GFA-OOT

Geared Front Attachment

Product Information

General Information

Safety Signal Words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER | DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

WARNING | WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

CAUTION | CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

NOTICE | NOTICE is used to address practices not related to personal injury. |

Country of Origin

For the Country of Origin, please refer to the information on the product label.

Overview

System Description

The Gear Front Attachment (GFA) system is used for tightening and loosening of screws and nuts. The system can be used for screw connections in locations that are difficult to access.

The tightening operation is controlled by a separate drive unit to which the system is fitted. The drive unit can be of either pneumatic or electric type.

The modular structure of the system allows for a wide range of configurations available for different screw connections and tightening processes.

System Components

The modular GFA system is made up of the following main components:

Position | Component | Function |

|---|---|---|

A | Adapter | With an adapter the GFA system can be fitted to different interfaces. The interface varies depending on the drive unit model. |

B | Gear Front Attachment (GFA) module | The GFA module comprises a housing which contains a number of gears, that is, the gear stage. The gear stage depends on the length of the GFA module. The output gear, or output socket, can be of type open-end or closed-end. The open-end type can be used for pipe and hose connections. The closed-end type is used for regular screw connections. |

C | Output socket | With different sockets the GFA system can be used for various screw profiles. |

GFA Shaft Lid generations

The open end GFA module's shaft lid comes in two generations (1 and 2). Assembly of the GFA module with a shaft lid of generation 1 or 2 are the same, until the shaft lid is assembled on the module, then the assembly varies between generation 1 and 2.

To identify the shaft lid generation

The shaft lid generation 1 does not have splines and the shaft lid is tightened with a pin spanner. The shaft lid generation 2 has splines and the shaft lid is assembled on the module by tightening two screws securing the shaft lid plate.

GFA performance

For maximum recommended torque see SI.

Accuracy 3σ: 15%.

Never exceed the recommended maximum torque.

The estimated product life of the OOT is 250,000 tightenings.

The socket will be subject to wear and is therefore considered as a consumable product.

Installation

Installation Instructions

Assembling Instructions

Assembling the GFA Module with Shaft Lid generation 1

For service tool, see Service Equipment for the specific GFA model.

Grease the inside of the idler gears and place over the shafts.

Repeat for all idler gears. The number of idler gears depend on the configuration of the GFA module.

Insert the needle roller bearings. Make sure to insert as many needle roller bearings as there is space for. There should not be any gaps.

Make sure that the parallel pin is inserted.

Apply grease to the idler gears.

Apply grease to the socket gear and place it in the housing. Make sure to place it in the right direction, according to the specification.

Place the upper part of the housing on top of the lower part. Use a press tool and press evenly over the housing.

Make sure that there is no gap between the upper and lower parts of the housing.

Tighten the screws to the specified torque. The number and type of screws depend on the GFA model.

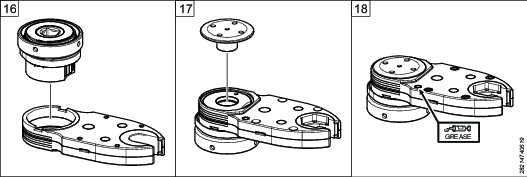

Grease the inside of the input gear and the needle carrier. Place the needle carrier in the input gear.

Use a press tool to push the ball bearing onto the input gear. Use a cylinder with the correct measurements to make the ball bearing go all the way down.

Insert the input gear into the bearing housing.

Place the nut over the bearing housing.

Place the cover plate on the collar back latch. Grease the pawl and spring and insert into the collar back latch.

The collar back latch can include a torque arm flange depending on the configuration.

Push in the pawl and put the collar back latch over the bearing housing. The pawl should go into one of the two grooves of the input gear. Depending on the gear stage and the desired rotational direction, the collar back latch can be placed either with the cover plate facing downwards (A) or upwards (B).

GFA Gear Model

Tightening Rotational

Direction of Output GearMounting Direction of

Collar Back Latch2-stage

Clockwise

Cover plate facing downwards, image A

Counterclockwise

Cover plate facing upwards, image B

3-stage

Clockwise

Cover plate facing upwards, image B

Counterclockwise

Cover plate facing downwards, image A

Turn the input square all the way to locked position. Make sure that the output gear is in open position and insert the input gear into the housing. The teeth of the gears should mesh. Push the input gear all the way down until the input gear is flush with the housing. Make sure that the output gear is in open position when the input gear is in locked position.

Secure the housing in a vice and insert the cover cap into the housing. Push the input gear up from below while tightening the cover cap.

Use a grease gun to fill the housing with grease through the grease nipple. Note that the GFA module can have a different amount of grease nipples depending on the model.

Screw the adapter onto the bearing housing until it stops. Secure the housing in a vice and tighten the nut to specified torque.

