Runtime Diagrams

Fixtured Tightening Module

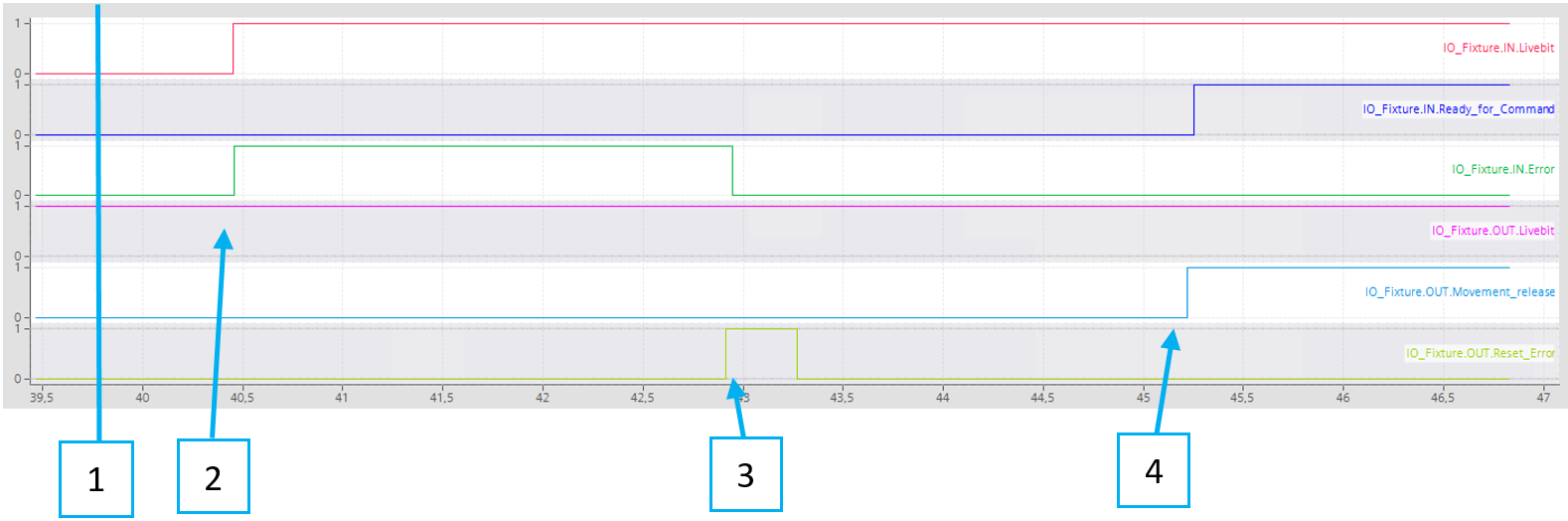

Startup

After powering on the feeder, it will need about 5 sec until it is ready for operation. Livebit is set to TRUE from the PLC.

Livebit is responsive. Error is true. Screw in head is true.

Reset error. Error from the feeder is low.

Movement release is TRUE. Feeder is ready for command.

