EP15PTX250 HR20-AT

Nutrunner

Product Information

General Information

Safety Signal Words

The safety signal words Danger, Warning, Caution, and Notice have the following meanings:

DANGER | DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. |

WARNING | WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury. |

CAUTION | CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. |

NOTICE | NOTICE is used to address practices not related to personal injury. |

Warranty

Product warranty will expire 12+1 months after dispatch from Atlas Copco's Distribution Center.

Normal wear and tear on parts is not included within the warranty.

Normal wear and tear is that which requires a part change or other adjustment/overhaul during standard tools maintenance typical for that period (expressed in time, operation hours or otherwise).

The product warranty relies on the correct use, maintenance, and repair of the tool and its component parts.

Damage to parts that occurs as a result of inadequate maintenance or performed by parties other than Atlas Copco or their Certified Service Partners during the warranty period is not covered by the warranty.

To avoid damage or destruction of tool parts, service the tool according to the recommended maintenance schedules and follow the correct instructions.

Warranty repairs are only performed in Atlas Copco workshops or by Certified Service Partners.

Atlas Copco offers extended warranty and state of the art preventive maintenance through its ToolCover contracts. For further information contact your local Service representative.

For electrical motors:

Warranty will only apply when the electric motor has not been opened.

Website

Information concerning our Products, Accessories, Spare Parts and Published Matters can be found on the Atlas Copco website.

Please visit: www.atlascopco.com.

ServAid

ServAid is a portal that is continuously updated and contains Technical Information, such as:

Regulatory and Safety Information

Technical Data

Installation, Operation and Service Instructions

Spare Parts Lists

Accessories

Dimensional Drawings

Please visit: https://servaid.atlascopco.com.

For further Technical Information, please contact your local Atlas Copco representative.

Safety Data Sheets MSDS/SDS

The Safety Data Sheets describe the chemical products sold by Atlas Copco.

Please consult the Atlas Copco website for more information www.atlascopco.com/sds.

Country of Origin

For the Country of Origin, please refer to the information on the product label.

Dimensional Drawings

Dimensional Drawings can be found either in the Dimensional Drawings Archive, or on ServAid.

Please visit: http://webbox.atlascopco.com/webbox/dimdrw or https://servaid.atlascopco.com.

Overview

General Description

The Pistol ErgoPulse PTX shut-off tool is the ideal choice if your operators need to speed up production with fast rundowns and short tightening cycles. It is a reliable and powerful shut-off pulse tool that automatically shuts off the air supply when the pre-set torque has reached. Suitable for continuous heavy production, the PTX series has some air on top HRF models, making it possible to feed the air from above to the tool. All PTX models can also be used as lubrication free, just like other ErgoPulse tools and is available in StandardTrim and AutoTrim version.

Benefits

High reliability and durability

One-handed operation

Light and well-balanced tool

Low noise level

Features

Consistent torque over time

Automatic two-stage trim valve

High power-to-weight ratio

No springs to wear out

High precision components

Applications

This pneumatic shout-off impulse tool can be used for various applications where reaction free tightening and/or high productivity is needed.

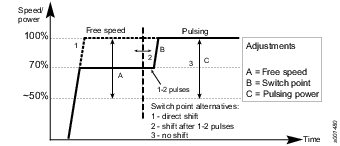

AutoTrim Valve Overview

This tool is equipped with an AutoTrim valve, which gives the tool optimal performance on mixed hard and soft joints. (For applications where the tool is used for tightening joints with similar characteristics, Trim Valve can be used.)

The AutoTrim valve is factory preset to suit a majority of applications. It gives a reduced speed during rundown. After 1-2 pulses it shifts automatically to full speed/power for the rest of the tightening. Regularly check the correct operation of the AutoTrim valve. Non-switching (from restricted to open operation) will cause longer tightening time with risk of over-tightening of the joint. Premature switching to open position (i.e. when tool is running free) might cause erratic shut-off due to too few pulses.

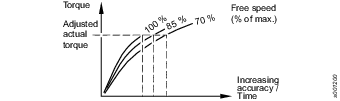

The AutoTrim valve gives a reduced speed during rundown. After 1-2 pulses on a joint it shifts automatically to full speed/power for the rest of the tightening, as shown in illustration below.

Possible adjustments:

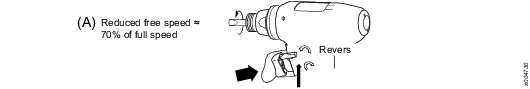

Free speed (factory set to approx 70% of full speed). See Adjusting the Free Speed.

Switch point from reduced to full power (factory set to 1-2 pulses) for standard, non reporting (RE) applications. See Adjusting the Switch Point.

Power during pulsing (factory set to full power). See Adjusting the Pulsing Power.

In most cases the factory settings give the best performance.

Technical Product Data

Technical Product Data can be found on either ServAid, or the Atlas Copco website.

Please visit: https://servaid.atlascopco.com or www.atlascopco.com.

Installation

Installation Requirements

Air Quality

For optimum performance and maximum product life we recommend the use of compressed air with a maximum dew point of +10°C (50°F). We also recommend to install an Atlas Copco refrigeration type air dryer.

Use a separate air filter which removes solid particles larger than 30 microns and more than 90% of liquid water. Install the filter as close as possible to the product and prior to any other air preparation units to avoid pressure drop.

For impulse/impact tools make sure to use lubricators adjusted for these tools. Regular lubricators will add too much oil and therefore decrease the tool performance due to too much oil in the motor.

