Hydraulic Fluid

The behaviour “In-service” of hydraulic equipment heavily depends on the quality and characteristics of the hydraulic fluid selected. The choice of the specification and viscosity of the hydraulic fluid should be based on the conditions of use, taking into account several factors as follows:

The range of environmental temperature.

The range of oil viscosity defined for the equipment.

The application (range of pressures, sources of contamination of the hydraulic fluid, the type of pump…)

The ease of getting a proper replacement or equivalent hydraulic fluid.

In general, hydraulic fluids recommended for this kind of portable hydraulic equipment should be manufactured under these specifications:

AFNOR NF E 48-603 HV

ISO 6743/4 HV

DIN 51524/ P3 HVLP

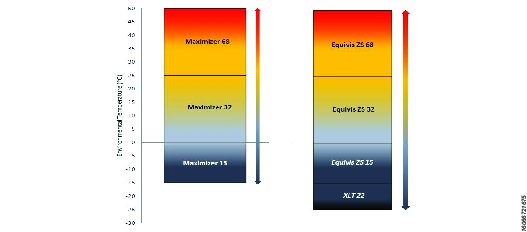

It is always recommended to use fluids with a high viscosity index fluid (V.I. > 140) to ensure a good stability under a wide range of temperatures. The user could cover a wide range of temperatures using the high V.I. TOTAL Equivis ZS or, Maximizer fluids. Refer below given chart for the hydraulic oil selection

For Artic Climates, we recommend a fluid such as the TOTAL XLT 22, which allows for a good start-up below -20ºC. For applications with critical conditions of service, environmental restrictions, or similar, please contact Atlas Copco to select the appropriate hydraulic fluid for each service.