configure a new joint.

). On the upper-right corner of the Joints page, tap Add to configure a new joint.to delete the link to the joint: tap the Delete icon (

) near the joint box.

) near the joint box.

If the joint is linked to the inspection, the Target torque and Target angle are the values defined in the joint configuration.

If the joint is not linked to the inspection, type the torque and angle values in the respective pages.

Number of samples: type the number of results to do.

The value can range from 0 to 1000. If the number of sample is not defined or equal to 0, the test is run with no batch count.

Cm Cmk minimum sample number: minimum number of samples to display the result status. This value is set in the Inspection default values page.

Auto restart: select the checkbox to enable the automatic restart of the batch count when it is completed.

Measurement device type: the only available measuring device is the IRC-Connect

Measurement device S/N: type the serial number of the measuring device connected to the device.

Transducer S/N: type the serial number of the transducer linked to the measuring device connected to the device.

Filter frequency: type the value of the filter frequency. The allowed range is from 100 Hz to 2000 Hz. The default value is 500 Hz.

Tightening direction: from the drop down list select the tightening direction. The available items are:

Clockwise

Counterclockwise

Open Protocol ID: type the Open Protocol ID or tap on the Search icon (

) to automatically fill the parameter.

) to automatically fill the parameter.

Torque category

Below is a list of all the torque parameters available for the Cm/Cmk Inspection.

The parameters displayed by the device in the Torque category of each Cm/Cmk inspection change according to the Tool type and Strategy selected.

Cycle complete: the default value is managed by the measuring device and it is indicated as Automatic value.

It is possible to type the cycle complete value; it must be lower/equal to the cycle start.

Cycle start: the default value is managed by the measuring device and it is indicated as Automatic value.

It is possible to type the cycle start value; it must be higher than the transducer Minimum Load and lower/equal to the Final angle monitoring torque.

If the Cycle start is set to zero, the device gives automatically a Cycle Start equal to the transducer Minimum Load.

Final angle monitoring torque: the default value is managed by the measuring device and it is indicated as Automatic value and corresponds to the lowest value between [50% of the target torque] and the [minimum torque].

It is possible to type the final angle monitoring torque value; it must be lower/equal to the Minimum torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the Final angle monitoring torque defined in the Joint configuration.

Control mode: select how to define the torque limits. The available options are:

Min/Max

Target/tolerance

Minimum torque: type the value of the minimum value of the torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the minimum torque defined in the Joint configuration.

Target torque: type the value of the target torque. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value equal to the Target torque defined in the Joint configuration.

Maximum torque: type the value of the maximum value of the torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the Maximum torque defined in the Joint configuration.

Torque tolerance: type the value of the tolerance of the torque. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value equal to the Torque tolerance defined in the Joint configuration.

Measure torque at: from the drop down list, select one of the following options:

Torque peak

Angle peak

Slip torque: the default value is managed by the device and it is indicated as Automatic value. It is possible to type a value of the slip torque smaller/equal to the Target torque.

Minimum Cm Torque: type the minimum value of the Cm index for the torque.

Minimum Cm Torque ranges from 0 to 9999.

Minimum Cmk Torque: type the minimum value of the Cmk index for the torque.

Minimum Cmk Torque ranges from 0 to 9999.

Unit of measurement: select the unit of measurement to use.

If a Joint is linked to the inspection, this is an unavailable value equal to the Unit of measurement selected in the Joint configuration.

Angle category

Below is a list of all the angle parameters available for the Cm/Cmk Inspection.

The parameters displayed by the device in the Time category of each Cm/Cmk inspection change according to the Check type selected.

This category is not displayed only for the Pulse tools.

Control mode: select how to define the angle limits. The available options are:

Min/Max

Target/tolerance

Minimum angle: type the minimum value of the angle.

If a Joint is linked to the inspection, this is an unavailable value set to the Minimum angle defined in the Joint configuration.

Target angle: type the value of target angle. This parameter is available if the Control mode is set to Target/Tolerance

If a Joint is linked to the inspection, this is an unavailable value set to the Target angle defined in the Joint configuration.

Maximum angle: type the maximum value of the angle.

If a Joint is linked to the inspection, this is an unavailable value set to the Maximum angle defined in the Joint configuration.

Angle tolerance: type the value of the tolerance of the angle. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value set to the Angle tolerance defined in the Joint configuration.

Minimum Cm Angle: type the minimum value of the Cm index for the angle.

Minimum Cm angle ranges from 0 to 9999.

Minimum Cmk Angle: type the minimum value of the Cmk index for the angle.

Minimum Cmk angle ranges from 0 to 9999.

Time category

Below is a list of all the time parameters available for the Cm/Cmk Inspection.

The parameters displayed by the device in the Torque category of each Cm/Cmk inspection change according to the Tool type and Strategy selected.

Measure delay time: type the value of the measure delay time.

During the measure delay time the torque trace is not analyzed and the click-point is not detected.

The measure delay time ranges from 0.0 s to 5.0 s.

Reset time: type the value of the reset time.

During the reset time, the torque trace is not analyzed.

The reset time ranges from 0.0 s to 5.0 s.

End cycle time: type the value of the end cycle time.