Make sure that the hose and couplings are clean and free from dust before connecting to the tool.

Both lubricated and lubrication free products will benefit from a small quantity of oil supplied from a lubricator.

Air Lubrication Guide

Recommended air lubricators:

Atlas Copco Optimizer (1 liter) 9090 0000 04

Q8 Chopin 46

Shell Air Tool Oil S2 A 320

Compressed Air Connection

For correct air pressure and hose size, see the Technical Product Data on - https://servaid.atlascopco.com or www.atlascopco.com.

Make sure that the hose and couplings are clean and free from dust before connecting to the tool.

Air Pressure Regulation

A pressure regulator is recommended for each tool.

A pressure regulator will give the following advantages:

A stable air pressure which results in better accuracy

An easy way to adjust the power of the tool

Make sure to adjust the regulator to the lowest expected pressure on the line.

Adjusting the air pressure will have the following consequences:

Decreasing the air pressure will result in a slower but more accurate tool

Increasing the air pressure will result in a faster but less accurate tool

If the pressure from the airline is below five bar, a tool from the EP L-series (designed for low pressure installations) is recommended.

Installation Instructions

Installation of Vibrating Tools

We recommend using a minimum length of 300 mm (12") of flexible hose for compressed air between a vibrating tool and the quick-action coupling.

Initial Setting of Torque

To minimize the risk of damage to the actual joint we recommend to set the torque slightly lower on the test joint than the torque wanted for the application. Make sure to use the same equipment, such as for example extensions, sockets and air pressure on the test joint as will be used on the actual joint.

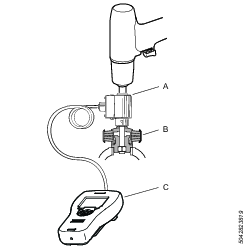

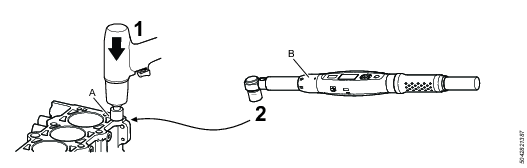

A | Torque transducer IRTT |

B | Test joint |

C | ST Analyzer |

Make sure to always verify the torque settings on your actual joint.

Operation

Ergonomic Guidelines

Consider your workstation as you read through this list of general ergonomic guidelines and see if you can identify areas for improvement in posture, component placement, or work environment.

Take frequent breaks and change work positions frequently.

Adapt the work area to your needs and the work task.

Adjust for convenient reach range by determining where parts or tools should be located to avoid static load.

Use workstation equipment such as tables and chairs appropriate for the work task.

Avoid work positions above shoulder level or with static holding during assembly operations.

When working above shoulder level, reduce the load on the static muscles by reducing the weight of the load. You can also reduce the load on the static muscles by holding the load close to the body.

Make sure to take frequent breaks.

Avoid extreme arm or wrist postures, particularly for operations requiring a degree of force.

Adjust for convenient field of vision by minimizing movement of the eyes and head during the work task.

Use the appropriate lighting for the work task.

Use ear protection equipment in noisy environments.

Use dust extraction system or mouth protection mask in dusty environments.

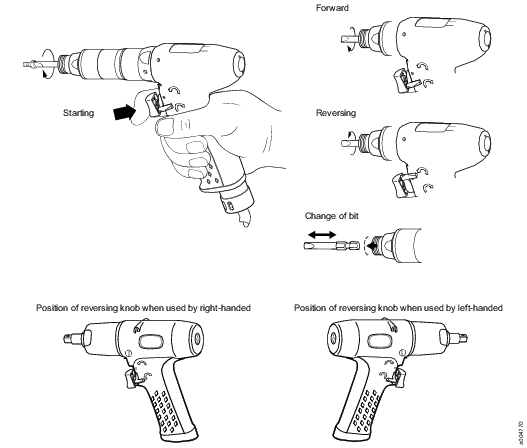

Operating Instructions

Operating the Tool

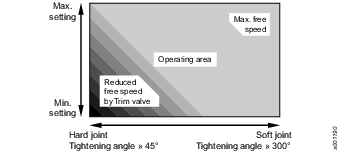

Operating Area

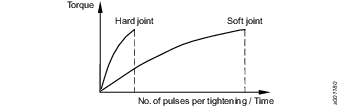

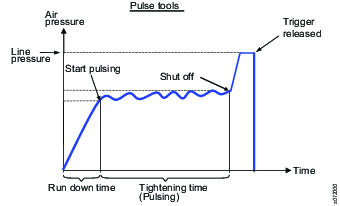

Tightening Time

The tightening time is depending on joint hardness. Hard joints give short operation time, and soft joints give longer operation time.

Max. recommended tightening time is 3 seconds. Longer time indicates that the joint is too soft for the machine used. If so it is recommended to choose a bigger size of machine or another type of nutrunner.

Pulses per Tightening

An increased number of pulses per tightening implies improved accuracy. Fewer pulses per tightening implies an increased scatter.

Min. recommended number of pulses per tightening is 3. Few pulses per tightening at a low setting indicates that the free speed ought to be reduced by the trim valve.

Free Speed Reduction

A reduced free speed implies improved accuracy and an increased number of pulses per tightening.

A reduced free speed may effect the torque level installed and the tightening time.

If the free speed is reduced, the number of pulses, as well as the torque level, will increase. After a reduction of the free speed the torque level might have to be reduced.

