Introduction

In this section, you can find the basic information about the product and also the formatting conventions used in the topics.

General Data Protection Regulation (GDPR)

This product offers the possibility to process personal identifiable information such as system user name, role and IP-address. The purpose of this processing capability could be to enhance quality control through traceability and proper access management.

If you decide to process personal data you need to be aware of and comply with relevant personal data protection rules, including, in the EU the GDPR as well as other applicable laws, directives and regulations. Atlas Copco can in no way be held liable for any use made by you of the product.

Liabilities and Warnings

Liability

Many events in the operating environment may affect the tightening process and shall require a validation of results. In compliance with applicable standards and/or regulations, we hereby require you to check the installed torque and rotational direction after any event that can influence the tightening result. Examples of such events include but are not limited to:

initial installation of the tooling system

change of part batch, bolt, screw batch, tool, software, configuration or environment

change of air- or electrical connections

change in line ergonomics, process, quality procedures or practices

changing of operator

any other change that influences the result of the tightening process

The check should:

Ensure that the joint conditions have not changed due to events of influence.

Be done after initial installation, maintenance or repair of the equipment.

Occur at least once per shift or at another suitable frequency.

Warnings

About the User Guide

This user guide describes how to set up and configure an IxB tool using the IxB Software.

Revision History

Document Revision | IXB Software Version | Changes |

|---|---|---|

1.0 | 3.3 | First edition |

Target Group

This user guide is intended for anyone configuring or operating an IxB tool using the IxB Software.

Prerequisites

Anyone interested in learning more about the IxB Software can benefit from reading this user guide.

For a complete understanding of the technical aspects in the user guide the following is recommended:

Knowledge about tightening techniques

Experience of working with Power Focus 6000

For more information about Power Focus 6000, refer to the Power Focus 6000 User Guide.

Conventions

To enhance user understanding, certain formatting conventions are used throughout this document. The formatting conventions used are listed below.

Element | Notation | Description | Output |

|---|---|---|---|

General emphasis | In the Program workspace. | To make certain text elements stand out, or to highlight. | Text in Bold |

Graphical User Interface (GUI) items | Select the Function button. | Any reference to items found on screen in the GUI (for example, command buttons, icon names and field names). | Text in Bold |

Graphical User Interface (GUI) Path > | Generally, on the top of the GUI. | Navigation aid which keeps track of the location in the GUI. | For example: Controller > Program > Edit |

User input | Enter a Description for the program. | Any text input by the user. | Text in Bold |

File names | Enter a File Name for the export. | Files either exported from, or imported into the system. | Text in Bold Italic |

Variable and parameter names | Enter a Name for the export. | Variable and parameter names (not values). | Text in Italic |

Variable and parameter values | Enter a VALUE for the export. | Variable and parameter values. | Text in BOLD CAPS |

System output | Client.Domain.Models.ExportImportConfiguration | Any text output by the system. | Text in Monospace |

External links | Links to external sites that have information connected to the document or subject content. These could include:

| Selectable text to external sites | |

Internal documentation links |

If available, these links will be presented below the text. | Selectable text to internal content |

System Overview

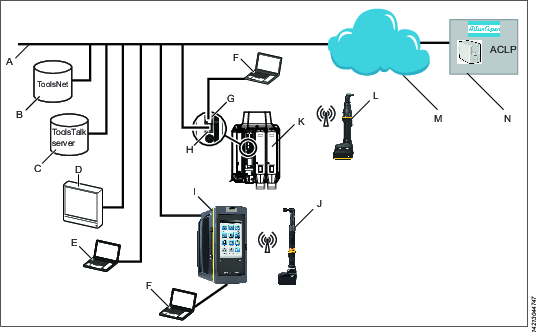

A manufacturing system may consist of the functional blocks in the figure:

A | Factory network. | H | Controller factory port: connected to the factory network. |

B | ToolsNet server: for storing tightening results and for statistical analysis. | I | Power Focus 6000 controller: used with handheld tools. |

C | ToolsTalk 2 server: for configuration and parameter settings for controllers and IXB tools. | J | Handheld battery tool: uses a wireless connection to the controller. |

D | Industrial PC (IPC): can be used as client terminal to the ToolsTalk 2 and ToolsNet servers. | K | PF6 Flex controller: used with fixtured tools. |

E | Portable computer connected to the factory network: can be used as client terminal to the ToolsTalk 2 and ToolsNet servers. | L | IXB handheld battery tool: uses a wireless connection to the factory network. |

F | Service computer: can be connected to the service port of a controller or an IXB tool. | M | The internet cloud. |

G | Controller service port: can be used to connect a service computer. | N | Atlas Copco Licensing Portal (ACLP): located at Atlas Copco and provides support to licensed functionality in the Functional Management System (FMS). |

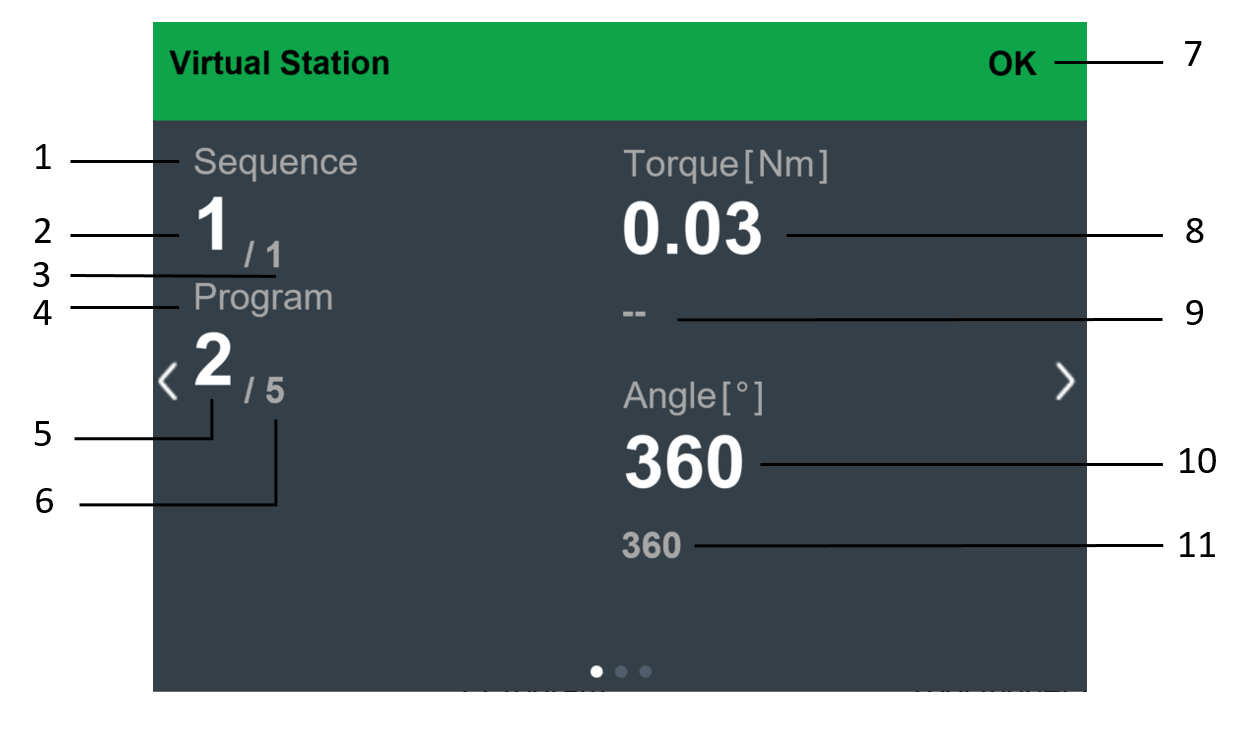

The User Interface

Home Menu

The home menu contains the following items:

Menu Item | Description |

|---|---|

| Tightening The Tightening menu shows a list of existing tightening programs stored in the tool. Selecting an individual program opens the different menus to configure and set parameters for the selected tightening program. |

| Batch Sequence A batch sequence is one or more repetitive tightening programs in various combinations. Batch sequences are created and configured in the Batch sequence menu. |

| Sources The Sources menu lists available options for controlling the selection of a tightening program, or a batch sequence, via digital input from different hardware. |

| Configurations In this menu the following can be configured:

|

| Integrated Controller Tool This menu includes items such as:

This menu also includes functions for software update and export/import of configuration parameters. |

| Reports Displays the latest tightening results, events and NOK ratio. |

| Settings This menu is used to set up specific settings such as:

|

| License Assignment This menu gives an overview of the current license status and license sources. |

| Help The Help menu contains the IxB Software user guide. |

Icons

The following table gives an overview of the icons and buttons available in the user interface:

Icon | Name | Description |

|---|---|---|

| Back | Return to previous view. |

| Home | Go to the Home screen. |

| Go to Results | Go to the live results screen. |

| Padlock | Opens a dialog box for PIN code. |

| Events | Displays the latest tightening events. Define what events to display in the event configurations in the Settings menu. |

| Validate | Validates tightening parameters against tool values. |

| Add | Adds an item. |

| Delete | Deletes an item. |

| Protocol Status | Displays the Status Protocol pop-up window, which shows open protocol information. |

| Notice | Sign showing that a parameter is configured incorrectly. |

Installation and Upgrade

In this section, you can find information to help with the initial installation of the product, or upgrading from one version to another.

