Residual Torque / Angle

This strategy evaluates the residual torque on a joint, looking for the residual point of the Torque / Angle trace.

Parameter | Description |

|---|---|

Required tag number | A specific number must be written in the TAG of the end fitting tool. |

Name | Name of the tightening program. |

Program start | Torque value from which the tightening operation starts. |

Torque min | Lower torque limit. |

Torque max | Higher torque limit. |

Maximum torque limit | If the torque applied reaches this limit, the message Change screw is shown on the wrench display. |

Target torque | The torque target. |

Trigger torque | Torque value from which the angle measurement starts (usually set to 50% of the Target torque). |

Angle min | Lower angle limit. |

Angle max | Higher angle limit. |

Target angle | The angle target. |

Torque units | This parameter is not editable. |

Angle limit for rehit | If the Torque min value is reached within the specified angle, the message Joint already tightened is shown on the wrench display. |

Stop condition | Select between Torque peak and Angle peak. |

Breakaway angle threshold | The maximum angle for the residual torque (measured from the Trigger torque). |

Residual angle threshold | The maximum angle (measured from the Trigger torque) for the residual torque when the residual torque is lower than the breakaway point. |

Only breakaway for results | When this parameter is enabled, the detection of the residual point is disabled. |

Torque correction coefficient | When extensions are used, the wrench measurement might be compensated to show a more accurate torque value. To calculate the correction coefficient, please refer to How to calculate the Torque Correction Coefficient. When extensions are not used, Torque correction coefficient = 1. |

Angle correction | When extensions cause additional wrench bending, the wrench angle measurement can be compensated to show a more accurate angle value. When extensions are not used, Angle correction = 0. |

Batch size | Number of tightenings the batch will perform. |

Max consecutive NOK | Number of accepted consecutive NOK to have an OK result. |

End cycle time | Starts when the torque goes below the Program start after reaching the 3rd percentage. |

Ratchet time | Starts when the torque goes below the Program start without reaching the 3rd percentage value. This allows the operator to release the torque for a while and recharge during the tightening operation. |

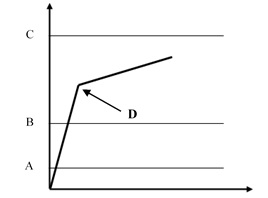

A | Program start | B | Torque min |

C | Torque max | D | Breakaway = Residual |

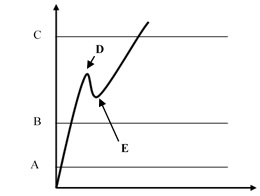

A | Program start | B | Torque min |

C | Torque max | D | Breakaway |

E | Residual |

Define the torque upper and lower limits to get an OK result.

The Trigger torque, which must be greater than the Program start, defines the point from which the device algorithm starts analyzing the torque/angle trace. This is useful to filter all the noise that may occur at low torque value, and that could be detected as a false residual point.

Torque result:

If the residual point is detected, the result is associated with the residual point; the test is OK if the residual falls within the limits.

If the residual is not detected or the torque goes over the maximum torque, the torque result is the maximum measured value. Therefore, if the maximum value falls within the limits, the torque result is still OK, but the overall result is marked as Not OK.

If the torque goes over the Maximum torque limit value, the residual is no longer detected and the torque result is the maximum torque.

In the configuration of the Residual torque/angle strategy, there are two advanced parameters:

Breakaway angle threshold: it specifies the maximum angle for the residual torque (measured from the Trigger torque).

Residual angle threshold: it specifies the maximum angle for the residual torque (measured from the Trigger torque) when the residual torque is lower than the breakaway point.

If the residual point precedes the Residual angle threshold, the residual torque is detected. This is the normal condition for a residual torque test.

If the residual point is over the Residual angle threshold, the breakaway point is the result of the test. In this case, the Residual angle threshold should be increased to detect the proper residual point.

If the breakaway point is over the Breakaway angle threshold, the residual point is not detected even if the residual point precedes the Residual angle threshold

During the test operation, LEDs, buzzer and vibration are activated as follows:

LED:

White LED: activated when the torque value goes over the smartHEAD's Min load value.

First, second and third radial gradient LEDs turn green in sequence when the three thresholds defined for the tool in use are reached.

For further information, refer to Tool LEDs.All three radial gradient LEDs green: torque between Torque min and Torque max.

All three radial gradient LEDs red: torque over Torque max.

Buzzer:

The beep starts when the torque goes over the Program start value; the signal increases when the residual torque is detected / the tightening process has been completed.

Vibration:

Starts when the residual torque is detected.

At the end of the test operation, LEDs, buzzer and vibration are activated as follows:

LEDs behave according to the configuration of Result Indicator and Duration defined for the tool in use.

For further information, refer to Tool LEDs.Buzzer

Two beeps indicate the end of the operation; if the final result is in the red area, the signal in continuous.

To stop the buzzer, start a new tightening operation or press a button on the tool controller.

Vibration:

Stays active until the torque applied is released.