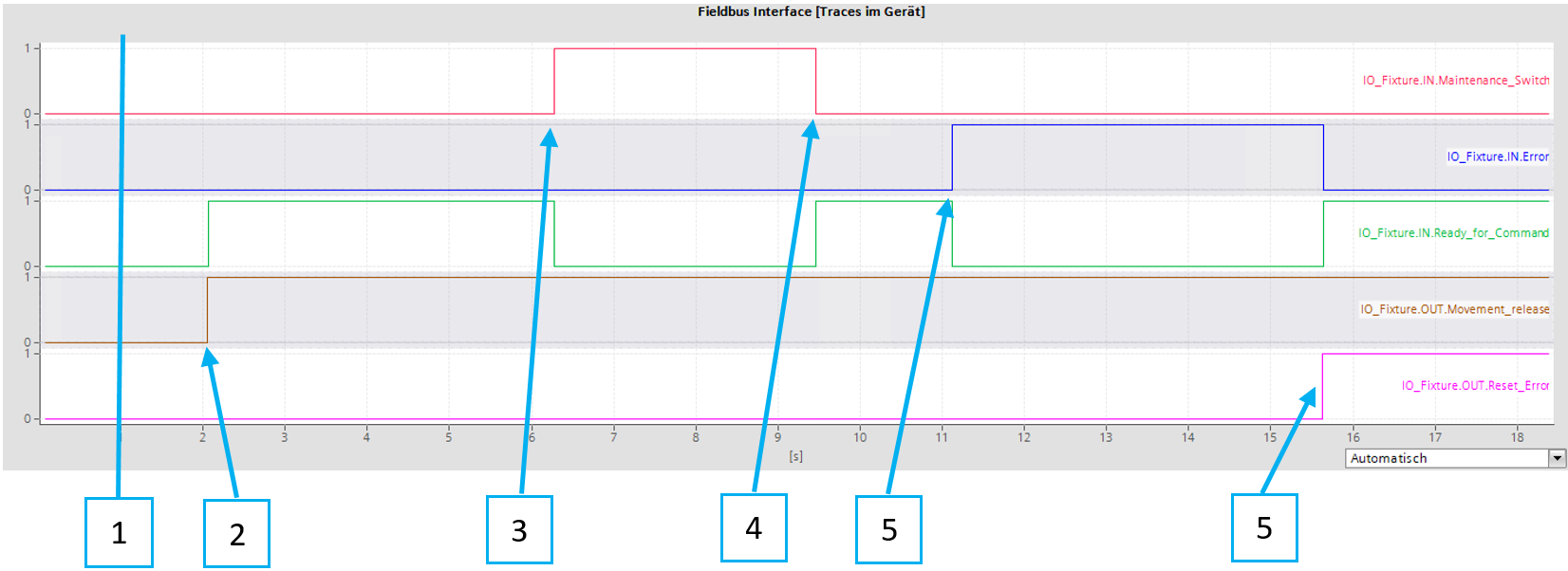

Movement release

No error is present. The maintenance switch is OFF. The movement release is OFF.

Movement release is set to TRUE. Ready for command turns TRUE.

Maintenance Switch is activated. Ready for command turns FALSE.

Maintenance switch is deactivated. Ready for command turns TRUE.

Error occurs. Error-bit turns TRUE. Ready for command turns FALSE.

Error is resolved and reset Error turns FALSE. Ready for command turns TRUE.

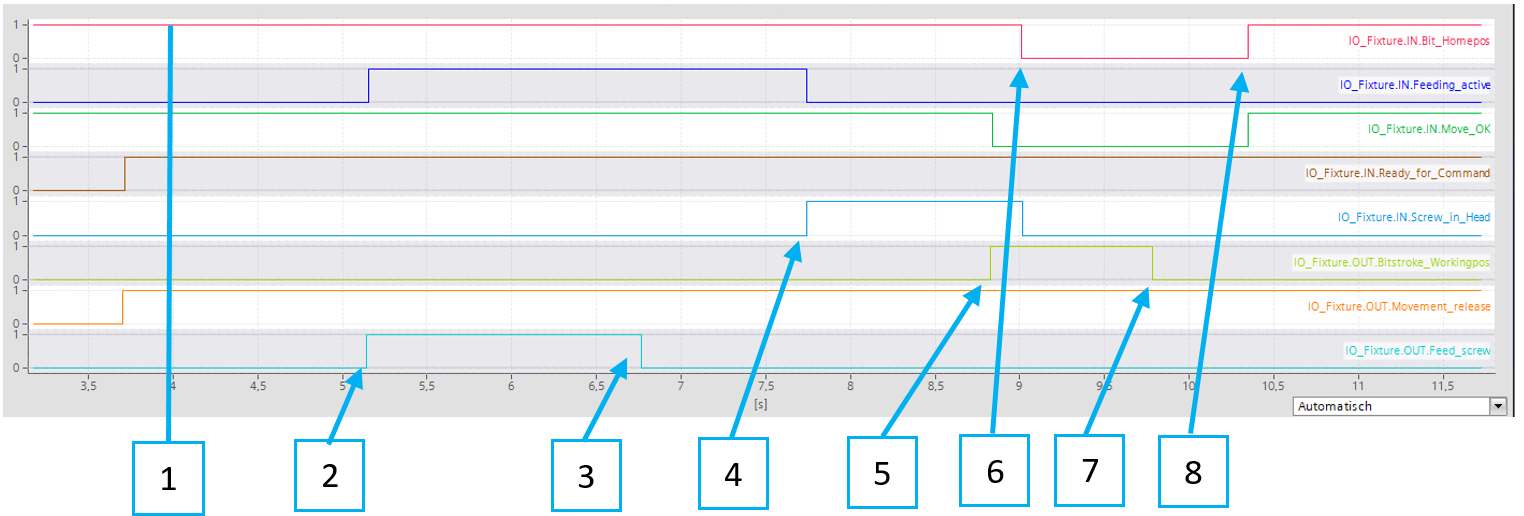

Feeding a screw and tightening process

Feeder is ready for command.

