Maintenance intervals

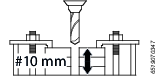

One cycle is calculated on a standard stack of 10 mm.

Heavy Usage | Medium Usage | Light Usage | |||||

|---|---|---|---|---|---|---|---|

Cycles | Total drilling length (meter) | Action | Spare part | Use kit, | Use kit, | Use kit, | |

a Independent from the drilling thickness | |||||||

10,000 | 100 | Replace | Bevel gear | 4141 0410 91 | |||

20,000 | 200 | Replace | Chiplet | 4141 0713 9X | |||

Ratcheta | 4141 0713 9X | ||||||

25,000 | 250 | Replace | Ratcheta | 4141 0713 9X | 4141 0713 9X | ||

50,000 | 500 | Replace | Bevel gear | 4141 0410 91 | |||

Thrust bearing | 4141 0509 91 | ||||||

Chiplet | 4141 0713 9X | ||||||

Piston | 4081 0496 90 | 4081 0496 90 | 4081 0496 90 | ||||

Re-grease | Planetary shaft | Grease (Type A) | Grease (Type A) | N/A | |||

Overload clutcha | Grease (Type A) | Grease (Type A) | Grease (Type A) | ||||

100,000 | 1000 | Replace | Bevel gear | 4141 0410 91 | |||

Thrust bearing | 4141 0509 91 | 4141 0509 91 | |||||

Chiplet | 4141 0713 9X | ||||||

Planetary shaft | 4141 0444 90 | ||||||

Overload clutcha | 4141 0498 92 | 4141 0498 92 | 4141 0498 92 | ||||

200,000 | 2000 | Replace | Planetary shaft | 4141 0444 90 | |||

The drilling operation may produce different efforts (torque, thrust) than the estimated value due to different cutting tools geometry, material properties or lubrication. Therefore, the same operation can be categorized differently.

Heavy Usage | Medium Usage | Light Usage | |

|---|---|---|---|

Rotational speed and Drilling efforts | Speed 350-1200 rpm

| Speed 1600-3200 rpm | Speed 3200-7300 rpm |

Example of operations |

|

|

|