Tells the user whether it is possible to configure the event through the "Configure Event" page.

Power Focus HC (3.9)

Software

Introduction

In this section, you can find the basic information about the product and also the formatting conventions used in the topics.

General Description

The Smart Tensioning System is a traceable and guided bolt tensioning solution which consists of three main components. The smart tensioner (STT) comes with integrated electronics and sensors, giving instant feedback to the operators. The Hand Controller (PFHC) is the brain of the system, controlling the process including; scanning with integrated barcode reader, operating the power pack and collecting data. The whole system works in a closed loop, with all commands given by the hand controller. The Power Pack comes with our heavy-duty motor and high-performance electronics.

Features

Data collection

Pressure, torque and angle sensors

LED's on the tool

Integrated electronics

Tool and power pack identification

Digital cycle counter

Intuitive HMI

Benefits

Full traceability of process

Reduced process time

Instant feedback for each step

Minimum peripherals

Process accuracy

Conventions

To enhance user understanding, certain formatting conventions are used throughout this document. The formatting conventions used are listed below.

Element | Notation | Description | Output |

|---|---|---|---|

General emphasis | In the Program workspace. | To make certain text elements stand out, or to highlight. | Text in Bold |

Graphical User Interface (GUI) items | Select the Function button. | Any reference to items found on screen in the GUI (for example, command buttons, icon names and field names). | Text in Bold |

Graphical User Interface (GUI) Path > | Generally, on the top of the GUI. | Navigation aid which keeps track of the location in the GUI. | For example: Controller > Program > Edit |

User input | Enter a Description for the program. | Any text input by the user. | Text in Bold |

File names | Enter a File Name for the export. | Files either exported from, or imported into the system. | Text in Bold Italic |

Variable and parameter names | Enter a Name for the export. | Variable and parameter names (not values). | Text in Italic |

Variable and parameter values | Enter a VALUE for the export. | Variable and parameter values. | Text in BOLD CAPS |

System output | Client.Domain.Models.ExportImportConfiguration | Any text output by the system. | Text in Monospace |

External links | Links to external sites that have information connected to the document or subject content. These could include:

| Selectable text to external sites | |

Internal documentation links |

If available, these links will be presented below the text. | Selectable text to internal content |

General Data Protection Regulation (GDPR)

This product offers the possibility to process personal identifiable information such as system user name, role and IP-address. The purpose of this processing capability could be to enhance quality control through traceability and proper access management.

If you decide to process personal data you need to be aware of and comply with relevant personal data protection rules, including, in the EU the GDPR as well as other applicable laws, directives and regulations. Atlas Copco can in no way be held liable for any use made by you of the product.

Liabilities and Warnings

Liability

Many events in the operating environment may affect the tightening process and shall require a validation of results. In compliance with applicable standards and/or regulations, we hereby require you to check the installed torque and rotational direction after any event that can influence the tightening result. Examples of such events include but are not limited to:

initial installation of the tooling system

change of part batch, bolt, screw batch, tool, software, configuration or environment

change of air- or electrical connections

change in line ergonomics, process, quality procedures or practices

changing of operator

any other change that influences the result of the tightening process

The check should:

Ensure that the joint conditions have not changed due to events of influence.

Be done after initial installation, maintenance or repair of the equipment.

Occur at least once per shift or at another suitable frequency.

Warnings

About the User Guide

The User Guide describes how to set up and configure the PFHC.

It is intended for anyone operating or servicing the PFHC.

Revision History

Release Number | Revision Date | Revision Description |

|---|---|---|

item | item | none |

3.9 | 01/2023 | NEW content: UPDATED content: Exported Information and File Format |

3.8 | 09/2022 | First official release of the User Guide for Power Focus HC. |

Prerequisites

Anyone interested in learning more about PFHC can benefit from reading this User Guide.

For a complete understanding of the technical aspects described in the User Guide, we recommend the following:

Knowledge about tightening techniques

Experience of working with the previous versions of Power Focus

System Overview

Software Structure

Menu Overview

Web GUI which is accessed on the external computer, has several menus available to perform the following:

Configure tensioning and hardware accessories

Perform tool maintenance

Manage software

View reports

Controller GUI, shown on the hand controller's display, is a user interface for operation and monitoring of the system.

Web GUI

Tensioning Tab

The Tensioning tab lists the Tensioning programs stored on the hand controller that are available for an individual tensioning.

Tensioning configurations are described in the Tensioning tab.

Configuration Tab

A list of configurations is given in the Configurations tab. Common configurations are independent of the type of the connected tensioner and hydraulic pump.

Tensioner Controller Tab

The Controller tab lists hardware and software components.

The software versions stored and used in the hand controller are listed and can be updated.

It is also possible to import or export settings to and from the hand controller.

Reports Tab

The Reports tab lists the tensioning results and events.

Settings Tab

The Settings tab is used to set up the hand controller's specific settings, such as date and time, pin code, events, and wireless network.

Help Tab

The Help tab contains useful help sections about the hand controller.

Controller GUI

Tasks Tab

The Tasks tab lists the tensioning programs stored on the hand controller that are available for an individual tensioning. Tensioning configurations are described in the Tensioning tab in Web GUI.

Reports Tab

In the Reports tab, the tensioning results are listed and the report can be generated and saved on a USB flash drive.

Controller Information Tab

The Controller Information tab lists hand controller unit data such as serial number, IP address and software version.

Settings Tab

The Settings tab allows to set date and time and clear results.

Connected Devices Tab

The Connected Devices tab shows the connection status of the tensioner and pump that are connected to the hand controller.

It lists unit data of the connected tensioner and pump, such as serial number and software version. It also shows the current tensioner puller bar count.

Operating and Handling

Web GUI

GUI Buttons and Icons

Button | Name | Description |

|---|---|---|

Add | Add an additional item. | |

Remove | Remove an item. | |

| Ellipsis | Edit an item. |

Go back | Return to previous view. | |

Scroll up Scroll down | Move in a list that is too long for the screen. | |

Maximize Minimize | Maximize or minimize a section with parameters. | |

Back (to the start) (in a list) Back (in a list) | Move back in pages of a list. | |

Forward (to the end) (in a list) Forward (in a list) | Move forward in pages of a list. | |

Close | Tap to close the window. | |

Notice | Sign showing that a parameter is configured wrong. | |

WARNING | Sign leading to a warning about the risk of injury. | |

Validate program | Tap to check if a program is valid. | |

Download manual | Tap to download a manual. | |

Go home | Go to the Home screen. | |

Go result | Go to the live results screen. |

Controller GUI

GUI Buttons and Icons

Buttons on the hand controller keypad are context sensitive. Active buttons are represented by icons on the controller GUI. These icons show the current functionality of the keypad buttons. For example, on the Home view, active buttons are represented by the following icons, see the picture below:

Previous (left)

Next (right)

Up

Down

Enter

To navigate, use the left, right, up and down buttons on the keypad. To enter a menu or confirm a choice, use the Enter button in the middle.

For information about all icons on the controller GUI, see the table below.

1 | Previous |

2 | Next |

3 | Up |

4 | Down |

5 | Enter (select) |

6 | Wi-Fi and ToolsNet connection status |

Button | Name | Description |

|---|---|---|

| Back | Return to previous view |

| Forward | Continue. |

| Up Down | Move up or down in a list. |

| Enter | Confirms the selected choice. |

| More | Additional information or actions. |

| Next | Go to the next view. |

| Previous | Go to the previous view. |

| Wi-Fi connection status | Connected to Wi-Fi |

| Wi-Fi connection status | Not connected to Wi-Fi |

| ToolsNet connection status | Connected to ToolsNet |

| ToolsNet connection status | Not connected to ToolsNet |

LED Status Indicator

The LED matrix on the tensioner is mimicked on the hand controller GUI during the tensioning process. For more information about LED Status Indicator, see Product Instructions STT Tensioner.