The “quick programming” test stops when the torque continues to be applied but it is under the Cycle complete for a time longer than the End cycle time.

The end cycle time ranges from 0.1 s to 5.0 s.

Pulse category

This category is displayed only for the Pulse tools.

Minimum pulse: minimum number of pulses to be done by the tool during the test.

Maximum pulse: maximum number of pulses to be done by the tool during the test.

SPC parameters

General category

Name: type the name of the inspection.

Barcode identifier: it identifies the inspection. If left blank, the identifier corresponds to the inspection name.

Strategy: select the tool strategy to use. The available strategies for each tool type are

Click, Cam-over for click wrenches.

Direct driven for power tools.

Peak for peak tools.

Pulse tool, ACTA pulse tool for pulse tools.

Check type: from the drop down list, select the check type. The available check types are:

Torque and angle

Only torque

Only angle

Angle and torque

Two step: select the check box to enable the dual step strategy of the tool.

This parameter is available only for Direct driven strategy.

Joint: it is possible:

to select a joint: near the joint box, tap the Search icon (

) and then select an already configured joint in the Joints page.

) and then select an already configured joint in the Joints page.to add a new joint: near the joint box, tap the Search icon (

). On the upper-right corner of the Joints page, tap Add to configure a new joint.

). On the upper-right corner of the Joints page, tap Add to configure a new joint.to delete the link to the joint: tap the Delete icon (

) near the joint box.

) near the joint box.

If the joint is linked to the inspection, the Target torque and Target angle are the values defined in the joint configuration.

If the joint is not linked to the inspection, type the torque and angle values in the respective pages.

Subgroup size: type the number of results on which the statistics are calculated. The subgroup size ranges from 1 to 25.

Subgroup frequency: type the frequency of the averages displayed in the X chart and in the SPC rules.

For example:

Subgroup Frequency = 1: all subgroups are considered.

Subgroup Frequency = 2: one subgroup every 2 subgroups is considered.

Subgroup Frequency = X: one subgroup every X subgroups is considered

Number of samples: type the number of results to do.

The value can range from 0 to 1000. If the number of sample is not defined or equal to 0, the test is run with no batch count.

Auto restart: select the checkbox to enable the automatic restart of the batch count when it is completed.

Measurement device type: the only available measuring device is the IRC-Connect.

Measurement device S/N: type the serial number of the measuring device connected to the device.

Transducer S/N: type the serial number of the transducer linked to the measuring device connected to the device.

Filter frequency: type the value of the filter frequency. The allowed range is from 100 to 2000 Hz. The default value is 500 Hz.

Tightening direction: from the drop down list select the tightening direction. The available items are:

Clockwise

Counterclockwise

Torque category

Below is a list of all the torque parameters available for the SPC inspection.

The parameters displayed by the device in the Torque category of each SPC inspection change according to the Tool type and Strategy selected.

Cycle complete: the default value is managed by the measuring device and it is indicated as Automatic value.

It is possible to type the cycle complete value; it must be lower/equal to the cycle start.

Cycle start: the default value is managed by the measuring device and it is indicated as Automatic value.

It is possible to type the cycle start value; it must be higher than the transducer Minimum Load and lower/equal to the Final angle monitoring torque.

If the Cycle start is set to zero, the device gives automatically a Cycle Start equal to the transducer Minimum Load.

Final angle monitoring torque: the default value is managed by the measuring device and it is indicated as Automatic value and corresponds to the lowest value between [50% of the target torque] and the [minimum torque].

It is possible to type the final angle monitoring torque value; it must be lower/equal to the Minimum torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the Final angle monitoring torque defined in the Joint configuration.

Control mode: select how to define the torque limits. The available options are:

Min/Max

Target/tolerance

Minimum torque: type the value of the minimum value of the torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the minimum torque defined in the Joint configuration.

Target torque: type the value of the target torque. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value equal to the Target torque defined in the Joint configuration.

Maximum torque: type the value of the maximum value of the torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the Maximum torque defined in the Joint configuration.

Torque tolerance: type the value of the tolerance of the torque. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value equal to the Torque tolerance defined in the Joint configuration.

Measure torque at: from the drop down list, select one of the following options:

Torque peak

Angle peak

Slip torque: the default value is managed by the device and it is indicated as Automatic value. It is possible to type a value of the slip torque smaller/equal to the Target torque.

Unit of measurement: select the unit of measurement to use.

If a Joint is linked to the inspection, this is an unavailable value equal to the Unit of measurement selected in the Joint configuration.

Angle category

Below is a list of all the angle parameters available for the SPC inspection.

The parameters displayed by the device in the Time category of each SPC inspection change according to the Check type selected.

This category is not displayed only for the Pulse tools.

Control mode: select how to define the angle limits. The available options are:

Min/Max

Target/tolerance

Minimum angle: type the minimum value of the angle.

If a Joint is linked to the inspection, this is an unavailable value set to the Minimum angle defined in the Joint configuration.

Target angle: type the value of target angle. This parameter is available if the Control mode is set to Target/Tolerance

If a Joint is linked to the inspection, this is an unavailable value set to the Target angle defined in the Joint configuration.

Maximum angle: type the maximum value of the angle.

