Step Restrictions

To make sure the tightening stops if something unexpected happens, it is possible to add restrictions to the multistep tightening program. For each restriction, select Repairable = Yes to allow retry when tightening stops. For each of the steps in a multistep program it is possible to have up to four restrictions.

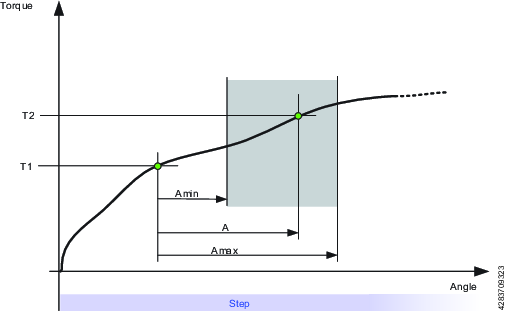

CTh – Cross Thread

This restriction checks the angle from the point where torque passes Start torque (T1) to the point where the torque passes End torque (T2). If the angle measured from Start torque (T1) is higher than Maximum limit (Amax), the tool is stopped immediately and the program jumps to the next synchronization point.

When the torque passes End torque (T2), the measured angle is checked against the limit Minimum limit (Amin). If the angle is lower than this limit, the tool is stopped immediately and the program jumps to the next synchronization point.

Parameter | Description | In illustration |

|---|---|---|

Start torque | Must be <=0. | T1 |

End torque | Must be <=0. | T2 |

Minimum limit | The low angle limit. | Amin |

Maximum limit | The high angle limit. | Amax |

A – Maximum Angle

This restriction measures the angle. If the measured angle reaches the Maximum limit, the tool is stopped immediately and the program jumps to the next synchronization point. The angle is measured from the start of the restriction or, if specified, from the point where the torque passes Trigger torque for the first time during the restriction.

Parameter | Description |

|---|---|

Trigger torque | If specified, this is the torque from where the angle is measured. |

Maximum limit | If this limit is reached the tool is stopped immediately and the program jumps to the next synchronization point. |

T – Maximum Torque

This restriction checks the torque. If the measured torque exceeds the Maximum limit, the tool is stopped immediately and the program jumps to the next synchronization point.

Parameter | Description |

|---|---|

Maximum limit | If the torque reaches this specified limit the tool is stopped immediately and the program jumps to the next synchronization point |

RH – Rehit

This restriction checks the torque. If the measured torque exceeds the Torque Limit, the tool is stopped immediately and the program jumps to the next synchronization point, or the end of the program.

Parameter | Description |

|---|---|

Torque Limit | If the torque reaches this specified limit the tool is stopped immediately and the program jumps to the next synchronization point, or the end of the program. |

RT – Rescinding Torque

This restriction checks the torque. If the measured torque is lower than the limit Torque low limit, the tool is stopped immediately and the program jumps to the next synchronization point, or the end of the program.

Parameter | Description |

|---|---|

Rescinding torque limit | Default: 10 Nm. Must be > 0. |

TG – Torque Gradient

This restriction checks the gradient and if it is outside the limits the tool is stopped immediately and the program jumps to the next synchronization point or the end of the program.

Parameter | Description |

|---|---|

Gradient Angle Window | Specifies Angle Window:

|

Angle Window | Available when Gradient Angle Window is set to Manual. Must be > 0 and <= 100. |

Trigger Torque | Must be > 0 and < Tool MaxTorque. |

Damping | Frequency in which the gradient is being calculated. Must be > 0 and < 100 and < Angle window. |

Minimum Limit | Must be >= -100. |

Maximum Limit | Must be > -100 and > Low limit. |

Torque Filter Type | The type of the filter:

|

Cut-off Frequency | Needs to be specified when Torque Filter Type is set to Low pass:

|

Number of Samples | Needs to be specified when Torque Filter Type is set to Sliding Average:

|

TAW – Torque in Angle Window

This restriction checks that the measured torque in the angle window is within its limits. If the measured torque is outside the limits the tool is stopped immediately and the program jumps to the next synchronization point, or the end of the program.

Parameter | Description |

|---|---|

Trigger torque | Must be >= 0 |

Start angle | Must be >= 0 |

Window length | Must be >0 |

Minimum limit | Must be >= 0 |

Maximum limit | Must be <= Minimum limit |

TCD - Torque vs Current Deviation

This restriction verifies that all current measurements converted to the corresponding torque are, at most, the Maximum deviation away from the actual torque measured with the torque transducer. The restriction starts when the torque reaches Trigger Torque for the first time during the step and is active until the step reaches its target.

If Trigger Torque is never reached, the monitor will report OK.

Parameter | Description |

|---|---|

Trigger torque | Must be >= 0 |

Maximum deviation | Default: 1, Must be > 0 |

PCH - Pulse Count High

Before using Pulse Count High step restriction, it is mandatory that the following license type is installed on the controller:

Low Reaction Strategies

Pulse Count High is valid only for the following tools: ETV-STR61-100-13, ETV-STR61-70-13, ETV-STR61-50-10.

This restriction gives a limit to the number of pulses, and makes sure that those are below the specified pulse count high limit.

If the measured number of pulses is higher than the pulse count high limit, the tool is stopped immediately and the program goes to the next synchronization point or the end of the program.

If the torque trigger level is set, the check starts as soon as the measured torque is above the torque trigger level.

If running a tightening step with Pulse Count High step restriction, use the necessary PulseDrive socket/adapter.

If the tightening step runs without the PulseDrive socket/adapter, all the tightenings are NOK. The step error “PulseDrive socket/adapter not detected” shows for no PulseDrive socket/adapter.

Parameter | Description |

|---|---|

Pulse Count High Limit - n+ | Pulse count high limit must range from 1 through 9999999. |

Torque Trigger - Tt | Torque Trigger must range from 0 through the maximum torque of the tool. |