Overview of the Four Step Strategy

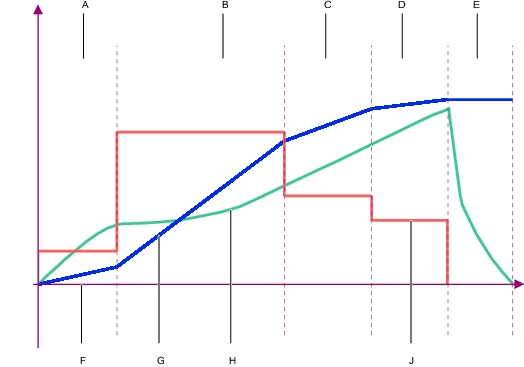

A graphical representation of the different steps and curves for speed, torque and rotation angle seen over time.

The graphical representation is used in the documentation to describe the configuration setting and the meaning of the parameter values. The graphs are not used in any GUI.

A | Start step |

B | Rundown step |

C | First step of the Tightening step |

D | Final step of the Tightening step |

E | Stop step |

F | Speed over time curve |

G | Torque over time curve |

H | Angle over time curve |

I | Time direction |

Each step is configured with respect to torque, angle, time and tool speed. Each step has one target value which is either torque or angle, and monitors the other values.

Step | Function |

|---|---|

Start | Target = Angle The step is used to engage the threads and to detect if a tightening has already occurred. Time, angle and torque limits can be monitored. |

Rundown | Target = Torque The step is used to run down a screw or a nut to the snug level, with a defined torque value. Time, angle and torque limits can be monitored. |

Tightening | The tightening step is divided into two steps: first tightening and final tightening. First tightening target = Torque. The step is used to tightening the screw or nut to a defined first target torque level. Final tightening target = Angle or Torque. The step is used to continue the tightening from the first tightening target to a final target angle or to a higher final target torque. Time, angle and torque limits can be monitored. |

Stop | The Stop step terminates the tightening so that the socket can be released. |