Installation Restrictions

Compatibility Matrix

IXB Software | ToolsTalk | ToolsNet |

|---|---|---|

3.3 | 2.14 | 8.14 |

Web Browser Requirements

The following web browsers are recommended for the IxB Software user interface:

Firefox

Google Chrome

Microsoft Edge

Licenses

Feature licenses are managed through the Functionality Management System (FMS). This allows customers to tailor tool functions to their specific needs through a dynamic licensing scheme.

Licenses can be obtained for individual features or collections of features and can be deployed across multiple virtual stations. The licenses can be returned to the pool when they are no longer required.

Licenses can be downloaded from the Atlas Copco License Portal (ACLP) and managed/distributed through ToolsTalk, or can be stored on a FMS Portable (USB drive) to be inserted into the tool.

Note that the creation and management of a customer account in the ACLP is not covered in this documentation. Contact the local Atlas Copco representative for more information.

There are three types of licenses:

Virtual Station Type

A fixed collection of features bundled together in a single package. The Virtual Station Type license determines, among other things, what tools can be run, how many programs and sequences can be used, which tightening strategies are available, and the type of reporting that can be done. The features contained in each Virtual Station Type are features that often are used in conjunction with each other, or which have internal dependencies that require the presence of other features in the package. Virtual Station Types are assigned in their entirety to a virtual station. The virtual station can then make use of all features contained in the Virtual Station Type. In order to be able to perform tightenings, a Virtual Station has to be assigned a Virtual Station Type license. Depending on the license type, various tightening options will be enabled or blocked.

Virtual Station Feature

Individual features can be purchased as a single licenses to complement the virtual station type licenses.

Controller Feature

These are features such as Soft PLC and Step Sync, which are assigned to a controller and once assigned can be used by all virtual stations on that controller.

License Sources

Licenses used on a tool can be pulled from several different sources. The number of simultaneous sources is limited to 10 (either 10 FMS Portable sources, or one License Server (TT2) in addition to nine FMS Portable sources). If a license is to be added from a source when the source limit (10) has been reached, all licenses from one source need to be removed from the tool to make room for licenses from the other source.

The Source Overview tab (License assignment > Source Overview) provides an overview of the licenses installed on the tool, as well as where they were installed from. A maximum number of 10 different sources can be displayed here, and each will be designated with FMS P (for FMS Portable, or dongle), or License Server (TT2).

Selecting any license source will present that source's detailed license source information. It lists the source name and type, as well as the number and type of licenses in each category (Virtual Station Type, Virtual Station Feature and Controller Feature).

Configuration of features governed by licenses can be done even in the absence of an installed license, for example, configuration of tightening programs. Assigning these features to a tool or virtual station is also possible. However, running the feature without a valid license will require the installation of the appropriate license.

License enforcement is performed at two stages: assignment and runtime (trigger pressed). If a feature for which no license is installed is assigned to a virtual station, a red exclamation mark will appear in the tool or task section of the user interface (depending on what is missing). If a feature, for which no license is installed, is started, an event will be presented informing which license is missing. It will not be possible to proceed without a correct license installed. Running an unlicensed feature will, in most cases, result in a locked tool.

Installing Licenses on the Tool

Note that license sources are limited to one (1) License Server (TT2) and nine FMS Portables (USB dongles) simultaneously. Licenses are either installed via the server (ToolsTalk2) or via FMS Portable. If the license source limit is reached, all licenses from one source need to be removed from the tool in order to add licenses from another source.

Existing licenses are checked against the license server every two hours. If no response from the license server is obtained within a period of 14 days, the affected licenses will be revoked. The user will also be warned when licenses are about to expire. When a license is within 7 days of expiration, the user will be presented with a warning once every two hours. If licenses are not renewed, they will expire and the affected functions will no longer be available.

Installing Licenses from the Server

Server based licenses are distributed through ToolsTalk2. For instructions on how to install server licenses, refer to ToolsTalk2 User Guide.

To enable license installation using ToolsTalk2, the correct license server settings must be configured in the tool.

Go to Settings in the home menu ans select Server connections in the left pane.

In the Atlas Copco License Manager field, set the switch to On.

Insert the correct Server port and Server host IP address (usually the same as the IP address for ToolsTalk2).

Select Apply.

Installing Licenses from FMS Portable (USB Dongle)

The Functionality Management System (FMS) uses a special FMS Portable device to transfer functionality to and from a tool. The USB flash drive contains both a general purpose memory area and a trusted storage area that is only accessible by the License Manager in a tool. The purchased feature items are downloaded from Atlas Copco to the general purpose area. The first time the FMS Portable is inserted into a tool with a License Manager, the file is detected and decoded and the feature items are transferred to the trusted storage area that is only accessible from a License Manager.

Connect the USB dongle to the tool via a USB adapter cable.

Prior to the license installation, make sure that the tool has a wireless connection set up to the factory network.

The USB License Management window will appear. The Pool column will show the total license count on the tool from all sources. The Available on FMS P column shows the licenses available on this dongle, while the From this FMS P column shows the number of licenses that have been moved to this tool from this particular FMS P.

Select the left-pointing arrow next to the license you want to install on the tool.

The number in the Available on FMS P column will decrease by 1 and the number in the From this FMS P column will increase by 1.

Removing Licenses from the Tool

Removing Licenses Installed on the Server

For instructions on removing server-installed licenses, refer to the ToolsTalk2 User Guide.

Removing FMS Portable-installed Licenses

Connect the USB dongle to the tool via a USB adapter cable.

Prior to the license removal, make sure that the tool has a wireless connection set up to the factory network.

If the USB License Manager window is not visible, go to License Assignment in the home menu.

Select the USB icon in the top right of the window. The USB License Manager dialog box appears.

Select the right-pointing arrow next to the license that is to be removed from the tool.

Licenses that are assigned to the virtual station can be removed from the tool. However, as a result the virtual station cannot be used.

Upgrading

Software Versions

Two software versions can be installed in the tool simultaneously. Installing a second version of the software is useful when performing upgrades on multiple tools. When production is ready for switching to the upgraded software, activation of the new software version is done from the IXB Software user interface, or with ToolsTalk 2.

Changing software versions does not transfer the tool configurations or tightening programs.

Software Activation

The tool can store two installed software versions. By using the Software activation, it is possible to choose which software version to use.

Go to Integrated Controller Tool in the home menu and select Software in the left pane.

Select Current or Stored in the Software Activation window.

The tool is automatically restarted for the activation to take effect.

Update Software Version

Go to the Integrated Controller Tool menu and select Software in the left pane.

Go to the Software Update field and select BROWSE.

Browse and choose the zip file with the applicable software and follow the instructions to finish installation.

Configuration

In this section, you can find detailed information about how to create, modify, and verify product settings.

Configuration Options

The configuration and setting up of the tool can be done in the following ways:

IxB Software:The tool can be directly connected to a PC via a USB cable. If the tool is connected to a wireless network and its IP address is known, it can be accessed from a computer anywhere on the network.

ToolsTalk 2: If the tool is connected to a ToolsTalk 2 server, a ToolsTalk 2 client (PC) can access all connected tools and controllers through ToolsTalk 2. IxB tools, as well as Power Focus 6000 controllers and Flex controllers can be accessed.

ToolsTalk 2 in Station Setup mode: Provides a ToolsTalk 2 interface on a PC without a server installation. The PC is connected to the controller service port and provides access to one controller at a time.

Controller: This is applicable to Power Focus 6000 controllers which have a touchscreen. A controller can be configured regardless whether it is connected to the network or not.