Assembling the GFA Module with Shaft Lid generation 2

For service tool, see Service Equipment for the specific GFA model.

Grease the inside of the idler gears and place over the shafts.

Repeat for all idler gears. The number of idler gears depend on the configuration of the GFA module.

Insert the needle roller bearings. Make sure to insert as many needle roller bearings as there is space for. There should not be any gaps.

Make sure that the parallel pin is inserted.

Apply grease to the idler gears.

Apply grease to the socket gear and place it in the housing. Make sure to place it in the right direction, according to the specification.

Place the upper part of the housing on top of the lower part. Use a press tool and press evenly over the housing.

Make sure that there is no gap between the upper and lower parts of the housing.

Tighten the screws securing the lower housing to the specified torque. The number and type of screws depend on the GFA model.

Grease the inside of the input gear and the needle carrier. Place the needle carrier in the input gear.

Use a press tool to push the ball bearing onto the input gear. Use a cylinder with the correct measurements to make the ball bearing go all the way down.

Insert the input gear into the bearing housing.

Place the nut over the bearing housing.

Place the cover plate on the collar back latch. Grease the pawl and spring and insert into the collar back latch.

The collar back latch can include a torque arm flange depending on the configuration.

Push in the pawl and put the collar back latch over the bearing housing. The pawl should go into one of the two grooves of the input gear. Depending on the gear stage and the desired rotational direction, the collar back latch can be placed either with the cover plate facing downwards (A) or upwards (B).

GFA Gear Model

Tightening Rotational

Direction of Output GearMounting Direction of

Collar Back Latch2-stage

Clockwise

Cover plate facing downwards, image A

Counterclockwise

Cover plate facing upwards, image B

3-stage

Clockwise

Cover plate facing upwards, image B

Counterclockwise

Cover plate facing downwards, image A

Turn the input square all the way to locked position. Make sure that the output gear is in open position and insert the input gear into the housing. The teeth of the gears should mesh. Push the input gear all the way down until the input gear is flush with the housing. Make sure that the output gear is in open position when the input gear is in locked position.

Turn the GFA module upside down. Insert the shaft lid into the housing. Check that the keys are in the correct position.

Put the shaft lid plate onto the shaft lid, the shaft lid should fit into the hole in the middle. Make sure the keys fits into the holes in the shaft lid plate. Use a pin spanner to make sure that the shaft lid plate is in the correct position.

Tighten the screws securing the shaft lid plate to the specified torque.

Use a grease gun to fill the housing with grease through the grease nipple. Note that the GFA module can have a different amount of grease nipples depending on the model.

Place the GFA module with the right way up. Screw the adapter onto the bearing housing until it stops. Secure the housing in a vice and tighten the nut to specified torque.

Attaching a Fixed Index Adapter

For service tool, see Service Equipment for the specific GFA model.

Clean the threads of the drive unit and the adapter.

Apply Loctite 2701, or similar, to the threads of the drive unit.

Fasten the drive unit in a vice and tighten the adapter to specified torque, using a C-spanner.

Attach the adapter to the nut.

Tighten the nut to specified torque, using a C-spanner.

Attaching a Fork Adapter

For service tool, see Service Equipment for the specific GFA model.

Remove the bearing shell from the angle head of the tool.

Attach the fork adapter to the angle head.

Fasten the tool to a vice. Clean the threads. Apply Loctite 2701, or similar, to the bearing shell adapter, push it into the fork adapter and tighten to specified torque. Note: this is not the same bearing shell as the one for the angle head, in Step 1.

Clean the threads. Apply Loctite 2701, or similar, to the threads of the adapter. Screw it onto the fork adapter and tighten to specified torque, using a C-spanner.

Attach the nut with the GFA module to the adapter of the drive unit.

Tighten the nut, using a C-spanner.

Dismantling Instructions

Dismantling the GFA Module with Shaft lid generation 1

The instruction below shows an example of a GFA module. The module comprises a housing which contains a number of gears depending on model of the GFA system.

For service tool, see Service Equipment for the specific GFA model.

Secure the housing in a vice and loosen the nut.

Loosen the cover cap.

Remove the bearing housing.

Loosen the hex screws. The module can be fastened with two or four hex screws, depending on the model (2, 3, or 4-stage).

Place the GFA module on a rubber mat. Hit the shafts to loosen the upper and lower part of the housing, and separate the housings.

Remove the output gear.

Note the direction of the output gear (hexagonal shape up or down). It should be placed in the same way when assembling the GFA module.

Remove the idle gears, needle roller bearings, and shafts.

Turn the input gear all the way back to the locked position. Then turn it forward 1/4 of a revolution. Push in the pawl by using a 0.1 mm feeler gauge. Remove the collar back latch.

Remove the pawl and the spring from the collar back latch.

Remove the nut from the bearing housing.

