Assembly Control Node 2

Product Information

General Information

Safety Signal Words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER | DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

WARNING | WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

CAUTION | CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

NOTICE | NOTICE is used to address practices not related to personal injury. |

Website

Information concerning our Products, Accessories, Spare Parts and Published Matters can be found on the Atlas Copco website.

Please visit: www.atlascopco.com.

ServAid

ServAid is a portal that is continuously updated and contains Technical Information, such as:

Regulatory and Safety Information

Technical Data

Installation, Operation and Service Instructions

Spare Parts Lists

Accessories

Dimensional Drawings

Please visit: https://servaid.atlascopco.com.

For further Technical Information, please contact your local Atlas Copco representative.

Safety Data Sheets MSDS/SDS

The Safety Data Sheets describe the chemical products sold by Atlas Copco.

Please consult the Atlas Copco website for more information www.atlascopco.com/sds.

Country of Origin

For the Country of Origin, please refer to the information on the product label.

Dimensional Drawings

Dimensional Drawings can be found either in the Dimensional Drawings Archive, or on ServAid.

Please visit: http://webbox.atlascopco.com/webbox/dimdrw or https://servaid.atlascopco.com.

Warranty

Product warranty will expire 12 months after the product is first taken into use, but will in any case expire at the latest 13 months after delivery.

Normal wear and tear on parts is not included within the warranty.

Normal wear and tear is that which requires a part change or other adjustment/overhaul during standard maintenance typical for that period (expressed in time, operation hours or otherwise).

The product warranty relies on the correct use, maintenance, and repair of the unit and its component parts.

Damage to parts that occurs as a result of inadequate maintenance or performed by parties other than Atlas Copco or their Certified Service Partners during the warranty period is not covered by the warranty.

To avoid damage or destruction of system parts, service the unit according to the recommended maintenance schedules and follow the correct instructions.

Warranty repairs are only performed in Atlas Copco workshops or by Certified Service Partners.

Atlas Copco offers extended warranty and state of the art preventive maintenance through its ToolCover contracts. For further information contact your local Service representative.

Warranty will only apply when the system has not been opened.

Position of the S/N label

Overview

Applications

The Industrial PC is a computer system which can support several applications, including:

An interface between the factory network and tightening equipment

A platform to operate error proofing systems with PC-based visualization

Internal I/O Module

Inputs/outputs: | 8 digital inputs and outputs (24VDC) |

Communication protocol: | Modbus |

Expandable by adding: | Up to 7 extension modules each with 8 inputs and outputs; |

Current per output (internally limited by PTC): | 0,2A (500mA over all 8 outputs at a time loadable) |

Current consumption per input: | 7mA |

Outputs are protected against short circuits, overload, load dump (inductive voltage spikes) as well as the loss of ground connection.

Reversing the polarity of the supply voltage will destroy the internal soldered fuse.

Installation

Installation Requirements

Primary Interface Connections

Panel PC ports and COM-console are present on the back of the panel PC. The panel PC ports can be used to connect the panel PC to an external device.

Digital I/O Module

I²C-Bus for I/O Extension Modules

Only for standard patch cables. Do not use crossover cables with extension modules.

COM Ports/Serial Ports

PIN | Pinout @ RS232 |

|---|---|

1 | DCD |

2 | RxD |

3 | TxD |

4 | DTR |

5 | Signal Ground |

6 | DSR |

7 | RTS |

8 | CTS |

9 | 5V |

Case | Shielding |

PROFINET TCP/IP

Some products have PROFINET ports. Two PROFINET ports are installed on the following products:

8434230221 - AC Node 2 Value Pro LEGIC PN

8434230223 - AC Node 2 Value Pro HID PN

8434230225 - AC Node 2 Value Pro HID ULTRA PN

Detailed view:

1 | Port 2 |

2 | Port 1 |

Secondary Interface Connections

Loosen the cover on the bottom of the panel PC. Once removed, a USB 3.1 Type A adapter is accessible. The USB adapter can be used, for example, for service purposes.

IP protection class decreases from IP54 to IP23 when the cover is removed.

Power Supply Cord

Power Supply Cord 100-240 VAC

The power supply cord has to be a three wire AWG 16. The length of the power supply cord must be between 1.5 meters and 4.5 meters.

The plug of the power cord must be easily accessible. For instance, in a main wall outlet or in a cabinet outlet. The outlet must be marked as safety disconnect in case of emergency.

External Circuit Breaker

The Industrial PC has to be installed with an external two pole circuit breaker rated current 6A e.g. Eaton FAZ-C6/2. Use one of the cord types listed below,

4222 1801 13 | POWER CORD EU - type E/F |

4222 1802 13 | POWER CORD US - type B |

4222 1803 13 | POWER CORD UK - type G |

4222 1804 13 | POWER CORD IN/ZA - type M |

4222 1805 13 | POWER CORD CH - type J |

4222 1806 13 | POWER CORD IT - type L |

4222 1807 13 | POWER CORD AU - type I |

4222 1809 13 | POWER CORD CN - type I |

4222 1810 13 | POWER CORD BR - type N |

4222 1811 13 | POWER CORD IL - type H |

Software Installation Requirements

Installation via any of the following methods is possible:

PXE boot (network)