Air Pressure Monitoring, RE-signal

It is possible to connect the tool to a pressure monitoring equipment to monitor the tightening. The pressure signal from the tool (differential pressure over the motor) can be used to detect:

Missed fasteners

Trigger release before set torque is reached

Stripped threads

Cross-threading

Re-hits

Drop in air supply

To connect the tool to a pressure monitoring equipment we recommend using a Reporting Connection Kit, see Accessories https://servaid.atlascopco.com.

The pressure monitoring equipment does not measure torque.

Air Pressure Signal Diagram

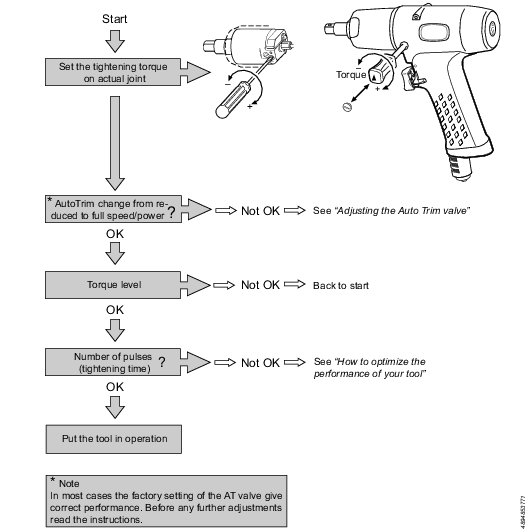

Optimizing the Tool Performance

Recommended number of pulses

A Pulse tool well suited for your application should reach the target torque (with shut off) within 5-20 pulses. The number of pulses it takes for the tool to reach target torque can be measured with an analyzer. The tightening time can also be used as a guide, to know if the tool is appropriate for your application:

≤ 1 second for tools up to 30 Nm

≈ 1 second for tools up to 80 Nm

≈ 2 seconds for tools up to 150 Nm

≈ 5 seconds for tools up to 450 Nm

≤ 10 seconds for tools up to 850 Nm

If the target torque is achieved with less than 5 pulses (= short tightening time), the torque scatter will increase and it can be difficult to adjust to the right level, especially on hard joints.

If the target torque is achieved with more than 20 pulses (= too long tightening time) the wear will increase and more frequent oil filling and service will be required. Too long tightening time, in combination with high production rate, may also result in excessive heating of the oil. In that case the power will decrease with longer tightening time and sometimes no shut off.

If the target torque is achieved with less than 5 pulses this can be fixed by:

Decreasing the air pressure.

Reducing the speed by means of the AutoTrim or Trim valve.

If the above is not possible or does not give wanted results, a smaller tool may be a better choice.

If the target torque is achieved with more than 20 pulses this can be fixed by:

Increasing the dynamic air pressure to 6-7 bar for standard EP tools, or up to 5 bar for low pressure EP L-tools.

Adjust the AutoTrim or Trim valve to give maximum power/speed.

If the above is not possible or does not give wanted results, a bigger tool may be a better choice.

When changing the air pressure, the target torque must be measured again and adjusted if needed.

Setting of Tightening Torque

The adjusting screw (the slotted screw) is the only screw that initially should be adjusted. Start at a low torque adjustment and gradually increase the setting until you reach the desired torque level. See detailed illustrations for setting of the tightening torque when using AutoTrim function and Trim function respectively.

Using the tool at a higher torque, than recommended maximum torque, might result in improper function and faster wear.

Always check the setting on your actual joint.

Setting of Tightening Torque When Using AutoTrim Function

When using a tool with AutoTrim function make sure that it is correctly adjusted. When correctly adjusted the AutoTrim reduces the speed during rundown and will automatically switch to full speed/power after approximately 1-2 pulses.

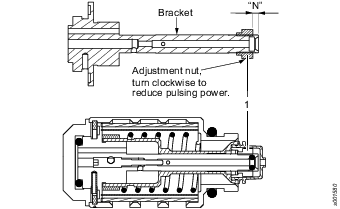

Adjusting the Pulsing Power

The AutoTrim valve is factory set to full pulsing power, that is, the length of N is set according to the table below.

To improve accuracy (more pulses before shut off) on hard or medium hard joints, reduce the power. The power is reduced by turning the nut (1) clockwise (increased lenght of N).

AutoTrim Valve | Length of N (mm) |

|---|---|

4250 1878 43 | 1.5 |

4250 1878 90 | 1.5 |

4250 1878 91 | 1.0 |

4250 1878 92 | 0.5 |

4250 1878 93 | 0 |

4250 1878 94 | 0 |

4250 1878 95 | 0 |

4250 1878 97 | 1.5 |

4250 1878 98 | 1.0 |

4250 2675 91 | 0 |

4250 2675 92 | 0 |

4250 1878 50 | 2.0 |

4250 1878 51 | 2.0 |

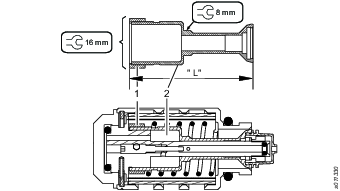

Adjusting the Free Speed

The AutoTrim valve is factory set to approximately 70% of full speed. To reduce the free speed, reduce the length of L. To increase the free speed, increase the length of L.

Adjust the length of L by turning the support ring (1).

On very hard joints (<30°) at low torque levels, further speed reduction might be necessary. When the tool is used only on soft joints, less or no speed reduction is needed.

The factory set length of L is depending on the tool size, see table.