This user guide covers the IxB Software. For information about ToolsTalk 2 and Power Focus 6000, refer to ToolsTalk 2 User Guide and Power Focus 6000 User Guide.

Getting Started

To create a better overview of the system, this section provides a quick guide covering the basic steps required to get started with the Tensor IxB tool and IxB Software. The section does not explain every feature of the system, but instead focuses on the most basic ones.

Connect the tool to a PC and access the user interface. Set up a wireless connection between the tool and the network.

Define a tightening program containing all relevant parameters of a tightening, for example target angle and target torque.

If applicable, create a batch sequence. One or several tightening programs can be added to a batch sequence which works as a series of tightening programs. A batch sequence can for example be a certain number of tightenings with a tightening program, or a sequence of different tightening programs.

Assign a task to the virtual station of the tool. The task can be either a tightening program, a batch sequence, or a specified digital input (from for example a barcode scanner).

Accessing the IxB Software User Interface

Remove the cover of the tool's USB connection port.

Connect the tool to the USB-port of the PC.

Open a web browser and type in the address of the IxB Software user interface: 169.254.1.1.

To access the user interface wirelessly, refer to the instructions in the section Configure a Wireless Client.

Creating a Tightening Program

Go to Tightening in the home menu.

Select the plus icon.

In the Choose Operation Mode window, select Tightening.

Open the Properties window and type in a valid Maximum Torque Limit for the specific tool. Type Enter. Close the Properties window.

Open the Steps pane on the right and drag and drop the steps to create a tightening program.

Set Monitors and Restrictions for each step as applicable and press the Enter key.

The tightening program must have a loosening program configured.

Go to Tightening in the home menu.

Select the plus icon.

In the Choose Operation Mode window, select Loosening.

Open the Properties window and type in a valid Maximum Torque Limit for the specific tool. Type Enter. Close the Properties window.

Open the Steps pane on the right and drag and drop the steps to create a loosening program.

Set Monitors and Restrictions for each step as applicable and type Enter.

Go to Tightening in the home menu and select a tightening program from the list.

Expand Properties by selecting the arrow.

Under General settings, select Loosening Program and choose a loosening program in the list. Type Enter.

Assigning a Task to the Virtual Station

Go to Integrated Controller Tool in the home menu.

Under Virtual Station > Task select Choose task.

Choose a Tightening program from the list.

Working with the Tightening Tab

This section describes the multistep tightening strategy and how to create a tightening program.

Some features require licenses distributed through the Functionality Management System (FMS). Whereas configuration of features is possible without specific licenses, the assignment and use of those features will require the correct license to be installed on the tool.

Multistep Tightening Strategy

A multistep tightening is a tightening done in several steps. The number of steps and the type of the steps vary depending on the tightening to be done. A multistep tightening program is highly configurable, including monitoring functions and restrictions. A total of 10 steps can be added to a multistep program.

Restrictions are used to make sure the tightening stops if something unexpected occurs. These restrictions could, for example, test that a maximum set torque is not reached or that a part of the multistep tightening does not take too long to run. Every step can have up to four restrictions each. Each step has mandatory step restrictions and optional step restrictions. The mandatory restrictions are included when dragging a new step to the multistep program.

Monitors are used to verify that the tightening was made according to the specification. This can be, for example, angle limits or torque limits. Every step can have up to eight monitors each. Each step has mandatory step monitors and optional step monitors. The mandatory monitors are included when dragging a new step to the multistep program.

Multistep Configuration User Interface

The user interface for configuring a multistep program can be divided into three main areas:

In the top there is a drop-down menu containing the Properties of the multistep tightening program. Here general properties such as program name, overall program monitor and validation can be set.

To the right there are three tabs containing the Steps, Monitors and Restrictions that can be used to build the multistep program. To use any of the items, select the appropriate tab, and drag the item in the list to the tightening area. Depending on its function, either drop the item between the beginning and the end of the program (for steps), or on top of a particular step (for monitors and restrictions).

The main area of the user interface is made up of the tightening area. This is the area that includes all the steps in the tightening program.

Step Parameters

The following step parameters are common for many of the step types. The parameters are set in the step properties window which is displayed when selecting a step in the tightening program.

Parameter | Description |

|---|---|

Name | Name of the step. |

Rotational direction | Each of the tightening steps can run either forward, that is to make a tightening, or reverse, to loosen the screw slightly. The arrows indicate this direction. Many of the tightening steps have a direction hard-coded to forward, for example Tighten to Angle, or Tighten to Torque. Steps such as Loosen to Angle or Loosen to Torque have their direction automatically set to reverse. The reverse setting is not allowed for tools configured with Gear Front Attachment (GFA) of type open end. The tightening direction of the tightening program must be the same as the tightening direction of the open end tool for a tightening to be allowed to be run. It is possible to assign a loosening program to a tightening program for an open end tool, but if the direction switch is set to run the loosening program, the tool will be locked. |

Step category | For each step, there is an option to choose a step category. By selecting step category, the NOK tightenings will be listed in the event result view with related detailed status together with the corresponding multistep error information. If no selection is made, the detailed status will be set to "uncategorized multistep error". The related detailed status can be customized. |

Angle window | A joint is considered Hard if the screw is tightened to its full torque and it rotates 30 degrees (or less) after it has been tightened to its snug point. A Soft joint rotates 720 degrees or more after it has been tightened to its snug point. The hardness parameter defines the Angle Window for the gradient calculation. The harder the joint - the smaller the angle window. |

Speed Ramp / Acceleration (only available in ToolsTalk 2) | For most of the steps it is possible to specify how the acceleration to the target speed should be achieved. Three different settings are possible; Hard, Soft and Manual. The acceleration defined will be used whenever a step is started. Regardless whether the tool is already running with speed at the beginning of the step, the ramp will be used to accelerate to the target speed of the step. This will be the case even if the speed at the start of the step is higher, or lower than the target speed. |

Speed ramp - Hard and Soft mode |

|

Speed ramp - Manual mode |

|

Using speed shifts | 1−5 angle triggers or torque triggers can be defined during a step, where the speed will shift. Within one step, all the speed shift triggers are based on the same property, that is either torque or angle. They cannot be mixed within one step. The Torque triggers and Angle triggers must be less than the step target, depending on the type of the step and the trigger type. The Torque trigger and Torque speed also validate against the Max torque and Max speed of the tool. A warning or error indicator occurs whenever the Speed Shift settings exceed either the tool max values, or step max values. The Torque triggers and Angle triggers must be less than the step target, depending on the type of the step and the trigger type. The Torque trigger and Torque speed also validate against the Max torque and Max speed of the tool. A warning or error indicator occurs whenever the Speed Shift settings exceed either the tool max values, or step max values. It is possible to push the settings to the tool when a tightening program has a warning, but not when a tightening program has an error (fault) indicator. |

Brake type | The braking behavior of a multistep tightening program can be controlled at two possible locations in the program: in a step preceding a reversal of direction of the tightening, and/or at the final step of the tightening program. At other locations in the tightening program, the braking parameters will not be available in the step's general settings. Braking can be set to either Ergo stop or Inertia. Inertia will brake the tool completely, while Ergo stop will allow for a more ergonomic slowing down of the tightening. Inertia has no additional parameters. Ergo stop parameters:

|

Overview of Available Steps

The following steps are available for creation of multistep tightening programs:

W – Wait

In this step the tool waits the specified amount of time. The tool does not rotate while waiting.

The tool waits the specified time. If the hold position is set to On the tool holds the position during the Wait time.

SR - Socket Release

This step runs the tool with speed n in the backward direction until the target angle is reached. The target angle is measured from the start of the step.

This step is only allowed to use as the last step in the tightening path of a multistep tightening program. However, it is possible to add a sync point after this step.

Parameter | Description |

|---|---|

Target angle | The angle target. Default: 3º , must be > 0 |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Speed | Default: 60 rpm. |

A – Tighten to Angle / Loosen to Angle

A – Tighten to Angle

This step runs the tool until the target angle is reached. The target angle is measured from the start of the step.

A – Loosen to Angle

This step runs the tool with the speed n in the backward direction until the angle target is reached. The target angle is measured from the start of the step.

Parameters

Parameter | Description |

|---|---|

Target angle | The angle target. Must be > 0. |

Speed | Default: 60 rpm. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

TrR – Loosen to Trigger Release

This step runs in the backward direction until the tool trigger is released (loosen). It can only be used as a last step in a program.

