Four Step Tightening Strategy

The four step tightening strategy is divided into separate steps, that can be switched On or Off, to customize the tightening task.

Controller features, such as the Low Reaction Tightening Strategies and controller-wide functions among others, require licenses distributed through the Functionality Management System (FMS). Whereas configuration of features is possible without specific licenses, the assignment and use of those features will require the correct license to be installed on the controller. Please refer to Licenses (FMS) for more detailed information on licenses.

Each step has a target value and may monitor other values , this is divided up as follows:

Step | Function |

|---|---|

Start | The start step is used to engage the threads and to detect if a tightening has already occurred. |

Rundown | The rundown step is used to run down a screw to the snug level. |

Tightening | The tightening step is used to tightening the screw to a defined torque level, and may be divided into several steps. This final target value may be either a target torque or a target angle. |

Stop | The stop step is to finalize the tightening in an ergonomic way. |

Example 1: If the start and rundown steps are used to tighten a screw to the snug level, a final tightening can be made in a later step.

Example 2: If the tightening steps are used in a previous snug level tightening, a final assembly can be made to tighten the joint to the final target value.

Parameter definition

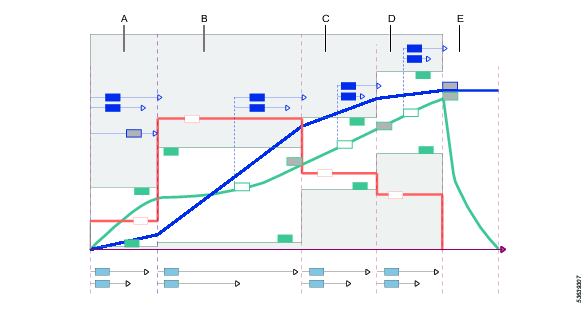

Different parameters control the four step tightening. To illustrate the parameters and their position they are shown in the combined speed-over- time curve, angle-over-time curve and torque-over-time curve.

The graphical representation is used in the documentation to describe the configuration setting and the interpretaion of the parameter values. The graphs are not used in any GUI.

A | Start stage |

B | Rundown stage |

C | Tightening stage: First step |

D | Tightening stage: Final step |

E | Stop stage |