Refill the Pulse-Unit with Oil

For optimum machine performance the pulse unit must be correctly filled with oil. Due to a possible microleakage of oil from the pulse unit, it could be necessary to refill the unit between the regular overhaul intervals. The frequency of this procedure depends on the type of application, number of cycles, tightening time etc. An accurate refill of the pulse unit gives long service intervals.

Too much oil in the pulse unit implies a low pulse frequency and slow tightening.

Too little oil in the pulse unit implies a high pulse frequency and there will be a risk of a decreasing tightening torque. In particular at the first tightening after a break the machine might race.

Use Atlas Copco Pulse Unit Oil Bio.

Running the machine with too little oil may damage the pulse unit.

After the refill – Check the tightening torque.

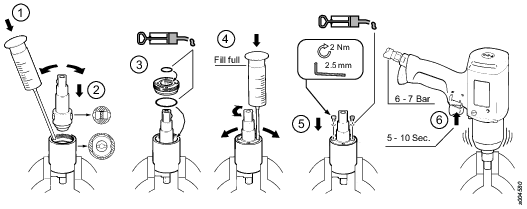

Steps

Fill the pulse unit with oil according to steps No. 1-3 seen in the picture, after the disassembly of the pulse unit. Run the machine in a vice for 10 seconds according to step No. 4. Complete the rest of the steps. For best performance use Atlas Copco Pulse Unit Oil Bio.

A bottle of Atlas Copco Pulse Unit Oil Bio and the required syringe or syringes are orderable as a kit. See Service Kits for ordering numbers.

Low oil level

How to detect a low oil level in the pulse unit:

Longer tightening time

Very high pulse frequency, especially when the tool has not been used for a while.

Low torque or abnormal torque changes (increased scatter).

No shut off

To measure the pulse frequency use a static torque transducer or an inline transducer connected to torque testing equipment, se Testing/Measuring section.