Square Drive Tool

Hydraulic Torque Wrench

Product Information

General Information

DO NOT DISCARD - GIVE TO USER

Statement of Use

For professional use only.

This product and its accessories must not be modified in any way.

Do not use this product if it has been damaged.

If the product data or hazard warning signs on the product cease to be legible or become detached, replace without delay.

The product must only be operated and serviced by trained and qualified personnel.

Safety Signal Words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER | DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

WARNING | WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

CAUTION | CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

NOTICE | NOTICE is used to address practices not related to personal injury. |

Warranty

Product warranty will expire 12 months after the product is first taken into use, but will in any case expire at the latest 13 months after delivery.

Normal wear and tear on parts is not included within the warranty.

Normal wear and tear is that which requires a part change or other adjustment/overhaul during standard tools maintenance typical for that period (expressed in time, operation hours or otherwise).

The product warranty relies on the correct use, maintenance, and repair of the tool and its component parts.

Damage to parts that occurs as a result of inadequate maintenance or performed by parties other than Atlas Copco or their Certified Service Partners during the warranty period is not covered by the warranty.

To avoid damage or destruction of tool parts, service the tool according to the recommended maintenance schedules and follow the correct instructions.

Warranty repairs are only performed in Atlas Copco workshops or by Certified Service Partners.

Atlas Copco offers extended warranty and state of the art preventive maintenance through its ToolCover contracts. For further information contact your local Service representative.

For electrical motors:

Warranty will only apply when the electric motor has not been opened.

ServAid

ServAid is a portal that is continuously updated and contains Technical Information, such as:

Regulatory and Safety Information

Technical Data

Installation, Operation and Service Instructions

Spare Parts Lists

Accessories

Dimensional Drawings

Please visit: https://servaid.atlascopco.com.

For further Technical Information, please contact your local Atlas Copco representative.

Safety Data Sheets MSDS/SDS

The Safety Data Sheets describe the chemical products sold by Atlas Copco.

Please consult the Atlas Copco website for more information www.atlascopco.com/sds.

Country of Origin

For the Country of Origin, please refer to the information on the product label.

Dimensional Drawings

Dimensional Drawings can be found either in the Dimensional Drawings Archive, or on ServAid.

Please visit: http://webbox.atlascopco.com/webbox/dimdrw or https://servaid.atlascopco.com.

Overview

Technical Product Data

Technical Product Data can be found on either ServAid, or the Atlas Copco website.

Please visit: https://servaid.atlascopco.com or www.atlascopco.com.

Service Overview

Service Recommendations

Preventive maintenance is recommended at regular intervals. See the detailed information on preventive maintenance. If the product is not working properly, take it out of service and inspect it.

If no detailed information about preventive maintenance is included, follow these general guidelines:

Clean appropriate parts accurately

Replace any defective or worn parts

Operation

Ergonomic Guidelines

Consider your workstation as you read through this list of general ergonomic guidelines to identify areas for improvement in posture, component placement, or work environment.

Take frequent breaks and change work positions frequently.

Adapt the workstation area to your needs and the work task.

Adjust for a convenient reach range by determining where parts and tools need to be located to avoid static load.

Use workstation equipment such as tables and chairs appropriate for the work task.

Avoid work positions above shoulder level or with static holding during assembly operations.

When working above shoulder level, reduce the load on the static muscles by lowering the weight of the tool, using for example torque arms, hose reels or weight balancers. You can also reduce the load on the static muscles by holding the tool close to the body.

Take frequent breaks.

Avoid extreme arm or wrist postures, particularly during operations requiring a degree of force.

Adjust for a convenient field of vision that requires minimal eye and head movements.

Use appropriate lighting for the work task.

Select the appropriate tool for the work task.

In noisy environments, use ear protection equipment.

Use high-quality inserted tools and consumables to minimize exposure to excessive levels of vibration.

Operating Instructions

Electric Connections

Ensure proper power availability to prevent motor failure or dangerous electrical overloading. Use the recommended amperage listed on the motor nameplate. Do not use electric pump if ground is not connected on plug.

Minimize the length of extension cords and be sure they are of adequate wire size, with ground connections.

Extension cord should be #10 AWG gauge.

General Setup

All our hydraulic torque wrenches are supplied completely assembled, ready for use. An Atlas Copco hydraulic power pack, for use with your Atlas Copco hydraulic torque wrench, is recommended to provide the speed, pressure and portability that make your Atlas Copco System efficient and accurate.

The accuracy of your Atlas Copco hydraulic torque wrench is +/-3% based upon our manufacturer's specifications. This accuracy is certified through calibration tests conducted by Atlas Copco or any other qualified calibration facility whose program is traceable to the National Institute of Standards and Technology (N.I.S.T). We strongly suggest using Atlas Copco certified gauges (with a class 1 accuracy) to enhance the accuracy your torquing system.