Quick Start Guide

To create a better overview of the system, this section provides a quick guide covering the basic steps required to get started with the Smart Tensioning System and Power Focus Software.

The section does not explain every feature of the system, but instead focuses on the most basic ones.

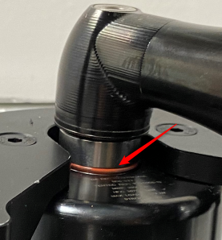

To start the system, the pump and the tensioner must be connected to the hand controller before turning on power on the hydraulic pump with the power switch.

Rundown the tensioner straight on top of the bolt. Make sure that the socket inside the tensioner is engaged on the nut by moving the click wrench. Listen for the click sound. Observe that the tensioner rotates as the wrench applies some force on the nut.

When the Tasks icon on the hand controller is active, run Manual mode by using the keypad buttons on the hand controller.

Set the target pressure to a low pressure, for example, 500 bars, and then press the pressurize button.

If the motor is running, but there is no pressure increase, the most common problem is that the motor runs backwards. Power off the system and reverse the phases of the power connector, then try again.

When the system is pressurized, move the click wrench to see the Angle and Torque readings update.

For more detailed information about system startup of the Smart Tensioning System, see Smart Tensioning System Working Guide.

Installation and Upgrade

In this section, you can find information to help with the initial installation of the product, or upgrading from one version to another.

Web Browser Requirements

For optimal performance, use a web browser that has good JavaScript performance, and enable browser caching.

It is possible to run the software through the following web browsers:

Google Chrome 70 or later

Microsoft Edge 79 or later

Firefox 63 or later

Configuration

In this section, you can find detailed information about how to create, modify, and verify product settings.

Connecting to PFHC Configuration GUI

For optimal performance, use a web browser that has good JavaScript performance and enables browser caching.

Open the cover of the hand controller's USB connection port.

Connect a PC to the USB-C connector on the hand controller. To make sure that the PC gives enough power to the hand controller, use USB-3.0 ports.

To enter the configuration GUI, enter the following address in your browser: http://169.254.1.1/config.html.

See more information in the section Web Browser Requirements.

Web GUI

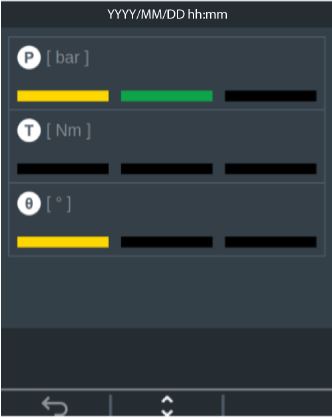

Live results

Open live result view by clicking the results icon in the lower left corner when it is visible.

Status, torque and angle are displayed.

Click on the connection icon in the upper right corner in the live results view to open the protocol status view.

Working with the Tensioning Tab

This section describes the multistep tensioning strategy and how to create a tensioning program.

On the Home view, go to Tensioning tab, then select Multistep Program Library.

Multistep Configuration User Interface

The user interface for configuring a multistep program consist of the following main areas:

In the left pane under the Properties tab, there is a General Settings of the multistep tensioning program containing Program name.

In the left pane, the Program tab has a drop-down menu containing Steps.

To build the multistep program, click on Steps, then drag the appropriate step icon - Tensioning or Tensioning Service from the list to the tensioning area. Drop the selected step icon between the beginning and the end of the program.

The Tensioning Manual program is created automatically by the hand controller and can be edited as needed.

The main area of the user interface is made up of the tensioning area. This is the area that includes all the steps in the tensioning program.

Default Manual Program

In the Multistep Program Library, select Default Manual Program. The Default Manual Program is automatically created. The manual program can be run with all sizes and types of tensioner tools.

The manual program contains three settings for controlling the behavior of the manual mode. The name of the manual program can be edited in General Settings > Properties.

General Settings

General Settings consists of the field Name.

Select a program, go to Properties tab to edit General Settings by entering the name in the free text string field.

The chosen program name is displayed in the controller GUI in the listed programs under different job types in the Tasks tab.

Manual Mode Parameters

In the Default Manual Program, click on the Tensioning Manual icon in the tensioning area to edit the following parameters:

Name

Default manual hydraulic pressure (bar)

Max system hydraulic pressure (bar)

Parameter | Default | Description | Comment |

|---|---|---|---|

Name | Manual Mode Step | String name of the step | Not used since the manual mode does not generate any results. |

Default manual hydraulic pressure (bar) | 1000 | Used to populate the manual mode set pressure window when the manual mode runs for the first time after a system start. | The default manual pressure makes sure that the operator does not just reuse a previous pressure from an earlier manual mode run. Set the default pressure to a value applicable to your application. Once the manual mode has been used, the system will assume that this is the pressure that suits the ongoing operation. The last used pressure will be used as the manual mode pressure until the system is powered off. It is always possible to change the target pressure in the controller GUI. |

Max system hydraulic pressure | 1980 | The highest pressure target that is allowed when using this configuration. | The system is using the lowest max pressure of its connected units. If any of the connected units have a lower max pressure, the pressurization will stop at this pressure level. |

Tensioning Program

On the Home view, select the Tensioning Tab. Multistep Program Library is selected automatically.

To add a tensioning program, click on the Plus icon above the program list to open the Program tab, then click on Steps.

If any tensioning program is already available, select the program to edit it.

Drag and drop the tensioning steps in the tensioning area.

Steps can only be placed between the start and the end point of the program.

Buttons Delete Tightening Program and Copy Tightening Program are available at the lower-right corner for deleting and copying the program.

A tensioning system uses only one step per configuration.

Changes made to tightening programs in any section need to be actively applied by clicking the Apply button in the bottom right corner of the GUI. Alternatively, changes can be undone by clicking the Undo button in the same location.

When navigating away from the section where changes have been made (by using the Back, Home or Result button), the user will be presented with a warning pop-up where the changes can also be applied or undone. The user cannot proceed without applying or undoing changes.

Function | Description | |

|---|---|---|

Start and end points |  | Start and end points of the Multistep program. All steps must be placed between these two points. |

Showing step properties |  | Click on the step to reveal the properties. |

Closing step properties |  | Click anywhere in the tightening area to close the properties menu. |

Deleting a step |  | Click on the step properties and then Delete at the bottom of the menu. |

Step error |  | When a validation error occurs in a step, that step will be marked. Note that when the step properties are opened, the parameter causing the error will also be marked. Click on the red mark for more information about the error. |

Forbidden placement |  | When a particular placement of a step is not allowed, the placeholder icon will not be shown. |

Tensioning Parameters

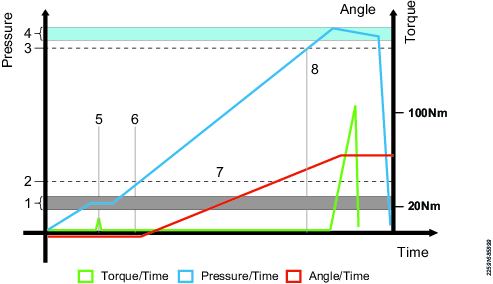

Under Program tab, click on the Tensioning item to open it and edit the parameters. The tensioning parameters are listed in the table below. See also Diagram of the tensioning process in the section Tensioning process.