Remove the input gear from the bearing housing. Remove the ball bearing from the input gear if needed.

Remove the needle roller bearing from the input gear.

Dismantling the GFA Module with Shaft lid generation 2

The instruction below shows an example of a GFA module. The module comprises a housing which contains a number of gears depending on model of the GFA system.

For service tool, see Service Equipment for the specific GFA model.

Secure the housing in a vice and loosen the nut.

Turn the GFA module upside down and secure it in the vice. Loosen the two screws securing the shaft lid plate.

Remove the shaft lid plate.

Remove the shaft lid.

Remove the bearing housing.

Loosen the hex screws. The module can be fastened with two or four hex screws, depending on the model (2, 3, or 4-stage).

Place the GFA module on a rubber mat. Hit the shafts to loosen the upper and lower part of the housing, and separate the housings.

Remove the output gear.

Note the direction of the output gear (hexagonal shape up or down). It should be placed in the same way when assembling the GFA module.

Remove the idle gears, needle roller bearings, and shafts.

Turn the input gear all the way back to the locked position. Then turn it forward 1/4 of a revolution. Push in the pawl by using a 0.1 mm feeler gauge. Remove the collar back latch.

Remove the pawl and the spring from the collar back latch.

Remove the nut from the bearing housing.

Remove the input gear from the bearing housing. Remove the ball bearing from the input gear if needed.

Remove the needle roller bearing from the input gear.

Removing a Fixed Index Adapter

For service tool, see Service Equipment for the specific GFA model.

Fasten the drive unit, together with the GFA system, in a vice.

Loosen the nut from the adapter.

Remove the GFA unit from the adapter.

Loosen the adapter clockwise to remove it from the drive unit.

The adapter is fixed to the drive unit with Loctite. Loosening the tool from the adapter requires strong force. It is recommended to use a heat gun to facilitate the loosening.

Removing a Fork Adapter

For service tool, see Service Equipment for the specific GFA model.

Fasten the drive unit in a vice and loosen the nut, using a C-spanner.

Remove the GFA module.

Loosen and remove the adapter from the fork adapter, using a C-spanner.

The adapter is fixed with Loctite. Loosening the adapter requires strong force. It is recommended to use a heat gun to facilitate the loosening.

Loosen and remove the bearing shell adapter from the fork adapter, using a C-spanner.

The bearing shell is fixed with Loctite. Loosening the bearing shell requires strong force. It is recommended to use a heat gun to facilitate the loosening.

Remove the fork adapter from the angle head.

If applicable, fasten the tool's bearing shell to the angle head. Note: this is not the same bearing shell as the one for the adapter, in Step 4.

Screw Tightening Instructions

For tightening the screws in the GFA module housings, see tightening torque in the table below.

GFA model | Screw Tightening Torque [Nm] |

|---|---|

OOT25 | 2.1 |

OOT35 | 2.1 |

OOT50 | 2.1 |

OOT70 | 4.9 |

OOT100 | 4.9 |

Adapter Tightening Instructions

Crowfoot | Bearing Shell Fork Adapter  | Fixed Index Adapter  | Nut for Fix Index Adapter  |

OOT-25 | Acc. to tool spec. | 40 Nm Loctite 2701 | 30 Nm Loctite 243 |

OOT-35 | Acc. to tool spec. | 50 Nm Loctite 2701 | 30 Nm Loctite 243 |

OOT-50 | Acc. to tool spec. | 60 Nm Loctite 2701 | 30 Nm Loctite 243 |

OOT-70 | Acc. to tool spec. | 90 Nm Loctite 2701 | 40 Nm Loctite 243 |

OOT-100 | Acc. to tool spec. | 120 Nm Loctite 2701 | 40 Nm Loctite 243 |

Crowfoot alignment

Find the spline engagement closest to the specified position (angle).

Tighten the adapter to specified torque.

If the closest spline engagement is not a specified position (angle), tighten the adapter slightly more to the driving tool to align the driving tool and GFA.

Functional Test

The functional test is done on the GFA module disconnected from the tool.

Perform a functional test before the first tightening operation and after any performed maintenance activity.

Turn the output gear wheel by hand or by using a socket. Turning it in one direction should lock the wheel. In the other direction the gear wheel should be turned easily. The direction for locking (clockwise or counterclockwise) depends on the configuration of the specific GFA module.

If it is hard to turn, open the housing and check that all components are in the correct position. If issues persist, contact Atlas Copco Customer Center.

Lubricate the system.

Operation

Ergonomic Guidelines

Consider your workstation as you read through this list of general ergonomic guidelines to identify areas for improvement in posture, component placement, or work environment.

Take frequent breaks and change work positions frequently.

Adapt the workstation area to your needs and the work task.

Adjust for a convenient reach range by determining where parts and tools need to be located to avoid static load.