Parameter | Description |

|---|---|

Speed | Numerical value for rotation speed; in rpm. |

Speed Ramp Type | List of options where speed ramp can be chosen [Hard, Soft, Manual] |

TTTR – Tighten to Trigger Release

This step runs until the tool trigger is released (tighten). It can only be used as a last step in a tightening program.

Parameter | Description |

|---|---|

Speed | Numerical value for rotation speed; in rpm. |

Speed Ramp Type | List of options where speed ramp can be chosen [Hard, Soft, Manual] |

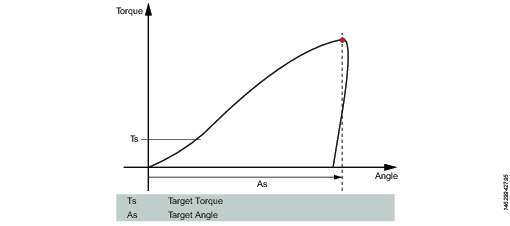

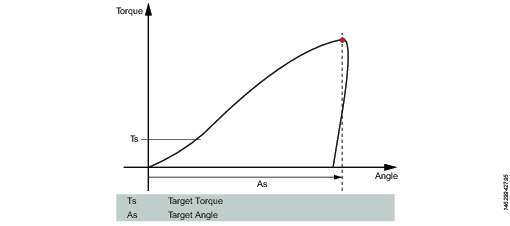

T - Tighten to Torque / Loosen to Torque

T – Tighten to Torque

This step runs the tool with the programmed speed in forward direction until the target torque is reached.

Parameter | Description |

|---|---|

Target torque | The torque target. Must be > 0. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed | Default: 60 rpm. Must be > 0. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

T – Loosen to Torque

This step runs the tool with the speed in the backward direction. For the step to be active, the torque must first exceed 110 % of the Target torque. The Target torque should be set to a positive value. After reaching the target torque, the step runs until the torque drops below the target torque.

Parameter | Description |

|---|---|

Target torque | The torque target. Must be > 0. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed | Default: 60 rpm. Must be > 0. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

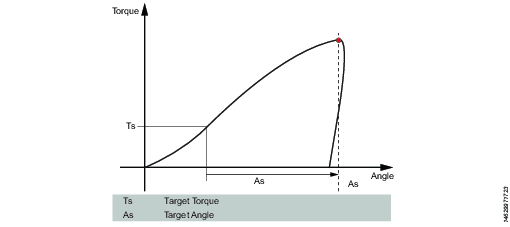

T+A – Tighten to Torque Plus Angle

This step runs the tool until the target torque is reached. From this point it continues to run an additional target angle.

Parameter | Description |

|---|---|

Target torque | The torque target. Must be > 0. |

Target angle | The angle target. Must be > 0. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Speed | Default: 60 rpm. |

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

T|A – Tighten to Torque or Angle

This step runs the tool with the speed n in the forward direction until the first of either torque target or angle target is reached. The torque and angle measurements start at the beginning of the step.

Parameter | Description |

|---|---|

Target torque | Must be > 0. |

Target angle | Must be > 0. |

Speed | Default: 60 rpm. Must be > 0. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

T&A – Tighten to Torque and Angle

The tool runs until with the specified speed in the forward direction until both target torque and target angle are reached. The target torque and the target angle must be set to > 0.

Parameter | Description |

|---|---|

Target torque | Must be > 0. |

Target angle | Default: 0. Must be > 0. |

Speed | Default: 60 rpm. Must be > 0. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

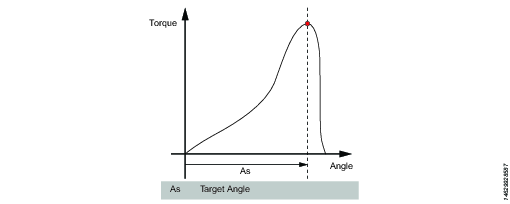

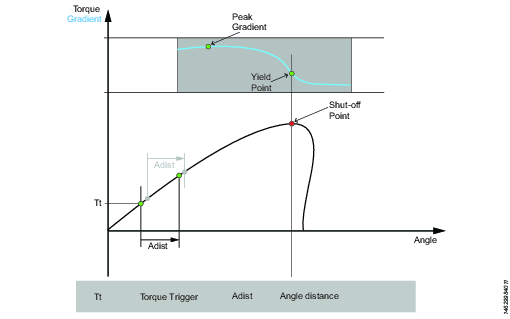

Y – Tighten to Yield

This strategy runs the tool with the speed in the forward direction until the yield point is detected. The yield point is found by monitoring the torque gradient from the point where the torque goes above the Trigger Torque level, calculated based on Torque and Angle distance measurements. The Angle distance parameter is set according to the specified hardness of the joint.

Set the Gradient angle window (for hard joint, for soft joint or for manually setting of the Angle window). If Manual is selected, the Angle Window must be set. A joint is considered Hard if the screw is tightened to its full torque and it rotates 30 degrees or less after it has been tightened to its snug point. A Soft joint rotates 720 degrees or more after it has been tightened to its snug point. The hardness parameter defines the Angle Window for the gradient calculation. The harder the joint - the smaller the angle window.

Parameter | Description |

|---|---|

Gradient Angle Window | Specifies Angle Window:

|

Angle Window | Available when Gradient Angle Window is set to Manual. Must be > 0 and <= 100. |

Trigger Torque | The angle measurement starts at this trigger. Must be >= 0 and < Tool MaxTorque. |

Damping | Frequency in which the gradient is being calculated. Must be > 0 and < 100 and < Angle window. |

Yield Point Percentage | Must be >= 20 % |

Speed | Default: 60 rpm. Must be > 0. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Torque Filter Type | The type of the filter:

|

Cut-off Frequency | Needs to be specified when Torque Filter Type is set to Low pass:

|

Number of Samples | Needs to be specified when Torque Filter Type is set to Sliding Average:

|

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

ThCT – Thread Cutting to Torque

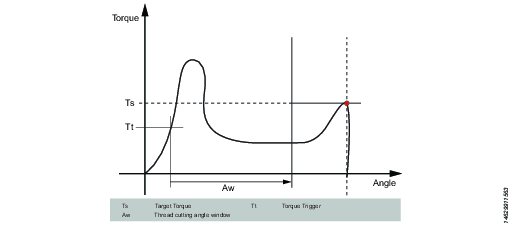

The Thread Cutting to Torque function enables tightening where the Rundown torque required is greater than the Rundown complete torque, for example when tightening thin layers of metal using self-threading (or selftapping) screws. The tool runs in forward direction until the Thread Cutting Angle (Aw) is reached. The thread cutting angle window is measured from when the torque passes Thread Cut Trigger Torque (Ttc) for the first time. From the point where Thread cutting angle is reached, the step continues to run until the Target Torque (Tt) is reached.

Parameter | Description |

|---|---|

Target torque | Must be > 0. |

Thread Cutting Angle Window | Default: 0. Must be > 0. |

Trigger Torque | The angle measurement starts at this trigger. |

Speed | Default: 60 rpm. Must be > 0. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

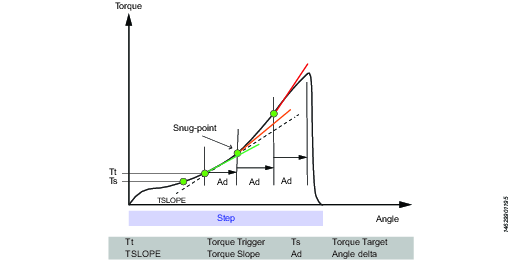

RD – Rundown

Rundown step is the part of the tightening from when the screw enters the thread until just before the screw head touches the underlying surface and snug point is reached. The torque required during rundown does not contribute to any clamping force.

This step runs the tool with the speed in the forward direction, and depending on the Rundown Type, Torque or Snug the step behavior is as follows:

Rundown Type: To Torque: The step stops when the specified target torque is found.

Rundown Type: To Snug: The snug gradient calculation starts at the specified torque trigger level Tt. If no torque trigger is set the gradient calculation is started at the start of the step.

The slope calculation is made between two angle points Ad degrees apart and is calculated as: (Tn – Tn-1) / (An – An-1) and as soon as two slopes after each other are larger than TSLOPE the snug point is found.