Signal Feed screw is set to TRUE. Signal Feeding active returns with TRUE.

Once Feeding active is TRUE, Feed Screw can be reset to FALSE. The feeding process will keep activated until the screw is in the head, or an error occurs.

The screw arrived in the head, Feeding process is finished.

Now the Bitstroke is extended to the working position with the signal Bitstroke Workingpos. Because the Bitstroke is in movement, Move OK goes FALSE.

Bitstroke left the home position. The screw in the Head goes to FALSE. Once the Screw in the Head is FALSE, the feeding process can be triggered again, to prepare the next screw.

Bitstroke Workingpos is reset, and the bit will retract to the home position.

Bitstroke arrived in the home position. Move OK returns to TRUE, it is now safe to move the fixture.

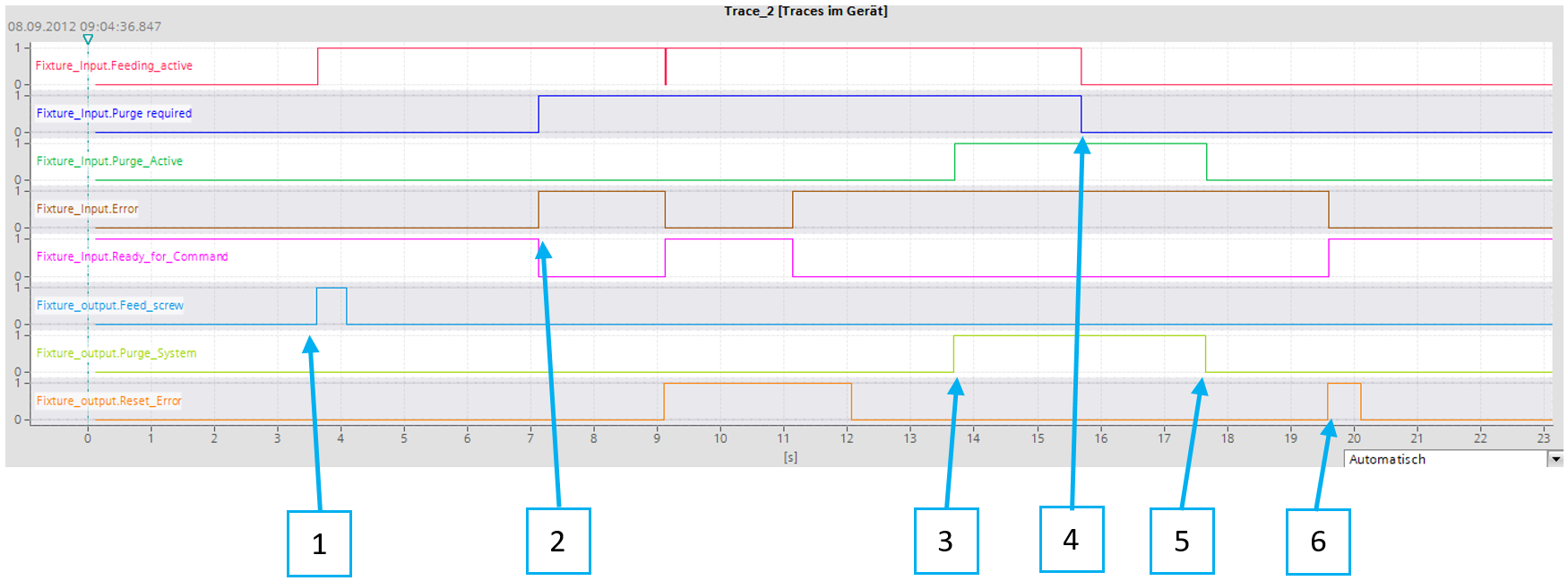

Feeding error

The error can be acknowledged with the yellow button or with the Reset Error Bit in the Fieldbus interface. However, there are errors that might lead to congestion in the feeding tube if they are reset. For that reason, there is the bit Purge Required. This bit is true when the feeder control cannot be certain of the state of the screw. After the System was purged, the error can be reset.

