STRwrench Controller Advanced

Modular Electronic Wrench

Product Information

General Information

Safety Signal Words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER | DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

WARNING | WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

CAUTION | CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

NOTICE | NOTICE is used to address practices not related to personal injury. |

Warranty

Product warranty will expire 12+1 months after dispatch from Atlas Copco's Distribution Center.

Normal wear and tear on parts is not included within the warranty.

Normal wear and tear is that which requires a part change or other adjustment/overhaul during standard tools maintenance typical for that period (expressed in time, operation hours or otherwise).

The product warranty relies on the correct use, maintenance, and repair of the tool and its component parts.

Damage to parts that occurs as a result of inadequate maintenance or performed by parties other than Atlas Copco or their Certified Service Partners during the warranty period is not covered by the warranty.

To avoid damage or destruction of tool parts, service the tool according to the recommended maintenance schedules and follow the correct instructions.

Warranty repairs are only performed in Atlas Copco workshops or by Certified Service Partners.

Atlas Copco offers extended warranty and state of the art preventive maintenance through its ToolCover contracts. For further information contact your local Service representative.

For electrical motors:

Warranty will only apply when the electric motor has not been opened.

Website

Information concerning our Products, Accessories, Spare Parts and Published Matters can be found on the Atlas Copco website.

Please visit: www.atlascopco.com.

ServAid

ServAid is a portal that is continuously updated and contains Technical Information, such as:

Regulatory and Safety Information

Technical Data

Installation, Operation and Service Instructions

Spare Parts Lists

Accessories

Dimensional Drawings

Please visit: https://servaid.atlascopco.com.

For further Technical Information, please contact your local Atlas Copco representative.

Safety Data Sheets MSDS/SDS

The Safety Data Sheets describe the chemical products sold by Atlas Copco.

Please consult the Atlas Copco website for more information www.atlascopco.com/sds.

Country of Origin

For the Country of Origin, please refer to the information on the product label.

Dimensional Drawings

Dimensional Drawings can be found either in the Dimensional Drawings Archive, or on ServAid.

Please visit: http://webbox.atlascopco.com/webbox/dimdrw or https://servaid.atlascopco.com.

Overview

System Functionality

The STRwrench is equipped with an integrated controller for setting and running inspections and route, and for configuring device's features and functions.

By connecting the wrench to a PC via USB, or by setting up a wireless connection to the factory network, the controller can be accessed through the STRwrench QA Inspector Software Web User Interface.

Tool Functionality

Position | Description |

|---|---|

1 | Battery |

2 | Handle |

3 | LED indicators |

4 | NFC |

5 | EHMI (Display with push button) |

6 | smartHEAD |

7 | Front LED light |

8 | End-fitting tool RFID TAG reader |

9 | Barcode scanner |

10 | USB-C port |

EHMI Description

The EHMI (Extended Human Machine Interface) is located on the wrench controller and consists of a touch-sensitive control display and a push button. The display serves as a tool-integrated interface for the operator, and can be used to configure, select and run inspections and routes; to display tests' results and traces; and to configure device settings.

Position | Name | Definition |

|---|---|---|

1 | Display | Touchscreen serving as a tool-integrated interface for the operator. |

2 | ON/OFF / Barcode | Physical button for turning on/off the wrench and for triggering the barcode scanner. |

Indicator bar

The indicator bar is presented at the top of all menus. The icons in the indicator bar provide information on the elements listed below.

Icon | Description |

|---|---|

| The wireless connection icon indicates the signal strength of the tool's factory network connection. When no connection is established, the icon is crossed out. |

| The direction icon indicates whether the tightening must be done in clockwise (CW) or counterclockwise (CCW) direction. |

| The battery icon indicates the charge status of the battery attached to the tool. |

The battery charge levels are listed below:

Battery Icon | Icon behavior | Remark |

|---|---|---|

| Steady | Full charge |

| Steady | High charge |

| Steady | Medium charge. Charge battery when possible. |

| Flashing | Low charge. Charge battery. |

| Steady | Critical level, not possible to perform tightening. Charge battery. |

Dimensions and Weight

Product | L* | K | X | Y | Z | H | Weight | E |

|---|---|---|---|---|---|---|---|---|

STRwrench Controller Advanced + smartHEAD 15 Nm | 374 | 437 | 145 | 278 | 13.4 | 356 | 1.57 | 9x12 |

