Maintenance and conservation program

The checking and operations maintenance program depends on the equipment working conditions, so the frequencies indicated here are only an orientation and it is for the user to adapt them to the conditions of use.

Frequency | Verification / Task to be carried out |

|---|---|

Prior to each use | Check oil level in the tank is between maximum and minimum indicators. Set zero pressure and 100% pressure and check for noise (absence of friction, tapping, etc.) Check for leaks when the pressure is 150 bar. |

Monthly | Check that the unit reaches the maximum pressure. Check condition of power cable, free of erosion, joints, etc. Check hydraulic hoses and couplings. Replace if It is damaged. |

After 100 hours of use | It is recommended to perform a complete maintenance check. Consult authorized service centres, supplier or manufacturer directly. |

Total hours of use by the pump and maintenance hours from last maintenance can be seen as follows:

In the main screen press & hold the “ESC” and “down” arrow. The language screen is shown.

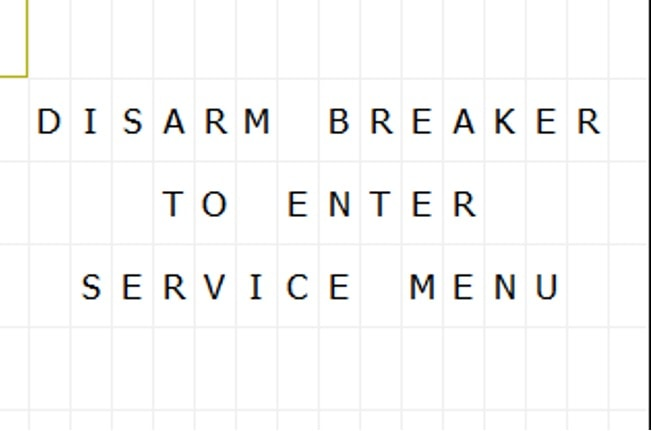

To continue in the menu, press & hold the “ESC” and “down” arrows again. If the breaker is up, the display will show a message: “disarm breaker to enter service menu”.

Once the breaker is disarmed, the screen shows information about firmware. Press & hold “ESC”+”down” arrow + “RED button” in the handgrip. Now, total hours and cycles is showed.

If you continue press “ESC”+”down” arrow, you can see maintenance counter since last maintenance, oil filter counter and oil counter.

To go back to the main screen, press “ESC”+ “UP” arrow several times.