USB stick

External USB drive

Hard disk allocation / image distribution via removable hard disk

Installation Instructions

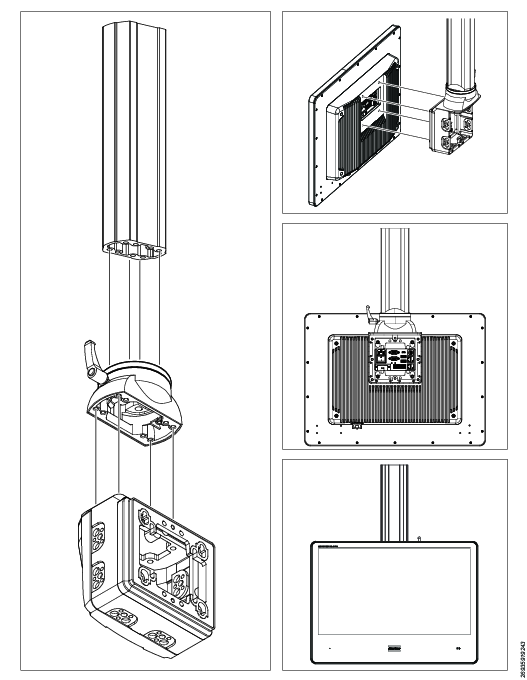

Assembly of Panel PC

Only approved personnel may assemble and operate this device. Only suspended or standing assembly with standard screen orientation is permitted. No vertical screen orientation is permitted.

Assemble the console as follows:

Preassemble both bottom screws on the panel PC.

The original size of the screws is M6x18. The distance between the panel PC and screw head should be approximately 13 mm.

Loosen the two screws of the connection console cover and remove the cover.

Slide the preassembled screws of the panel PC into the bottom holes of the console. Install the two upper screws and tighten all four screws.

Connect all cables to the industrial PC and put the cover of the connection console back in place.

Suspended assembly:

Standing assembly:

Connecting the Power Cable

Connect the appliance coupler to the Assembly Control Node.

Plug supply connector power cable into the mains socket.

Switch on the external circuit breaker.

Operation

Ergonomic Guidelines

Consider your workstation as you read through this list of general ergonomic guidelines and see if you can identify areas for improvement in posture, component placement, or work environment.

Take frequent breaks and change work positions frequently.

Adapt the work area to your needs and the work task.

Adjust for convenient reach range by determining where parts or tools should be located to avoid static load.

Use workstation equipment such as tables and chairs appropriate for the work task.

Avoid work positions above shoulder level or with static holding during assembly operations.

When working above shoulder level, reduce the load on the static muscles by reducing the weight of the load. You can also reduce the load on the static muscles by holding the load close to the body.

Make sure to take frequent breaks.

Avoid extreme arm or wrist postures, particularly for operations requiring a degree of force.

Adjust for convenient field of vision by minimizing movement of the eyes and head during the work task.

Use the appropriate lighting for the work task.

Use ear protection equipment in noisy environments.

Use dust extraction system or mouth protection mask in dusty environments.

Operating Instructions

Additional Information

The rear surface of the panel PC can become very warm. Be careful when touching the rear surface.

Switching On/Off the Computer

Open the cover of the connection console.

Use the On/Off breaker to switch On/Off the computer.

Starting up/Shutting down the Panel PC

Set the switch to ON, which starts the panel PC.

When panel PC starts, it boots up the operating system automatically.

To turn off the PC, select and click Shutdown command in your operating system.

Opening/Closing the Panel PC

Remove the four screws on the back of the PC unit.

Carefully lift up the back unit of panel PC max. 25° to make internal cabling to the front unit accessible. Be careful to not damage LVDS, USB and backlight cables.

Disconnect all cables carefully from the front unit of the panel PC before removing the parts from each other. The connectors are small and must be handled with care so as not be accidentally destroyed. This applies in particular to the display connectors.

Put aside the front unit with care to not damage the glass surface while maintaining the back unit.

Assemble in reverse order. Make sure not to damage the yellow gasket and ensure that the gasket is in the right place before closing the housing. Put all screws back in place and tighten lightly. Then apply a torque of 1.4 Nm to each screw.

By opening the Assembly Control Node housing all warranty claims are lost!

Service

Preventing ESD Problems

The components inside the product and controller are sensitive to electrostatic discharge. To avoid future malfunction, make sure that service and maintenance is carried out in an ESD approved work environment. The figure below shows an example of an appropriate service work station.

Replacing the Bios battery

When BIOS buffer battery is replaced, it should be original part type CR2032. Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according to the local or regional regulations or instructions.

Maintenance recommendations

The Panel PC can generally be operated without maintenance, but should be cleaned regularly in very dusty environments.

Especially the cooling fins should be kept clean and not be covered by any material and proper ventilation always assured to prevent the computer from overheating.

For preventive maintenance purposes and depending on operating conditions and availability requirements, the power supply and SSD may be replaced as a precautionary measure.

If the device does not function flawlessly, it should be shut down immediately and inspected. During an overhaul, all parts should be carefully cleaned and damaged and worn out parts replaced.

Recycling

Environmental Regulations

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.

Batteries shall be taken care of by your national battery recovery organization.

Recycling Instructions

Pos. | Part | Recycle as |

|---|---|---|

1. | Front module | Aluminium, Glas |

2. | Connector plate | Aluminium |

3. | RFID Reader | Electronics |

4. | Power LED Module | Electronics |

5. | Screw | Metal |

6. | Screw | Metal |

7. | Power Supply cover | Metal |

8. | Space bolt | Metal |

9. | Power supply | Electronics |

10. | Wifi BT Module | Electronics |

11. | Screw | Metal |

12. | Washer | Metal |

13. | SSD | Electronics |

14. | Screw | Metal |

15. | Screw | Metal |

16. | Baseboard | Electronics |

17. | Plug | Plastic |

18. | COMEx Board | Electronics |

19. | RAM | Electronics |

20. | Heatsink | Aluminium, Copper |

21. | ProfiNet | Electronics |

22. | On off switch | Electronics |

23. | Interface plate | Aluminium |

24. | Externa USB Port | Electronics |

25. | Cast housing | Aluminium |

26. | Screw | Metal |