STRwrench Controller Advanced+ smartHEAD 80 Nm | 374 | 437 | 145 | 278 | 13.4 | 356 | 1.6 | 9x12 |

STRwrench Controller Advanced + smartHEAD 250 Nm | 499 | 554 | 262 | 278 | 13.4 | 473 | 2.2 | 14x18 |

STRwrench Controller Advanced + smartHEAD 250 Nm Long | 699 | 754 | 462 | 278 | 13.4 | 673 | 2.31 | 14x18 |

STRwrench Controller Advanced + smartHEAD 400 Nm | 820 | 874 | 583 | 278 | 13.4 | 794 | 2.95 | 14x18 |

STRwrench Controller Advanced + smartHEAD 500 Nm | 833 | 874 | 583 | 278 | 13.4 | 794 | 3.4 | 14x18 |

STRwrench Controller Advanced + smartHEAD 600 Nm | 1272 | 1352 | 1061 | 278 | 13.4 | 1339 | 4.78 | 21x26 |

STRwrench Controller Advanced + smartHEAD 1000 Nm ALU | 1585 | 1470 | 1178 | 278 | 13.4 | 1456 | 8.58 | Ø28 |

STRwrench Controller Advanced + smartHEAD 1000 Nm CAR | 1707 | 1593 | 1301 | 278 | 13.4 | 1579 | 6.55 | Ø28 |

*Dimension L is the standard arm, measured from the center of the handle to the center of the end fitting tool. This information is used to calculate the Torque Correction Coefficient when an extension is used. This dimension is calculated for the standard Atlas Copco end fitting tools used during calibration (L-H); if a different end fitting tool is used, this measure must be recalculated.

For more information, refer to STRwrench QA Inspector Software User Guide.

Product Data

Operating torque measuring range | from 10 % to 100 % of the smartHEAD capacity |

Maximum torque accuracy error (related to the value read by the STRwrench controller) | ± 0.1 % |

Maximum torque linearity error (related to the value read by the STRwrench controller) | ± 0.015 % |

Torque measurement accuracy (smartHEAD 15 Nm) | 0.5% readout ±1 digit (from 20% to 100% of nominal torque) |

Torque measurement accuracy (smartHEAD 80-1000 Nm) | 0.5 % readout ±1 digit (from 10% to 100% of nominal torque) |

Overload capacity | 120% of smartHEAD capacity |

Temperature stability of torque measurement | 0.1% of capacity/10°C |

Maximum angular speed | 150 °/s |

Angle measurement accuracy | ±1° over 360° without torque preload ±1% over 360° with torque preload |

Weight | 854.3 g |

Wireless LAN Information

Regulatory Domain | Band | TxChannels |

ETSI | 2.4 GHz | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 |

U-NII-1 | 36, 40, 44, 48 | |

U-NII-2 | 52, 56, 60, 64 | |

U-NII-2e | 100, 104, 108, 112, 116, 120, 124, 128, 132, 136, 140 | |

FCC/IC | 2.4 GHz | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 |

U-NII-1 | 36, 40, 44, 48 | |

U-NII-2 | 52, 56, 60, 64 | |

U-NII-2e | 100, 104, 108, 112, 116, 132, 136, 140 | |

U-NII-3 | 149, 153, 157, 161, 165 |

Technical Product Data

Technical Product Data can be found on either ServAid, or the Atlas Copco website.

Please visit: https://servaid.atlascopco.com or www.atlascopco.com.

Environmental Conditions

Indoor use only | |

Altitude | Up to 2000 m |

Ambient temperature range | +5 to +40 °C |

Maximum relative humidity 80 % for temperatures up to 31 °C decreasing linearly to 50 % relative humidity at 40 °C |

|

Environmental class | II |

Pollution degree | 2 |

IP Index (only when the USB port cover is closed) | 40 |

Accessories

Accessory Information

Visit the tool's product page on ServAid for information about compatible accessories.