Hydraulic Connections

Our hydraulic pumps are equipped with a zero-pressure relief valve. However, it could be possible that the retract side remain pressurized after the pump has been switched “off”. This trapped pressure prevents the user from loosening the retract-side fittings by hand. To release the pressure, simply push the black button on top of the solenoid. All fittings are free to be manually tightened.

Never disconnect or connect any hydraulic hoses or fittings without first unloading the wrench and the pump. If the system includes a gauge, double check the gauge to assure pressure has been released. When making connections with quick disconnect couplings, make sure the couplings are fully engaged. Threaded connections such as fittings, gauges etc. must be clean and securely tightened and leak free.

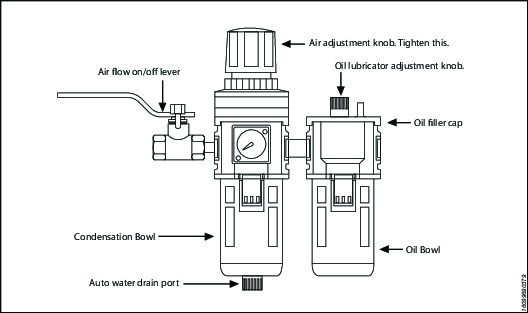

Air Connections

Ensure that you have sufficient air flow (58 up to 100 PSI / 4 up to 7 bar) to operate you pneumatic pump. If in doubt, compare the pump manufacturer's recommended air flow rating prior to pressurizing pump. Improper air flow may damage the pump motor.

For best results use air hoses equal or larger than 3/4” internal diameter.

Use of a F.R.L. (Filter Regulator Lubricator) is highly recommended. Fill with oil and adjust the air admission with the adjustment knob.

Working Pressure

The tool's maximum working pressure is 10,000 psi (700 bar). Make sure that all hydraulic equipment (pumps, hoses, couplers) used with this tool are rated for 10,000 psi (700 bar) working pressure. Review the documentation for the hydraulic pump in use to ensure pressure does not exceed 10,000 psi.

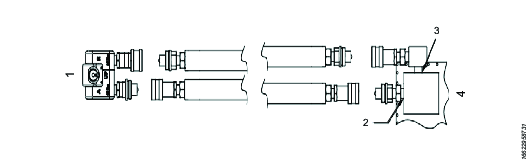

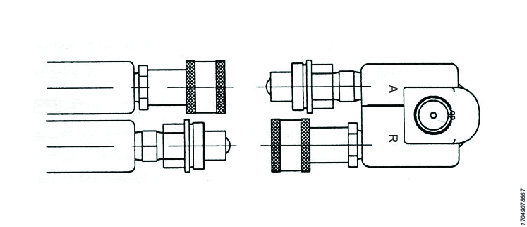

Connecting the System

The Atlas Copco hydraulic torque wrench and the power pack are connected by a 10,000 psi (700 bar) operating pressure twinline hose assembly. The safety ratio of the Atlas Copco hydraulic hose is 4/1. On each twin hydraulic hose, one line must be MALE-MALE and the other line must be FEMALE-FEMALE in order to assure a correct interaction between pump and machine. Connect the twinline hose to the swivel as shown:

Reference | Description |

|---|---|

1 | Wrench |

2 | Port 'A' |

3 | Port 'R' |

4 | Pump |

Check all coupler connections because, after the system has been pressurized, you will not be able to tighten the couplers by hand and using tools will damage the couplers.

Check all coupler connected properly with no gaps between collar and fittings. Never use spanners and other tools to tighten or loose couplers.

Ensure connectors are fully engaged and screwed snugly together.

Never use two twin hydraulic hoses between pump and machine. If so, you have the high pressure on the retract side and your machine will not work properly. To avoid tool malfunction, do not reverse connectors. Do not try to loosen the swivel assembly at any moment.

Operating Hydraulic Pump

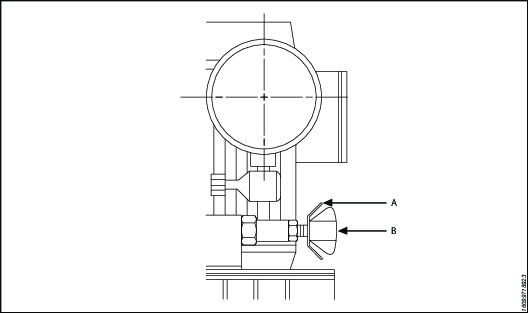

Setting Working Pressure on the Pump

To set the pressure on the pump, follow this procedure:

Loosen the knurled locking ring below the "T" handle on the pump's external pressure regulator. Then turn the "T" handle counter clockwise (CCW) until it turns freely and easily.

Turn the pump "on". Using the pump's remote control pendant, push down the advance switch (or button on air pumps) and hold it.

