Overhaul

Have the tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the tool is maintained. Service must only be carried out by qualified personnel who have been trained for service on IxB tools.

The electric motor is a sealed unit and may under no circumstances be opened by anyone else than Atlas Copco Industrial Technique AB. If it is judged that the electric motor is defect or in need of service, the complete motor unit should be returned to Atlas Copco Industrial Technique AB for exchange. Motors which have been opened by anyone else than Atlas Copco Industrial Technique AB will not be serviced.

Overhaul and preventive maintenance is recommended at regular intervals once per year or after maximum 250.000 tightenings, depending on which occurs sooner.

The ball bearings in the 110° angle head must be exchanged at each of these regular service occasions.

More frequent overhaul may be needed if the machine is used in heavy-duty operations. If the machine is not working properly, it should immediately be taken out of service for inspection.

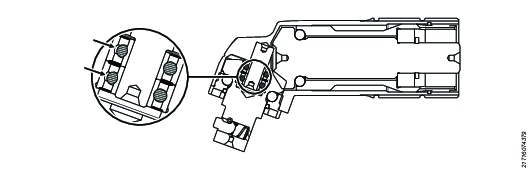

When dismantling the tool always use the specially designed service tool(s) recommended in the Spare Parts section on ServAid - https://servaid.atlascopco.com.