Maintenance and Conservation Program

The checking and operations maintenance program depends on the equipment working conditions. The frequencies indicated here are only an orientation and it is for the user to adapt them to the conditions of use.

Frequency | Verification / Task to be carried out |

|---|---|

Prior to each use | Check that the oil level in the tank is between maximum and minimum indicators. Set zero pressure and 100% pressure and check for noise (absence of friction, tapping, etc.) Check for leaks when the pressure is 150 bar. |

Monthly | Check that the pump reaches the maximum pressure. Check condition of power cable, free of erosion, joints, etc. Check hydraulic hoses and couplings. Replace if there is any damage. |

After 200 hours of use | It is recommended to perform a complete maintenance check. Consult your local Atlas Copco sales representative directly. |

Total hours of use since the last pump maintenance can be checked as follows:

Remove the lid of the control box to gain access inside by using a 2.5 mm allen key to remove 4 screws. Be aware of the earth cable attachment behind the lid.

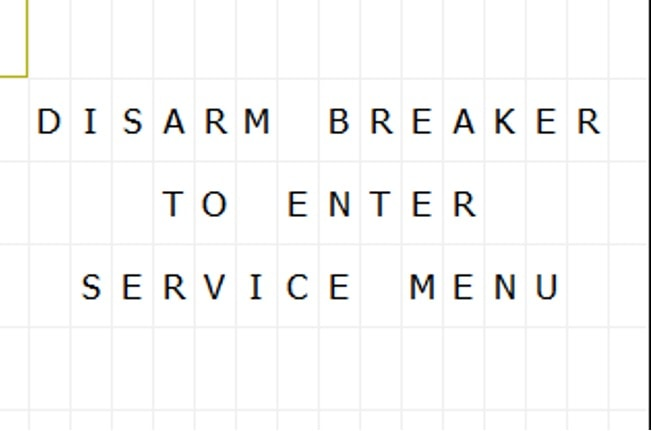

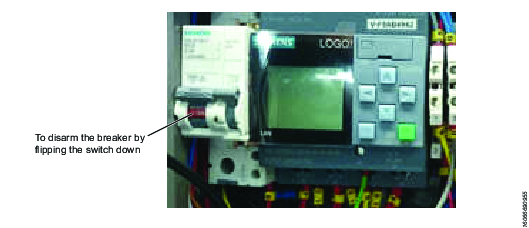

To continue in the menu, press and hold the “ESC” and “down” arrows again. If the breaker is up, the display will show a message: “Disarm breaker to enter service menu”.

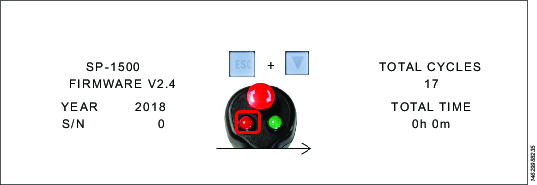

Screen of the logic module

SP1500 hydraulic pump. Disarm system Once the breaker is disarmed, the screen shows information about the firmware. Press and hold “ESC” + ”down” arrow + “RED button” in the handgrip. Now, total hours and cycles is showed.

Logic module If you continue pressing “ESC”+”down” arrow, you can see maintenance counter since last maintenance, oil filter counter and oil counter.

To go back to the main screen, press “ESC”+ “UP” arrow several times. A re-arm warning screen will appear before the main screen is reached. Re-arm the breaker and the main screen is shown.

SP1500 hydraulic pump. Re-arm system

When re-placing the control box lid, be careful not to trap the earth wire.