The feeding process has started.

The error occurs, and a purge is required.

Purge is activated by the Line-PLC.

After enough time has passed, the purge required is reset to FALSE.

Purging is deactivated.

The error is reset, and the feeder is ready again.

Make sure that after a fault has occurred, the system is inspected for excess screws in the jaws, swivel arm, or in/after the separation, to avoid congestion that may lead to damage to the system.

Vacuum Tightening Module

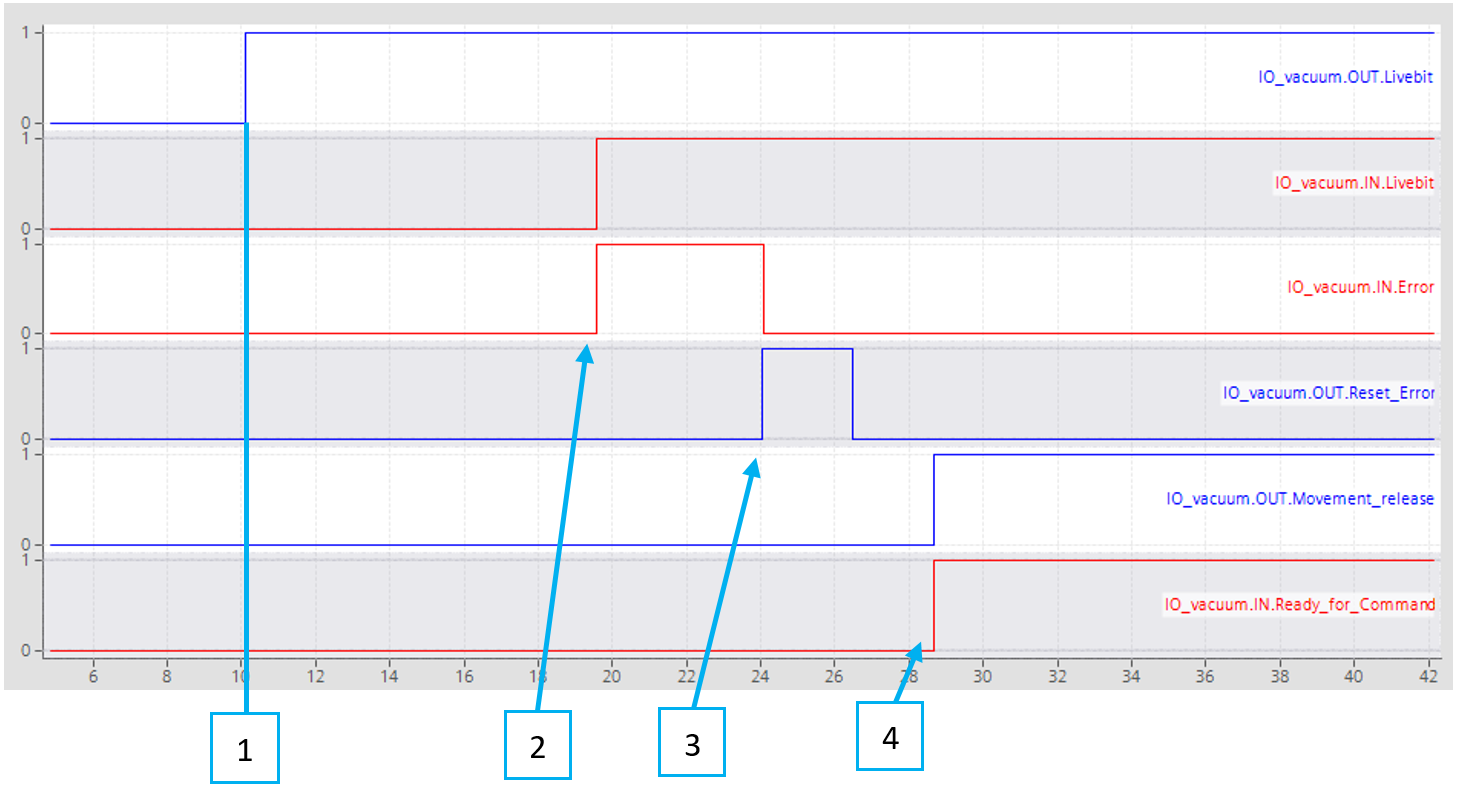

Startup

After powering on the feeder, it will need about 5 sec until it is ready for operation. Livebit is set to TRUE from the PLC.

