Setting Hydraulic Pump Stall Pressure

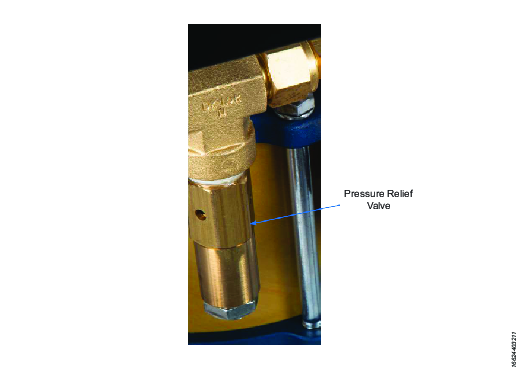

The pressure relief valve (See also Hydraulic Pump Assembly for part 3) is factory set by Atlas Copco not to exceed 1650 bar. If the air pressure is increased by the operator by accident, the pressure relief valve will blow or vent preventing excessive hydraulic pressure from being created.

The hydraulic pump in this unit has a hydraulic to pneumatic ratio of 330:1, hence for a maximum working pressure of 1500 bar, the required pneumatic air pressure is (1500 / 330) = 4.545 bar.

Setting Pneumatic / Air Pressure to Create Hydraulic Pressure

Atlas Copco have supplied a pump unit with a pressure filter regulator set to stall the hydraulic pump at 1650 bar. This has been achieved by setting the pressure relief valve, to blow / vent at 5 bar air input.

Connect the main air supply to the hydraulic pump, see also Before and After Connecting Air Supply. Check the air pressure gauge on the filter regulator is set to zero or minimum air pressure. This is performed by lifting up the adjustment cap on the air filter regulator valve and rotating clockwise to stop.

Close the pressure release valve via the clutch mechanism i.e. rotate in a clockwise direction.

De-press the dead-mans handle to activate the hydraulic pump. The hydraulic pump will stall, due to the lack of air pressure.

With the dead-mans handle de-pressed, slowly increase the air pressure to the required level, by rotating the adjustment cap on the air filter regulator valve anti-clockwise. As the air pressure increases, the hydraulic pressure will increase also. Continue until the desired hydraulic pressure is obtained.

Release dead-mans handle, push down the adjustment cap on the filter regulator. Double check the hydraulic pressure, if suitable release the On/OFF valve.