Parameter | Description |

|---|---|

Rundown type | To Torque or To Snug. |

Target torque | Default: "not set". Must be > 0. |

Speed | Default: 60 rpm. Must be > 0. |

Speed ramp type | Hard, soft, or manual. Default: Hard. If you select Manual, the Speed ramp field opens. |

Speed ramp | If Speed ramp type is Manual, this field opens. Default: 500 rpm/s. |

Trigger Torque | If Rundown type is To Snug, the Trigger torque field is displayed. Default: "not set". Must be > 0. |

Delta Angle | If Rundown type is To Snug, the Delta angle field is displayed. Default: "0". Must be > 0. |

Torque Rate | If Rundown type is To Snug, the Torque rate field is displayed. Default: "0". Must be > 0. |

Brake (Only valid for PF6 Flex and PF6 Stepsync controllers). | If On the tool will be stopped when the target is reached. If Off the program goes directly to the next step without stopping the tool. |

Engage (E)

This step runs the tool in both directions until the socket engages the screw. The step continues until Target torque or Target angle is reached, provided that Continue if not Engaged is set to Yes. If Target Angle is reached in any direction, the direction is reversed. Limit the search iterations by entering Max Engage Attempts. If Target Torque is reached in any direction the step will finish with OK status.

Ext - External Result

External result is a strategy used when an OK tightening is indicated by an external digital signal (and not by torque or angle values measured during tightening). This external signal can be provided through any means that can provide a digital signal to the tool.

When the signal is sent, the result view (logged data) will show the value of the Target parameter provided in the tightening program (specified torque value, angle value, or text string). These (torque and angle) values do not represent actual measured values, but only inserted text.

Parameter | Description |

|---|---|

Torque <Target torque> | Numerical value for desired displayed target torque value. A signal could for example come from a Click Wrench and display <Target torque>. |

Angle <Target angle> | Numerical value for desired displayed target angle value. A signal could for example come from a Click Wrench and display <Target angle>. |

Text | Alphanumerical string for desired displayed text. For example: "Oil has been changed". |

The following steps are not supported:

Step Label | Name |

|---|---|

DI | Run until Digital Input - N/A |

DT | Tighten to DynaTork - N/A |

MWR | Mechatronic Wrench - N/A |

WP | Wrench Production - N/A |

WQ | Wrench Quality - N/A |

C | Clutch - N/A |

CL | Clutch Loosening - N/A |

TM | Manual Tighten to Torque - N/A |

Overview of Available Step Monitors

Step monitors are used to verify that the tightening was achieved according to the specification, for example, angle limits or torque. Each step has mandatory step monitors and optional step monitors. The mandatory monitors are included when dragging a new step to the multistep program. The optional monitors are flexible and can be added as needed in the multistep program. Each step can have up to eight monitors.

The Angle and Peak Torque monitors are automatically added by default to every step in a multistep tightening program.

A – Angle

This step monitor measures the maximum angle reached during the monitor and checks that it is between High limit and Low limit. The angle measurement starts at the start of the monitor or, if specified, at the point where the torque passes Trigger torque for the first time during the monitor.

Parameter | Description |

|---|---|

Type | Four angle types are available: Peak angle (default), Angle at peak torque, Shut off angle, and Angle at end. |

Trigger torque | The angle measurement starts at this trigger. |

Low Limit | Lowest acceptable angle. |

High Limit | Highest acceptable angle. |

YA – Angle from Yield

This monitor measures the peak angle reached from the yield point and checks that the peak angle is within the limit.

This step monitor is not available for the STB tools.

Parameter | Description |

|---|---|

Gradient Angle Window | Specifies Angle Window:

|

Angle Window | Available when Gradient Angle Window is set to Manual. Must be > 0 and <= 100. |

Yield Point Percentage | Must be >= 20 % |

Trigger Torque | The angle measurement starts at this trigger. Must be > 0 and < Tool MaxTorque. |

Damping | Frequency in which the gradient is being calculated. Must be > 0 and < 100 and < Angle window. |

Low Limit | Lowest acceptable angle. Must be >= 0 |

High Limit | Highest acceptable angle. Must be > 0 |

Torque Filter Type | The type of the filter:

|

Cut-off Frequency | Needs to be specified when Torque Filter Type is set to Low pass:

|

Number of Samples | Needs to be specified when Torque Filter Type is set to Sliding Average:

|

MT – Mean Torque

This monitor measures the average torque during the monitor and checks the calculated value is within the limits.

Parameter | Description |

|---|---|

Type | Specifies start condition:

|

Torque Trigger | Available when Type is set to Trigger Torque, Angle Trigger or Angle Window. Must be >= 0 and < Tool Max Torque. |

Angle Trigger | Available when Type is set to Angle Trigger or Angle Window. Must be > 0. |

Angle Window | Available when Type is set to Angle Window. Must be > 0.

|

Time Interval | Available when Type is set to Time Interval. Must be > 0. |

Low Limit | Lowest acceptable torque. |

High Limit | Highest acceptable torque. |

PT – Peak Torque

This step monitor measures the maximum torque reached during the monitor, including any over shoot, and checks that it is between High limit and Low limit.

Parameter | Description |

|---|---|

Low Limit | Lowest acceptable torque. |

High Limit | Highest acceptable torque. |

PTCA – Post Thread Cut Angle

Measures the angle achieved during the monitoring and checks that it is between the specified angle limits. The Trigger Torque level is ignored until the end of the Thread cut angle window is reached. After that, the angle measuring starts as soon as the measured torque is above Trigger Torque. The parameter Stop Condition specifies where the angle measurement should end.

Parameter | Description |

|---|---|

Trigger torque | Must be >= 0 |

Thread cutting angle window | Must be > 0 |

Angle measurement type | Peak angle Angle at peak torque Shut off angle Angle at end |

Thread cut trigger torque | Must be >= 0 |

Low Limit | Must be >= 0 |

High Limit | Must be > 0 Must be > Low limit |

PTCPT – Post Thread Cut Peak Torque

Measures the maximum torque achieved during the monitoring, including any over-shoot, and checks that it is between the Torque limits. All torque values are ignored until the end of the Thread cut angle window has been reached.

Parameter | Description |

|---|---|

Thread cut trigger torque | Must be >= 0 |

Thread cutting angle window | Must be > 0 |

Low Limit | Must be >= 0 |

High Limit | Must be > 0 Must be > Low limit |

PVTH – Post View Torque High

This monitor checks that all torque values in the angle window are below the limit.

All torque values in the Angle Window Length should be below the High limit. The Angle Window starts at the angle degrees set in Start Angle in reverse direction from the shut-off point. This then spans for the angle degrees set in Angle Window Length in reverse direction. If Start Angle is left blank the Angle Window starts at the shut-off point. The torque values used in the monitor are based on the mean torque value, calculated over Number of Samples. If the total angle of the step is less than Start Angle plus Angle Window Length the monitor will report NOK.

Parameter | Description |

|---|---|

Start Angle | Must be >= 0 |

Window length | Must be <= 0 |

Number of samples | 1 |

High Limit | Highest acceptable torque. |

PVTL – Post View Torque Low

Same as monitor Post View Torque High but this monitor checks that all torque values in the Angle Window Length are above Low Limit instead.

Parameter | Description |

|---|---|

Start Angle | Must be >= 0 |

Window length | Must be <= 0 |

Number of samples | 1 |

Low Limit | Lowest acceptable torque. |

PrT – Prevailing Torque

The monitor calculates the prevailing torque value in the Window Length and checks that it is between the Torque limits. The Angle Window starts at the angle degrees set in Start Angle in reverse direction from the shut-off point. This then spans for the angle degrees set in Angle Window Length in reverse direction. If Start Angle is left blank the angle window starts at the shut-off point. The calculated prevailing torque value is the mean or peak torque value (depending on the parameter set by the user) during the Window Length. The calculated value is saved as result data Prevailing Torque Measured. If Torque compensation is set to On, the Prevailing Torque Measured will be subtracted from all torque result values in consecutive steps. Any previously calculated prevailing torque compensation values will no longer be subtracted from torque result values. If Torque compensation is set to No, no subtraction will be made in consecutive steps.

If the total angle of the step is less than the Start Angle plus Window Length, then the monitor will report NOK.

Prevailing torque can be measured as an average of measured values, or at peak torque. To choose between these two modes, set the Use Value parameter to either Mean torque (for average values), or Peak torque (for peak value).