While holding the pump in the advance mode, slowly turn the "T" handle clockwise and observe the pump pressure gauge rise.

Always adjust the regulator in order to increase the pressure up - Never down. Never adjust the regulation with the tool on the application

When your gauge reaches 4,000 psi stop turning the "T" handle and let the gauge settle out.

If the pressure continues to rise (above 4,000 psi), release the advance button and back off your pressure slightly-by turning CCW on the "T" handle. Then re-depress the advance switch on you remote and slowly bring pressure up to 4,000 psi again.

When the pressure is correct, turn the pump "off" and tighten the knurled lock nut provided under the "T" handle. This sets pump pressure, which determines torque tool output.

Reference

Description

A

Locking ring

B

T - Handle

Once your target pressure is set and locked, cycle the pump once more to ensure that your pressure setting did not change as you turned down the knurled knob.

Applying Torque to Wrench

Having set your target pressure, cycle the tool three or four times to full pressure. Cycling the tool ensures that the system is operating properly and removes trapped air, if any.

Verify that any impact sockets used are rated to accept the full torque output of the tool they are to be used with. Ensure the correct size impact socket for the nut A/F has been selected, placed on the square drive and secure with a locking pin and ring.

Place the tool and the socket on the nut, making sure that the socket has fully engaged the nut, check that the drive retainer is engaged.

Make sure the reaction arm is firmly abutted against a stationary object (i.e. an adjacent nut, flange, equipment housing etc.). When positioning the wrench, make sure that the hose connections are well clear of any obstructions and that all body parts are safely out of harm's way. Then apply momentary pressure to the system to ensure proper tool placement. If it doesn't look or act right, stop and re-adjust the reaction arm.

Read Safety Instructions supplied with the torque wrench for further guidance on tool usage.

By pushing down on the remote control button in the advance position, the rear of the tool will be pushed back until its reaction arm will contact its reaction point.

Continue to hold down the button as the socket turns until you hear an audible "click" which will signify the hydraulic cylinder inside the tool is fully extended and will not turn the advance further.

Continuing to hold down the remote control button will result in a rapid build up of pressure to the point of where the gauge reads what was preset prior to applying the wrench.

The reading of full preset pressure after the cylinder is extended DOES NOT INDICATE that this pressure (torque) is applied to the bolt. It only indicates that the cylinder is fully extended and cannot turn the socket or the ratchet link further until the tool automatically resets itself.

Releasing the remote control button will retract the cylinder. The tool will automatically reset itself and the operator will hear an audible "click" indicating he can again push the remote control button and the socket will turn. Each time the cylinder is extended and retracted, it is called a cycle. Successive cycles are made until the tool "stalls" at the pre-set Torque/psi with an accuracy of +/-3%. Repeatability is +/- 1%.

Always attempt one final cycle to ensure the "stall" point has been reached.

Should the tool "lock-on" after the final cycle, push down on the remote control button once more (to build pressure) and, while maintaining this pressure, pull back on the external disengagement lever (RT) or reaction Pawl (RTX). Releasing the remote control while continuing to hold back on the pawl lever/reaction pawl will allow the tool to be removed easily.

Loosening Procedures

First, set the pump to 9,000 psi (Do not try directly at 10.000 psi). Change the drive and the reaction arm to the loosening mode (Left = Loose), assuring the reaction arm abuts squarely off a solid reaction point. Press and hold the remote control button down. Pressure will decrease as the socket begins to turn. As the cylinder extends fully, you will hear an audible "click". Release the remote control button, and the cylinder automatically retracts, at this time you will again hear the audible "click". Repeat this process until the fastener can be removed by hand.

If the bolt does not loosen with the above procedure, it is an indication that you need a larger tool to loosen the bolt.

Setting Torque

All Atlas Copco power packs operate at a pressure range from 500 to 10,000 psi and are fully adjustable. They have been engineered and designed for portability and high flow for increased speed. Before using your Atlas Copco power pack, check the following points.

Is the reservoir filled with oil?

Where is the closest electrical outlet at the job site?

Is there enough air pressure (60 to 100 psi) and Air flow at the job site? (Air units only)

Is the gauge mounted and rated for 10,000 psi / 700 bar?

Working Pressure

The pump's maximum working pressure is 10,000 psi / 700 bar. Make sure all hydraulic equipment and accessories are rated for 10,000 psi / 700 bar operating pressure. Hydraulic pumps are available with higher pressure outputs, if not using an Atlas Copco power pack verify maximum operating pressure of the unit being used and ensure the system maximum operating pressure (10,000 psi / 700 bar) is not exceeded.

Hydraulic Connections

Never disconnect or connect hydraulic hoses or fittings without first unloading the wrench. Unplug the electrical cord of the pump, and open all hydraulic controls several times to assure that the system has been depressurized. If the system includes a gauge, double check the gauge to assure pressure has been released. When making a connection with quick disconnect couplings, make sure the couplings are fully engaged threaded connections such a fittings, gauges etc. must be clean and securely tightened and leak free.