If a Joint is linked to the inspection, this is an unavailable value set to the Maximum angle defined in the Joint configuration.

Angle tolerance: type the value of the tolerance of the angle. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value set to the Angle tolerance defined in the Joint configuration.

Time category

Below is a list of all the time parameters available for the SPC inspection.

The parameters displayed by the device in the Torque category of each SPC inspection change according to the Tool type and Strategy selected.

Measure delay time: type the value of the measure delay time.

During the measure delay time the torque trace is not analyzed and the click-point is not detected.

The measure delay time ranges from 0.0 s to 5.0 s.

Reset time: type the value of the reset time.

During the reset time, the torque trace is not analyzed.

The reset time ranges from 0.0 s to 5.0 s.

End cycle time: type the value of the end cycle time.

The “quick programming” test stops when the torque continues to be applied but it is under the Cycle complete for a time longer than the End cycle time.

The end cycle time ranges from 0.1 s to 5.0 s.

Pulse category

This category is displayed only for the Pulse tools.

Minimum pulse: minimum number of pulses to be done by the tool during the test.

Maximum pulse: maximum number of pulses to be done by the tool during the test.

CAM/Cpk CNOMO parameters

General category

Name: type the name of the inspection.

Barcode identifier: it identifies the inspection. If left blank, the identifier corresponds to the inspection name.

Strategy: select the tool strategy to use. The available strategies for each tool type are:

Click, Cam-over for click wrenches.

Direct driven for power tools.

Peak for peak tools.

Pulse tool, ACTA pulse tool for pulse tools.

Check type: select the check type from the drop down list. The available check types are:

Torque and angle.

Only torque.

Only angle.

Angle and torque.

Two steps: select the check box to enable the dual step strategy of the tool.

This parameter is available only for Direct driven strategy.

Joint: it is possible:

to select a joint: near the joint box, tap the Search icon (

) and then select an already configured joint in the Joints page.

) and then select an already configured joint in the Joints page.to add a new joint: near the joint box, tap the Search icon (

). On the upper-right corner of the Joints page, tap Add to configure a new joint.

). On the upper-right corner of the Joints page, tap Add to configure a new joint.to delete the link to the joint: tap the Delete icon (

) near the joint box.

) near the joint box.

If the joint is linked to the inspection, the Target torque and Target angle are the values defined in the joint configuration.

If the joint is not linked to the inspection, type the torque and angle values in the respective pages.

Number of samples: type the number of results to do. This parameters must be a number multiple of 5 withing the range from 15 to 95

Measurement device type: the only available measuring device is the IRC-Connect

Measurement device S/N: type the serial number of the measuring device connected to the device.

Transducer S/N: type the serial number of the transducer linked to the measuring device connected to the device.

Filter frequency: type the value of the filter frequency. The allowed range is from 100 to 2000 Hz. The default value is 500 Hz.

Tightening direction: from the drop down list select the tightening direction. The available items are:

Clockwise

Counterclockwise

Open Protocol ID: type the Open Protocol ID or tap on the Search icon (

) to automatically fill the parameter.

) to automatically fill the parameter.

Torque category

Below is a list of all the torque parameters available for the CAM/Cpk CNOMO Inspection.

The parameters displayed by the device in the Torque category of each CAM/Cpk CNOMO inspection change according to the Tool type and Strategy selected.

Cycle complete: the default value is managed by the measuring device and it is indicated as Automatic value.

It is possible to type the cycle complete value; it must be lower/equal to the cycle start.

Cycle start: the default value is managed by the measuring device and it is indicated as Automatic value.

It is possible to type the cycle start value; it must be higher than the transducer Minimum Load and lower/equal to the Final angle monitoring torque.

If the Cycle start is set to zero, the device gives automatically a Cycle Start equal to the transducer Minimum Load.

Final angle monitoring torque: the default value is managed by the measuring device and it is indicated as Automatic value and corresponds to the lowest value between [50% of the target torque] and the [minimum torque].

It is possible to type the final angle monitoring torque value; it must be lower/equal to the Minimum torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the Final angle monitoring torque defined in the Joint configuration.

Control mode: select how to define the torque limits. The available options are:

Min/Max

Target/tolerance

Minimum torque: type the value of the minimum value of the torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the minimum torque defined in the Joint configuration.

Target torque: type the value of the target torque. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value equal to the Target torque defined in the Joint configuration.

Maximum torque: type the value of the maximum value of the torque.

If a Joint is linked to the inspection, this is an unavailable value equal to the Maximum torque defined in the Joint configuration.

Torque tolerance: type the value of the tolerance of the torque. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value equal to the Torque tolerance defined in the Joint configuration.

Measure torque at: from the drop down list, select one of the following options:

Torque peak

Angle peak

Slip torque: the default value is managed by the device and it is indicated as Automatic value. It is possible to type a value of the slip torque smaller/equal to the Target torque.

Minimum CAM Torque: type the minimum value of the CAM index for the torque.

Minimum CAM torque ranges from 0 to 9999.

Minimum Cpk Torque: type the minimum value of the Cpk index for the torque.

Minimum Cpk torque ranges from 0 to 9999.

Unit of measurement: select the unit of measurement to use.

