Machining a nozzle with press fit

Definitions

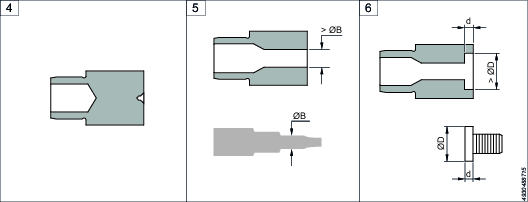

B = Distance from the telescope to bit end.

d = Thickness of the screw head.

L>S,

L = Clearance between bit and nozzle

S = Screw length.

Procedure

Perform the following steps to machine the nozzle:

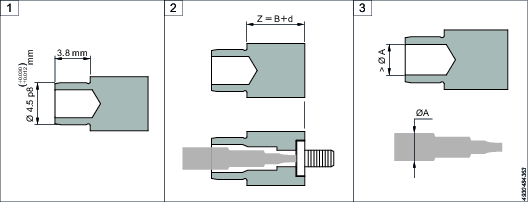

Make sure that the nozzle have the correct dimension:

3,8 mm long.

Ø4,5 p8 HM4 Ø8,5 P9 I06

Shorten the nozzle to the correct length (Z).

The length (Z) depends on the bit (B) and position of the screw inside the nozzle (d). Z=B+d .

Enlarge the inner diameter of the nozzle.

The inner diameter of the nozzle must be larger than the outer diameter of the bit (ØA).

Make a hole with a center drill.

Before drilling the inner hole you must drill a hole with a center drill. This hole will guide the drill and maintain concentricity.

Drill the hole for the bit. Minimum diameter is bit diameter +0,2. Bigger gap between bit and nozzle results in a bigger vacuum force.

The inner diameter of the inner hole must be 0.2 mm larger than the outer diameter of the bit (ØB).

Drill the hole for the screw head.

The depth of the hole (d) depends on the application.

The diameter of the hole (D) must be 0.02 mm larger than the outer diameter of the screw head.

Note! If you don’t have a screw drawing, measure the thickest screw and add 0,05 mm instead of 0,02 mm.

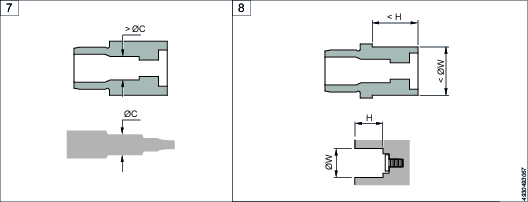

If necessary, widen the hole to fit the pole of the bit.

The inner diameter of the nozzle must be larger than the outer diameter of the bit (ØC).

Machine the outline of the nozzle.

The nozzle height must be larger than the depth of the hole (H).

The outer diameter of the nozzle must be less than the diameter of the hole (W).