Loose or improperly threaded couplers can be potentially dangerous if pressurized, however, severe over tightening can cause premature thread failure. Fittings need to be only tightened secure and leak free. Never grab, touch or in any way come in contact with a hydraulic pressure leak. Escaping oil can penetrate the skin and cause injury. Do not subject the hose and potential hazard such as sharp surfaces, extreme heat or heavy impact. Do not allow the hose to kink and twist. Inspect the hose for wear before it is used.

Electrical Power

Check the proper electrical supply before connecting.

This motor may spark. Do not operate in an explosive atmosphere or in pressure of conductive liquids.

Do not use a power or extension cord that is damaged or has exposed wiring.

All single phase motors come equipped with a three prong grounding type plus to fit the proper grounded type electrical outlet. Do not use a two prong ungrounded extension cord as the pump's motor must be grounded.

Compare motor nameplate against power availability to prevent motor burnout or dangerous electrical overloading.

Prior to Use

Check hydraulic oil (Use Atlas Copco maximiser range Grade 46) level to prevent possible pump burnout. Open the filler plug located on the reservoir plate. Look at oil fill level on the oil sight gauge. The oil level should be approximately 2" from the top of the reservoir plate- with motor off. Add oil as necessary. Do not mix different grades of oil. Make sure all desired gauge, valve, hose and quick coupler connections are tight and secure before operating. The use of a pressure gauge is required for normal pump operation. Mounted on the manifold, the gauge permits the operator to monitor the load on the wrench. Class1 certified calibrated gauges are available for most applications.

Operating Square Drive

Changing Drive Direction

To remove the square drive, push the round button on the drive retainer and gently pull on the square end of the square drive (for RT20, 25 & 50, push on the drive retainer while turning it counter-clockwise). To insert the drive in the tool, place the drive in the desired direction, engage drive and bushing splines, then twist drive and bushing until ratchet Spline can be engaged. Push drive through ratchet.

Push drive retainer button, engage retainer with drive and release button to lock the square drive in position.

Reaction Arm

All Atlas Copco hydraulic torque wrenches are equipped with a universal reaction arm. These reaction arms will absorb and counteract forces created as the unit operates. The reaction arm should extend in the same direction of the square drive; however, slight adjustments may be made to suit your particular application. The RT reaction arm is made of special aircraft alloy and is 360° adjustable.

Reference | Description |

|---|---|

A | Right = Tight |

B | Left = Loose |

The standard RT reaction arm cannot be welded on and should not be modified.

The reaction arm for all RT Monobloc Housing is splined to slide over the rear (cylinder) portion of the tool. In operation, the reaction arm must be fully engaged and secured by inserting the spring loaded reaction arm lever at the base of the housing (end cap). Ensure the reaction arm is fully engaged prior to operation.

Setting Torque

Once the system is fully connected and proper power supply available, the operator may now adjust the pump pressure to the level needed for the application.

When tightening, use the manufacturer's specifications to determine the torque value which you will ultimately require.

Torque sequence may vary from plant to plant and even within individual plants, depending upon the gasket material, etc. Always follow local procedures.

Refer to the pressure-torque conversion table applicable to the tool which you intend to use, Torque chats are available on ServAId .

Square/Allen Drive Working Torque

Drive Size: The square or hex drive of each drive is limited in its maximum output by its material and its engagement area. Since Atlas Copco uses a specially suited alloy-steel for its drive members, the following maximum torque output can be achieved without drive failure, provided the reaction member abuts close to the same plane as the nut to be turned.

If the reaction arm cannot abut on the same plane as the nut to be turned, less torque should be applied, as the additional side load has to be taken into consideration. When toque requirements are close in excess of the values listed above, use RT's/-9/ Sockets Hex-Drive with replaceable Hex Insert Bits.

RT series is available with square drive (standard) or option hexagonal/Allen drive. The table below reviews ideal working range for the respective drives.

Drive Size Inch or mm | Drive Type | Maximum Working Pressure | Probable Failure | ||

