Assembling the screw housing

Required tools

Allen keys or bits 4-10 mm

Screw bits and sockets

Torx® keys or bits T6-T25

Torque wrench

Lifting device

Screwdrivers

Pliers

Bearing puller (optional)

Feeler gauge

Lubricant | Description |

|---|---|

Klüberlub® BE 71-501 | http://www.klueber.com/en/product-detail/id/404/ |

Required spare parts

Spare parts | Amount |

|---|---|

Roller bearings | 3 |

Leaf springs | 3 |

Shim rings | 4 |

Rollers | 3 |

Shaft seal (o-ring or scraper seal) | 3 |

Glide bearing | 1 |

Load cell (if needed) | 1 |

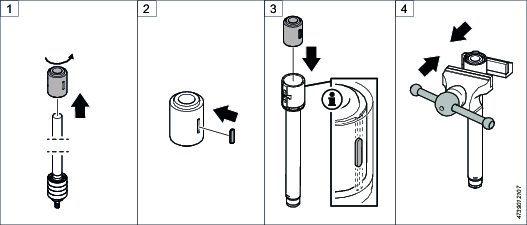

Unscrew the roller screw nut from the roller screw shaft delivered from SKF.

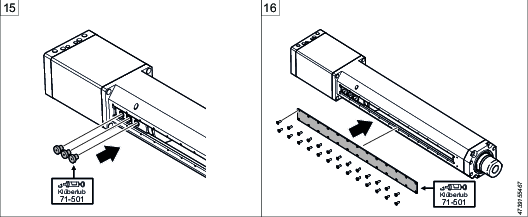

Assemble the shaft key on to the roller screw nut.

Add a small amount of grease to all surfaces and slide the roller screw nut into the roller nut housing.

Clamp over roller nut housing using a vice with soft jaws.

Assemble the upper flange using new screws.

Tighten the screws crosswise, first to 50% torque, then to 100% torque. Torque according to Installation overview.

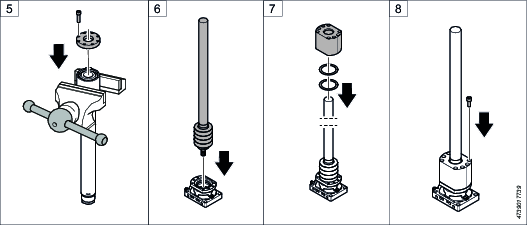

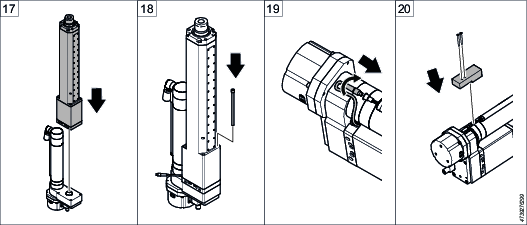

Assemble the roller screw bearing, disc spring and all washers.

Assemble the convex side of disc spring towards the bearing. Use washer(s) between housing and disc spring.

Assemble the shim, washer and the Inner bearing cover onto the roller screw shaft.

Assemble the load cell using new screws. Tighten the screws crosswise using a long hexagon socket, first to 50% torque, then to 100% torque. Torque according to Installation overview.

Clamp over load cell/housing using a vice with soft jaws.

Assemble the outer bearing cover.

Assemble the upper disc spring (and support washer).

Convex side towards gearbox. Washer between housing and disc spring.

Assemble the screw nut and piston shaft assembly by rotating the whole assembly onto the inner shaft.

Apply a thin layer of grease (Klüberlub® BE 71-501) on the screw.

Assemble the center roller holder and the screw housing.

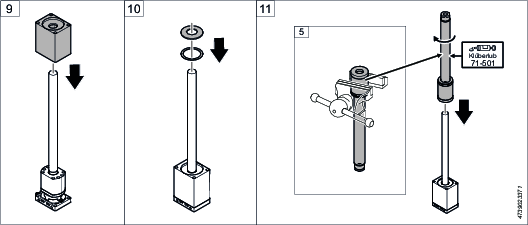

If needed, assemble the glide bearing, the shim rings (3x) and the roller bearings (3x), see Changing the roller bearings.

Apply a thin layer of grease (Klüberlub® BE 71-501) on all parts.

Assemble the leaf springs (4x).

Apply a thin layer of grease (Klüberlub® BE 71-501) on all parts.

Assemble the guide rollers (3x).

Apply a thin layer of grease (Klüberlub® BE 71-501) on all parts.

Assemble the front cover using the screws.

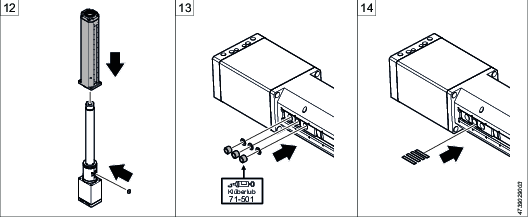

Slide on the screw housing assembly onto the spline joint in gearbox.

Assemble the screw housing assembly to the gearbox using new bolts (4x).

Tighten the screws crosswise, first to 50% torque, then to 100% torque. Torque according to Installation overview.

Assemble the load cell cable onto the motor cable.

Assemble the connector cover using the screws (2x).