If a Joint is linked to the inspection, this is an unavailable value equal to the Unit of measurement selected in the Joint configuration.

Angle category

Below is a list of all the angle parameters available for the CAM/Cpk CNOMO Inspection.

The parameters displayed by the device in the Time category of each CAM/Cpk CNOMO inspection change according to the Check type selected.

This category is not displayed only for the Pulse tools.

Control mode: select how to define the angle limits. The available options are:

Min/Max

Target/tolerance

Minimum angle: type the minimum value of the angle.

If a Joint is linked to the inspection, this is an unavailable value set to the Minimum angle defined in the Joint configuration.

Target angle: type the value of target angle. This parameter is available if the Control mode is set to Target/Tolerance

If a Joint is linked to the inspection, this is an unavailable value set to the Target angle defined in the Joint configuration.

Maximum angle: type the maximum value of the angle.

If a Joint is linked to the inspection, this is an unavailable value set to the Maximum angle defined in the Joint configuration.

Angle tolerance: type the value of the tolerance of the angle. This parameter is available if the Control mode is set to Target/Tolerance.

If a Joint is linked to the inspection, this is an unavailable value set to the Angle tolerance defined in the Joint configuration.

Minimum CAM angle: type the minimum value of the CAM index for the angle.

Minimum CAM Aagle ranges from 0 to 9999.

Minimum Cpk angle: type the minimum value of the Cpk index for the angle.

Minimum Cpk angle ranges from 0 to 9999.

Time category

Below is a list of all the time parameters available for the CAM/Cpk CNOMO Inspection.

The parameters displayed by the device in the Torque category of each CAM/Cpk CNOMO inspection change according to the Tool type and Strategy selected.

Measure delay time: type the value of the measure delay time.

During the measure delay time the torque trace is not analyzed and the click-point is not detected.

The measure delay time ranges from 0.0 s to 5.0 s.

Reset time: type the value of the reset time.

During the reset time, the torque trace is not analyzed.

The reset time ranges from 0.0 s to 5.0 s.

End cycle time: type the value of the end cycle time.

The “quick programming” test stops when the torque continues to be applied but it is under the Cycle complete for a time longer than the End cycle time.

The end cycle time ranges from 0.1 s to 5.0 s.

Pulse category

This category is displayed only for the Pulse tools.

Minimum pulse: minimum number of pulses to be done by the tool during the test.

Maximum pulse: maximum number of pulses to be done by the tool during the test.

Adding Tool check inspection(s) through the template file

Generate the Template file for inspections and save it on a PC (for more information, see Generating Tool check / Joint check template).

On the PC, open the file STpad_ToolInspectionImportFile.xlsm. The following is displayed:

Complete the file STpad_ToolInspectionImportFile.xlsm to define the necessary inspection(s).

When all the mandatory fields are filled in, the Wrong field column becomes green.

The file STpad_ToolInspectionImportFile.xlsm defines not only inspection(s), but also the linked tool(s). These are automatically imported on the device through the file STpad_ToolInspectionImportFile.stpad.

Check the Excel option for the workbook calculation. Open a Excel file and click File > Options. On left side of the Excel options dialog box, select Formulas > Automatic option for the Calculation options section.

When the Wrong field column in correspondence of the new inspection(s) is green colored, click the blue button Sort and export to automatically generate the file STpad_ToolInspectionImportFile.stpad.

The file STpad_ToollnspectionImportFile.stpad is automatically saved on the PC.

Only the STpad_ToolInspectionImportFile.stpad can be correctly imported on the device (for more information about how to import inspections, see Import inspections).

Save the file STpad_ToolInspectionImportFile.xlsm.

Close the file STpad_ToolInspectionImportFile.xlsm.

Import the inspection(s) saved in the file STpad_ToolInspectionImportFile.stpad on the device (for more information about how to import routes, see Importing the inspection(s) on the device).

Click the Menu icon > Tools to check the import of the inspection(s) is correctly done.

Deleting an inspection

In the Inspections page, select the check box near the name of the inspection to delete.

On the upper-right corner of the Toolbar, tap the More options icon (

). Then, select Delete.

). Then, select Delete.In the Confirmation required window, tap OK.

Editing a Tool inspection

From the Inspections page, tap an existing inspection.

In the categories ( General, Torque, Angle, Time, Traceability) of the Edit inspection page, edit the necessary parameter(s) according to customer needs.

On the upper-right corner of the Edit tool page, tap the Save icon (

).

).

The Save icon is available after one item has been edited.

If the inspection is sent by an external software, it is not possible to edit it.

Running a Tool inspection

In the Home page, tap the Menu icon (

). Then, select Tools.

). Then, select Tools.In the Tools page, tap Play (

) for running the inspection.

) for running the inspection.

If the configured wrench is not connected or its range is out of the test range, an Information message appear.

On the lower-right corner of the Information message, tap the Manage devices button to add/edit/pair another wrench to use during the test.

In the Select inspection dialog box, select the inspection to do. The instruction page opens, where the characteristics of the inspection are displayed.

On the upper-left corner of the screen, tap the Menu icon (

), then tap one of the following options:

), then tap one of the following options:Exit from measure to exit from the test.

Instruction to see the instruction to perform the test.

