Assembling the Tool

When assembling the inlet with sleeve valve (14"), first lubricate the O-ring lightly with a good rubber lubricant and place it in a counterbored air port in inlet. Lubricate the two O-rings and assemble them in the grooves on either side of the air port. To avoid cutting the O-rings in the air port, align the indicator mark on the valve with the OFF on the inlet and slide the valve carefully on the inlet. Place the retaining ring in the groove in inlet, lubricate a third O-ring and assemble the in groove next to the shoulder between the retaining ring groove and the threads on the inlet. Make sure this O-ring is assembled between the slight ridge and the shoulder to prevent the O-ring from being forced into the inlet threads.

When installing a new piston in the cylinder, it may be necessary to lap the piston to secure a close and free fit in the cylinder. No. 12-24 UNC internal threads in the piston allow handling during this operation. Use a good grade fine lapping compound, thoroughly clean the parts and lubricate with the recommended air tool oil before assembly.

After assembling the piston and cylinder, lubricate and install the O- ring on the inlet and carefully slip the cylinder on the inlet. Do not damage the O-ring. Align the transverse holes in the cylinder and the inlet and carefully install the roll pin through the parts. Support the parts firmly and avoid damaging the parts while driving the roll pin.

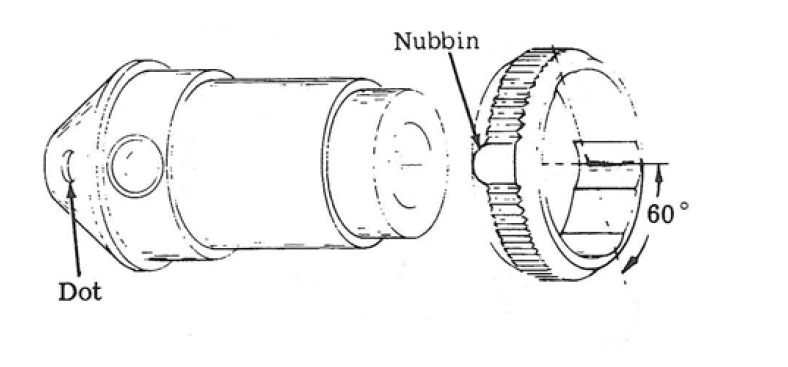

Assemble the O-ring and the 1/8'' steel ball in the accessory bushing with lubricant to hold in place. Lubricate and assemble the 5/32" steel ball in the larger opening. Refer to the illustration below to align the nubbin at a smooth spot on the Iock ring with dot on the accessory bushing. The nubbin should be on the side of the lock ring toward the bushing. Slip the ring on the bushing. Orient the dot on the bushing with any corner of the hex. on the cylinder sleeve and press the bushing into the sleeve up to the bushing shoulder.