Livebit is responsive. Error is true. Screw in head is true.

Reset error. Error from the feeder is low.

Movement release is TRUE. Feeder is ready for command.

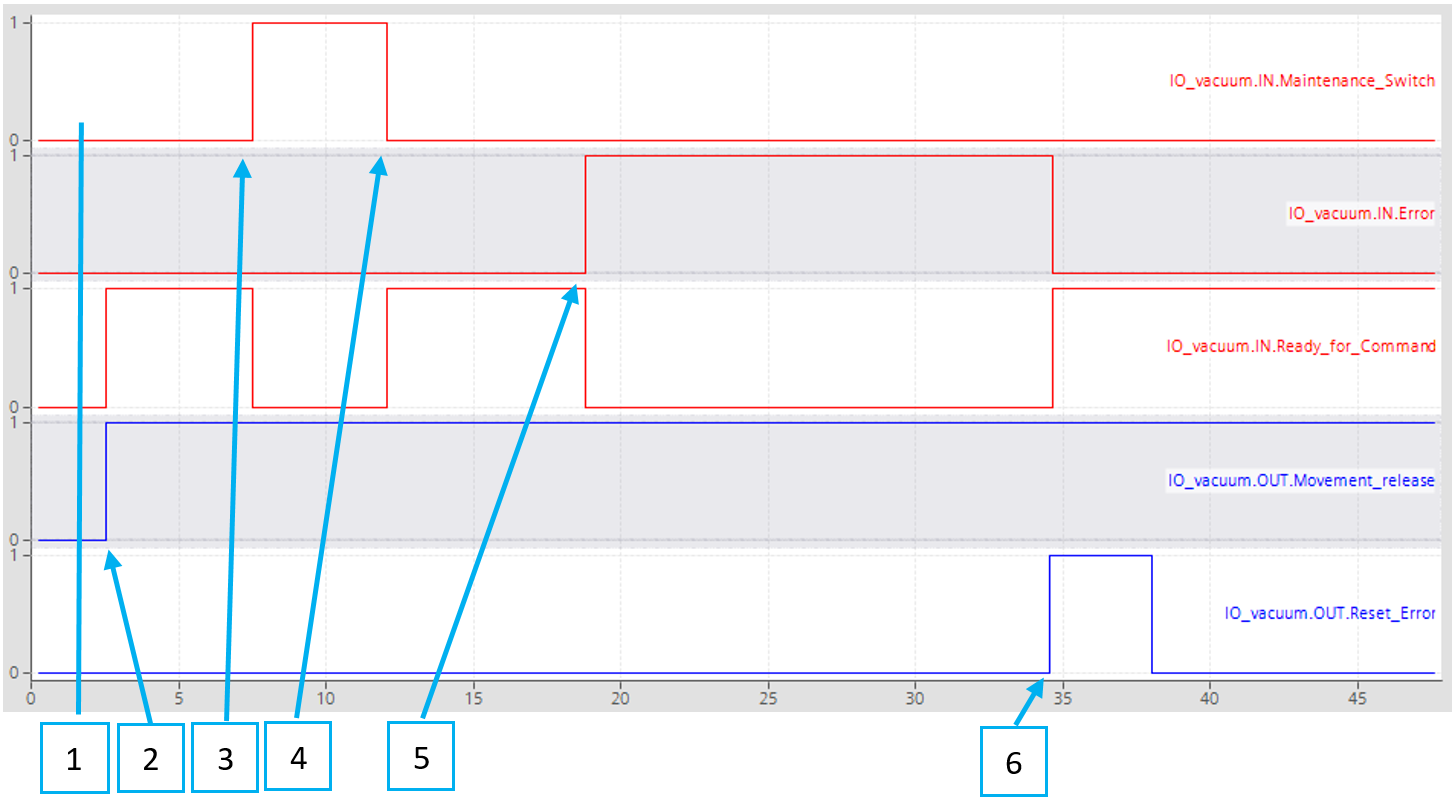

Movement release

No error is present. The maintenance switch is OFF. The movement release is OFF.