Parameter | Default value | Unit | Description | Comment | |

|---|---|---|---|---|---|

a All default values are tailored for an M36 bolt running with min angle 40 degrees and no max angle. b The rotation detection parameters define an expected play in the wrench-socket-gear box chain. The experience is that this can vary a lot depending on, mainly bolt geometry – even when the tool is attached to the same bolt but the socket aligns to different sides of the nut. c The rotation detection parameters define an expected play in the wrench-socket-gear box chain. The experience is that this can vary a lot depending on, mainly bolt geometry – even when the tool is attached to the same bolt but the socket aligns to different sides of the nut. | |||||

Name |

| User name of the step configuration, written in the xml report file and reported in the step Results. | |||

Bolt size | M36 a | mm | The size of the bolt for the intended configuration. The bolt size is compared to the connected tool and if it does not match, an invalid configuration event is emitted. | The controller GUI filters out the configurations that fit the connected tools. Configurations made for other tool sizes are not displayed in the list under Tasks > Assembly or Tasks > Batch Assembly. | |

Tensioner type | Flange bolt | Tensioner type must match the connected tensioner. The string is compared to the string that identifies the type of tensioner which is programmed in the tensioner during its production. The string is case sensitive when compared to the string in the tensioner. | The controller GUI filters out the configurations that fit the connected tools. Configurations made for other tensioner types are not displayed in the list under Tasks > Assembly or Tasks > Batch Assembly. | ||

Min nut rotation angle | 40 | Degrees | The minimum nut rotation angle for an OK tensioning. | The field can be left empty if the tensioning process does not depend on minimum tightening angle. | |

Max nut rotation angle | Degrees | The maximum nut rotation angle for an OK tensioning. | The field can be left empty if the tensioning process does not depend on the maximum tightening angle. | ||

Angle approval | Approve last angle | Controls the behavior of the angle measurement when re-tensioning after NOK result. Choices are:

| For configurations that require max angle, it is recommended to use only the last angle. For configurations that require min angle, use angle summarization in order to consider the sum of all attempts for OK/NOK results. For configurations that define an angle range, consider which behavior applies for the job the that the configuration is tailored for. | ||

Use clamping force estimation | On | Controls which clamping force estimation is used for the result. On -> Clamping force estimation is used: tensioning force – Estimated Initial mean settlement Off -> clamping force is calculated according to Load Transfer Factor equation: tensioning force / (1.01 + (bolt diameter / clamping length)) | The Atlas Copco (AC) Load Transfer Factor (LTF) equation utilized in the STS is for use on ‘Flange’ connected joints only. Do NOT use on foundation style joints. | ||

Clamping length | mm | The height of the flange, i.e. the distance between the nuts on each side of the flange. Active when: Use clamping force estimation is ’Off’. | Visible if Use clamping force estimation is ’Off’. | ||

Estimated initial mean settlement | 99 | kN | An estimation of the average force loss when releasing the pressure. Active when: Use clamping force estimation is ’On’. | Visible if Use clamping force estimation is ’On’. It is used in the xml report generation. The value depends on the tensioner size and the type of the flange. | |

Estimated initial max settlement | 155 | kN | An estimation of the maximum force loss when releasing the pressure. Active when: Use clamping force estimation is ’On’. | Visible if Use clamping force estimation is ’On’. It is used in the xml report generation. The value depends on the tensioner size and the type of the flange. | |

Min required average clamping force | 510 | kN | The minimum average clamping force for all bolts on the flange used in flange summary section in the xml report. Active when: Use clamping force estimation is ’On’. | Visible if Use clamping force estimation is ’On’. It is used in the xml report generation. The value depends on the tensioner size and the type of the flange. | |

Batch job report type | General | Controls the flange summary generation in the xml reports:

| Taylored for Vestas xml report requirements: First round, Second round, User General for Service jobs. | ||

Angle sensor reset force | 100 | kN | The force at which the angle measurement reference for 0 degrees is set. | The expected angles are calculated depending on the force increase from the angle sensor reset force to Min bolt tensioning pressure. This evaluates to different pressures depending on the tensioner size, see the table in the section Pressures for Different Tensioner Sizes. The larger the tensioner is, the higher the angle reset force must be set, due to issues with control of low pressures in installation check step. This is necessary in order to avoid overshooting of Installation check hydraulic pressure higher than pressure equivalent of angle sensor reset force. | |

Min bolt tensioning pressure | 1900 | Bar | The min pressure for an OK tensioning result. | The pressure control in the system will set a target value higher than the Min bolt tensioning pressure to avoid pressure drop ending in a NOK result. See the picture in the section Hydraulic Pressure Target Window. | |

Max system hydraulic pressure | 1980 | Bar | The highest pressure the pressure control in the hand controller allows for this configuration. | The actual max pressure is the lowest of the max pressures in the pump and tensioner and the Max system hydraulic pressure of the configuration. | |

Min bolt tensioning force | 698 | kN | Force equivalent of the Min bolt tensioning pressure parameter. | Value manually calculated from bolt pressure. This value is written in the xml report files, but it is not used by the hand controller's software. | |

Installation check torque | 20 | Nm | The required torque for an acknowledged installation check. | ||

Installation check torque duration | 1.0 | S | The required time the Installation check torque must be applied for an acknowledged installation check. | ||

Tightening target torque | 100 | Nm | The required torque for an acknowledged tightening of the nut. | ||

Tightening torque duration | 1.0 | S | The required time the Tightening target torque must be applied for an acknowledged tightening of the nut. | ||

Tightening unexpected clockwise rotation detection angle | 5 | Degrees | The maximum allowed change of the nut rotation angle in clockwise direction when the process is waiting for pressure release. | To avoid the risk of nut rotation while the system waits for pressure release, activate automatic pressure release (see section Tool Configuration). b | |

Tightening unexpected counter clockwise rotation detection angle | 5 | Degrees | The maximum allowed change of the nut rotation angle in counter clockwise direction when the process is waiting for pressure release. | To avoid the risk of nut rotation while the system waits for pressure release, activate automatic pressure release (see section Tool Configuration). c | |

Installation check hydraulic pressure | 20 | Bar | The pressure set point for installation check. | The installation check pressure fixes the tensioner to the flange during the installation check. The installation check pressure, including overshoot, must not exceed the pressure equivalent of Angle reset force. | |

Hydraulic pressure set point factor | 1.025 | The actual set point for the pressure regulation is calculated as follows: Min bolt tensioning pressure times Hydraulic pressure set point factor. See the picture in the section Hydraulic Pressure Target Window. | When pressing and holding the pressurization button, the system is pressurized, the pressure will be held inside a pressure window above Min bolt tensioning pressure. | ||

Tensioning Process

1 | Installation check hydraulic pressure |

2 | Angle reset force |

3 | Min bolt tensioning pressure |

4 | Pressure target window. With the pressurize button held, the system will keep the pressure within this window |

5 | Installation check. Sets mechanics in a known position. The nut does not rotate. The play in ratchet and gearbox is fixed in the tightening direction. |

6 | The angle reference point is sampled. Tightening angle measurement starts from this point. |

7 | Pressure builds up, rotation of the nut OK but no need to apply any high torque. Let the hydraulics do the work. |

8 | Min bolt pressure reached. Final fixation of the nut. |

If the installation check pressure ends higher than the pressure that corresponds to angle reset force, the tensioning process cannot set its angle reference point (6).

Therefore, the parameter angle reset force may have to be adjusted, depending on tensioner size, to include some margin for installation check pressure overshoots. The actual installation check pressure depends on, for example, oil type or oil temperature. See the table in section Pressures for Different Tensioner Sizes.

Pressures for Different Tensioner Sizes

Angle reset force 100kN with calculated equivalent pressures for different tensioner sizes are shown in the Table 1.

Tensioner | Angle reset force (kN) | Angle reset pressure (in bar) |

|---|---|---|

M36 | 100 | 272 |

M42 | 100 | 198 |

M48 | 100 | 151 |

M56 | 100 | 109 |

M64 | 100 | 83 |

M72 | 100 | 64 |

Angle reset force settings for different tensioners with margin for installation check pressure are shown in the Table 2.