Results chart to see the chart of the measured values.

On the lower-right corner of the Result chart page, tap the More options icon (

) to see the following values:

) to see the following values:Minimum: minimum measured value.

Maximum: maximum measured value.

Average: average value of all measured values.

STD (σ): standard deviation of the measured values.

Cm and Cmk value for the Cm/Cmk inspection. These index are updated in real time.

X, R and S for the SPC inspection. These index are updated in real time.

Results to see the list of the measured value.

Statistics to see the statistics of the results done.

Traceto see the trace of the result. If the Double results function is enable on the device and on the STwrench, both the residual point and the peak point are marked on the trace.

Summary to see the test results and the Cm/Cmk values.

For Cm/Cmk inspection: Cm and Cmk values change after three results.

For SPC (tool) inspection: X and R values changes after three results.

When the subgroup (S) is completed, the SPC rules check result window is displayed. In this window, the status of the SPC rules is shown. The inspection result depends on the enabled rules. If the rules results are positive, the inspection result is OK.

Below is the list of the rules results that can occur:

Green mark: the rule result is OK.

Red mark: the rule result is NOK.

Gray mark: the rule result is not enabled or it is not possible to make an analysis on it.

Do the results. During the test, the selected page is updated in real time.

To delete one result (when enabled by external software): select the result and on the upper-right corner of the screen tap the More options icon ( ) > Delete

) > Delete

To delete all results (when enabled by external software): on the upper right-corner of the Toolbar, tap the More options icon ( ) > Delete all.

) > Delete all.

For the SPC (tool) inspection, it is not possible to delete a result if the subgroup is completed.

If a result is NOK, the measured value is highlighted in red.

To add a note to one result: in the Results chart page or in Results page, select a result. Then on the upper-right corner of the Toolbar, tap the More options icon ( )> Add note. In the Edit note dialog box, type the note. Then tap Edit.

)> Add note. In the Edit note dialog box, type the note. Then tap Edit.

To add a picture to one result: in the Results chart page or in Results page, select a result. Then on the upper-right corner of the Toolbar, tap the More options icon ( )> Add photo. In the Add photo dialog box, frame the object to be photographed . Then tap Capture.

)> Add photo. In the Add photo dialog box, frame the object to be photographed . Then tap Capture.

To exit the test: on the upper-right corner of the Summary category, tap End test.

If the batch is completed, after the End test is tapped, the test is closed without showing any Confirmation message. If the batch is not completed or the batch is set to zero, after the End test is tapped, a Confirmation massage is displayed.

Joints

The set of parameters that controls a test process is within a joint. This section describes how to setup the joint parameters necessary to do a test.

The device can store up to 20000 joints into its own memory.

Tap the Menu icon in the Home page. Then, select Joints.

The following is displayed:

A | Barcode button | B | Command button |

C | Play button | D | List of Joint |

E | Search button |

In each row, the following information about the Joint are shown:

Name

Torque range

When enabled by external software, the Barcode button ( ) allows to scan a barcode to search the corresponding Joint inspection(s) on the measuring device. If the search finds a single Joint inspection, it is automatically run; if the search finds multiple Joint inspections with the same barcode identifier, run the inspection of interest from the list.

) allows to scan a barcode to search the corresponding Joint inspection(s) on the measuring device. If the search finds a single Joint inspection, it is automatically run; if the search finds multiple Joint inspections with the same barcode identifier, run the inspection of interest from the list.

Play ( ) gets active only after adding Inspection(s) to the Joint. If enabled, tap Play to run the test.

) gets active only after adding Inspection(s) to the Joint. If enabled, tap Play to run the test.

Adding a Joint

In the Home page, tap the Menu icon (

). Then, select Joints.

). Then, select Joints.On the upper-right corner of the Joints page, tap Add icon (

). The following is displayed:

). The following is displayed:

A

Save button

B

Categories

C

Parameters

In General category of the Add joint page, configure the general parameters of the joint.

In the Add joint page, tap Torque.

In the Torque category of the Add joint page, configure the torque parameters of the joint.

In the Add joint page, tap Angle.

In the Angle category of the Add joint page, configure the angle parameters of the joint.

On the upper-right corner of the Add joint page, tap theSave icon (

).

).

The Save icon is available after all the require items have been completed.

Joint parameters

General category

Name (*): type the Joint name. The maximum number of characters permitted is equal to 50.

Description: type the Joint description. The maximum number of characters permitted is equal to 50.

Identifier: type the Joint identifier. The maximum number of characters permitted is equal to 50.

Tightening direction: select the tightening direction. The available items are Clockwise and Counterclockwise.

Notes: type the optional Joint notes.

Torque category

Unit of measurement: select the unit of measurement to use.

Final angle monitoring torque: type the final angle monitoring torque value.

The final angle monitoring torque must be equal or higher than the Minimum torque.

By default the value is the 50% of the Target torque.

Control mode: select how to define the torque limits. The options are: Min/Max and Target/tolerance.

Minimum torque (*): type the minimum value of the torque. This parameter is available if Control mode is set to Min/Max.

Target torque (*): type the value of the target torque.

Maximum torque (*): type the maximum value of the torque. This parameter is available if Control mode is set to Min/Max.

Torque tolerance (*): type the value of the tolerance of the torque. This parameter is available if Control mode is set to Target/Tolerance.

Angle category

Control mode: select how to define the angle limits. The options are: Min/Max and Target/tolerance.

Minimum angle (*): type the minimum value of the angle. This parameter is available if Control mode is set to Min/Max.

Target angle (*): type the value of target angle.

Maximum angle (*): type the maximum value of the angle. This parameter is available if Control mode is set to Min/Max..

Angle tolerance (*): type the value of the tolerance of the angle. This parameter is available if Control mode is set to Target/Tolerance.

Items marked with an asterisk (*) are required.

Deleting a Joint

In the Joints page, select the check box near the name of the joint to delete.

On the upper-right corner of the Toolbar, tap the More icon (

). Then, select Delete.

). Then, select Delete.In the Confirmation required window, tap OK.

Editing a Joint

From the Joints page, tap an existing joint.

The following is displayed:

A

Categories

In the categories (General, Torque, Angle, Inspections) of the Edit joint page, edit the necessary parameter(s) according to customer needs.

On the upper-right corner of the Edit joint page, tap the Save icon (

).

).

The Save icon is available after one item has been edited.

Tap the More options icon > Linked inspection to displayed all the tool inspection linked to the joint.

Searching a Joint

From the Menu, select Joints.

Above the list of Joint, tap the Search icon (

).

).In Search text box, type the string to search.

Partial matching is supported: joints whose name, identifier, torque range or angle range match the text string are shown.

To reset the typed string, tap the Reset icon ( ).

).

To exit the search function, tap the Left arrow icon ( ).

).

Joint inspections

The available inspection types for the joints are:

Cp/Cpk ISO

SPC (joint)

It is possible to save two inspection with the same name and the same target objet.

A warning message is displayed to advise the operator an inspection with the same name already exists.

Select Yes to save the inspection.

Select No not to save the inspection.

Adding a Joint inspection

In the Joints page, select a Joint already configure.

On the upper part of the Edit joint page, tap the More options icon (

). Then, select Inspections

). Then, select InspectionsOn the upper-right corner of the Inspections page, tap the Add icon (

).

).In the Test type window, select the inspection type.

In the General category, configure the general parameters of the inspection.

In the upper part of the Add inspection, tap Torque.

In Torque category, configure the torque parameters of the inspection.

On the upper part of the Add inspection, tap Angle.

In Angle category, configure the angle parameters of the inspection.

In the upper part of the Add inspection, tap More options icon (

). Then, select Time.

). Then, select Time.In Time category, configure the time parameters of the inspection.

In the upper part of the Add inspection, tap the More options icon (

). Then, select Picture.

). Then, select Picture.In the Picture category, it is possible to:

Add an image/video: connect the STpalm to a PC. In the Download folder of the STpalm add a new folder named media_items and save in this folder the image/video to upload. In the Picture category of the Add inspection page, tap the Add icon (

) and select the media to upload.

) and select the media to upload.The maximum size of images is 5 MB, the maximum size of videos is 10 MB.

Remove an image/video: on the upper part of the Picture category, tap the Remove icon (

).

).

In the upper part of the Add inspection, tap the More options icon (

). Then, select Traceability.

). Then, select Traceability.In the Traceability category, configure the following parameters:

Verification code: type the verification code that must be entered or scanned when the inspection is run. This field is case-sensitive.

Verification code description: to guide the operator, type the description of the verification code dialog box that is displayed when the inspection is run.

Assignable causes: it is possible to:

List:

select an assignable causes list: tap the Search icon (

) and then select an already configured item in the Assignable causes list page.

) and then select an already configured item in the Assignable causes list page.add a new assignable causes list: tap the Search icon (

); on the upper-right corner of the Assignable causes list page, tap Add to configure a new item.

); on the upper-right corner of the Assignable causes list page, tap Add to configure a new item.delete the link to the assignable causes list: tap the Delete icon (

).

).

Mandatory: if the check box is selected, the operator must select/type an assignable cause to continue the test.

Force selection from list: select between:

No: the operator can type the assignable cause, without selecting it from the list.

Yes: the operator can only select the assignable cause from the list.

Inherit: the selection from list can be forced or not forced, depending on the definition of this parameter in the Assignable causes list page.

Corrective actions: it is possible to:

List:

select a corrective actions list: tap the Search icon (

) and then select an already configured item in the Corrective actions list page.

) and then select an already configured item in the Corrective actions list page.add a new corrective actions list: tap the Search icon (

); on the upper-right corner of the Corrective actions list page, tap Add to configure a new item.

); on the upper-right corner of the Corrective actions list page, tap Add to configure a new item.delete the link to the corrective actions list: tap the Delete icon (

).

).

Mandatory: if the check box is selected, the operator must select/type a corrective action to continue the test.

Force selection from list: select between:

No: the operator can type the corrective action, without selecting it from the list.

Yes: the operator can only select the corrective action from the list.

Inherit: the selection from list can be forced or not forced, depending on the definition of this parameter in the Corrective actions list page.

On the upper-right corner of the Add inspection, tap the Save icon (

).

).

Cp/Cpk ISO parameters

General category

Name: type the name of the inspection.