Movement release is set to TRUE. Ready for command turns TRUE.

Maintenance Switch is activated. Ready for command turns FALSE.

Maintenance switch is deactivated. Ready for command turns TRUE.

Error occurs. Error-bit turns TRUE. Ready for command turns FALSE.

Error is resolved and reset Error turns FALSE. Ready for command turns TRUE.

Picking a screw and tightening process

The feeding to the slider module happens automatically and does not need to be triggered. The command feed screw initiates the picking of the screw that is already in the slider.

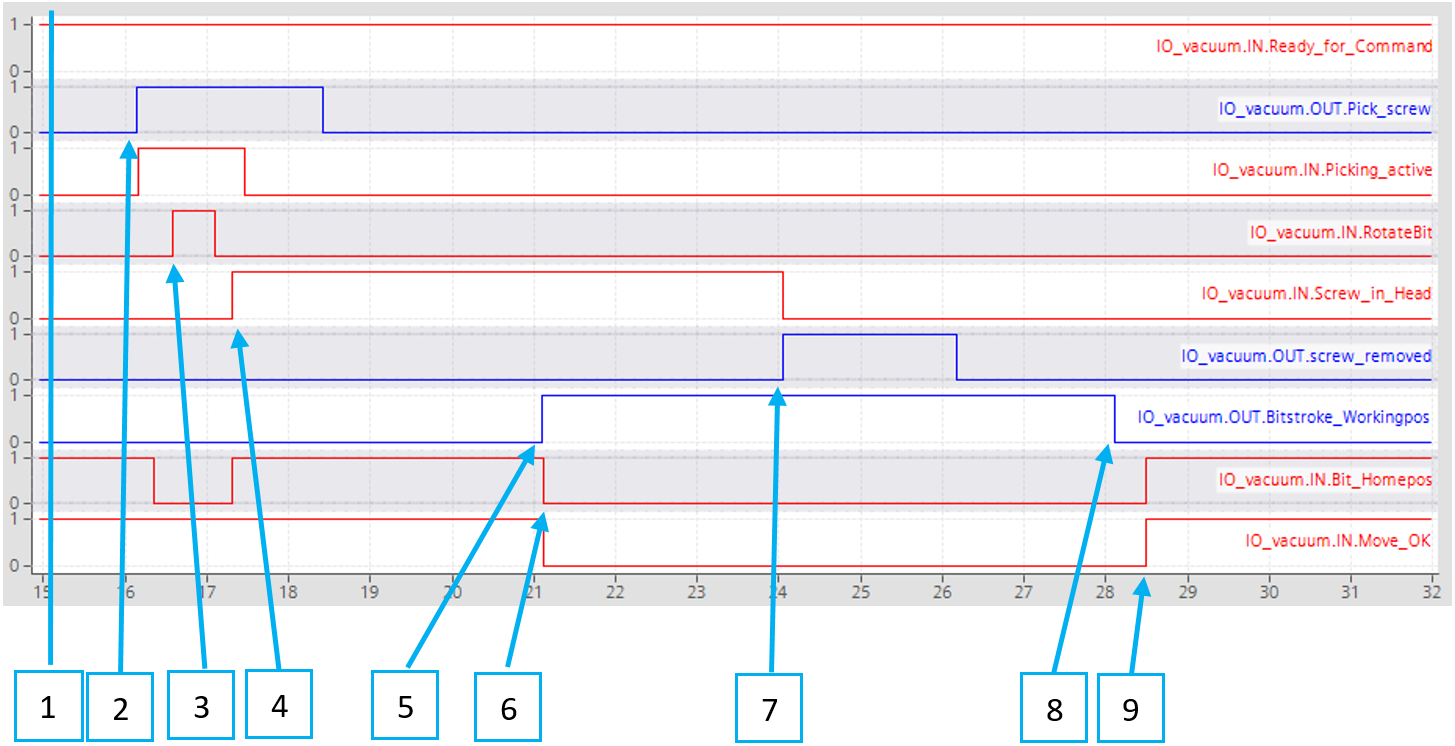

Feeder is ready for command.

The signal pick screw is set to TRUE. It reacts only to the rising edge and can be reset right after signal picking active returns with TRUE. The picking process will keep activated until the screw is in the head, or an error occurs.