ft lbs | Nm | ft lbs | Nm | ||

1/2" | Hex | 353 | 478 | 392 | 531 |

1/2" | Square | 367 | 497 | 408 | 553 |

5/8" | Hex | 689 | 934 | 766 | 1038 |

3/4" | Hex | 1191 | 1614 | 1324 | 1794 |

3/4" | Square | 1239 | 1679 | 1377 | 1865 |

7/8" | Hex | 1892 | 2565 | 2102 | 2848 |

1" | Hex | 2824 | 3827 | 3138 | 4252 |

1" | Square | 2937 | 3980 | 3263 | 4422 |

1-1/8" | Hex | 4021 | 5448 | 4468 | 6054 |

1-1/4" | Hex | 5516 | 7474 | 6129 | 8304 |

1-3/8" | Hex | 7341 | 9948 | 8157 | 11053 |

1-1/2" | Hex | 9531 | 12915 | 10590 | 14350 |

1-1/2" | Square | 9912 | 13432 | 11014 | 14924 |

1-5/8" | Hex | 12118 | 16420 | 13465 | 18245 |

1-3/4" | Hex | 15135 | 20508 | 16817 | 22787 |

1-7/8" | Hex | 18616 | 25224 | 20684 | 28027 |

2" | Hex | 22593 | 30613 | 25103 | 34015 |

2-1/4" | Hex | 32168 | 43588 | 35742 | 48431 |

2-1/2" | Hex | 44126 | 59791 | 49029 | 66435 |

2-1/2" | Square | 45891 | 62183 | 50990 | 69092 |

12mm | Hex | 298 | 404 | 331 | 449 |

17mm | Hex | 847 | 1147 | 941 | 1275 |

19mm | Hex | 1182 | 1602 | 1313 | 1780 |

22mm | Hex | 1835 | 2486 | 2039 | 2763 |

24mm | Hex | 2382 | 3228 | 2647 | 3587 |

27mm | Hex | 3392 | 4596 | 3769 | 5107 |

32mm | Hex | 5647 | 7652 | 6275 | 8502 |

36mm | Hex | 8040 | 10895 | 8934 | 12105 |

41mm | Hex | 11878 | 16094 | 13197 | 17882 |

46mm | Hex | 16774 | 22730 | 18638 | 25255 |

50mm | Hex | 21542 | 29190 | 23935 | 32433 |

Service

Maintenance Instructions

Service and Maintenance Recommendations

Always wear impact-resistant eye and face protection when involved with or near the operation, repair or maintenance of the tool or changing accessories on the tool.

All investigation, maintenance or repair work should only be carried out when the complete system is at zero pressure.

For optimum performance, frequently inspect tool, power pack, hoses, connectors, electric cables, and accessories for visual damage. Always follow instructions for tool and pump maintenance.

Service Interval Guidance

Trained personnel with correct maintenance schedule can use hydraulic wrenches for many years without problems. However, all tools wear out after long use. Factors that affect the life of tool:

High cycle rate

High load use

Impact

Operating in dirty, hot or humid environments

Different reaction methods

Poor maintenance

Regular lubrication and overhaul is recommended to make sure that the wrench remains in good working order. More frequent service intervals may be needed if used at high torque, high cycle rate or long tightening times. If the wrench is not working properly, immediately take it away for inspection.

The following service intervals are for guidance only. Each use case and application is different, so it is the responsibility of the end user to implement suitable planned maintenance specific to the working environment and usage. Keep a record of tool operation. This record helps to plan for service, calibration, and replacement of tool or components.

Light Duty

Example: Infrequent use at low pressures, <40% capacity.

Lubrication: every 6 months

Overhaul: every 12 months

Normal Duty

Example: Regular use, <80% capacity.

Lubrication: every 3 months

Overhaul: every 12 months, including drive pin replacement. See section Lubrication.

Heavy Duty

Example: Constant use at any pressure; use >80% Capacity; regular use to loosen corroded bolts.

Lubrication: every 1 month

Overhaul: every 6 months, including drive pin and drive pawl replacement. See section Lubrication.

Tool Replacement

The product owner must implement a service plan for the tool replacement policy. This policy ensures that operating tools are replaced before the tool is no longer useful. Due to different operational environments and potential inconsistencies in tool servicing, it is difficult to define the tools lifespan.

Visual signs of wear, such as scars, dents, or missing material, indicate that the tool is no longer useful. Service tools that show signs of wear. To maintain the condition of the tools, replace any damaged parts. If the tool shows major damage to the pressure containing components or reaction arms, the correct action is to remove the tool for safety reasons.

For more information, see the Service Interval Guidance.

Preventive Maintenance

To keep the hydraulic torque wrench system in good working condition, do the following maintenance steps after each period of use.

Wipe clean all external surfaces and visually inspect the tool for signs of damage. Investigate if needed.

Examine all hydraulic joints and connections for signs of hydraulic leaks. Investigate if needed.

Make sure that all hydraulic couplings are clean and free from debris.

Inspect the full length of the hose; look for cuts or abrasions. Pay close attention to the swaged ends and look for any signs of leaks.

If the equipment is in good working order, spray with a suitable rust inhibitor oil, such as Shell Ensis or Castrol Rustillo, and store ready for next use.

Overhaul Instructions

Connect the wrench to a pump.

Pressure test to make sure that all mechanisms function as expected.

Investigate any malfunctions or hydraulic leaks.

Depressurize the system and disconnect all couplings.

Disassemble the wrench.

Replace all seals and springs.

Replace the drive pin.

Replace any other components showing signs of damage or wear.