Installation

Installation Instructions

Connecting to STRwrench QA Inspector Software Web User Interface

Switch on the wrench and open the USB-C port cover.

Do not remove the cover of the USB-C port completely.

Connect the tool to the USB port of the PC. Open a web browser and type in the address of the STRwrench QA Inspectore Software Web User Interface:

169.254.1.1.

Attaching the Battery

Unscrew the battery cap placed at the end of the wrench handle.

Insert the battery into the wrench handle by aligning it with the nut inside until the mechanic stops.

Screw the battery cap on the wrench handle.

Removing the Battery

Unscrew the battery cap placed at the end of the wrench handle.

Pull the battery out of the wrench handle.

Screw the battery cap on the wrench handle.

Attaching the End-Fitting Tool

Insert the End-Fitting Tool by aligning the PIN with the reference guide inside the smartHEAD.

Push the End-Fitting Tool until the mechanic stops and the PIN is locked.

There is only one way to insert the End-Fitting Tool into the smartHEAD. The PIN must be inserted into its housing: do not force it in other positions.

Removing the End-Fitting Tool

Push the PIN on the smartHEAD to unlock it from its housing.

Remove the End-Fitting Tool from the smartHEAD.

Attaching the smartHEAD

Attach the smartHEAD to the wrench controller.

To optimize the vision of the EHMI during operations in special circumstances, the smartHEAD can be attached in 4 positions, each at 90° rotation.

Pull down the ferrule.

Rotate the ferrule clockwise while pushing it down to fasten the smartHEAD to the wrench controller.

Removing the smartHEAD

Rotate the smartHEAD's ferrule counterclockwise while pushing it down to unlock the smartHEAD from the wrench controller.

Pull up the ferrule.

Remove the smartHEAD from the wrench controller.

Initial Configuration

Tool Configuration

For information about establishing a wireless connection, installing licenses, configuring and running inspections, refer to STRwrench QA Inspector Software User Guide.

Firmware Installation and Upgrade

For information about firmware installation and upgrade, refer to STRwrench QA Inspector Software User Guide.

Operation

Ergonomic Guidelines

Consider your workstation as you read through this list of general ergonomic guidelines to identify areas for improvement in posture, component placement, or work environment.

Take frequent breaks and change work positions frequently.

Adapt the workstation area to your needs and the work task.

Adjust for a convenient reach range by determining where parts and tools need to be located to avoid static load.

Use workstation equipment such as tables and chairs appropriate for the work task.

Avoid work positions above shoulder level or with static holding during assembly operations.

When working above shoulder level, reduce the load on the static muscles by lowering the weight of the tool, using for example torque arms, hose reels or weight balancers. You can also reduce the load on the static muscles by holding the tool close to the body.

Take frequent breaks.

Avoid extreme arm or wrist postures, particularly during operations requiring a degree of force.

Adjust for a convenient field of vision that requires minimal eye and head movements.

Use appropriate lighting for the work task.

Select the appropriate tool for the work task.

In noisy environments, use ear protection equipment.

Use high-quality inserted tools and consumables to minimize exposure to excessive levels of vibration.

Minimize exposure to reaction forces.

When cutting:

A cut-off wheel can get stuck if the cut-off wheel is bent or not guided properly. Use the correct flange for the cut-off wheel and avoid bending the cut-off wheel during operation.

When drilling:

The drill might stall when the drill bit breaks through. Use support handles if the stall torque is high. The safety standard ISO11148 part 3 recommends using a device to absorb a reaction torque above 10 Nm for pistol grip tools and 4 Nm for straight tools.

When using direct-driven screwdrivers or nutrunners:

Reaction forces depend on the tool settings and joint characteristics. Strength and posture determine the amount of reaction force that an operator can tolerate. Adapt the torque setting to the operator's strength and posture and use a torque arm or reaction bar if the torque is too high.

In dusty environments, use a dust extraction system or wear a mouth protection mask.

Configuration Instructions

Vibration

This tool is equipped with a vibrating device, which can be configured to signal specific events or warnings.

For more information on the vibration functionality and configuration, refer to STRwrench QA Inspector Software User Guide.

Buzzer

This tool is equipped with a buzzer, which can be configured to signal specific events or warnings.

For more information on the buzzer functionality and configuration, refer to STRwrench QA Inspector Software User Guide.

smartHEAD Illuminating Light

The smartHEAD illuminating light provides illumination under the end fitting tool; it can be helpful for a better view of joints in dark areas. It is activated for 10 seconds when the barcode button on the wrench EHMI is pressed.

For more information on the light functionality and configuration, refer to STRwrench QA Inspector Software User Guide.

Operating Instructions

Smart Zeroing

An automatic zero adjustment occurs every time the STRwrench is powered on and every time a smartHEAD is connected to the STRwrench controller.

During the zero adjustment, the wrench must lay steady without applying any torque constraint.

If the STRwrench detects any movement during the procedure, the zero adjustment will start over again.

Automatic Shutdown on Empty Battery

When the battery charge level dips below the critical threshold (12%), the STRwrench is configured to automatically shutdown. As soon as the critical level is reached, the tool starts emitting an intermittent acoustic notification and turns off after 5 minutes.

When the battery charge level is below 12%, it is not possible to perform tightening. When trying to perform tightenings with this charge level, a notification is displayed reminding of the inability to operate.

Charging the battery

The STRwrench battery has to be charged by means of the STRwrench charger (Article nr. 8059 0924 10).

Battery charge LED indicators

The wrench is powered by a Lithium-ion battery.

The LED indicators on the battery indicate the State of Charge (SOC) of the battery. To activate the LEDs, press the button placed on the battery.

1 | LED indicators | 2 | Button |

The LEDs indicate the remaining capacity of the battery as follows:

Battery charge indicator | Remark |

|---|---|

1 LED | Critical level, not possible to perform tightening. Charge battery. |

2 LEDs | Low charge. Charge battery. |

3 LEDs | Medium charge. Charge battery, when possible. |

4 LEDs | High charge. |

5 LEDs | Full charge. |

LED indicators Flash Patterns

The standard flash patterns of the LED indicators are shown below:

General description | Light pattern description | Light color | Illustration* |

|---|---|---|---|

Starting up / booting | Pulse light All LEDs | White |

On (left image) - Off (right image) |

Tightening initiation | Spot light Central LED in both front and back view light up. | White |

|

Tightening progress | Radial gradient light, 2 directions LEDs light from the center towards the sides in both front and back view simultaneously. | White |

|

OK Result | Solid light All LEDs | Green |

|

NOK Result | Alternating light All LEDs | Red |

|

Batch Done | Radial gradient light, 1 direction Starts from central LED in the front view, and continues radially until reaching the central LED. | White |

|

*Illustration description:

A | Light behavior | B | Back |

C | LED ring (section) | D | Front |

EHMI operations

For more detailed information on how to use the EHMI to configure and run operations with the STRwrench, refer to STRwrench QA Inspector Software User Guide.

