How to calculate the Torque Correction Coefficient

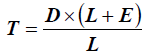

D | Torque value displayed | T | Torque applied |

L | Standard arm (from the center of the handle to the center of the end fitting tool) | L+E | Total arm |

E | Extension arm |

From the relation between the displayed and applied torque  , the Torque correction coefficient is given by the following formula:

, the Torque correction coefficient is given by the following formula:

Torque correction coefficient =

The Torque correction coefficient alters the wrench torque measurement; a wrong value for this coefficient may cause an improper torque reading, and the risk of doing a tightening at a target torque different from the one expected. Ensure you have calculated the proper value when an extension is used.

For end fitting tools used without wrench extensions, the Torque correction coefficient must be left set to 1.

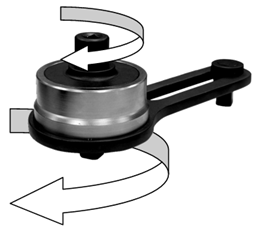

When using an extension, the handling position affects the torque reading. Always position the hand on the center of the STRwrench handle.

If a torque multiplier is used on the STRwrench, the Torque Correction Coefficient must be set equal to the torque multiplying coefficient of the torque multiplier.

The Torque correction coefficient is given by the following formula:

Torque correction coefficient = Torqueoutput / Torqueinput