Residual Point Detection Algorithm

To detect the torque/angle residual point, the STRwrench uses an algorithm that calculates the gradient αt of the torque/angle trace by linear regression each time a new sample is collected. The algorithm then calculates the average of six different αt values:

The αaverage value is used to identify the residual point.

Algorithm application scenarios

Scenario A

When high static friction builds up into the joint (for example due to lack of lubrication), as soon as the bolt moves the torque decreases and the real residual torque is lower than the peak torque necessary to overcome the static friction. In this cases, the STRwrench algorithm monitors the αaverage: if αaverage has a negative value, the algorithm waits until the αaverage goes back to a positive value. The point in which the αaverage goes back to a positive value is considered the residual torque point.

A | Maximum torque | B | Minimum torque |

C | Final angle monitoring torque | D | Cycle start |

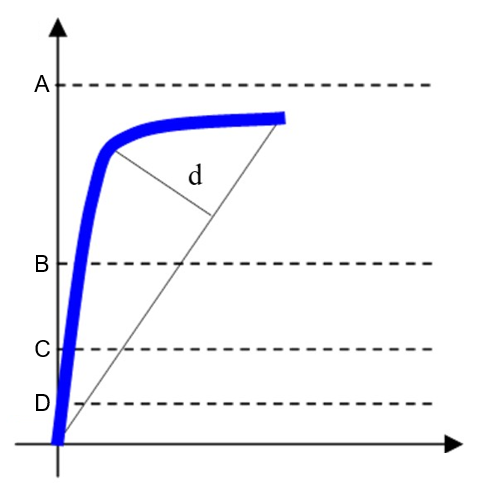

Scenario B

Normally, during breakaway there is a rapid change of the gradient of the torque/angle function when the bolt starts moving. The STRwrench algorithm takes as breakaway point the point of maximum distance (d) between the torque/angle trace and the straight line drawn from graph's origin to the actual point of the trace. This distance must be greater than the threshold and must be consistent for more samples.

In addition, the average slope of the part of the trace after the breakaway point must be less than 60% of the average slope of the part of the trace before the breakaway point.

If all these conditions are met, the test ends and the breakaway/residual point is detected.

A | Maximum torque | B | Minimum torque |

C | Final angle monitoring torque | D | Cycle start |

d | Maximum distance between the trace and the straight line. | ||

Recommended settings

Cycle start | Set a value that is ≥ 2% of the smartHEAD capacity. |

Final angle monitoring torque | Set a value between Cycle start and Minimum torque. |

Minimum torque | Set the minimum residual torque value to get an OK result. |

Maximum torque | Set the maximum residual torque value to get an OK result. |

For instance, a proper setting for detecting the residual point on a bolt tightened to 50 N∙m using an STRwrench with a 80 N∙m smartHEAD could be the following:

A | Maximum torque | B | Minimum torque |

C | Final angle monitoring torque | D | Cycle start |