Anchor positions

Read this page before ILM Anchors are put in place.

A localization cell consists of four ILM Anchors. Tool tags must be put inside of the cell.

ILM Anchors must be put so that they cannot be shaken or moved.

Make sure that there is no blockage between a tool tag and an ILM Anchor. Potential blockages include and are not limited to moving production machines, the human body, vehicle lifts, manipulators, and light reflections that are caused by metallic surfaces.

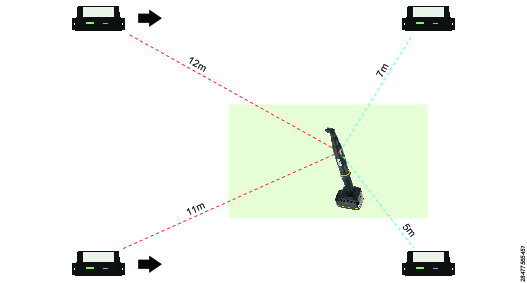

The minimum distance between an ILM Anchor and a tool tag: 1 meter.

The maximum distance between an ILM Anchor and a tool tag should not exceed 10 meters.

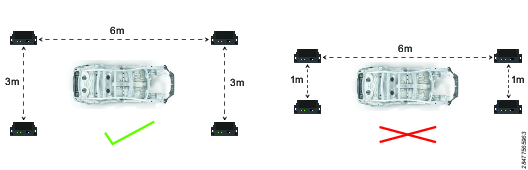

The distance ratio between the localization–cell axes must not be greater than 1:2. For example, if ILM Anchors are put at a distance of 6 meters from each other along the conveying direction (X) the width (Y) must be a minimum of 3 meters.

If possible, obey a production layout. Put the ILM Anchors at station transitions so that ILM Anchors are put at an equal distance apart from each other.

The distance between ILM Anchors should be 5–8 meters.

The height of the localization cell should be 2.5–3 meters. The height should be sufficient to protect localization cells from manipulation and to provide a sufficient line of sight.

To provide the best possible accuracy, put all ILM Anchors at the same height.