Fitting the Manifold Block

Procedure also suitable for WTB tensioners fitted with an integrated mechanical counter.

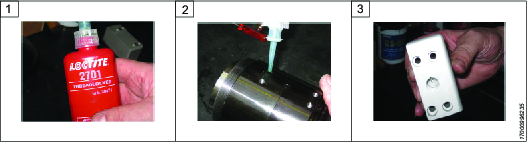

Use a suitable thread locking compound.

Apply a drop into each of the four manifold fixing holes.

The manifold block.

Smear a light grease into the two seal housing grooves.

Fit two new manifold seals to the circular housing.

The grease will help to keep the small seals in position.

Carefully offer the manifold up to the assembled load cells, being careful not dislodge the two manifold seals. Lightly turn down a single socket head cap screw, do not us much torque.

Repeat with a second screw, diametrically opposite the first screw, again just gently turn down.

Repeat with a third screw adjacent to the first screw; again just gently turn the screw down.

Repeat with the final screw; again just gently turn the screw down.

Using a suitable torque handle set to break at 10Nm, tighten the first screw.

Repeat on the diametrically opposite screw, applying 10Nm.

Repeat on the screw adjacent to the first screw, applying 10Nm.

Repeat on the last screw, again applying 10Nm.

Now go back to the first screw tightened and apply a 10Nm torque. Continue around the screws in the same sequence that you originally tightened them, applying a 10Nm torque. The Manifold Block has now been fitted.