Tensioner | Angle reset force (kN) | Angle reset pressure (in bar) |

|---|---|---|

M36 | 100 | 272 |

M42 | 100 | 198 |

M48 | 150 | 226 |

M56 | 200 | 219 |

M64 | 200 | 166 |

M72 | 250 | 161 |

Hydraulic Pressure Target Window

The picture below illustrates how the system keeps the pressure inside the pressure target window while holding the pressurize button pressed.

See also the Diagram of the tensioning process in the section Tensioning Process.

1 | Min bolt tensioning pressure (y) |

2 | Hydraulic pressure target (x) |

3 | Hydraulic pressure hysteresis level (x-y)/3 |

Calculation

Hydraulic pressure target (x) = Min bolt tensioning pressure (y) × Hydraulic pressure target factor (k)

Hydraulic pressure hysteresis level = 1/3 of the distance between Hydraulic pressure target (x) and Min bolt tensioning pressure (y).

The pressurization starts at this level to keep it above the minimum level.

Bolt Service Parameters

Parameter | Default value | Unit | Description | Comment | |

|---|---|---|---|---|---|

a All default values are tailored for an M36 bolt running with min angle 40 degrees and no max angle. b The rotation detection parameters define an expected play in the wrench-socket-gear box chain. The experience is that this can vary a lot depending on, mainly bolt geometry – even when the tool is attached to the same bolt but the socket aligns to different sides of the nut. c The rotation detection parameters define an expected play in the wrench-socket-gear box chain. The experience is that this can vary a lot depending on, mainly bolt geometry – even when the tool is attached to the same bolt but the socket aligns to different sides of the nut. | |||||

|

Name | User name of the step configuration, written in the xml report file and reported in the step Results. | ||||

Bolt size | M36 a | mm | The size of the bolt for the configuration intended for it. The bolt size is compared to the connected tool and if it does not match, an invalid configuration event is emitted. | The controller GUI filters out the configurations that fit the connected tools. Configurations made for other tool sizes are not displayed in the list under Tasks > Bolt Service or Tasks > Batch Bolt Service. | |

Tensioner type | Flange bolt | Tensioner type must match the connected tensioner. The string is compared to the string that identifies the type of tensioner which is programmed in the tensioner during its production. The string is case sensitive when compared to the string in the tensioner. | The controller GUI filters out the configurations that fit the connected tools. Configurations made for other tensioner types are not displayed in the list under Tasks > Bolt Service or Tasks > Batch Bolt Service. | ||

Max delta nut rotation | 13 | Degrees | The max total allowed rotation of the nut for the bolt service process, i.e. the maximum nut rotation in tightening direction compared to the starting point. | See also section Bolt Service Process. | |

Min delta nut rotation | 0 | Degrees | The minimum actual nut rotation that is allowed for the bolt service process. | Min delta nut rotation and max delta nut rotation create a range of accepted result of the bolt process, e.g. 0.13 - the nut needs to return to its original position (Min delta nut rotation = 0) but must not rotate more than 13 degrees in the tightening direction Max delta nut rotation = 13). A value < 0 for Min delta nut rotation allows that the nut does not return completely to the original position. | |

Use clamping force estimation | On | Controls which clamping force estimation is used for the result. On -> Clamping force estimation is used: tensioning force – Estimated Initial mean settlement Off -> clamping force is calculated according to Load Transfer Factor equation: tensioning force / (1.01 + (bolt diameter / clamping length)) | The Atlas Copco (AC) Load Transfer Factor (LTF) equation utilized in the STS is for use on ‘Flange’ connected joints only. Do NOT use on foundation style joints. | ||

Clamping length | mm | The height of the flange, i.e. the distance between the nuts on each side of the flange. | |||

Estimated initial mean settlement | 99 | kN | An estimation of the mean force loss when releasing the pressure. Active when: Use clamping force estimation is ’On’. | Visible if Use clamping force estimation is ’On’. It is used in the xml report generation. The value depends on the tensioner size and the type of the flange. | |

Estimated initial max settlement | 155 | kN | An estimation of the maximum force loss when releasing the pressure. Active when: Use clamping force estimation is ’On’. | Visible if Use clamping force estimation is ’On’. It is used in the xml report generation. The value depends on the tensioner size and the type of the flange. | |

Min required average clamping force | 510 | kN | The minimum average clamping force for all bolts on the flange used in flange summary section in the xml report. | It is used in the xml report generation. The value depends on the tensioner size and the type of the flange. | |

Batch job report type | General | Controls the flange summary generation in the xml reports:

| |||

Nut loosening attempt count torque | 75 | Nm | The torque limit for a loosening attempt. If the number of attempts passes Nut loosening number of attempts, the bolt service process prompts the user to tighten the bolt again because it was not possible to loosen it. | ||

Nut loosening number of attempts | 3 | The number of attempts with torque higher than Nut loosening attempt count torque before prompting the user to tighten the nut again since it was not possible to loosen it. | |||

Nut loosening min loosening angle | 10 | Degrees | The required loosening angle for an acknowledged bolt service operation. | ||

Angle sensor reset force | 100 | kN | The force at which the angle measurement reference for 0 degrees is set. | The expected angles are calculated depending on the force increase from the angle sensor reset force to Min bolt tensioning pressure. This evaluates to different pressures depending on the tensioner size, see the table in the section Pressures for Different Tensioner Sizes. The larger the tensioner is, the higher the angle reset force must be set, due to issues with control of low pressures in installation check step. This is necessary in order to avoid overshooting of Installation check hydraulic pressure higher than pressure equivalent of angle sensor reset force. | |

Min bolt tensioning pressure | 1900 | Bar | The min pressure for an OK tensioning result. | The pressure control in the system will set a target higher than the Min bolt tensioning pressure to avoid pressure drop ending in a NOK result. See picture in the chapter Hydraulic Pressure Target Window. | |

Max system hydraulic pressure | 1980 | Bar | The highest pressure the pressure control in the hand controller allows for this configuration. | The actual max pressure is the lowest of the max pressures in the pump and tensioner and the Max system hydraulic pressure of the configuration. | |

Min bolt tensioning force | 698 | kN | Force equivalent of the Min bolt tensioning pressure parameter. | Value manually calculated from bolt pressure. This value is written in the xml report files, but it is not used by the hand controller's software. | |

Installation check torque | 20 | Nm | The required torque for an acknowledged installation check. | ||

Installation check torque duration | 1.0 | S | The required time the Installation check torque that must be applied for an acknowledged installation check. | ||

Tightening target torque | 100 | Nm | The required torque for an acknowledged tightening of the nut. | ||

Tightening torque duration | 1.0 | S | The required torque for an acknowledged tightening of the nut. | ||

Tightening unexpected clockwise rotation detection angle | 5 | Degrees | The maximum allowed change of the nut rotation angle in clockwise direction when the process is waiting for pressure release. | To avoid the risk of nut rotation while the system waits for pressure release, activate automatic pressure release (see section Tool Configuration). b | |

Tightening unexpected counter clockwise rotation detection angle | 5 | Degrees | The maximum allowed change of the nut rotation angle in counter clockwise direction when the process is waiting for pressure release. | To avoid the risk of nut rotation while the system waits for pressure release, activate automatic pressure release (see section Tool Configuration). c | |

Installation check hydraulic pressure | 20 | Bar | The pressure set point for installation check. | The installation check pressure fixes the tensioner to the flange during the installation check. The installation check pressure, including overshoot, must not exceed the pressure equivalent of Angle sensor reset force. | |

Hydraulic pressure set point factor | 1.025 | 1.025 | The actual set point for the pressure regulation is calculated as follows: Min bolt tensioning pressure timesHydraulic pressure set point factor. See the picture in the section Hydraulic Pressure Target Window. | When pressing and holding the pressurization button, the system is pressurized, the pressure will be held inside a pressure window above Min bolt tensioning pressure. | |

Bolt Service Process

To guarantee the results for loosening and tightening angle, follow the bolt service process:

Position the tool on the bolt.