AutoTrim Valve | Length of L (mm) |

|---|---|

4250 1878 43 | 39.2 +/-0.1 |

4250 1878 90 | 39.2 +/-0.1 |

4250 1878 91 | 39.7 +/-0.1 |

4250 1878 92 | 40.2 +/-0.1 |

4250 1878 93 | 40.7 +/-0.1 |

4250 1878 94 | 40.3 +/-0.1 |

4250 1878 95 | 40.5 +/-0.1 |

4250 1878 97 | 39.2 +/-0.1 |

4250 1878 98 | 39.7 +/-0.1 |

4250 2675 91 | 40.5 +/-0.1 |

4250 2675 92 | 40.3 +/-0.1 |

4250 1878 50 | 38.7 +/-0.1 |

4250 1878 51 | 38.7 +/-0.1 |

Controlling the AutoTrim Function

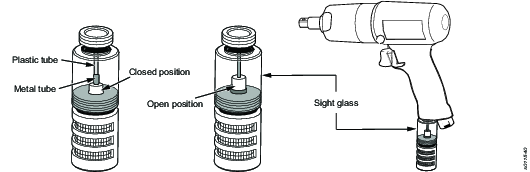

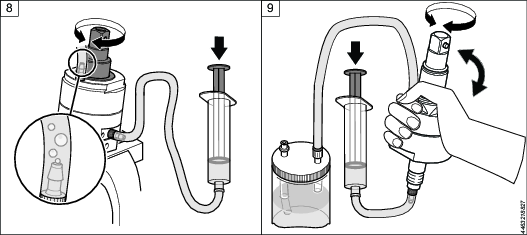

Controlling the Function Using Sight Glass

For a better understanding of the behavior of the AutoTrim valve, a sight glass is recommended. Find a sight glass suitable for the tool on ServAid.

Assemble the sight glass with the tube adapter between the AutoTrim valve and the tool.

Check that the valve remains in closed position when running in the air.

Run the tool on a joint and notice the change from closed to open position when the pulsing starts.

If the behavior in “2” or “3” above is not correct, the valve is in need of adjustment or service, see Adjusting the Switch Point.

Controlling the Function Using Speed Change

Make sure that any socket is firmly attached. The tool should run at reduced speed.

Run the tool in the air (A).

With the reversing knob in reversing direction, pull the trigger and (with trigger still pressed) quickly pull the reversing knob to forward direction. (B) The AutoTrim valve should then switch from reduced to full speed. If the tool is running with full speed at (A) or still remaining at reduced speed at (B) the AutoTrim valve is in need of adjustment or service, see Adjusting the Switch Point.

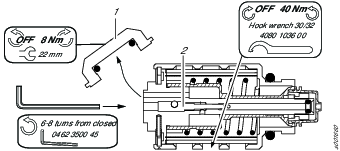

Adjusting the Switch Point

Remove the cover (1) with 22 mm wrench while holding the valve casing with hook wrench.

Adjust the valve (2) with 1.5 mm Allen key supplied with AutoTrim valve. From fully closed (+) position to normal operation the needle valve is opened between 6 and 8 turns (-) depending on tool size.

Restore cover (1).

Perform a function control.

If the valve is too much closed, the AutoTrim valve will not shift to open position when pulsing starts. If the valve is too much open, the AutoTrim will directly open to full speed and power.

Clockwise (+) rotation delays the switch point (closes the needle valve) and vice versa.

If the tool is used for reporting applications (RE) the needle valve has to be turned more open (-) to compensate for the air volume in the signal hose.

Service

General Service Information

If the tool is not working properly, take it out of operation for inspection. Preventive maintenance is recommended at regular intervals. See detailed information on Preventive Maintenance.

Make sure to use the service tools, service kits and spare parts recommended by Atlas Copco.

Make sure to follow the Service instructions provided by Atlas Copco.

Make sure to work in a clean environment and that all parts are cleaned before re-assembling. Foreign particles, even small fibers from paper tissue, may affect the service life of the Pulse unit.

Maintenance Instructions

Daily Inspection

Make sure that the tool is in good condition, no visual damage.

Make sure that the air connection and air installation is done correctly. Listen for any air leakage.

Make sure that sockets and extensions have no visual damage.

Make sure to have the correct air pressure.

Listen to make sure that there is no unexpected noise when running the tool.

Preventive Maintenance

Preventive maintenance is recommended once per year or after a maximum of 250.000 tightenings. A complete overhaul include:

Clean the pulse unit and change worn or damaged parts.

Clean the air motor and change worn or damaged parts.

Clean the silencer and the strainer of the inlet adapter, change the filter and change worn or damaged parts.

Clean the trigger and reversing valve and change worn or damaged parts.

Service Instructions

Overhaul and preventive maintenance is recommended at regular intervals once per year or after maximum 250.000 tightening depending on which occurs sooner. More frequent overhaul may be needed, specially replacing of oil in the pulse unit, if used at high torque and long tightening times. If the machine is not working properly, it should immediately be taken away for inspection.

The strainer at the air inlet and the exhaust silencer should be cleaned frequently or replaced in order to prevent clogging, which decreases the capacity.

At the overhauls, all parts should be cleaned accurately and defective or worn parts should be replaced.

All o-rings should be greased before assembling; especially important are the o-rings in the pulse unit.

Dismantling/Assembling

It is important that threaded connections are tightened properly, that is, in accordance with the specifications. See Spare Parts for details.

Cleaning

Clean all parts (except electrical parts) thoroughly using white spirit or similar cleaning agent. To prevent clogging and decreased power, clean the strainer (if used) and the exhaust filter between the overhauls.

Inspection

After the cleaning, inspect all parts. Damaged and worn parts should be replaced.