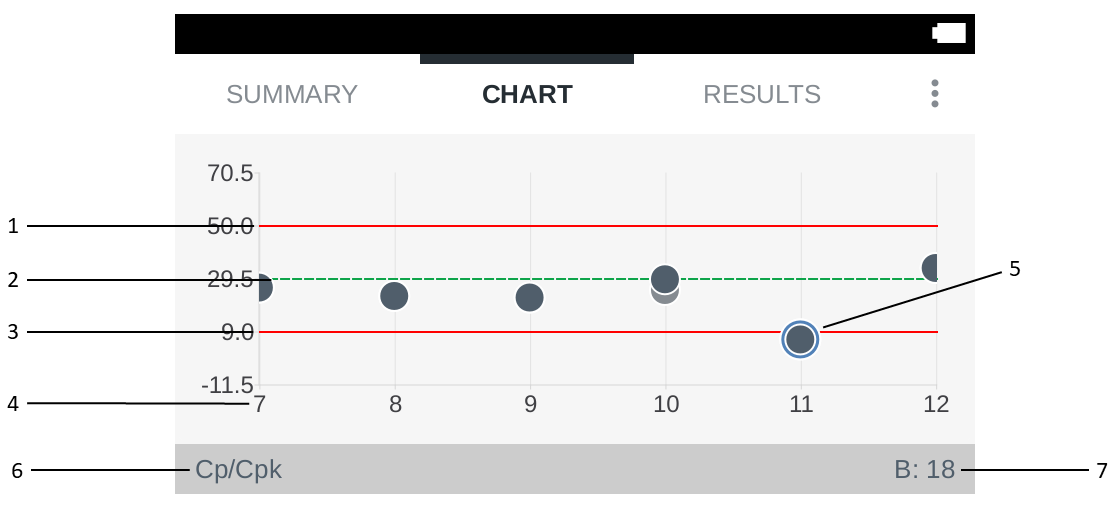

Reading the Chart Category

Position | Name | Definition |

|---|---|---|

1 | Upper limit | Torque upper limit value specified for the inspection. |

2 | Target value | Torque target value specified for the inspection |

3 | Lower limit | Torque lower limit value specified for the inspection. |

4 | Sample number | Number of the sample inside the inspection. |

5 | Result | Torque value measured during each test inside the inspection. |

6 | Inspection name | Name of the selected inspection |

7 | Batch count | Number of times the test has been executed inside the inspection. |

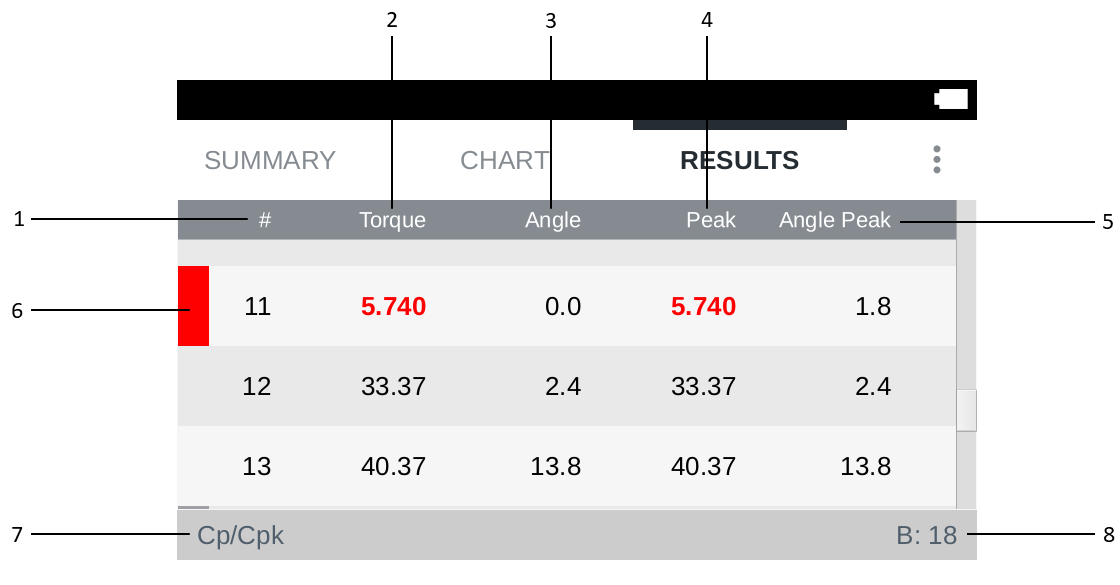

Reading the Results Category

Position | Name | Definition |

|---|---|---|

1 | # | Column displaying the sequence number of each test inside the inspection. |

2 | Torque | Column displaying the measured torque values for each test. |

3 | Angle | Column displaying the measured angle values for each test. |

4 | Peak | Column displaying the torque peaks detected during each test. |

5 | Angle Peak | Column displaying the angle peaks detected during each test. |

6 | Results | List of the test results acquired inside the inspection. If a result is NOK, the measured value is highlighted in red. |

7 | Inspection name | Name of the selected inspection. |

8 | Batch count | Number of times the test has been run inside the inspection. |

Reading the Trace Category

Position | Name | Definition |

|---|---|---|

1 | Upper limit | Upper limit value for the function under control. |

2 | Result | Test result value. If the Double result function is enabled, both the residual point and the peak point are shown in the plot. |