Pressurize to Installation check hydraulic pressure.

Do an installation check for bolt service:

Apply torque >20 Nm in tightening direction. Hand controller takes angle reference point in tightening direction.

Apply torque >20 Nm in loosening direction. Hand controller takes angle reference point in loosening direction.

Hand controller stores the angle of the mechanical play.

While keeping the wrench and gearbox in loosening position, press and hold the pressurize button until the pressure reaches Min bolt tensioning pressure bar.

Loosen the nut to an angle greater than or equal to the bolt service parameter Nut loosening min loosening angle.

The controller UI will show the loosening angle as a negative measurement from the loosening angle reference point.

Tighten the bolt to the parameter Tightening target torque. The tightening angle is recorded.

Loosening and tightening angles refer to actual nut rotation. Hand controller compensates for mechanical play. The controller GUI will start updating the angle when the nut starts to rotate, i.e. disregarding the mechanical play. Thereby the displayed angle will reflect the nut movement, and when the angle measurement is 0, the nut is back to the original position.

The delta nut rotation in tightening direction must not be higher than parameter Max delta nut rotation with default of 13 degrees. In practice, this means that the nut must not rotate to an angle more than 13 degrees higher than the original position.

Release pressure and store result. The following conditions must be true to get OK results:

The recorded loosening angle is greater than or equal to Nut loosening min loosening angle.

The recorded delta angle after tightening must be in the range between Min delta nut rotation and Max delta nut rotation.

Min delta nut rotation is equal to D in the picture Bolt service process.

1 | Wrench transport to tightening alignment |

2 | Nut rotation starts here |

3 | Tightened to original position |

A | Loosening angle |

B | Fix point loosening |

C | Play |

D | Fix point tightening |

E | Allowed tightening range after loosening is between minimum and maximum delta nut rotation parameters |

F | Max nut rotation |

Working with the Configurations Tab

Configurations of the tools are made in the Configurations menu.

Tool Configuration

On the Home view, go to the Configurations > Tool Configuration to configure the available functions in the system.

Enter a name in the Name field.

Edit a configuration by clicking on the Edit button. See the table below.

To create additional configuration with different settings, click on the plus icon at the top of the page.

For example, create a configuration with Automatic pressure release = ON, or Pump motor timeout with different time.To choose a configuration to use, go to the Home view, Tensioner Controller > Tool.

Parameter | Default value | Unit | Description | Comment |

|---|---|---|---|---|

Pump motor time-out | 30 | s | Timer for pump motor cooldown, also controlling the hydraulic oil return valve. The pump motor stops when the timer expires and the hydraulic return valve closes. When pressure is released, the hydraulic oil return valve is opened and the motor runs for 6 seconds. Then the pump motor time-out starts and when it expires, the valve is closed and the motor stops. | When the system is used in warm conditions, the hydraulic oil may overheat if the motor stops. For larger tensioners, the transport of hydraulic oil back to the pump oil container may need more than the minimum time of 6 seconds. |

Automatic pressure release | OFF | When the automatic pressure release is ON, the pressure is automatically released when the nut is tightened according to settings - the tensioning is completed. | The pressure is released when the torque is relaxed after being applied for the required torque and the required time. See the Diagram of the tensioning process in the section Tensioning Process. Recommended setting for this parameter is ON for the following reasons:

|

Working with the Tensioner Controller Tab

Virtual Station

A virtual station is a software abstraction of a hand controller. The hand controller has an integrated controller with one connected virtual station. Various configurations can be assigned to the virtual station as needed.

Tool

Tool information shows data from the tensioner.

Model: socket size and tensioner type. A compatible configuration must have the fields Bolt size and Tensioner Type identical to the string (case sensitive) under Model to be compatible with the connected tensioner. If a configuration is not displayed under HCGUI -> Tasks -> Assembly bolt service the reason is likely to be identified in these two properties.

Gear ratio: the ratio of the gear box in the tensioner.

Serial number: the serial number of the tensioner.

Max torque: the highest torque that does not damage the torque sensor.

Software version.

Product number: the article number of the tensioner.

Intelligent Application Module

The Intelligent Application Module (IAM) is a non-volatile storage that is located in the hand controller. The storage module contains all the tool programs, configurations and results.

Go to Tensioner Controller tab in the home menu and select IAM.

Apply a string field Name to the hand controller.

The Name will be used in the Web GUI and on the hand controller GUI.

Software Versions

Two software versions can be installed in the tool simultaneously. Installing a second version of the software can be useful as preparation when upgrading multiple hand controllers for synchronized activation.

Changing software versions does not transfer the tool configurations or tensioning programs.

Software Activation

The hand controller can store two installed software versions. By using the Software activation, it is possible to choose which software version to use.

Go to Tensioner Controller in the home menu and select Software in the left pane.

Select Current or Stored in the Software Activation window.

The hand controller is automatically restarted for the activation to take effect.

Update Software Version

If the software package to be installed is not compatible with the hand controller's hardware, the software update will be cancelled. A warning message will be shown, pointing out which parts of the hardware that caused the cancellation.

For information on the current tool hardware, go to Tensioner Controller > Hardware.

Go to the Tensioner Controller menu and select Software in the left pane.

Go to the Software Update field and select BROWSE.

Browse and choose the zip file with the applicable software and follow the instructions to finish installation.

Hardware

The Hardware tab contains Controller information, such as model designation and serial number.

It is possible to do a warm restart of the hand controller in the window Restart Controller. Click on the RESTART button.

Exporting and Importing Configurations

The export and import functions are used to export events and tensioning results for analysis in external programs, as well as allowing for transferring of tensioning programs and tool configurations between tools.

The export function is used to:

Export tensioning results and events for further processing.

Export log files for debug assistance from an Atlas Copco service engineer.

Export tool configuration that can be used to copy settings to another tool.

Go to Tensioner Controller in the home menu. Select Export/Import in the left pane.

Select what to export from the tool:

All information

Settings and configurations

System logs and information

Results

When exporting parameters to be imported in other controllers, choose Settings and configurations.

When Settings and configurations is chosen, no file with results or events will be exported into the archive. With this setting the export takes less time to do.

Select EXPORT. A prompt to select where to save or retrieve the exported file is shown.

Go to Tensioner Controller in the home menu. Select Export/Import in the left pane.

Select IMPORT. When using the import function, all settings for tensioning programs and configurations are replaced by the settings from the import file. However, settings for network, PIN, and results and events are not imported.

Select CONTINUE in the dialog box to start the import.

Exported Information and File Format

The exported file is a compressed file archive containing the following files:

All information

PFExport_<datetime>_Results.csv

PFExport_<datetime>_Events.csv

ExportInfo.txt

settings/settings.zip

atlas_tool_i.zip

atlas_sys_i.zip

atlas_subsystems_info.zip

atlas_plc.zip

jsonConfigurations.zip

Settings and configurations

ExportInfo.txt

settings/settings.zip

jsonConfigurations.zip

File | Description |

|---|---|

PFExport__<Tool name>_<Time stamp>_Events.csv | A semicolon-separated file containing the following information:

|

PFExport__<Tool name>_<Time stamp>_Results.csv | A semicolon-separated file containing the following information:

|

ExportInfo.txt | Information about the tool set-up and tool software. |

settings/settings.zip | A binary file containing all tightening programs and Batch settings, Accessory configurations, and tool settings such as: Language, Torque units, Date and time, and Result appearance. |

atlas_tool_i.zip | Tool logs (for debugging) |

atlas_sys_i.zip | Logfiles from IT application |

atlas_subsystems_info.zip | Info about subsystem software |

atlas_plc.zip | PLC configuration |

jsonConfigurations.zip | Multistep Tightening and Loosening programs |

Exporting "System Logs and Information"

With this export a service technician can share the system logs and its information with Atlas Copco Service technicians, in order to facilitate troubleshooting.

