Lubrication of roller screw housing guides and guide rollers

Add a small amount of grease (Klüberlub® BE 71-501) on all surfaces during reassembly.

Lubricant | Description |

|---|---|

Klüberlub® BE 71-501 | http://www.klueber.com/en/product-detail/id/404/ |

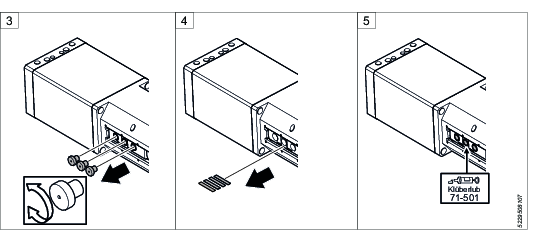

Remove the cover and wipe off grease from the inside using lint-free cloth.

Check for excessive wear.

Check:

the guides on the inside of the cover

the roller bearing surfaces

the roller screw surface

Look for irregular rotation by rotating the guide rollers in the roller bearings before removal.

If the roller bearings are damaged, change all roller bearings see Changing the roller bearings.

Remove leaf springs.

Add a small amount of grease (Klüberlub® BE 71-501) on the guide roller bearings .

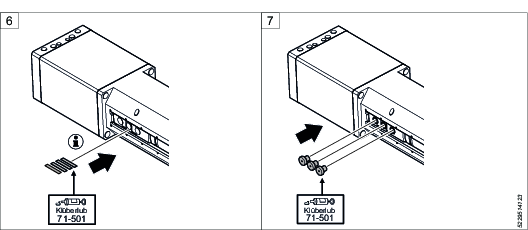

Add a small amount of grease (Klüberlub® BE 71-501) and assemble the leaf springs.

Assemble the guide rollers, add a small amount of grease (Klüberlub® BE 71-501).

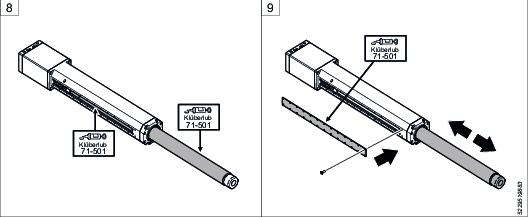

Lubricate the roller screw using grease (Klüberlub® BE 71-501).

Add a small amount of grease (Klüberlub® BE 71-501) on the inside of the cover and reassemble roller screw housing. Cycle the press from max OUT position to max IN position five times at 10mm/s to distribute the grease.

Light force may be needed to fit the center guide roller holder.