Barcode identifier: it identifies the inspection. If left blank, the identifier corresponds to the inspection name.

Strategy: select one of the following items:

Residual Torque/Angle.

Residual Torque/Peak.

Number of samples: type the number of results to do during the test. The maximum number of samples is 99.

Minimum Cp torque: the Cp index describes process capability; it is the number of times the spread of the process fits into the tolerance width. The higher the value of Cp, the better the process.

Minimum Cp Torque ranges from 0.00 to 9999.99.

Minimum Cpk torque: the Cpk index describes the capability corrected for position of the process capability in relation to the tolerance limits.

Minimum Cpk Torque ranges from 0.00 to 9999.99.

Measurement device type: the only measuring device available is STwrench.

Measurement device S/N: type the serial number of the measuring device.

Transducer S/N: type the serial number of the transducer, if used during the test.

Tightening direction: select the tightening direction. The available items are Clockwise and Counterclockwise.

Torque correction coefficient: type the torque correction coefficient. The value ranges from 0.10 to 99.99.

Angle correction coefficient: type the angle correction coefficient. The values ranges from 0 to 6553.

Torque category

Cycle start: the cycle start is the starting point of the test. It must be lower or equal of the Final angle monitoring torque.

If cycle start is set to zero or not defined, the STwrench automatically sets the value to the Mean load.

Final angle monitoring torque: the final angle monitoring torque specifies the torque value from which the angle measurement starts.

The final angle monitoring torque must be lower or equal to the Minimum torque.

If final angle monitoring torque is set to zero or not defined, the STwrench automatically sets the value to Cycle start.

Control mode: the control mode selects the condition to control the torque. It is possible to select either Min/Max or Target/Tolerance.

Minimum torque: minimum value of the torque. By default is the minimum torque defined in the joint configuration.

It is possible to change the default value typing a new value. This parameter is the available if Control mode is set to Min/Max.

Target torque: value of the target torque. By default is the target torque defined in the joint configuration.

It is possible to change the default value typing a new value.

Maximum torque: maximum value of the torque. By default is the minimum torque defined in the joint configuration.

It is possible to change the default value typing a new value. This parameter is the available if Control mode is set to Min/Max

Torque tolerance: the torque tolerance defines the maximum torque and the minimum torque according to the target torque specified. It is expressed in percentage. This parameter is the available if Control mode is set to Target/Tolerance

Change screw: type the change screw value. The value must be equal or higher than the Maximum torque.

Unit of measurement: unit of measurement set in the joint configuration.

Angle category

Residual angle threshold: type the value of the residual angle threshold. The value ranges from 1 to 45.

This parameter is available if Strategy is set to Residual torque/angle.

Breakaway angle threshold: type the value of the breakaway angle threshold. The value ranges from 1 to 20.

This parameter is available if Strategy is set to Residual torque/angle.

Target angle: type the value of the target angle.

This parameter is available if Strategy is set to Residual torque/peak.

Time category

Ratchet time: type the value in seconds of the ratchet time. The value ranges from 0.1 s to 30.0 s

SPC (joint) parameters

General category

Name: type the name of the inspection.

Barcode identifier: it identifies the inspection. If left blank, the identifier corresponds to the inspection name.

Strategy: select one of the following items:

Residual Torque/Angle.

Residual Torque/Peak.

Number of samples: type the number of results to do during the test. The maximum number of samples is 99.

Subgroup size: the subgroup size applies to a variable characteristic and controls how many samples (also called data values or readings) make up a single plotted point on a chart (called a subgroup). The subgroup size ranges from 1 to 25.

Subgroup frequency: type the frequency of the averages displayed in the X chart and in the SPC rules.

For example, if the subgroup frequency is equal to 2, one point every two points is analyzed.

Measurement instrument type: the only measuring device available is STwrench.

Measurement instrument S/N: type the serial number of the measuring device. The maximum number of characters permitted is equal to 50.

Transducer S/N: type the serial number of the transducer, if used during the test.

Tightening direction: from the drop down list select the tightening direction. The available items are Clockwise and Counterclockwise.

Torque correction coefficient: type the torque correction coefficient. The value ranges from 0.10 to 99.99.

Angle correction coefficient: type the angle correction coefficient. The values ranges from 0 to 6553.

Torque category

Cycle start: the cycle start is the starting point of the test. It must be equal/lower of the final angle monitoring torque

If cycle start is set to zero or not defined, the STwrench automatically sets the value to the mean load.

Final angle monitoring torque: the final angle monitoring torque specifies the torque value from which the angle measurement starts.

The final angle monitoring torque must be equal or higher than the Minimum torque.

If final angle monitoring torque is set to zero or not defined, the STwrench automatically sets the value to Cycle start.

Control mode: the control mode selects the condition to control the torque.

It is possible to select either Min/Max or Target/Tolerance.

Minimum torque: minimum value of the torque. By default is the minimum torque defined in the joint configuration.

It is possible to change the default value typing a new value. This parameter is the available if Control mode is set to Min/Max.

Target torque: value of the target torque. By default is the target torque defined in the joint configuration.

It is possible to change the default value typing a new value.

Maximum torque: maximum value of the torque. By default is the minimum torque defined in the joint configuration.