Lubrication

Lubricate specially gears, valve and clutch with grease containing molybdenum disulphide (e.g. Molykote BR2 Plus). Lubricate o-rings and threaded connections with grease before assembling.

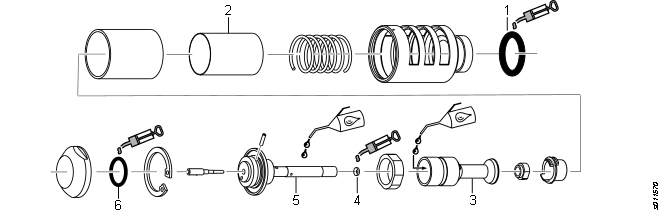

Servicing the AutoTrim Valve

Make sure all parts are clean. O-rings should be lightly greased. Valve and bracket should be sparsely oiled with light oil. Make sure that the valve moves easily on the bracket. When adjusting the throttle valve, start from fully closed position (clockwise) and open between 6-8 turns. Check and adjust again if needed.

Check and adjust the lengths of L and N corresponding to the ordering number of the AutoTrim valve (as of 2008 the ordering number is engraved on the AutoTrim casing). See Adjusting the Free Speed and Adjusting the Pulsing Power.

Test the valve function on the corresponding EP tool. Change the filter regularly to prevent clogging, decreased power, and incorrect function.

Ref.No | Description | Remark |

|---|---|---|

1 | O-ring | Lightly greased |

2 | Filter | Change regularly |

3 | Valve | Lightly oiled. Valve should slide easily onto bracket. |

4 | O-ring | Lightly greased |

5 | Bracket | Lightly oiled. Valve should slide easily onto bracket. |

6 | O-ring | Lightly greased |

Lubrication Instructions

Rust Protection and Cleaning

Water in the compressed air can cause rust. To prevent rust we strongly recommend to install an air dryer.

Water and particles can cause sticking of vanes and valves. This can be prevented by installing an air filter close to the product to avoid pressure drop.

Before longer stand stills always protect your tool by adding a few drops of oil into the air inlet. Run the tool for 5–10 seconds and absorb any access oil at the air outlet in a cloth.

Lubrication Guide

Brand | General purpose, Bearings and Gears |

|---|---|

BP | Energrease LS-EP2 |

Castrol | OBEEn UF 1 |

Esso | Beacon EP2 |

Q8 | Rembrandt EP2 |

Mobil | Mobilegrease XHP 222 NLG 2 |

Klüber Lub. | Klübersynth UH 1 14-151 |

Texaco | Multifak EP2 |

Molykote | BR2 Plus |

Oil Level in the Pulse Unit

The right oil level in the Pulse unit is important for the tool to work correctly.

The need to add oil to the Pulse unit will vary depending mainly on the number of tightening, torque level and number of pulses (tightening time).

Operating the tool on a low oil level will result in faster wear of the parts in the Pulse unit. It will also affect the tool performance and accuracy.

Always check the tightening torque after filling the oil.

Detect Low Oil Level in the Pulse Unit

Longer tightening time

Very high pulse frequency, especially when the tool has not been used for a while.

Low torque or abnormal torque changes (increased scatter).

No shut-off.

To measure the pulse frequency use a static torque transducer or an inline transducer connected to torque testing equipment, as per the Tool Condition Test.

Recommended Oil for the Pulse Unit

The recommended oil for the pulse unit is Atlas Copco Pulse Unit Oil.

A bottle of Atlas Copco Pulse Unit Oil and the required syringe or syringes are orderable as kits. Please see Service Kits for ordering numbers.

Filling the Pulse Unit with Oil

There are different methods to fill the pulse unit with oil, depending on available equipment:

Using an ST Analyzer and a Transducer. Follow the instructions in Method 1.

This method is the fastest. It will give an optimized tool performance and result in the longest filling intervals.Without an ST Analyzer and a Transducer. Follow the instructions in Method 2.

This method is not as fast and accurate as using Method 1.Using the Atlas Copco Oil filling equipment kit (4250 3220 90). Follow the instructions in Method 3.

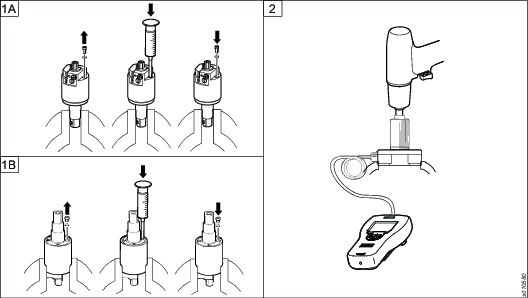

Method 1 (using an ST Analyzer and a Transducer)

Position the pulse unit in a vice. Remove the oil plug positioned on either the front (A) or the back (B) of the pulse unit. Add a small amount of oil to the pulse unit.

Assemble the tool and measure the pulse frequency.

If the pulse unit frequency is in the specified range the amount of oil is correct.

If the pulse unit frequency is too low reduce some oil and measure the pulse frequency again.

If the pulse frequency is to high add some oil and measure the pulse frequency again.

