Bolt Tensioning Procedure

Before applying pressure to the system

Read and understand the Safety Instructions that comes with the product.

Make sure you are aware of the correct operation of the hydraulic pump unit.

Make sure you are aware of the maximum working pressure of the tensioner.

Make sure you are aware of the maximum piston movement of the tensioner (See hard stamped on tensioner loadcells).

Make sure you are aware of the required working pressure that must be applied to the tensioner.

Lifting eyes and straps on tools should be checked before usage. Check for cracks or any other visible damage. Lifting straps or eyebolts which are found to be damaged should not be used.

Ready to Tension

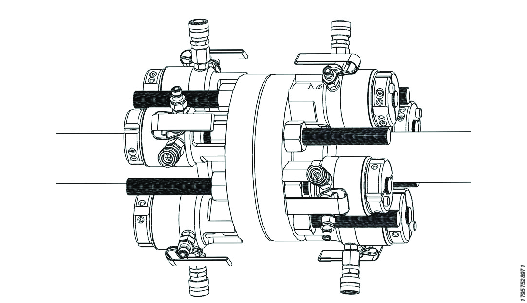

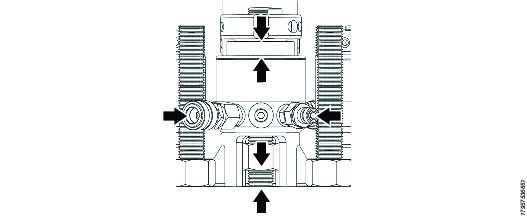

In the following illustrations the hydraulic link hoses have been removed for reasons of clarity.

Close the stop valve on the pump unit, then pressurize the system to the required pressure. Monitor the pressure continuously throughout the process. When the target pressure is reached, stop the pump (Hold Pressure). At this stage the bolt will be initially loaded with the load being held by the tensioner. The tensioner piston will be extended and the flange nut will rise off the flange surface.

Do not exceed the maximum piston stroke of the tensioner (a red band will become visible as maximum piston stroke is approached).

Check the pump gauge to ensure the pressure is holding firmly. When the pressure is stable, approach the tensioner and by using the tommy bar; rotate the nut, (through the tensioner access windows), back down towards the joint face. Seat the nut firmly against the joint, by the use of a mallet and tommy bar. If the nut is not seated firmly, the tensioning procedure will take much longer to complete. It is not important in which order the nuts are tightened but to be sure of not missing one, it is recommended they are tightened in sequence.

Now repeat the tensioning procedure from Step 1. The first pressurization was used to ‘bed’ the flange bolts and nuts. This is useful in order to maximize the amount of retained bolt load. Repeat from Step 1 a third time.

Release the pressure at the Hydraulic Pump Unit and once the oil has returned disconnect all of the hydraulic link hoses, cross-over link hose and down line. Release the split reaction nut and remove all the bolt tensioning tools.

Once the tensioning equipment is deployed topside, close all the piston rams, ready for next usage.