Parameter | Description |

|---|---|

Torque Compensation | On or off. |

Start Angle | Must be > 0 |

Window length | Must be >= 0 |

Low Limit | Must be > 0 |

High Limit | Must be >= 0 |

Use value | Mean torque (for average values), or Peak torque (for peak value). |

SOT – Shut Off Torque

The shut off point is the point where the step reaches its target. The torque is measured at the shut off point and checked to be between High limit and Low limit.

Parameter | Description |

|---|---|

Low Limit | Lowest acceptable torque. |

High Limit | Highest acceptable torque. |

SOC – Shut Off Current

The shut off point is the point where the step reaches its target. The current is measured at the shut off point and checked to be between High limit and Low limit .

Parameter | Description |

|---|---|

Low Limit | Lowest acceptable current. |

High Limit | Highest acceptable current. |

SSD - Stick Slip Detection

This step monitor detects and reports stick slip effects during a step. The detection is done by counting the number of times the torque falls below the Trigger Level. If the number of times is larger than Maximum Number of Oscillations then the stick slip error is reported. The monitor operates in two different modes, Dynamic or Fixed. The difference between the modes is the way that the Trigger level is calculated.

Dynamic Torque: Trigger Level is dynamically calculated as Peak Torque Percentage of the current max torque, which has been achieved so far during the monitoring. The monitoring is started as soon as the torque passes the Trigger Torque.

Fixed Torque: Trigger Level is the fixed Trigger Torque specified by the user. In this mode the percentage is not needed.

If the torque never reaches the Trigger Torque then the monitoring is not started, this will result in status NOK.

Parameter | Description |

|---|---|

Type | Specifies what type of Stick slip detection that will be done in the monitor Stick Slip detection. Default: Dynamic torque. |

Peak Torque Percentage | Default: 80%, Must be >=10 and < 100. |

Trigger Torque | Default: 5, Must be >= 0 and < Tool max torque. |

Maximum Number of Oscillations | Default: 5, Must be >= 3 and <20. |

Ti – Time

Measures the elapsed time during the monitor and checks that it is between the time limits. The time measurement starts at the start of the monitor and, if the Trigger Torque is specified, at the point where the torque passes Trigger Torque for the first time during the monitor.

Parameter | Description |

|---|---|

Trigger Torque | Must be >= 0 and < Tool max torque. |

Low Limit | Must be >= 0 |

High Limit | Must be > 0 Must be > Low limit |

TG – Torque Gradient

This monitor checks the gradient is within the limit.

Parameter | Description |

|---|---|

Gradient Angle Window | Specifies Angle Window:

|

Angle Window | Available when Gradient Angle Window is set to Manual. Must be > 0 and <= 100. |

End Point Check | If set to Yes, only the gradient measured at the shut off point of the step is checked to be within the limits. |

Trigger Torque | The angle measurement starts at this trigger. Must be > 0 and < Tool MaxTorque. |

Damping | Frequency in which the gradient is being calculated. Must be > 0 and < 100 and < Angle window. |

Low Limit | Lowest acceptable torque gradient. Must be >= -100. |

High Limit | Highest acceptable torque gradient. Must be > -100 and > Low limit. |

Torque Filter Type | The type of the filter:

|

Cut-off Frequency | Needs to be specified when Torque Filter Type is set to Low pass:

|

Number of Samples | Needs to be specified when Torque Filter Type is set to Sliding Average:

|

Angle Offset | Available when End Point Check is set to No. Specifies the degrees that the calculation of the gradient start after the trigger torque is passed for the first time. |

TAW – Torque in Angle Window

This monitor checks that all torque values in the angle window are within the torque limits.

Parameter | Description |

|---|---|

Trigger Torque | Must be >= 0 |

Start Angle | Must be > 0 |

Window Length | Must be <= 0 |

Low Limit | Must be >= 0 |

High Limit | Must be > 0 Must be > Low limit |

NOK if window is passed | If set to Yes, status of this monitor is NOK if the end of angle window is not reached. |

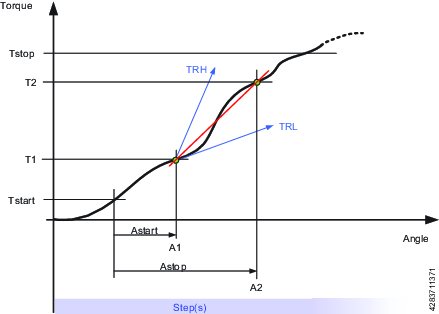

TRD – Torque Rate and Deviation

This step monitor measures and checks the torque rate, i.e. the ratio of torque vs. angle. The calculated torque rate is checked if it is within the torque rate limits defined by High Limit and Low Limit.

Parameter | Description |

|---|---|

Trigger Torque | Torque of the angle start point. |

Start Point Angle | When Start point angle has been measured from Trigger torque the measuring of the torque starts. |

End Point Angle | Angle point where the measuring of the torque is stopped. |

End Point Torque | Torque where the measuring of the torque is stopped. |

Low Limit | Lowest acceptable torque. |

High Limit | Highest acceptable torque. |

Limit | Must be > 0 |

Tstart = Torque from where AngleStart starts

Tstop = Torque where the measuring of the torque is stopped.

Astart = When AngleStart has been measured from TorqueStart the torque starts to be measured.

Astop = Angle point where the measuring of the torque is stopped.

TRL = Low Limit

TRH = High Limit

The following monitors are not supported:

Monitor | Description |

|---|---|

CL | Click - N/A |

LD | Loosening Detection - N/A |

Overview of Available Step Restrictions

To make sure the tightening stops if something unexpected happens, it is possible to add restrictions to the multistep tightening program. These restrictions could, for example, test that a maximum torque is not reached or that a part of the multistep tightening does not take too long to run. Each step has its own set of mandatory step restrictions and optional step restrictions. The mandatory restrictions are included when dragging a new step to the multistep program. All steps can have up to four restrictions each.

The following restrictions are automatically added to every step that is added to the multistep tightening program:

Step Restriction | Applicable Steps |

|---|---|

Maximum Time | All |

Maximum Torque |

|

Maximum Angle |

|

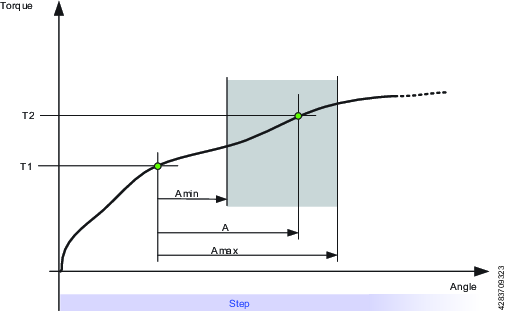

CTh – Cross Thread

This restriction checks the angle from the point where torque passes Start torque (T1) to the point where the torque passes End torque (T2). If the angle measured from Start torque (T1) is higher than Maximum limit (Amax), the tool is stopped immediately.

When the torque passes End torque (T2), the measured angle is checked against the limit Minimum limit (Amin). If the angle is lower than this limit, the tool is stopped immediately.

Parameter | Description | In illustration |

|---|---|---|

Start Torque | Must be <=0. | T1 |

End Torque | Must be <=0. | T2 |

Minimum Limit | The low angle limit. | Amin |

Maximum Limit | The high angle limit. | Amax |

A – Maximum Angle

This restriction measures the angle. If the measured angle reaches the Maximum Limit, the tool is stopped immediately. The angle is measured from the start of the restriction or, if specified, from the point where the torque passes Trigger Torque for the first time during the restriction.

Parameter | Description |

|---|---|

Trigger Torque | If specified, this is the torque from where the angle is measured. |

Maximum Limit | If this limit is reached the tool is stopped immediately. |

T – Maximum Torque

This restriction checks the torque. If the measured torque exceeds the Maximum limit, the tool is stopped immediately.

Parameter | Description |

|---|---|

Maximum Limit | If the torque reaches this specified limit the tool is stopped immediately. |

Ti – Maximum Time

This restriction checks the time. If Maximum Limit is reached, the tool is stopped immediately.

Parameter | Description |

|---|---|

Maximum Limit | If this time is elapsed, the tool is stopped immediately. |

Rh – Rehit

This restriction checks the torque. If the measured torque exceeds the Detection Torque, the tool is stopped immediately and the program jumps to the end of the program. It is only possible to add step Rehit restriction to the first step of the multistep tightening program. Once the Rehit restriction has been added to the first step it shall not be possible to move the step to any other position within the tightening program. The Rehit restriction has to be deleted from the first step in order to move it to other position in the tightening program.