Relubricate and reassemble the wrench.

Pressure test and make sure that all mechanisms function as expected.

Calibrate the wrench and make sure that the torque output is as expected.

Lubrication Instructions

Lubricant Guide

Drive Components | Molykote 1000 |

Seals | Rocol Sapphire Aqua-Sil |

Fasteners | Loctite 243 |

Tapered Hydraulic Threads | Loctite 577 |

Lubrication

To keep the wrenches in good working condition, lubricate the drive components periodically between service intervals.

Disassembly before lubrication:

Remove the square drive.

Remove the access plugs [×2].

Remove the shroud screws [×2] and the shroud.

Remove the retaining clips [×2].

Remove the drive sleeves [×2].

Position the drive pin in line with the access plug hole. Push the pin out of the housing to release the drive assembly.

Remove the drive assembly from the housing.

Do the following actions during lubrication maintenance:

Examine the drive pin for signs of wear or damage. Replace the pin if necessary.

Examine the edges of ratchet teeth for signs of damage. Replace the ratchet if necessary.

Examine the drive pawl teeth for signs of damage. Replace the drive pawl if necessary.

Examine the drive pawl springs for signs of damage. Replace the springs if necessary.

Lubricate the shaded areas with Molykote 1000.

The procedure for assembly is the same as for disassembly, but backwards.

Troubleshooting

Troubleshooting of Hydraulic Torque Wrench

Tool failure, although rare, does occur. Such failure is most often in the hydraulic couplers or hoses. These items are repairable or replaceable immediately, since they are available universally. Failures of structural members of the tool are quite rare, however, replacement parts are available from stock. All repairs to Atlas Copco tools may be made by reasonably experienced individuals according to the aforementioned instructions. Otherwise, please contact Atlas Copco to schedule a quick repair of the tool.

Recommended Service intervals are :

Heavy duty use or use in corrosive/harsh environments – every 3 months internal drive components may require frequent inspection and re-lubrication under heavy duty cycles, e.g. weekly.

Normal use – every 6 months.

Light or infrequent use – every 12 months.

Troubleshooting Powerpacks

Atlas Copco Hydraulic Power Packs are precision-built units and, as such, do require a certain amount of care and maintenance

Hydraulic Oil should be completely changed after every 300 hours of operation, or at least twice a year. Always make sure the reservoir is filled with fluid. Always use Atlas Copco Maximizer range of oils for best performance.

Couplers and fittings should be checked periodically for leaks. Dirt or foreign materials should be kept away from fittings. Clean before use.

Hydraulic Gauge: Some gauges are liquid filled. Should this liquid level drop, it indicates external leakage, and replacement is necessary. Should the gauge fill with hydraulic oil, it indicates internal failure and it should be discarded.

Filter on Pump: The filter should be replaced twice a year in normal use and more often if the pump is used daily or in a dirty, harsh environment.

Remote Control: (Air Unit) The airline to the remote control unit should be checked for obstructions or kinks in the line periodically. If there is a bend or break in the line, it must be replaced. The spring- loaded buttons on the remote handle should be checked in the event of operating difficulties. (Electric Unit) The switch buttons should be checked periodically if any indications of problems exist.

Air Valve: This valve should be checked twice a year.

Armature: (Electric Unit) Check yearly.

Pumping unit: The pump should be overhauled every 2 years. This can be done by Atlas Copco or by a qualified hydraulic service centre.

Troubleshooting Routines

Test 1

Attach hoses to pump and tool in the normal manner.

Press the advance button and hold it down.

If the pump pressure builds and the hoses "flex" but the tool still refuses to cycle, the problem is most likely a loose or defective coupling connection. To find out where the bad coupling is, remove the tool from the hoses and marry the loose ends together and cycle the pump. If the gauge pressure reads no more than 500 PSI, then the bad fitting is on the tool. A significantly greater pressure indicates that the problem is in either the pump or a hose fitting.

Test 2

Remove screws from pump motor to reservoir, slide pump motor to the back while keeping pistons into oil.

Turn pump on. If you have no oil coming out from the solenoid tube, change the solenoid.

Tight the regulating valve to maximum, Push on the advance button and while holding down, look if any oil is coming out from the regulating tube. If oil is coming out, change the regulating valve.

Test 3

Remove tool from hoses.

Cycle pump.

If pump fails to build pressure, the problem is with the pump. If it does build pressure, the problem is with hydraulic blow-by in the tool.

Test 4

This test should be run prior to every use of an Atlas Copco Tool

Connect the tool, pump and hoses together as normal.

Cycle the pump several times.

Cycle the system once more and observe the sequence of operation.

As you depress the advance button, the tool drive shroud turn about 24 degrees and you should hear an audible "click". You will also notice that the disengagement levers will move to the rear of the tool and spring forward.