While moving the bit or socket towards the picking position, the feeder will request RotateBit, to help engage with the screw. Especially with sockets rotating during picking is essential. Activating bit rotation must be done by PLC.

The screw is on the head, the vacuum level is reached, and the picking process is finished. A new screw will be pre-loaded to the slider automatically and does not require further action.

Now the Bitstroke is extended to the working position with the signal Bitstroke Workingpos. Because the Bitstroke is in movement, Move OK goes FALSE.

Bitstroke left the home position. Now the tightening process can be started.

The screw in the head is reset when the signal screw removed is TRUE. At this point, the vacuum generator also turns OFF.

Bitstroke Workingpos is reset, and the bit will retract to the home position.

Bitstroke arrived in the home position. Move OK returns to TRUE, it is now safe to move the fixture.

Feeding error

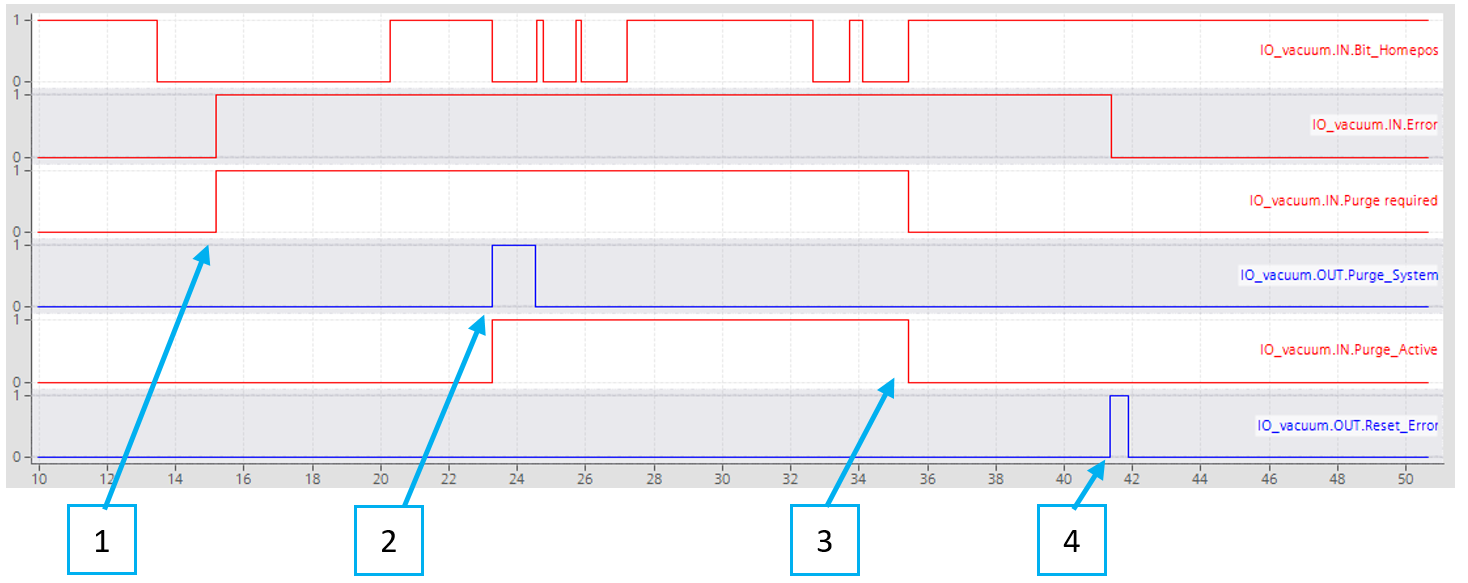

The error can be Acknowledged with the Yellow button or with the Reset Error Bit in the Fieldbus interface. However, there are errors that might lead to congestion in the feeding tube if they are reset. For that reason, there is the bit Purge Required. This bit is true when the feeder control cannot be certain of the state of the screw. After the System was purged, the error can be reset.

In this example, the ring sensor was disconnected, so no screw arrival was detected at the tool, after blowing the screw to the tool.

The error occurs, and a purge is required.

Purge is activated by the Line-PLC.

After the purge-cycle, purge required is reset to FALSE.

The error is reset, and the feeder is ready again.

Make sure that after a fault has occurred, the system is inspected for excess screws in the sliding mechanic or in/after the separation, to avoid congestion that may lead to damage to the system.