Parameter | Description |

|---|---|

Detection Torque | If the measured torque exceeds the Detection Torque, the tool is stopped immediately and the program jumps to the end of the program. Must be greater than zero. |

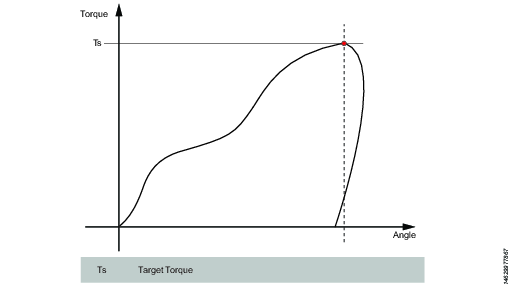

RT – Rescinding Torque

This restriction checks the torque and if the measured torque drops below the condition of the restriction the tool is stopped immediately and the program jumps to end of the program. There are two methods of Rescinding Torque Restrictions for Torque and Angle control processes

Parameter | Description |

|---|---|

Type | Torque control processes or Angle control processes. Torque control processes: Torque control processes checks the torque. If the measured torque drops below the Rescinding Torque Limit the tool is stopped immediately and the program jumps to the end of the program. For the restriction to be active the torque must first exceed 110 % of the Rescinding Torque Limit Angle control processes: This restriction checks the maximum torque reached during the restriction. For the restriction to be active the torque must first exceed the Trigger Torque. If the measured torque drops below the maximum torque for longer time than Rescinding Torque Time the tool is stopped immediately and the program jumps to the end of the program. |

Rescinding Torque Limit | Default: 10 Nm. Must be > 0. |

TG – Torque Gradient

This restriction checks the gradient and if it is outside the limits the tool is stopped immediately and the program jumps to the end of the program.

Parameter | Description |

|---|---|

Gradient Angle Window | Specifies Angle Window:

|

Angle Window | Available when Gradient Angle Window is set to Manual. Must be > 0 and <= 100. |

Trigger Torque | Must be > 0 and < Tool MaxTorque. |

Damping | Frequency in which the gradient is being calculated. Must be > 0 and < 100 and < Angle window. |

Minimum Limit | Must be >= -100. |

Maximum Limit | Must be > -100 and > Low limit. |

Torque Filter Type | The type of the filter:

|

Cut-off Frequency | Needs to be specified when Torque Filter Type is set to Low pass:

|

Number of Samples | Needs to be specified when Torque Filter Type is set to Sliding Average:

|

TAW – Torque in Angle Window

This restriction checks that the measured torque in the Angle Window Length is between the Torque limits. If the measured torque is outside the limits the tool is stopped immediately and the program jumps to the end. The Angle Window Length starts at the Start Angle from the point that the torque first passed the Trigger Torque. If Trigger Torque is not set, then the Start Angle begins at the start of the restriction.

If the end of the Angle Window Length is not reached, the status of the restriction is NOK.

Parameter | Description |

|---|---|

Trigger Torque | Must be >= 0 |

Start Angle | Must be >= 0 |

Window Length | Must be >0 |

Minimum Limit | Must be >= 0 |

Maximum Limit | Must be <= Minimum limit |

TCD - Torque vs Current Deviation

This restriction verifies that all current measurements converted to the corresponding torque are, at most, the Maximum deviation away from the actual torque measured with the torque transducer. The restriction starts when the torque reaches Trigger Torque for the first time during the step and is active until the step reaches its target.

If Trigger Torque is never reached, the monitor will report OK.

Parameter | Description |

|---|---|

Trigger Torque | Must be >= 0 |

Maximum Deviation | Default: 1, Must be > 0 |

Tightening Program Properties

General settings

Parameter | Description |

|---|---|

Name | A user-defined name for the multistep program. |

Thread Direction | Direction of the threads, either clockwise or counterclockwise |

Loosening Program | Indicate if a loosening program is available. Choose from the list of available loosening programs in the software. |

Type | Type of program, either Tightening or Loosening |

Program Start | Sets the torque level for generating a result. If left blank, the result is generated every time the tool is started; otherwise result is only generated from the set torque level. |

True Angle Compensation | Tools equipped with a gyro can measure the tool rotation during tightening. If the tool is rotated during tightening, the angle measurement may be corrupted. This leads to faulty tightening if made to angle references. With True Angle Compensation the tool can compensate for these rotations and make a correct tightening. Only tools equipped with a gyro have the capability to measure the tool rotation. True Angle Compensation is not supported for ICB tools. True Angle Compensation is not supported for tools with a crowfoot (Gear Front Attachment) installed. |

Program Monitor

Parameter | Description |

|---|---|

Angle | Turn angle monitoring On or Off for the entire program. If Active in steps and Trigger Torque are left blank, angle monitoring will start at program start. |

Active in steps | Sets a range of steps the angle monitoring is valid for. If no end step is specified, angle monitoring will stop at the last step of the program that is not a Socket Release step. |

Type | Type of angle monitoring. Choose between:

|

Trigger torque | Sets the value of the trigger torque for angle monitoring. |

Low limit | Sets angle monitoring (program) lower limit |

High limit | Sets angle monitoring (program) higher limit |

Program Restrictions

Parameter | Description |

|---|---|

Maximum Time Limit | Set amount in seconds. This restriction checks the total time for the tightening and if it exceeds the Time High limit the tool is stopped immediately. The time is measured from the start of the program. |

Maximum Torque Limit | This restriction checks the torque and if the measured torque exceeds the Torque High limit the tool is stopped immediately. |

Validation

During the configuration of tightening programs, the entered values are compared with the tool capability values to prevent parameters being outside the selected limits. User-defined maximum values are useful if many different tools are being used.

Parameter | Description |

|---|---|

Validate against tool values | On: entered values are compared with the tool capability values Off: no validation performed |

Tool | Shows the tool to compare the values with. |

Attachment Tuning

Attachment tuning gives the possibility to compensate for front attachments on the tool. The compensation can be made for each tightening program.

An operator can hot swap attachments and then select a tightening program tuned for that specific attachment.

Parameter | Description |

|---|---|

Use Attachment Tuning | Yes or No |

Gear Ratio | The Attachment gear ratio is needed to compensate the angle. Minimum: 0.5 Maximum: 3.6 Socket rotation speed = Tool speed / gear ratio |

Efficiency Tuning | Attachment gear ratio combined with the Efficiency tuning is needed to compensate the torque. Minimum: 0.5 Maximum: 1.0 For example 0.9 means 10% efficiency loss. |

Configuring a Tightening Program

Adding a Tightening Program

Go to Tightening in the home menu and select Multistep program library in the left pane.

Select the plus icon and choose the appropriate type of program in the dialog box (Tightening or Loosening).

Continue with adding steps, monitors, and restrictions to the program in the tightening area.

A maximum of 10 steps can be added to a tightening program.

Deleting a Tightening Program

Go to Tightening in the home menu and select Multistep program library in the left pane.

Select the multistep tightening program that is to be deleted.

In the program itself, at the bottom left, select Delete.

Confirm by selecting Yes in the dialog box.

Creating a Multistep Program

To create a multistep program, drag and drop steps, monitors and restrictions in the tightening area.

Steps can only be placed between the start and end points of the program, whilst monitors and restrictions can only be placed on steps.

Function | Description | |

|---|---|---|

Start and end points |  | Start and end points of the multistep program. All steps must be placed between these two points. |

Adding a step |  | Drag a step from the list and drop it in the desired position between the start and end points. |

Moving a step |  | Click and hold a step and move it to the desired position |

Showing step properties |  | Click on the step to reveal the properties |

Closing step properties |  | Click anywhere in the tightening area to close the properties menu |

Deleting a step |  | Open the step properties and click Delete at the bottom of the menu |

Adding a restriction/monitor |  | Drag a restriction/monitor from the list and drop it on the appropriate step. |

Moving a restriction/monitor |  | Click and hold the icon (checkmark for monitor, stop sign for restriction) and drag and drop it on the appropriate step |

Showing restriction/monitor properties |  | Click on the restriction/monitor icon to reveal the properties menu |

Closing restriction/monitor properties |  | Click anywhere in the tightening area to close the properties menu |

Deleting a restriction/monitor |  | Open the restriction/monitor properties and click on Delete at the bottom of the menu |

Step error |  | When a validation error occurs in a step, that step will be marked. Note that when the step properties are opened, the parameter causing the error will also be marked. |

Monitor/Restriction error |  | When a validation error occurs in a monitor or restriction, that monitor or restriction will be marked. Note that when the monitor/restriction properties are opened, the parameter causing the error will also be marked. |

Forbidden placement |  | When a particular placement (of a step, monitor or restriction) is not allowed, the placeholder icon will not be shown. |

Working with the Batch Sequence Tab

Batch sequences are used to perform a specified number of tightenings in a specific order.