It is possible to change the default value typing a new value. This parameter is the available if Control mode is set to Min/Max

Torque tolerance: the torque tolerance defines the maximum torque and the minimum torque according to the target torque specified. It is expressed in percentage. This parameter is the available if Control mode is set to Target/Tolerance

Change screw: type the change screw value. The value must be equal or higher than the Maximum torque.

Unit of measurement: select the unit of measurement to use.

Angle category

Residual angle threshold: type the value of the residual angle threshold. The value ranges from 1 to 45.

This parameter is available if the Strategy is set to Residual torque/angle.

Breakaway angle threshold: type the value of the breakaway angle threshold. The value ranges from 1 to 20.

This parameter is available if the Strategy is set to Residual torque/angle.

Target angle: type the value of the target angle.

This parameter is available if the Strategy is set to Residual torque/peak.

Time category

Ratchet time: type the value in seconds of the ratchet time. The value ranges from 0.1 s to 30.0 s

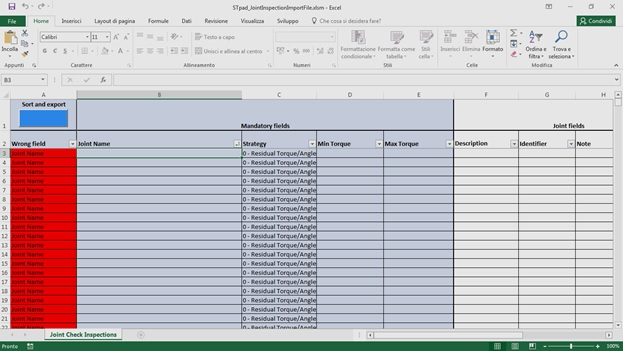

Adding Joint check inspection(s) through the template file

Generate the Template file for inspections and save it on a PC (for more information, see Generating Tool check / Joint check template).

On the PC, open the file STpad_JointnspectionImportFile.xlsm. The following is displayed:

Complete the file STpad_JointInspectionImportFile.xlsm to define the necessary inspection(s).

When all the mandatory fields are filled in, the Wrong field column becomes green.

The file STpad_JointInspectionImportFile.xlsm defines not only inspection(s), but also the linked joint(s). These are automatically imported on the device through the file STpad_JointInspectionImportFile.stpad.

Check the Excel option for the workbook calculation. Open a Excel file and click File > Options. On left side of the Excel options dialog box, select Formulas > Automatic option for the Calculation options section.

When the Wrong field column in correspondence of the new inspection(s) is green colored, click the blue button Sort and export to automatically generate the file STpad_JointInspectionImportFile.stpad.

The file STpad_JointlnspectionImportFile.stpad is automatically saved on the PC.

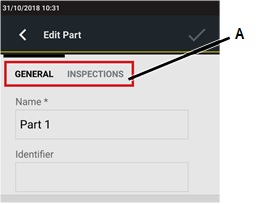

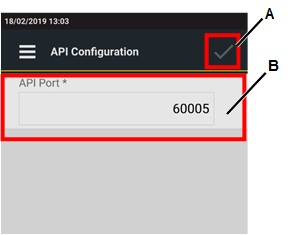

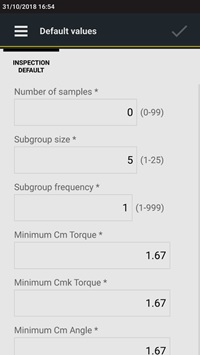

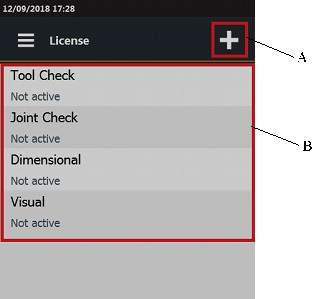

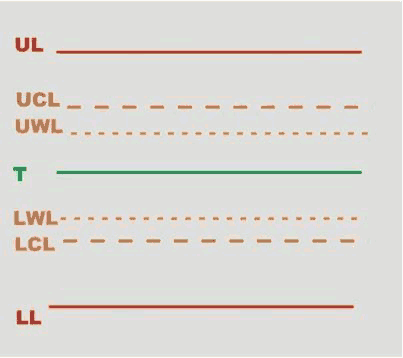

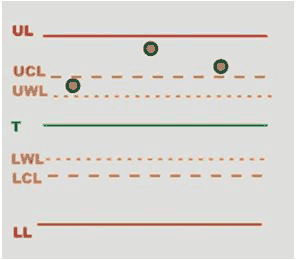

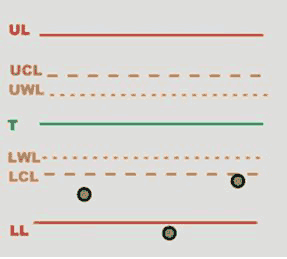

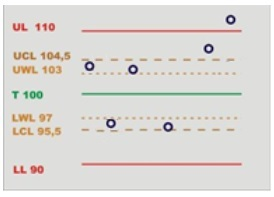

Only the STpad_JointInspectionImportFile.stpad can be correctly imported on the device (for more information about how to import inspections, see Import inspections).