The export of system logs and information does not include logs from the connected tool(s).

All data included in the export of system logs and information are stored in a file PFExport_<IAM name>_<datetime>.tar.gz, which includes the following files and directories:

atlas_sys_i.zip - Log files from IT application

atlas_protocol_log.zip – Log files from external protocol adapters

ExportInfo.txt - Text document containing information about the IAM and controller

licenseInformation.zip – License information and system capabilities

atlas_systeminformation.zip – Information to Atlas Copco R&D for current system health and setup

How to Export "System Logs and Information"

Go to Tensioner Controller in the home menu and select Export/Import in the left pane.

In the Export window, open the drop-down menu and select System logs and information.

In the Export window, select EXPORT.

At the end of the exporting process, an exporting pop-up window confirms that the export is done.

A PFExport_<IAM name>_<datetime>.tar.gz file is automatically downloaded.

Working with the Reports Tab

Viewing Results

This section describes how to access tensioning results from the hand controller, and how to read the information given in the different result views.

When a tensioning is performed, the result is stored in the hand controller. Results can also be sent to an external system such as ToolsNet, or exported for analysis using the export function. For more information about statistical analysis, result filtering and tensioning analysis using ToolsNet, refer to the ToolsNet 8 User Guide.

Stored Results

Each task is displayed as one result. A single tensioning can show results in a table with key parameters.

Stored Results View

The hand controller stores the result for every tightening or loosening performed.

Go to Reports in the home menu and select Results in the left pane.

Select View all results. The result list will show information about the following:

Date: date and time the tensioning was performed.

Tightening Program: Tightening Program column shows Multistep Tensioning Program name.

Force: measured force during tensioning.

Pressure: measured pressure during tensioning.

Result: Torque / Angle result.

Limits: Torque range, angle range and pressure range for an OK result. In NOK results the violated range limit is highlighted with red text.

Results marked with a red bar have status NOK.

Viewing Events

Events are used to notify the user of certain state changes or occurrences in the system. They are divided into three types; Information, Warnings and Errors and require different kinds of actions.

Each event has a default setting for whether it should be acknowledged (Ack), logged (Log) or displayed (Disp). These settings can be configured in the Settings menu under Events.

Go to Reports in the home menu and select Events in the left pane.

Select View all events.

Select an event in the list to open the event dialog box.

The Event Dialog Box

The event dialog box contains information about the occurred event describing what has happened, where and when.

Position | Description |

|---|---|

1 | Heading - Describes what part of the system the event concerns. |

2 | Event name - A short descriptive text of the event. |

3 | Code - A unique four-digit number that identifies the event. |

4 | Module - Describes in what part of the system the event concerns. |

5 | Type - Information, Warning or Error. |

6 | Time - Date and time when the event occurred. |

Event Codes

Different types of events are used to notify the user of certain state changes or occurrences in the system. Each event requires a different action.

Some of the procedures described can only be performed by Atlas Copco Service personnel.

For more information about a specific event code, use the below filters or enter the event code search criteria in the search box.

Log / Display / Ack / Conf | |||||||

|---|---|---|---|---|---|---|---|

none | item | none | none | none | column | list | list |

1000 | Info | Controller Started | The controller is started. | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC PFHC | Controller and Tool | ||

1001 | Warning | Controller Serial Number Updated | Generated at start-up if IT-board box serial number (controller serial number) differs from AUX-board box serial number. AUX-board is considered to be non-replaceable in field. The controller will reboot when the serial number is updated. | Replace IT-board or box. | Log Conf | Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Controller and Tool |

1010 | Info | Tool Connected | A tool is connected. | Log Display Conf | Flex Power Focus 6000 Power Focus 8 StepSync Power Focus XC PFHC | Controller and Tool | |

1011 | Info | Tool Disconnected | A tool is disconnected. | Log Display Conf | Flex Power Focus 6000 Power Focus 8 StepSync Power Focus XC PFHC | Controller and Tool | |

1012 | Info | Tool Rejected Controller Connection | This event can occur if the tool is into a skip-zone. | Verify if another controller is connected to the tool. Make sure that the tool settings are correctly set up. | Log Display Conf | Power Focus 6000 Power Focus 8 Power Focus XC | Controller and Tool |

2000 | Warning | Battery Low | Replace battery. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2001 | Warning | Battery Empty | Replace battery. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2002 | Warning | Tool Battery Health Low | Tool battery health problem is detected. | Replace battery. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2004 | Warning | Tool is not of the preferred type | Tool has been replaced by a tool with a different Tool Max Torque. | Change tool. | Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2006 | Warning | Tool Backup Battery Health low | The backup battery in the tool has too poor performance. | The backup battery should be replaced. | Log Display Ack Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2007 | Warning | Tool Backup Battery Missing | Tool backup battery is missing. | Insert battery | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2008 | Warning | Tool Backup Battery Error | Tool backup battery error detected. | Replace battery. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2009 | Warning | Backup Battery Voltage Low | The controller's backup battery is almost empty | Replace battery. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2010 | Error | Tool Software Version Mismatch | Tool and controller software versions not compatible. | Service tool - update tool software. | Log Display Ack Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2012 | Warning | Tool Communication Disturbance | Communication between tool and controller interrupted. | Relocate antenna placement. | Conf | Flex Power Focus 6000 Power Focus 8 StepSync Power Focus XC PFHC | Tool |

2013 | Warning | Illegal Ring Position | Tool direction switch in faulty position. | If occurring frequently - service the tool. | Log Display Conf | Flex Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2014 | Warning | Tool Overheated | Tool overheated. | Allow tool to cool down. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2015 | Error | Tool Temperature Sensor Error | SRB, TBP and IxB tools only. | Service the tool. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2016 | Warning | Tool Pulse Unit Overheated | Pulse unit overheated. Tool is not locked, but the warning is displayed whenever the tool is started as long as the pulse unit temperature is over threshold. | Allow tool to cool down. | Log Display Conf | Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2019 | Warning | Tool Could not Start Motor | Tool motor failure. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2020 | Warning | Tool Requires Motor Tuning | Tool requires motor tuning. | Perform a motor tuning. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2021 | Warning | Motor Tuning Failed | Motor tuning failed. | Complete motor tuning or service the tool. | Log | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2022 | Info | Motor Tuning Completed | Motor tuning completed. | Log Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool | |

2023 | Warning | The Tool Requires Open End Tuning | The tool requires open end tuning. | Perform open end tuning. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2024 | Warning | Open End Tuning Failed | Open end tuning failed. | Try to perform open end tuning one more time. If it fails again, service the tool. | Log Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2025 | Info | Open End Tuning Successful | Open end tuning successful. | Log Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2026 | Warning | Open End Position Failed | Open end position failed. | Press the tool trigger again and wait for the positioning to be completed. If it fails again, service the tool. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2027 | Warning | Usage Limited Due To High Tool Temperature | Temperature limit value has been reached. Tightening has been inhibited to reduce risk for tool shutting down due to overheating. | Wait until tool temperature has been reduced. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2030 | Error | Tool Memory Failure: Change Tool | Tool memory corrupt. | Service the tool. | Log Display Ack Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2031 | Error | Tool Accessory Memory Corrupt | Tool accessory memory corrupt. | Service the tool accessory. | Log Display Ack Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2040 | Error | System Check Failure | Log Display Ack Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool | ||

2041 | Error | Torque Transducer Error | Will be generated either on calibration error or if tool reports transducer error. | Service the tool. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2042 | Error | Angle Transducer Error | Service the tool. | Log Display Ack Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool | |

2043 | Error | Tool Ground Fault Error | Service the tool. | Log Display Ack Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool | |

2044 | Info | Tool Service Interval Expired | Indicates that servicing of the tool is needed. Triggered when the number of set tightenings has been exceeded. | Perform service of tool. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2045 | Warning | Tool Calibration Data Invalid | If validation of calibration data fails. | Service the tool. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2046 | Info | Tool: Next Calibration Date Has Passed | Indicates that calibration of tool is needed. Triggered when calibration alarm is enabled in settings and the current time is greater than next calibration date. | Service the tool. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2048 | Info | Tool Calibration Value Updated By QA Device | Tool calibration was updated when a calibration with a QA device was performed. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2050 | Error | Tool Parameter File Not Supported | Required tool parameters are missing. | Update tool parameters. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2060 | Info | Unexpected Trigger Behavior | Used to prevent start of tool if accessory is connected. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool | |

2071 | Error | Tool Memory Corrupt | Tool descriptor is corrupt. | Service the tool. | Log Display Conf | Flex Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2072 | Info | Unknown Device Connected | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool | ||

2073 | Warning | Tool Trigger Supervision Failure | HW channel failure. Mismatch between hardware and software of tool trigger. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2074 | Warning | Tool Indicator Board Failure | Tool indicator board failure. | Service the tool. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2075 | Warning | Tool Fan Voltage Failure | Tool fan voltage failure. | Service the tool. | Log Display Conf | Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2076 | Warning | Tool Accessory Bus Voltage Failure | Tool accessory bus voltage failure. | Service the tool. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2077 | Warning | Tool Trigger Sensor Error | Tool trigger sensor error. | Service the tool. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2078 | Info | Tool Tightening Program Updated | Tool locked due to tightening program update. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2079 | Error | Tool Cable Not Supported | Tool cable is corrupt. The chip in the cable is not responding or is damaged. | Switch cable. | Log Display Conf | Flex Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Tool |

2080 | Error | Tool Battery Failure | DC voltage too high or too low. Battery failure. | Contact the Atlas Copco service representative and send back battery to Atlas Copco (do not reuse it!). | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2081 | Error | Tool Current Limit Reached | The current limit value has been reached and the drive is disabled. | Service the tool. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2082 | Error | Tool Current Measurement Error | Current measurement error. Current cannot be measured with a reliable result. | Service the tool. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2083 | Error | Tool Internal Error | Various internal hardware errors. | Service the tool. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2084 | Error | Tool Internal Software Error | Various internal software errors. | Service the tool. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2085 | Error | Tool RBU Error | An RBU error was detected by the tool software. | Check that the RBU is correctly installed. If error is still present then service the tool. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2086 | Error | Tool Stall | Tool motor is stalling. | Service the tool. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2087 | Warning | Tool Motor Current High | Tool motor current limit value is exceeded, and the tool is locked. Tool will enter failsafe mode. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2088 | Warning | Tool Battery Current High | Tool battery current is too high. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2089 | Warning | Tool Drive Voltage Low | Tool drive voltage is below the monitored lower voltage limit value. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2090 | Warning | Tool Drive Voltage High | Tool drive voltage is above monitored higher voltage limit value. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2091 | Warning | Tool Main Board Error | Tool main board internal error. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2092 | Warning | Tool Power Module Error | Tool power module internal error. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool | |

2093 | Warning | Pulse Unit Oil Level Low | The oil level of the connected pulse tool is low. | Service the tool. | Log Display Conf | Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2094 | Warning | Pulse Unit Oil Level Empty | The oil level of the connected pulse tool is below required operational level. | Service the tool. | Log Display Ack Conf | Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2095 | Warning | Tool Battery Communication Lost | Tool lost communication with battery. | Make sure battery is snugged correctly. Otherwise change battery. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2096 | Error | Tool Battery Software Version Mismatch | Tool battery software incompatible with tool software. | Update software. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2100 | Info | STwrench smartHEAD Removed | STwrench smartHEAD has been removed. | Reconnect smartHEAD and restart the wrench. | Log Display Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Tool |

2101 | Warning | Wrench Tightening When Locked | A wrench tightening was performed when the tool status was locked in the controller. | Wait until the tool status in controller is unlocked. | Log Display Conf | Power Focus 6000 Power Focus 8 | Tool |

2120 | Warning | Unable To Start: Tool Has No Active Torque Transducer | Log Display | Flex | Tool | ||

2121 | Warning | Transducers Are Disabled For Connected Tool | Log Display | Flex | Tool | ||

2122 | Warning | Unable To Start: Tool Is Missing Required Torque Transducer | Log Display | Flex IxB | Tool | ||

2123 | Warning | Unable To Start: Tool Is Missing Required Angle Transducer | Log Display | Flex | Tool | ||

2124 | Error | Torque Transducer Error On Main Transducer | Shows that there is an error on the Main torque transducer of a Tool with dual transducers. | Log Display | Flex | Tool | |

2125 | Error | Torque Transducer Error On Secondary Transducer | Shows that there is an error on the Secondary torque transducer of a Tool with dual transducers. | Log Display | Flex | Tool | |

2126 | Error | Tool Torque Transducer Calibration Error On Main Transducer | Log Display | Flex | Tool | ||

2127 | Error | Tool Torque Transducer Calibration Error | Log Display | Flex StepSync | Tool | ||

2128 | Error | Tool Torque Transducer: Shunt Test Failed On Main Transducer | Log Display | Flex | Tool | ||

2129 | Error | Tool Torque Transducer: Shunt Test Failed | Log Display | Flex StepSync | Tool | ||

2130 | Error | Tool Torque Transducer: Zero Offset Compensation Failed On Main Transducer | Log Display | Flex | Tool | ||

2131 | Error | Tool Torque Transducer: Zero Offset Compensation Failed | Log Display | Flex StepSync | Tool | ||

2132 | Error | Tool Torque Transducer Hardware Error On Main Transducer | Log Display | Flex | Tool | ||

2133 | Error | Tool Torque Transducer Hardware Error | Log Display | Flex StepSync | Tool | ||

2134 | Error | Tool Torque Transducer Error: Overflow In A/D Converter On Main Transducer | Log Display | Flex | Tool | ||

2135 | Error | Tool Torque Transducer Error: Overflow In A/D Converter | Log Display | Flex StepSync | Tool | ||

2136 | Error | Tool Torque Transducer Calibration Error On Secondary Transducer | Log Display | Flex | Tool | ||

2137 | Error | Tool Torque Transducer Error: Shunt Test Failed On Secondary Transducer | Log Display | Flex | Tool | ||

2138 | Error | Tool Torque Transducer Error: Zero Offset Compensation Failed On Secondary Transducer | Log Display | Flex | Tool | ||

2139 | Error | Tool Torque Transducer Hardware Error On Secondary Transducer | Log Display | Flex | Tool | ||

2140 | Error | Tool Torque Transducer Error: Overflow In A/D Converter On Secondary Transducer | Log Display | Flex | Tool | ||

2202 | Error | Tool HMI overcurrent occurred | Tool HMI overcurrent was detected. | Service the tool. Replace tool HMI. | Log Display Ack Conf | IxB | Tool |

2203 | Error | Tool front light overcurrent occurred | Tool front light overcurrent was detected | Service the tool. Replace tool front light. | Log Display Ack Conf | IxB | Tool |

2204 | Error | Accessory bus overcurrent occurred | Accessory bus overcurrent was detected. | Service the tool. Replace accessory bus. | Log Display Ack Conf | IxB | Tool |