The tightening order can either follow a fixed scheme, or be left to the operator to decide in a free-order scheme. In either case, the sockets or signals can be used to communicate between the tool and the operator.

A Batch is set up to perform a specified number of consecutive tightenings using the same tightening program. Batches must have tightening program and batch size specified in order to run.

A Batch Sequence is an ordered set of batches, when the operation requires a combination of batches/tightening programs.

A batch sequence can consist of up to 99 batches, with a batch size of up to 99 tightenings. The batches in a batch sequence are carried out in the order listed, or by using a socket selector to choose which batch to run.

A batch sequence is completed (and the tool may be locked) when either:

All tightenings have been completed with an OK or NOK result.

The Sequence Abort Timer signal terminates the task. Unperformed tightenings are reported with NOK result.

Batch Sequence Settings

The Batch Sequence menu shows the details of a single batch sequence with the following configuration items:

Name: Sequence name and index number.

Settings: Parameters for controlling the flow and order of tightenings.

Batch Configuration: Function for creating the batch sequence from individual tightening programs. A batch consists of one single tightening program that is repeated a number of times.

Parameter | Description |

|---|---|

Name | The batch sequence name consists of an index number combined with optional characters. The index position cannot be changed. A new configuration is given lowest possible available index number. The index number is important when using sources and identifier numbers to be part of the task selection process. |

Parameter | Description | Default Value |

|---|---|---|

Lock tool on Batch sequence compl. | A batch sequence is completed when the batch sequence counter is equal to the batch sequence size. On: The tool is locked and a tightening program or batch sequence must be selected to continue performing tightenings. Off: After completion, the batch sequence is ready to be repeated. | On |

Free order | No: The configured batches will be executed in the order listed, provided they have been configured to perform tightenings. If socket has been specified, the system will prompt for the socket when the batch is to be performed. Yes: The configured batches can be executed in any order. The operator must indicate to the system which batch is to be executed by using a Socket selector. A batch is regarded as complete when all joints have been completed. | No |

Increment on NOK | Makes it possible to increment the batch counter value even though the tightening is reported as NOK. For Max consecutive NOK to work (the maximum number of times a single bolt can be tightenened), Increment on NOK must be set to No. Setting this parameter to Yes, will allow the sequence to move on to the next tightening. | No |

Max consecutive NOK | Maximum consecutive not OK (NOK) tightenings are a defined maximum allowed number of NOK consecutive tightenings in a batch. If the Max consecutive NOK number is reached, the event Too many NOK tightenings (4020) is displayed. | 0 |

Decrement on OK loosening | Decrements the counter within the currently active batch. Completed batch cannot be decremented. Never: The setting is off. Counter is not decremented when loosening is performed in the active batch. Always: decrements the counter in the active batch when loosening, if the last tightening was OK. When last tightening is OK: decrements the counter when performing a loosening in the active batch, regardless of the previous tightening result. | Never |

Sequence abort timer | On: The selected batch sequence can be aborted within a specified time limit Off: The selected batch sequence cannot be aborted. | Off |

Abort time | Time in seconds. | 10 s |

Parameter | Description |

|---|---|

Tightening program | The tightening program to use with the batch. |

Batch size | Number of tightenings the batch will perform. Max. number of tightenings in one batch is 99. Batch size 0 will give the batch an infinite number of tightenings. |

Identifier number | When using a socket selector, this is the socket position used to activate the batch. |

Adding a New Batch to a Batch Sequence

Go to Batch Sequence in the home menu. The workspace displays a list of batch sequences.

Select the plus icon in the top right corner.

Issue the batch sequence with a name.

Select the relevant parameters in the settings.

Select Batch Configuration > Edit.

Select a Tightening Program for the batch.

Enter the Batch Size, that is, the number of tightenings the batch will consist of.

Enter an optional Identifier Number.

The new batch sequence will be issued the first free position in the sequence list. If there are no free slots it will be placed at the bottom of the list and assigned the lowest available index number. It is not possible to change the index number to rearrange the batch tightening order.

Deleting a Batch from a Batch Sequence

Go to Batch Sequence in the home menu. The workspace displays a list of batch sequences.

Select the Batch Sequence to be deleted.

In the bottom of the workspace, select the Delete button.

When a batch is deleted from the batch sequence, the index sequence is compressed and updated, leaving no gaps. The index number of the deleted batch sequence will be assigned automatically to the next sequence that is created.

Working with the Sources Tab

External signals used as tasks for tightenings are configured in the Sources menu. Sources are accessories or similar connected to a virtual station. Two types of source tasks are available:

Source Tightening task: used to select a single tightening program.

Source Batch task: used to select a batch sequence, that is, a series of tightening programs.

Source Tightening

Source tightenings link a specific tightening program to an identifier number. When the identifier number is sent to the tool (either by external digital signal, or, in cases where a socket selector is used, by lifting the corresponding socket in the selector) the linked program will run over and over until a different signal is sent (or socket is picked up). There is no batch counting.

To link separate lists to the virtual station, a source task must be assigned to the virtual station. Go to Integrated Controller Tool > Virtual Station in the home menu and select Task > Change task.

Source Tightening Properties

Parameter | Description |

|---|---|

Name | The name issued to the source tightening. |

Selector mode | Control mode: An external source selects a tightening program by requesting an identifier number. The identifier number is linked to a corresponding socket in the socket selector, and by lifting the socket the tightening program is selected Confirm mode: The socket selector cannot be used as a controlling source. In this mode identifier numbers are linked to both a tightening program and a specific socket (indicated in an additional column in the list). When an identifier number is requested (by an external signal), the corresponding socket is prompted in the socket selector and the tightening program is activated when the operator lifts the socket (other sockets are disabled). If no socket is specified (that is, set to 0 in the Socket column), the tightening program is activated directly and the socket status is ignored. |

Max consecutive NOK per program | On: The batch will advance even if a NOK tightening is performed. Off: Set Max consecutive NOK for the tightening. The batch will only advance if a successful tightening is performed. |

Max consecutive NOK | Set the number of consecutive NOK results to be allowed. If the value is set to 0, there is no check performed for NOK tightenings. When reaching max consecutive NOK, the tool locks and the sequence execution is halted. |

Batch control | Select how the source tightening is to be executed. Internal: Configure how many times a source tightening is to be repeated. External: Configure how many times a source tightening should be executed by using Open protocol or an external protocol. Any configuration change clears the source tightening to start over from a clean and known state (the batch count in the batch will be reset to 0). Ongoing tightenings are able to finish before the changes take effect. |

Configuring a Source Tightening

Go to Sources in the home menu, and select Tightening in the left pane.

Select the plus icon in the top right.

Issue the source tightening with a Name and select the correct Selector mode (Control or Confirm, depending on what is required).

Max consecutive NOK can be set per source tightening or per individual program included in the source tightening. Set Max consecutive NOK per program parameter to Yes or No, depending on what is required:

To set the max consecutive NOK per source tightening, set Max consecutive NOK per program to No. Set the value in the Max consecutive NOK field.

To set the max consecutive NOK per program, set Max consecutive NOK per program to Yes. For every program in the Identifier selector configuration section, set the value in the Max NOK column.

By default, only one editable identifier number will be available when creating a new source tightening. At the bottom of the screen, select the plus icon to add more.

Give every item an identifier number.

If a socket selector is used, the identifier numbers will correspond to the positions in the socket selector, that is, identifier number 1 corresponds to socket number 1 in the socket selector.

Choose a tightening program to link to each identifier number by selecting a row and choosing from the list of tightening programs.

Source Batch

Configuring a Source Batch

Go to Sources in the home menu and select Batch Sequence in the left pane.

Select the plus icon in the top right.

Issue the source batch with a Name.

Set the Abort on new identifier to Yes if scanning a new identifier string should abort the previous scan.

Select the Identifier method (Strings for text, or Number for numerical values)

If the Identifier method is set to Strings, continue with the following steps:

Set Free order to On if the strings should be able to be scanned in any order.

Identifier strings can be made up of up to four different strings. When free order is set to Off, the strings must be scanned in a specific order for the system to recognize the string.

If required, add an identifier string by selecting the plus icon in the Identifier string configuration section.