Model

Minimum free speed (r.p.m)

Pulse frequency (Hz)

Max Torque (minimum) (Nm)

EP15PTX250HR20-AT

3800

12-15

285

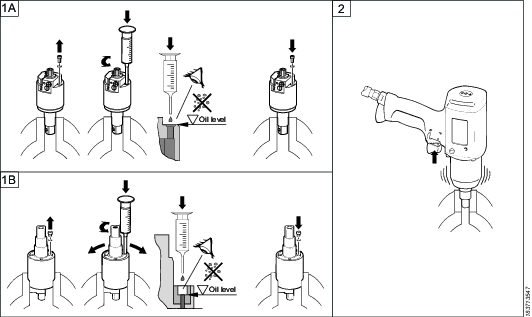

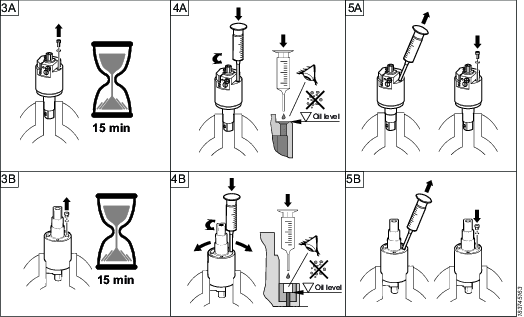

Method 2 (without ST Analyzer and Transducer)

Position the pulse unit in a vice. Remove the oil plug positioned on either the front (A) or the back (B) of the pulse unit. Fill the pulse unit to 100% full. Assemble the oil plug.

Assemble the tool and run in reverse for 3-5 seconds.

Position the pulse unit in a vice. Remove the oil plug. Wait for all air bubbles to disappear (approximately 15 minutes) and the temperature to drop down to 20 degrees.

Fill the pulse unit to 100% full.

Reduce the oil in the pulse unit with a specified volume according to table using a 1 ml syringe. Assemble the oil plug.

Oil volume to be

reduced from 100%

Approx. oil volume

in pulse-unit

2.3±0.05 ml

29 ml

Check torque and shut off function, for procedure see Testing/Measuring.

If everything is in order the amount of oil is right.

If everything is not in order repeat from step one.

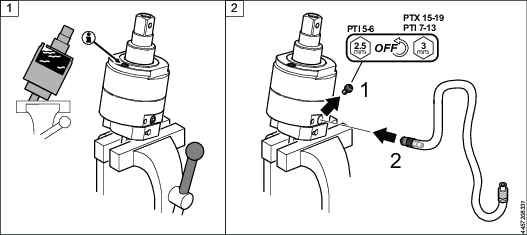

Method 3 (with Oil Filling Kit)

Required equipment for oil filling and oil changing:

Atlas Copco Pulse unit oil.

Atlas Copco Pulse unit Oil Filling Kit.

For ordering number for Spare Parts, see https://servaid.atlascopco.com.

Oil Filling Equipment Kit

2 x Adapter M3

2 x Adapter M4

4 x Hose length 540 mm

2 x Hose length 50 mm

1 x Hose length 120 mm

1 x Syringe 50 ml

1 x Syringe 1 ml

4 x Plug

5 x Connection

2 x Connection

2 x Can

2 x Cover

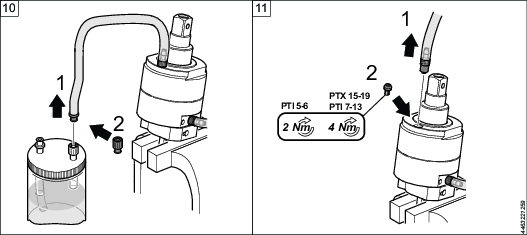

Place the Pulse unit in a vise at an angle so that the outlet hole is at the highest point.

Remove the screw covering the inlet opening. Make sure that the o-ring is on the screw and not left in the Pulse unit. Attach the filling hose by hand, with the hose connector end to the Pulse unit.

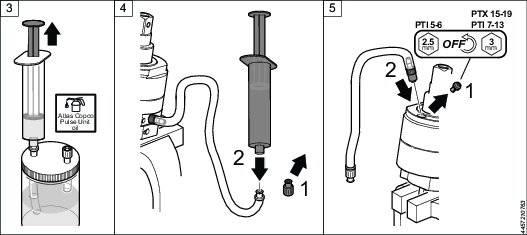

Fill the large syringe with oil to maximum capacity from the oil can.

Always use new Atlas Copco Pulse unit oil.

Remove the stop plug from the filling hose and then attach the syringe to the hose.

Remove the screw covering the outlet opening of the Pulse unit. Make sure that the o-ring is on the screw and not left in the Pulse unit. Attach the return hose to the Pulse unit.

Remove the stop plug from the return hose and then attach it to the oil can.

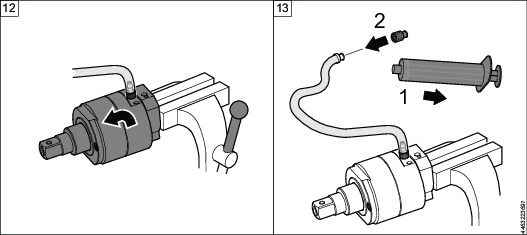

Start filling oil into the Pulse unit from the large syringe. When filling oil into the Pulse unit, there will be air bubbles exiting.

Rotate the anvil back and forth while filling the oil until no more bubbles are coming out of the Pulse unit.

Spin the complete Pulse unit around while filling the oil, to make sure that there are no air bubbles left inside of the Pulse unit.

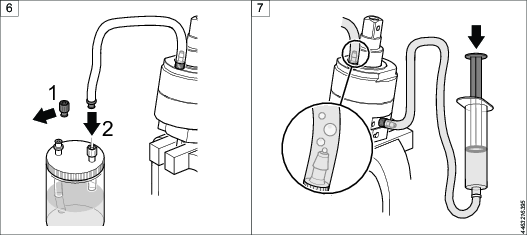

Remove the return hose from the oil can and attach the stop plug to the return hose end.

