Operating the Slim Link Wrench

Prerequisites

Wear personal protective equipment: Correct and appropriate safety equipment must be worn.

Always perform a task-based risk assessment before using the tool.

Frequently inspect the tool, power pack, hoses, connectors, electric cables, and accessories for visible damage. Always follow instructions for tool and pump maintenance.

Select the appropriate size slim link and insert it into the tool. Tool operation, bolt tightening and loosening, is determined by the position of the tool relative to the nut/bolt.

Connect the hoses: Make sure that all hose connections are secure and correctly made. Make sure that the hoses are free from defects.

Start up

Cycle the tool: Place the tool on a flat surface, not on a nut, turn the pump on. Press and hold the Advance [1] button on the pump remote control pendant until the hex ratchet stops turning. Release the button, wait for the tool to fully retract. Repeat.

Set the pump pressure to achieve the target torque.

Refer to the section “Setting the target torque”.

Place the tool on the nut to be tightened or loosened.

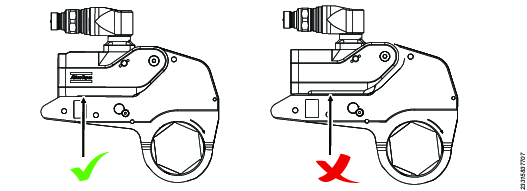

The driving stroke of the power head will always turn the hex ratchet (and therefore the nut) towards the front of the tool, that is, turning away from the reaction point. The Slim Links are designed with an integrated reaction arm to react against an adjacent nut or other suitable secure reaction point.

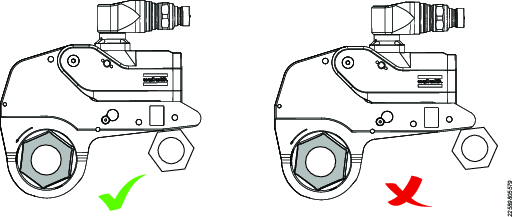

Make sure that the nut corresponds with the tool size.

Always make sure to use a solid reaction point during operation.

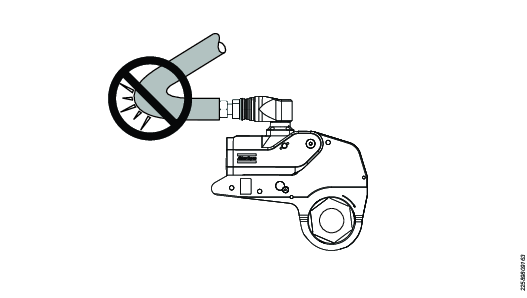

Never kink or bend hoses excessively:

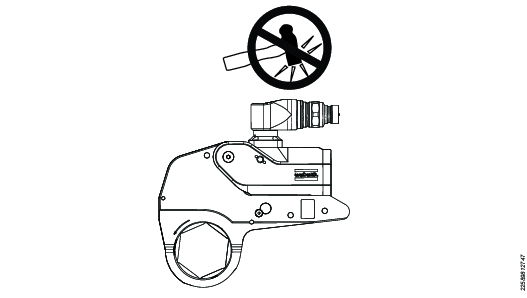

Never strike wrench to assist breakout: