Calculating Statistics

On the Home view, select the Reports Tab. Then, on the left, select Statistics.

In the SPC Configuration window, enter the parameters to collect results stored in the controller (Number of Subgroups, Subgroup Size, and Frequency).

Select the Plus icon at the upper-right corner of the GUI.

The SPC Variable window shows the new variable.

Configure the new SPC Variable.In the SPC Variable window, select Calculate.

Data is collected from the historical results stored in the controller that are aligned with the criteria set in the SPC Configuration window and SPC Variable window. The values of interest are collected into subgroups of the size set in the SPC Configuration window. The collected tightening results on the controller are used for statistics calculations.

It is not possible to calculate statistics for results from deleted tightening programs or Virtual Stations, unless the results are still stored on the controller.

Only 1 user at a time can calculate statistics.

Statistics Formulas

Data in a subgroup is calculated as:

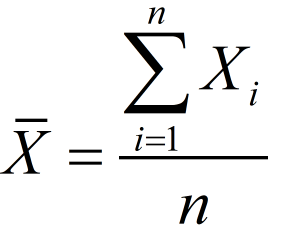

Average:

Range = R = max (Xi) - min (Xi), where i=1...n

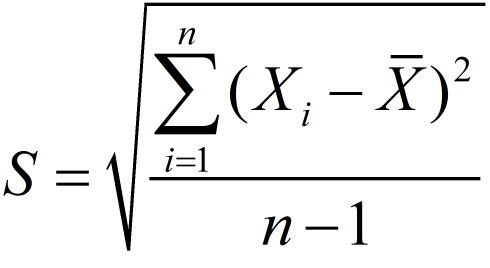

Standard deviation for a subgroup:

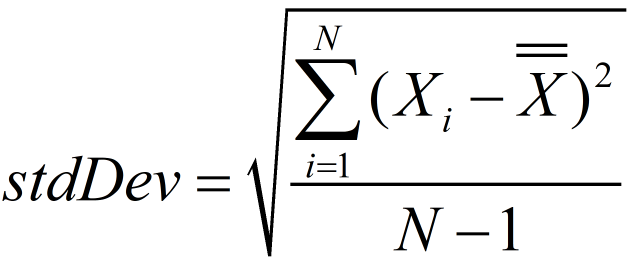

Total overall of the standard deviation:

Where N = total number of observations.

When specified number of subgroups to use for calculations has been collected, the SPC function starts calculations to determine the statistical stability.

Calculations are performed through the following steps: (m = number of subgroups)

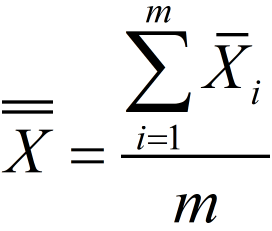

Calculation of Average of Average values:

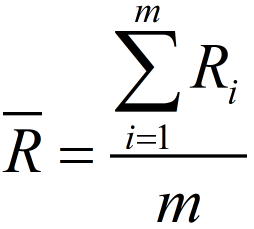

Calculation of Average of Range:

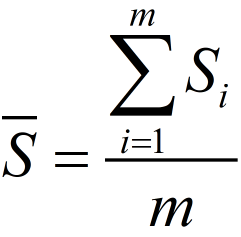

Calculation of Average of Standard deviation:

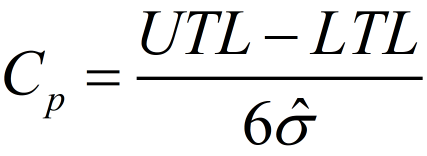

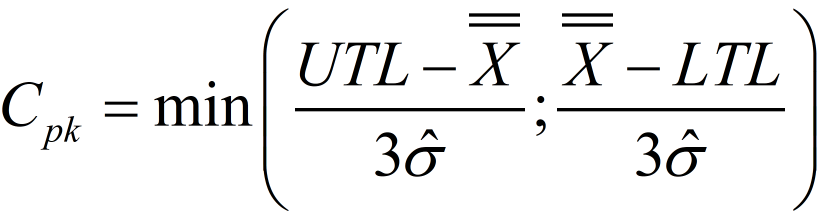

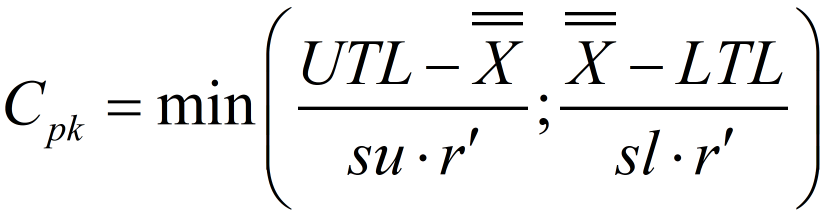

Calculation of the process capabilities Cp and Cpk with respect to Sigma:

Where:

is the overall arithmetic average of the observed characteristic values.

is the overall arithmetic average of the observed characteristic values.UTL is the Upper Tolerance Limit.

LTL is the Lower Tolerance Limit.

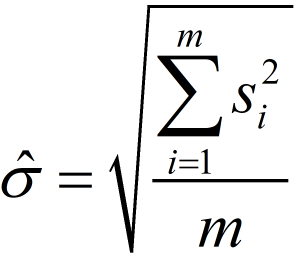

The sigma estimation is the mean square standard deviation within the subgroups:

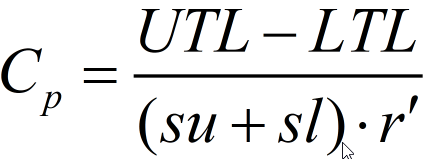

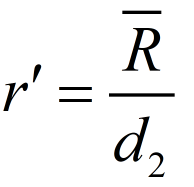

Calculation of the process capabilities Cp and Cpk with respect to Range:

Where for a normal distribution su = sl = 3.

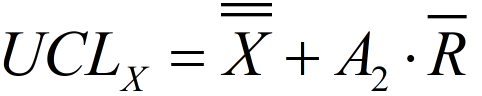

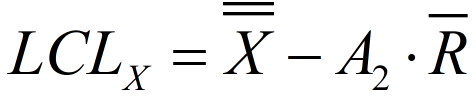

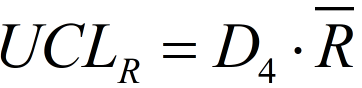

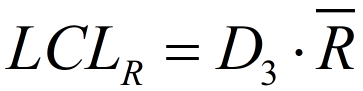

Calculations for control limits if, in the SPC Configuration window, the Auto calculate switch is set to Yes:

X-bar R (Mean)

X-bar R (Range)

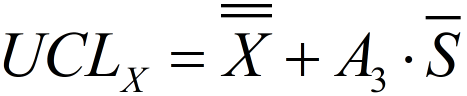

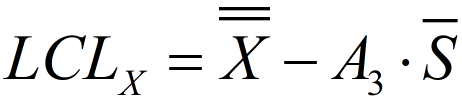

X-bar S (Mean)

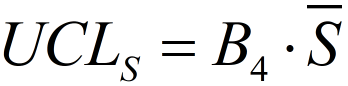

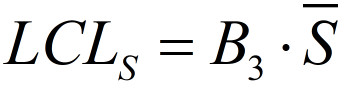

X-bar S (Sigma)

A2, A3, D3, D4, B3, and B4 are constants (for more information, see the "SPC Calculation Constants" paragraph).

SPC Calculations Constants

Subgroup Size | Divisors for estimate of standard dev. | Factors for Control Limits | |||||

|---|---|---|---|---|---|---|---|

Xbar R | Xbar S | ||||||

A2 | D3 | D4 | A3 | B3 | B4 | ||

n | d2 | ||||||

2 | 1.128 | 1.880 | - | 3.267 | 2.659 | - | 3.267 |

3 | 1.693 | 1.023 | - | 2.574 | 1.954 | - | 2.568 |

4 | 2.059 | 0.729 | - | 2.282 | 1.628 | - | 2.266 |

5 | 2.326 | 0.577 | - | 2.114 | 1.427 | - | 2.089 |

6 | 2.534 | 0.483 | - | 2.004 | 1.287 | 0.030 | 1.970 |

7 | 2.704 | 0.419 | 0.076 | 1.924 | 1.182 | 0.118 | 1.882 |

8 | 2.847 | 0.373 | 0.136 | 1.864 | 1.099 | 0.185 | 1.815 |

9 | 2.970 | 0.337 | 0.184 | 1.816 | 1.032 | 0.239 | 1.761 |

10 | 3.078 | 0.308 | 0.223 | 1.777 | 0.975 | 0.284 | 1.716 |

11 | 3.173 | 0.285 | 0.256 | 1.744 | 0.927 | 0.321 | 1.679 |

12 | 3.258 | 0.266 | 0.283 | 1.717 | 0.886 | 0.354 | 1.646 |

13 | 3.336 | 0.249 | 0.307 | 1.693 | 0.850 | 0.382 | 1.618 |

14 | 3.407 | 0.235 | 0.328 | 1.672 | 0.817 | 0.406 | 1.594 |

15 | 3.472 | 0.223 | 0.347 | 1.653 | 0.789 | 0.428 | 1.572 |

16 | 3.532 | 0.212 | 0.363 | 1.637 | 0.763 | 0.448 | 1.552 |

17 | 3.588 | 0.203 | 0.378 | 1.622 | 0.739 | 0.466 | 1.534 |

18 | 3.640 | 0.194 | 0.391 | 1.608 | 0.718 | 0.482 | 1.518 |

19 | 3.689 | 0.187 | 0.403 | 1.597 | 0.698 | 0.497 | 1.503 |

20 | 3.735 | 0.180 | 0.415 | 1.585 | 0.680 | 0.510 | 1.490 |

21 | 3.778 | 0.173 | 0.425 | 1.575 | 0.663 | 0.523 | 1.477 |

22 | 3.819 | 0.167 | 0.434 | 1.566 | 0.647 | 0.534 | 1.466 |

23 | 3.858 | 0.162 | 0.443 | 1.557 | 0.633 | 0.545 | 1.455 |

24 | 3.895 | 0.157 | 0.451 | 1.548 | 0.619 | 0.555 | 1.445 |

25 | 3.931 | 0.153 | 0.459 | 1.541 | 0.606 | 0.565 | 1.435 |