At this point, release the advance button. You should see no further movement and after a moment you will hear another audible "click". This is how the tools are designed to operate.

If you observe any other sequence of operation, the system is out of order and cannot deliver more than 10% of its designed capacity.

Take immediate corrective action. For reference, tools and pumps are designed from the factory plumbed as follows. This ensures that the tool, pump and ONE hose cannot possible be connected up incorrectly.

Test 5

Tool | Hose | Pump |

|---|---|---|

Advanced Side-Male | Advance side- Female to Female | Advance side-Male |

Retract side-Female | Retract Side-Male to Male | Retract Side-Female |

Note that connecting two (or any even numbers) of hoses together creates "one" hose which is plumbed backwards! Male to Female and Female to Male. This will cause the system to operate backwards per Test #5 above. If you hose isn’t long enough, connect 3 hoses together, move your pump or call Atlas Copco for a longer hose assembly.

Troubleshooting Symptoms and Required Action

Symptom | Probable Cause | Required Action |

|---|---|---|

Gauge shows pressure build-up but the tool will not cycle | Couplings are loose or not working. Solenoid is not working | Tighten and/or replace couplings. Use Test #1 to isolate problem Use test #2. if not working replace solenoid |

Cylinder will not retract | 1.See above. | 1. See above. |

2.Voltage to electric pump is too low to line drop or inadequate amperage is available. | 2. Get shorter extension cord or upgrade to 12AWG, 25 amp rating or better. | |

3.Linkage between piston rod and drive pawl are broken. | 3. Replace parts as necessary. | |

Cylinder pressure will not build | 1. Oil blow by in tool (Piston seal leak, blown O-ring, cracked piston) | 1. Replace defective parts. Contact Atlas Copco service |

2. Pump Problem. | 2. Remove screws from pump motor to reservoir, slide pump motor to the back while keeping pistons into oil. Turn pump on. If you have no oil coming out from the solenoid tube, change the solenoid. 2A. If pump sounds like a lot of pebbles in a tin can, the problem may be a worn motor coupling-remove motor from base plate-using a pair of needle nose pliers removes the motor coupling-if worn replace. Contact Atlas Copco service. 2B. If pump sounds like a lot of pebbles in a tin can, the problem may be a worn motor coupling-remove motor from base plate-using a pair of needle nose pliers removes the motor coupling-if worn replace. Contact Atlas Copco service. 2C. Air pump- Fault FRL due to excessive moisture and/or dirt in air supply. Disassemble and change. Contact Atlas Copco service. 2D. Air pumps- Replace faulty remote control valve cartridge. | |

Cylinder/tool leaks | 1. Safety relief valve on swivel has lifted. | 1A. Tighten all hose and couplers. If leak continues, adjust safety setting – Test #4. 1B. Check to see if the system is properly plumbed by running test #5 (high pressure on retract side will lift the safety relief valve). |

2. Blown O-ring in cylinder. | 2. Replace O-Ring with proper high pressure O-Ring. Contact Atlas Copco service. | |

3.Defective gland seal. | 3. Replace gland seal. Contact Atlas Copco service. | |

Tool operates backwards | 1. Couplings reversed. | 1. Run test #5. Replumb system as necessary. |

2. Multiple hoses in even numbers. | 2. As plumbed, Atlas Copco hoses may only be joined together in odd numbers ONLY if it is necessary to use 2, 4, 6 hoses-make an adapter from spare high pressure couplings and nipples. | |

Ratchet returns with retract stroke | Broken or otherwise inoperable reaction pawl. | |

Ratchet will not take successive strokes. | 1. Broken or otherwise inoperative drive pawl or spring. | 1. Replace drive pawl and/or spring. Contact Atlas Copco service. |

2. Cylinder not retracting completely. Ratchet will not take successive strokes. | 2.Remove tool from nut and cycle freely for several strokes. If problem persists, check pawls. 2A. Operator not allowing adequate time for cylinder to retract fully | |

3. Linkage between piston rod and drive plates is broken. | 3. Replace parts as necessary -Contact Atlas Copco service. | |

Tool locks onto nut. | 1. Reaction pawl is loaded when the tool is maxed out in torque. | 1. Press advance button on remote and build pressure- continue to press down on remote while pulling back on one of the disengagement levers- release remote while continuing to hold back on levers. |

2. Tool is operating backwards. | 2. Push advance button down-tool should immediately fall free- Run test #5. | |

3.Tool is wedged under a fixed object. | 3. Remove shroud from around ratchet. Using any tool available, pry the drive pawl out of the ratchet and at the same time pull back on the disengagement levers. Tool should swing free or turn away the socket or obstruction. | |

Gauge records no pressure | 1. Gauge connection is loose. | 1. Tighten coupling. |

2. Bad gauge. | 2. Replace gauge. | |

3. Pump will not build pressure. | 3. See cylinder will not build pressure above. See cylinder will not build pressure above. | |