3 | Lower limit | Lower limit value for the function under control. |

4 | Inspection name | Name of the selected inspection. |

5 | Full-screen button | Button for opening a full-screen view of the plot. In full-screen mode, it is possible to select and zoom in on a section of the curve. |

6 | Plot type button | Button for selecting the plot type to be displayed. Default plot is Torque over Angle. |

7 | Next button | Button for moving to the trace of the next result inside the inspection. |

8 | Previous button | Button for moving to the trace of the previous result inside the inspection. |

9 | Test number | Number of the test inside the inspection. |

10 | Batch count | Number of times the test has been run inside the inspection. |

Service

Preventing ESD Problems

The components inside the product and controller are sensitive to electrostatic discharge. To avoid future malfunction, make sure that service and maintenance is carried out in an ESD approved work environment. The figure below shows an example of an appropriate service work station.

Maintenance Instructions

Tool Calibration

The STRwrench must be calibrated at least once a year. Contact Atlas Copco Service Personnel for the tool calibration.

Service Recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

Clean appropriate parts accurately

Replace any defective or worn parts

smartHEAD Service Recommendations

It is recommended to replace the following smartHEAD components with the frequency specified in the table below:

Component | Frequency |

|---|---|

STR SH Gear | Every 10000 cycles |

STR SH Wave Spring | Every 2000 cycles |

Overhaul

Have the tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the tool is maintained. Service must only be carried out by qualified personnel who have been trained for service on STRwrench tools.

Troubleshooting

Tool connection via USB fails

Cause: the USB cable in use might not support data transmission.

Solution: make sure to use a USB data transfer cable (standard 2.0 or higher).

Recycling

Environmental Regulations

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.

Batteries shall be taken care of by your national battery recovery organization.

Recycling Instructions

Wrench controller

Position | Part | Recycle as |

|---|---|---|

1 | Glass | Glass |

2 | Display | WEEE |

3 | Keypad | Mixed waste |

4 | Damping system | Foam |

5 | Damping system | Foam |

6 | Washer | Steel |

7 | PCB | WEEE |

8 | Washer | Steel |

9 | Frame | Aluminum |

10 | Washer & Screws | Steel |

11 | Barcode glass | Glass |

12 | Glass support | Polyamide |

13 | Barcode glass support | Aluminum |

14 | Spring and electronic support | Steel |

15 | Pin connectors | Copper |

16 | Pin supports | Polyamide |

17 | Electronic cable | WEEE |

18 | Coupling | Steel |

19 | Body & ring | Aluminum |

20 | Shock sensor | Glass |

21 | USB cover | Rubber |

22 | LED suspension ring | Polyamide |

23 | Foam tape | Foam |

24 | LED PCB | WEEE |

25 | LED label fixture | Polyamide |

26 | LED overlay | Polyamide |

27 | LED label cover | Steel |

28 | Pins | Steel |

29 | Handle | Polyamide |

30 | Handle connector & pins | Steel |

31 | Ring label | Aluminum |

32 | O-Ring | Rubber |

33 | STRw handle cap | Steel |

34 | Foam tape | Foam |

35 | Metal sheet label | Steel |

36 | Spacers | Steel |

37 | Base PCB | WEEE |

38 | Spacers | Steel |

39 | Wi Fi PCB | WEEE |

40 | Screws | Steel |

41 | Controller cover | Polyamide |

42 | Screws | Steel |

43 | Screws | Steel |

44 | Hole handle cover | Polyamide |

45 | Washer & screws | Steel |

46 | Vibro support | Steel |

47 | Vibro | WEEE |

smartHEAD

Position | Part | Recycle as |

|---|---|---|

1 | Ferrule | Steel |

2 | Transducer | Mixed waste |

3 | Electronic support 1 | Steel |

4 | Electronic board 1 | WEEE |

5 | Tube | Mixed waste |

6 | Cable | WEEE |

7 | Electronic board 2 | WEEE |

8 | Electronic support 2 | Steel |

9 | Screw | Steel |

Standard screws and washers | Iron |