Remove the return hose from the outlet opening of the Pulse unit. Put the screw covering the outlet opening back in position.

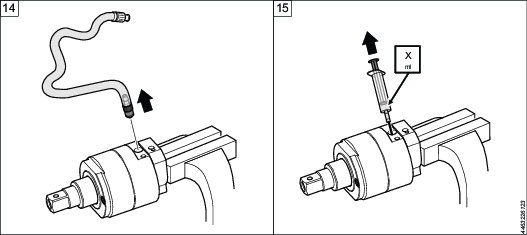

Now position the Pulse unit in the vise with the inlet opening facing upwards.

Remove the syringe from the filling hose and attach the stop plug to the filling hose.

Remove the oil filling hose from the Pulse unit.

Use the small syringe to extract the right amount of oil accordingly:

Oil reduction (X) from 100% full Pulse unit

Approximate oil volume in Pulse unit

2.3±0.05 ml

29 ml

Put the screw covering the inlet opening back in position.

Dismantling/Assembling Instructions

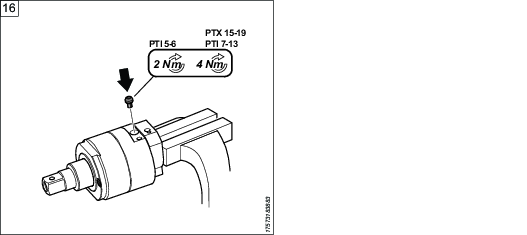

Tightening of Threaded Connections

The tightening torque indicated in the exploded views (see Spare parts section in https://servaid.atlascopco.com) will give the right clamping force and prevent parts from loosening. It is important not to exceed the clamping force, these parts must be able to open up without being damaged at service. After some time of operation and in special circumstances, depending on application and usage, the parts may however loosen somewhat. The tightening torque can then be increased by 10-20% and some type of low or medium thread locking fluid can be applied.

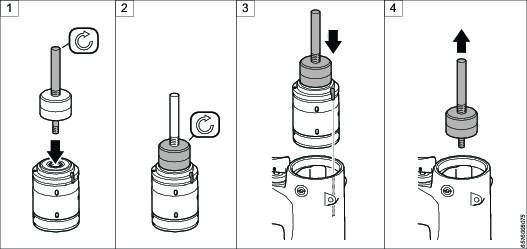

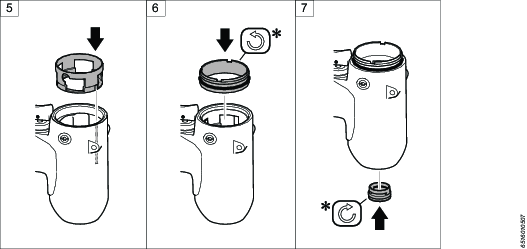

Assembling Motor in Housing

* For correct tightening torque, see Spare Parts https://servaid.atlascopco.com.

Tests and Adjustments after Service

Perform a tool condition test to make sure that the tool is working properly.

Test Method - Static or Dynamic

A static torque measurement is recommended for the ErgoPulse machines.

If dynamic torque measurement with an electronic inline torque transducer is used, always verify your measurement result by a static check with a torque wrench (electronic).

For more information, refer to Atlas Copco "Pocket Guide to Pulse Tools". Ordering No. 9833 1225 01.

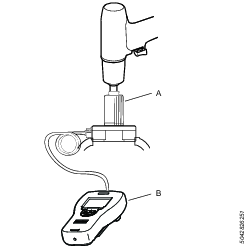

Tool Condition Test

Test Conditions

Temperature Pulse unit: approximately 20° C.

Dynamic air pressure: 6.3 bar (91 psi).

Hose size: Ø 13 mm Hose length: 3 m

A | Static Torque transducer SRTT |

B | ST Analyzer (set at 850 Hz) |

Test the free speed in the forward direction with the tachometer.

Make sure that the tool runs on full speed regardless of AutoTrim or Trim setting. If the tool is used with AutoTrim, also test the AutoTrim function.

Test the maximum torque and pulse frequency by setting the filter frequency in ST Analyzer to 850 Hz.

Test the max torque and pulse frequency in reverse direction using an SRTT static torque transducer. Tightening time approximately 1 second.

Check the shut-off mechanism.

Perform some tightenings to make sure that the tool shuts off correctly.

A tool in good condition should achieve the following values:

Model | Free speed (rpm) | Pulse frequency CCW static (Hz) | Max Torque CCW static (minimum) (Nm) |

|---|---|---|---|

EP15PTX250 HR20-AT | 4200 -10%/+25% | 12-15 | 300 |

Correct pulse frequency indicates that the air motor and the Pulse unit are in good condition. If the pulse frequency is too high - add more oil. If the pulse frequency is too low - reduce the oil level.

Torque Check - Residual Torque Measurement on Actual Joint

Make sure to use the same equipment, such as extensions, sockets and air pressure during the tightening, as will be used on the actual tightening application.

When performing a torque check on the actual joint we recommend using an ST Wrench with residual torque measurement* setting.

* Torque required to cause the threads of the fastener (including its head) on which torque is applied, to move relative to the mating thread.

A | The actual joint |

B | Torque wrench with monitoring |

Perform a tightening.

Measure the result with the Torque wrench with monitoring.

