Operating the Tool

To start the tool, turn the sleeve valve indicator approximately to the mid-point of the operating range. If necessary, jar the stylus lightly against the bench to start the piston. After starting, adjust the sleeve valve to the operating speed. The stylus will make a mark to the desired depth.

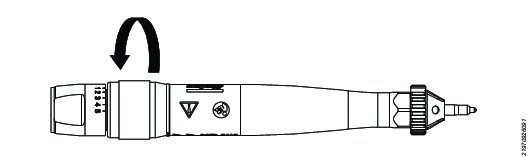

To turn on the tool, turn the sleeve valve clockwise.

To turn off the tool, turn the sleeve valve counter-clockwise.

This tool can mark material as hard as RC 64. When marking material of this hardness, make sure to regulate the impact of the stylus with the throttle valve so that the stylus makes a legible mark and no more than that. If the stylus is driven harder when working on very hard materials, there is a risk of excessive wear and breakage of the stylus point.

When operating the tool, do not bear down on the work and make stylus to dig in. Guide the tool and let the stylus do the work. The tool should be held approximately 15° off perpendicular to the work surface in order to scribe smoothly and to minimize excessive force on the side of the stylus point.

When using a chisel, it is necessary to bear the tool against the work as when working with a chipping hammer. Use the tool at full throttle on softer materials and adjust the speed to the job by varying the throttle setting. In this way, the operator is in full control of the tool. The amount of force that the operator exerts on the tool directly affects the chisel blow. Applying a lighter force when starting or stopping the work results in good control of the tool.