Use workstation equipment such as tables and chairs appropriate for the work task.

Avoid work positions above shoulder level or with static holding during assembly operations.

When working above shoulder level, reduce the load on the static muscles by lowering the weight of the tool, using for example torque arms, hose reels or weight balancers. You can also reduce the load on the static muscles by holding the tool close to the body.

Take frequent breaks.

Avoid extreme arm or wrist postures, particularly during operations requiring a degree of force.

Adjust for a convenient field of vision that requires minimal eye and head movements.

Use appropriate lighting for the work task.

Select the appropriate tool for the work task.

In noisy environments, use ear protection equipment.

Use high-quality inserted tools and consumables to minimize exposure to excessive levels of vibration.

Minimize exposure to reaction forces.

When cutting:

A cut-off wheel can get stuck if the cut-off wheel is bent or not guided properly. Use the correct flange for the cut-off wheel and avoid bending the cut-off wheel during operation.

When drilling:

The drill might stall when the drill bit breaks through. Use support handles if the stall torque is high. The safety standard ISO11148 part 3 recommends using a device to absorb a reaction torque above 10 Nm for pistol grip tools and 4 Nm for straight tools.

When using direct-driven screwdrivers or nutrunners:

Reaction forces depend on the tool settings and joint characteristics. Strength and posture determine the amount of reaction force that an operator can tolerate. Adapt the torque setting to the operator's strength and posture and use a torque arm or reaction bar if the torque is too high.

In dusty environments, use a dust extraction system or wear a mouth protection mask.

Operating Instructions

Operating the GFA System

Operating the GFA System with reaction bar

For angle tools using torque levels exceeding 50 Nm it is recommended to use a reaction bar, either mounted on the GFA reaction flange or on the tool.

Attach the tool to the application.

-

By using the reverse lever, the tool can be operated in both clockwise and counter-clockwise directions.

Make sure the tool is placed in the correct position on the work surface as described in the picture.

-

Press the push button to start the tool.

Continue pressing the push button while running down the nut. With pneumatic tools you can hear a sound, while the tool is running the nut down. When the sound decreases, release the push button to stop the tool. With electric tools the run down of the nut is controlled by the Power Focus.

Service

Service Overview

As the gear wheels of the GFA module are exposed to high surface pressure it is important to regularly check their condition. If any of the gear wheels are worn or damaged, all the gear wheels must be replaced. Needle bearings are to be replaced if damaged.

Unused gears may be subject to efficiency drift during break-in. After changing any of the input gear/socket/gears during service, it is recommended to increase the frequency of the calibration intervals during the first 3,000 tightenings.

At regular intervals between the service, additional grease is to be supplied through the grease nipples.

Service Instructions and Intervals

In case of faulty tightening results:

Inspect the input gear, output gear, and all interior parts for wear and change worn parts.

Daily service

Clean the GFA exterior.

Inspect the GFA for any damage.

Inspect all tightening elements on the GFA and the connection to the tool.

Run functional tests and listen for any abnormal noise.

Lubricate the system.

Yearly service

Clean the GFA interior.

Lubricate the GFA interior.

Run the GFA without load for 5 min to distribute the grease.

Calibrate the GFA to ensure correct torque.

Environment dependent service

Environment | Service interval |

|---|---|

Very dirty (e.g. heavy industry/outdoor environment) | Every 25,000 tightenings |

Dirty (e.g. industry where material removal on the same premises) | Every 75,000 tightenings |

Clean (e.g. typical assembly line) | Every 125,000 tightenings |

Very Clean (e.g. lab environment/office environment) | Every 250,000 tightenings |

Clean the GFA interior.

Lubricate the GFA interior.

Run the GFA without load for 5 min to distribute the grease.

Calibrate the GFA to ensure correct torque.

Maintenance Instructions

Cleaning the System

Clean the exterior of the GFA

To clean the system, wipe carefully with a clean, smooth cloth.

Clean the interior of the GFA

It is recommended to use hand washer or ultrasonic cleaner as grease remover.

Dismantle the GFA system.

Clean the interior of the housing with grease remover.

Clean the cogs, needles and bearings separately with grease remover.

Clean parts from eventual remainder of grease remover, use brake cleaner or equivalent.

Assemble the GFA system.

Lubrication Instructions

Lubrication for GFA

Component | Recommended | Quantity |

|---|---|---|

GFA module | Molykote Longterm 2 Plus | Until excess grease emerges on the output socket. |

Use a grease gun to apply lubrication to every grease nipple of the GFA module.

The number of grease nipples varies with the design of the GFA module.

Run the system without load to distribute the grease.

Remove any excess grease from the exterior with a clean, smooth cloth.

Recycling

Environmental Regulations

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.

Batteries shall be taken care of by your national battery recovery organization.

Recycling Information

Recycle the GFA as steel.