2207 | Error | Vibrator overcurrent occurred | Vibrator overcurrent was detected. | Service the tool. Replace the vibrator. | Log Display Ack Conf | IxB | Tool |

2208 | Warning | System CPU temperature high | System CPU temperature high. | Wait until tool temperature has been reduced. | Log Display Conf | IxB | Tool |

2209 | Error | System CPU temperature critical | System CPU temperature critical. | Wait until tool temperature has been reduced. | Log Display Conf | IxB | Tool |

2210 | Error | Unsupported power source: tightening not permitted | Battery with too low voltage attached to the tool. | Attach battery with higher voltage to the tool. | Log Display Ack Conf | IxB | Tool |

2500 | Error | Tensioner puller bar max number | Tensioner puller bar must be replaced. System is locked for usage. Pressure can only be released. | Send the tensioner to service organization for replacement of the puller bar. | Log Display Ack | PFHC | Tool |

2501 | Error | Pump motor protection alarm | The pump motor protection has stopped the motor. The system must stop. If the system is under pressure, it needs manual actions to release pressure. | Turn off the system. If under pressure, mechanically release the pressure and send the pump to service. | Log Display Ack | PFHC | Tool |

2502 | Error | Pump motor oil level low alarm | The pump motor oil level is low which has stopped the motor. If the system is under pressure, it needs manual actions to release pressure. | Turn off the system. If under pressure, mechanically release the pressure and top up oil. | Log Display Ack | PFHC | Tool |

2503 | Error | Pump motor oil temperature high alarm | The pump motor oil temperature is high. | Turn off the system and wait for the oil to cool down. | Log Display Ack | PFHC | Tool |

2504 | Error | Tensioner pressure sensor alarm | Failure in the pressure sensor electronics of the tensioner. No pressure can be read nor reported to the system. | Turn off the system. If under pressure, mechanically release the pressure and send the tensioner to service. | Log Display Ack | PFHC | Tool |

2505 | Error | Pump pressure sensor alarm | Failure in the pressure sensor electronics of the pump. No pressure can be read nor reported to the system. | Turn off the system. If under pressure, mechanically release the pressure and send the pump to service. | Log Display Ack | PFHC | Tool |

2506 | Error | Unexpected clockwise rotation detected | A clockwise nut rotation while waiting for pressure release after completed tensioning. The result is invalidated. | Release pressure and tension the nut again. | Log Display Conf | PFHC | Tool |

2507 | Error | Unexpected counter clockwise rotation detected | A counter clockwise nut rotation while waiting for pressure release after completed tensioning. The result is invalidated. | Release pressure and tension the nut again. | Log Display Conf | PFHC | Tool |

2508 | Error | Pump or tensioner pressure sensor failure | Too large difference between the pressure sensor readings in the pump and the tensioner. Pressurization is halted. | Problem in the hydraulics or the calibration of the pressure sensors. Restart the system and try again. If the problem repeats, contact your local Atlas Copco sales representative. | Log Display Ack | PFHC | Tool |

2509 | Error | Tensioner pressure sensor failure or hydraulic hose failure | The tensioner's pressure sensor indicates no pressure but the pump's sensor reads a pressure increase. Pressurization is halted. | Problem in the hydraulics or the calibration of the pressure sensors. Restart the system and try again. If the problem repeats, contact your local Atlas Copco sales representative. | Log Display Ack | PFHC | Tool |

2510 | Error | Set custom ID failed | Setting custom ID failed. | Restart the system and check the connected devices. If Custom ID for the unit is wrong, redo the setting. | Log Display Ack | PFHC | Tool |

2511 | Info | Custom ID is set | Setting custom ID succeeded. | Log Display Ack | PFHC | Tool | |

2512 | Warning | Malformed Barcode string, ignored | The scanned string could not be parsed as a tower data bar code. | Scan a proper tower data qr code or scan tower section id. | Log Display Ack | PFHC | Tool |

2513 | Error | No pump pressure detected | The system is trying to pressurize but no pressure increase is registered in the pump. Possible cause is incorrect phase order in the three phase connector. | Power off the system and reverse the phases of the power connector. | Log Display Ack | PFHC | Tool |

2514 | Warning | Tensioner overtorque alarm | Too high torque is applied to the click wrench. This causes damage to the torque sensor. | Relax the torque. | Log | PFHC | Tool |

2515 | Warning | Tensioner overpressure alarm | The pressure in the tensioner is too high. | Let the pressure drop, or release the pressure. Check the hydraulic pressure parameters. | Log | PFHC | Tool |

2516 | Warning | Unexpected Pump or Tensioner firmware | Unexpected Pump or Tensioner firmware version detected, restart system. If the problem persists, the system may be possible to run, but carefully observe any unexpected behaviour. | Power cycle system | Log Display Ack | PFHC | Tool |

2517 | Error | Incompatible Pump or Tensioner firmware version, restart system. The system cannot run. | Incompatible Pump or Tensioner firmware version, restart system. The system cannot run. | Restart system, if this doesn’t help replace the failing unit. Check connected devices to see which one has not connected. | Log Display Ack | PFHC | Tool |

3000 | Error | Controller Internal Software Error | Software error in the controller. | Contact service. | Log Display Ack Conf | IxB Power Focus 6000 Power Focus 8 Power Focus XC | Controller, Drive and StepSync |

3001 | Error | Controller Clock Battery Empty | Internal battery is getting close to end of life. | Replace battery. | Log Display Ack Conf | Flex Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Controller, Drive and StepSync |

3010 | Warning | System Overheated | The controller is overheated. | Cool down. | Log Display Conf | Power Focus 6000 Power Focus 8 Power Focus XC | Controller, Drive and StepSync |

3011 | Warning | Drive Overheated Controller Hardware | Cool down. | Log Display Conf | Flex | Controller, Drive and StepSync | |

3013 | Warning | Usage Limited Due To High Controller Temperature | Temperature limit value has been reached. Tightening has been inhibited to reduce risk for controller shutting down due to overheating. | Wait until controller temperature has been reduced. | Log Display Conf | Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Controller, Drive and StepSync |

3020 | Warning | Controller Hardware Failure | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Controller, Drive and StepSync | ||

3021 | Warning | System Voltage Problem | DC voltage too high or too low. | Log Display Conf | Flex IxB Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Controller, Drive and StepSync | |

3022 | Warning | Controller Voltage Problem: AC Input Voltage Too High | DC voltage too high or too low. | Fix the input voltage. | Log Display | Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Controller, Drive and StepSync |

3023 | Warning | Controller Voltage Problem: AC Input Voltage Too Low | DC voltage too high or too low. | Fix the input voltage. | Log Display | Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Controller, Drive and StepSync |

3024 | Warning | Drive Voltage Problem: AC Input Voltage Too High | DC voltage too high or too low. | Fix the input voltage. | Log Display | Flex | Controller, Drive and StepSync |

3025 | Warning | Drive Voltage Problem: AC Input Voltage Too Low | DC voltage too high or too low. | Fix the input voltage. | Log Display | Flex | Controller, Drive and StepSync |

3030 | Error | IP Address Conflicting With Another Node On The Network | The set IP address is in use by another device on the same network. | Change IP address on one of the devices. | Log Display Conf | Flex Power Focus 6000 Power Focus 8 StepSync Power Focus XC PFHC | Controller, Drive and StepSync |

3031 | Info | Network Cable Unplugged | The carrier of the factory port is lost (cable disconnected). | Check the cable connection. | Log Display Conf | Flex Power Focus 6000 Power Focus 8 StepSync Power Focus XC | Controller, Drive and StepSync |

3032 | Info | Pairing Started | Tool pairing started. | Log Display Conf | Power Focus 6000 Power Focus 8 Power Focus XC | Controller, Drive and StepSync | |