4. Tools seals are blown. | 4. Replace defective seals. Contact Atlas Copco service. |

Troubleshooting Symptoms and Required Action

Symptom | Probable Cause | Required Action |

|---|---|---|

Pump will not build pressure. | 1. Air Electric supply is low. | 1. Check air pressure or voltage. |

2. Defective relief or regulator valve. | 2. Replace valve. Contact Atlas Copco service. | |

3. Low oil or clogged filter. | 3. Fill reservoir and clean filter. | |

4. Internal leak in oil line from external relief valve to pump body. | 4. Open reservoir, inspect oil line while trying to build pressure- if leaking tighten fittings or replace. | |

5. Defective Solenoid or regulating valve. | 5. See “Cylinder will not build pressure-#2 above” | |

Motor sluggish and inefficient “sounds sick” slow to build pressure. | 1. Air or electric supply is low. | 1. See #1 in preceding block |

2. Clogged filter. | 2. Clean or replace filter | |

Pump heats up. | 1. Improper use. | 1. Operator is continuing to hold down on the advance stroke after the cylinder has reached end of stroke- this causes a lot of oil to go through a very small hole in relief-valve- causing heat build-up. Have operator release advance stroke after disengagement levers spring forward. |

2. Remote control is left in “on” position when pump is not actively in use. | 2. Turn pump off whenever not actually being used. DO NOT leave pump running when tool is not in use. | |

Pump cannot reach 10,000 psi, only 9,000psi | Change regulating valve | 1A.Remove 3 screws of 4 port block manifold IB. Remove regulating valve IC. Replace new regulating valve ID. Don’t forget metal ring IE. Check o’rings on block manifold IF. Replace block manifold IG. Place 1 drop of loctite on each screw IH. Tighten screws firmly - double check screws are fully tightened. |

Pressure can’t reach 4,000 psi | Change cut off valve(s) | IA. Remove the pump from tank IB. Change cut-off valves 3,250 psi /70 bar 90% Chance pump is workingIB. Change cut-off valves 3,250 psi /70 bar 90% Chance pump is working IC. If pump can’t get 10,000 psi change cut-off valve 1,250 psi/350 bar |

Pressure not stable (big variation) | Change solenoid (115v), (220v) | IA. Remove top solenoid IB. Replace new top solenoid IC. Check o’rings |

Pressure not stable (small variation) | Change check valves Part# 20374 Need special tooling | IA. Remove the pump from tank IB. Replace check valve IC. Do not tight too much |

No pressure | Check piping | IA. Remove the pump from tank or Check piping couplers IB. Check t-coupler inside the pump |

Uncontrolled pressure | 1. Check coupling Part#10190 | IA. Remove the pump from the tank IB. Remove piping IC. Remove block pump (screws# 20444) ID. Check attentively coupling IE. Do not forget to replace keys(part #10184) |

2. Check pumps Part# 10168-10169-10170 | 2A. Remove the pump from the tank 2B. Untighten pump’s screws 2C. Check seals 2D. Replace 2E. Tighten firmly |

Troubleshooting Symptoms and Required Action

Symptom | Probable Cause | Required Action |

|---|---|---|

Motor doesn’t run | 1.Check fuse 16 a Part# 10064 | 1. Change fuse 16 a (white - on top) |

2. Check electrical box | 2. Check for disconnection | |

3. Check 115v cord | 3.Check for wire cut or disconnect | |

4. Check plug | 4. Check for wire disconnect | |

5.Check remote control | 5. Check for wire disconnect | |

Motor start difficult | 1. Bearing Part#10198 & 10178 | IA. Remove the pump from the tank IB. Remove block pump IC. Disassemble block pump ID. Change bearing |

2. Remote control handswitch small white plastic support | 2A. Open the hand switch 2B. Replace small plastic parts | |

Blown fuses when starting | Check if fuse 16 a is blown Part# 10064 | To avoid the problem don’t run motor If hydraulic hose are not connected |

Hose or tool fitting is damaged or leaks. | 1. Broken or melted plastic outer covering. | 1. If underlying plastic is still intact continue operation. Inspect frequently.If underlying plastic is still intact continue operation. Inspect frequently. |

2. Frayed plastic strands. | 2. Cut hose in half and discard. Replace hose. | |

3. Oil leaks through fibres. | 3. Cut hose in half and discard. Replace hose. | |

4. Broken fittings. | 4. Remove old fitting and replace with STEEL high pressure fittings only. After changing fittings, always run test #5 to insure proper plumbing. | |

Electric pump will not run | 1. Loose electric connections in control box. | 1. Open control box and visually inspect for loose threaded or push-on connectors. |

2. Motor burned up. | 2. Replace motor components whichever is necessary. Contact Atlas Copco service. | |

Fuse | 3. Change defect fuse |

Recycling

Environmental Regulations

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.