Working with the Tool

Make sure that the lower corner of the inserts are always covered by the guide bearing before using the tool.

General beveling usage and instructions

Beveling operation is intended for aluminum, mild steel, and carbon steel. Operation is not suitable in any type of stainless steel or fine grain steel.

In some materials, flame plasma and laser cutting techniques can lead to hardening of the edges on the workpiece. This can result in hardening of the edge that needs to be removed before beveling operation starts.

In order to avoid the edge to build-up, use an appropriate cooling liquid for lubrication such as cooling oil or cutting wax.

The general instruction regarding feed force is 0,5-1 m/min, depending on the bevel size and material. For maximum bevel size allowed, see the section Adjusting the bevel height. Note that larger bevels should be performed in two or three steps. It is never recommended to exceed the bevel with of 4 mm in one operation. Larger bevels is recommended to be divided in equal steps of the operation. Never run the maximum bevel width in one operation!

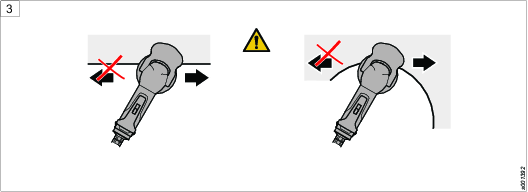

When starting the beveling operation, it is very important to slowly enter into the material.

To become acquainted with the tool, it is recommended that you perform a test run with the tool. Do the test working on a small bevel with a width of no more than 2 mm. Advance the tool slowly at first.

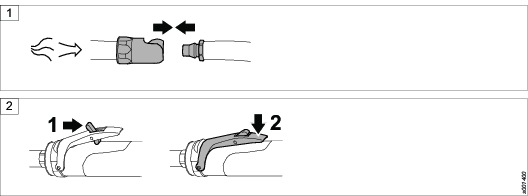

Connect the tool to the air supply.

Place the tool on the workpiece and start the tool by pushing the lever catch relase arm forward and then pressing down the throttle valve lever.

Advance the tool slowly. Make sure to operate the tool only in the recommended working direction .

To stop the tool, lift the tool from the workpiece and release the throttle lever.

Once the motor is switched off, wait for the tool to come to a standstill before placing it down on a surface.