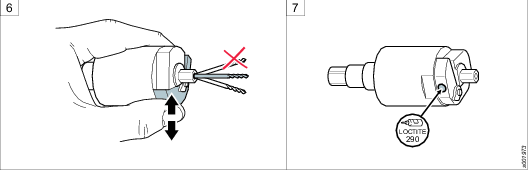

Adjusting the Position of the Stop Pin

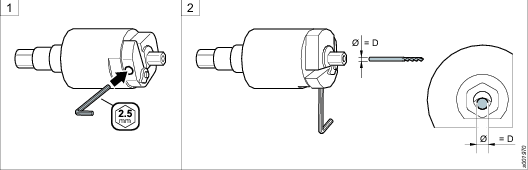

The position of the stop pin is correctly set at the factory. If the position has to be reset or adjusted due to service or replacement of spare parts, follow the instructions below.

Measurement D is the opening diameter for the gauge.

D = 1.55 mm

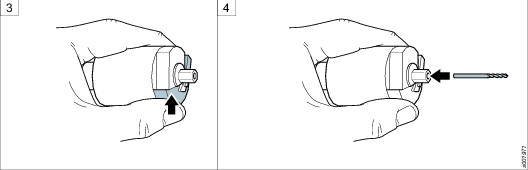

Fit a 2.5 mm Allen key in the adjustment screw.

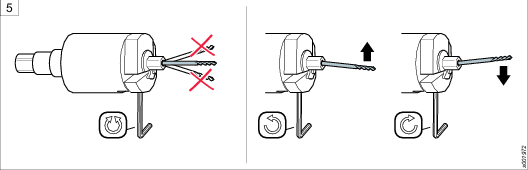

Hold the Pulse unit with both stop surface of inertia body and anvil in horizontal position and the Allen key pointing downwards.

Press the inertia body to open the hole for the gauge.

Place a gauge, for instance a drill bit, with the correct diameter of D in the hole.

Adjust the opening by turning the adjustment screw 45 degrees at the time until the gauge is in line with the pulse unit.

Avoid unnecessary turning of the adjustment screw.

Turn the screw anti-clockwise to raise the gauge.

Turn the screw clockwise to lower the gauge.

Check that the gauge is correctly inserted by repeatedly pressing and releasing the inertia body. The gauge should return to the correct position in line with the Pulse unit.

Apply Loctite 290 to the adjustment screw.

Troubleshooting

Troubleshooting Guide

Problem | Reason | Action |

|---|---|---|

The tool does not shut off, or the tightening time is too long. | Target torque close to maximum torque of the tool. | Chose a bigger tool with more power. |

Low dynamic air pressure. | Check the dimensions of the hose and couplings. Increase the air pressure. | |

Low rotation speed. | See problem "The rotation speed is too low". | |

The extension is too long. | Check the extension. | |

Worn extension or socket/bits. | Check the extension and socket/bits. | |

Torque setting screw is turned too much. | Adjust the torque setting screw CCW until tool shuts off. | |

The stop pin in the shut off mechanism is incorrectly adjusted. | Check with a gauge. | |

Incorrect oil level in the Pulse unit. | Adjust the oil level or refill the oil. | |

The joint is too soft for the tool. | Chose a bigger tool with more power. | |

Worn parts in the Pulse unit. | Inspect and replace any worn parts, see https://servaid.atlascopco.com. | |

Malfunctioning AutoTrim. | Check the AutoTrim function. | |

The yield point of the joint is reached. | Check the joint specification. | |

The pulse frequency is too high or too low. | Incorrect oil level in the Pulse unit. | Adjust the oil level or refill the oil. |

Inconsistent shut off or insufficient accuracy. | The target torque is not within the tool specification. | Change to a different tool size. |

Not enough pulses (hard joint and low torque setting). | See section Optimizing the Performance of Your ErgoPulse Tool. | |

Extension is too long. | Check the extension. | |

Worn extension or socket/bits. | Check the extension and socket/bits. | |

Pressure fluctuations in the air supply. | Use a pressure regulator (for each tool) to get a consistent air supply. | |

Incorrect oil level in the Pulse unit. | Adjust the oil level or refill the oil. | |

Friction is too low on the Torque setting screw. | Replace with new screw. | |

Worn parts in the Shut off mechanism. | Inspect and replace any worn parts. | |

Stop pin in the Shut off mechanism is not correctly adjusted. | Check with a gauge. | |

Malfunctioning AutoTrim. | Check the AutoTrim function. | |

The joint is too soft and max torque setting. | Reduce the torque setting slightly, or use a bigger tool with more power. | |

The rotation speed is too low. | Not enough air pressure. | Check the dimensions of the hose and couplings. Increase the air pressure. |

Wrong Trim valve setting | Adjust the Trim valve. | |

Dirt in the Inlet or the Silencer. | Clean or replace the air Inlet strainer and the Silencer filter if needed. | |

Worn parts in the motor. | Inspect and service the motor. | |

Wrong or damaged trigger valve. | Inspect the trigger valve. | |

AutoTrim is not working correctly. | Dirt in the silencer filter. | Replace the silence filter. |

Wrong adjustments or settings. | See section Adjusting the AutoTrim Valve. | |

Dirt or damaged parts in the AutoTrim. | Inspect and replace any worn parts. | |

The wrong auto-trim part has been used. | Check Spare Part for to use, see https://servaid.atlascopco.com. |

Recycling

Environmental Regulations

When a product has served its purpose it has to be recycled properly. Dismantle the product and recycle the components in accordance with local legislation.

Batteries shall be taken care of by your national battery recovery organization.

Recycling Instruction

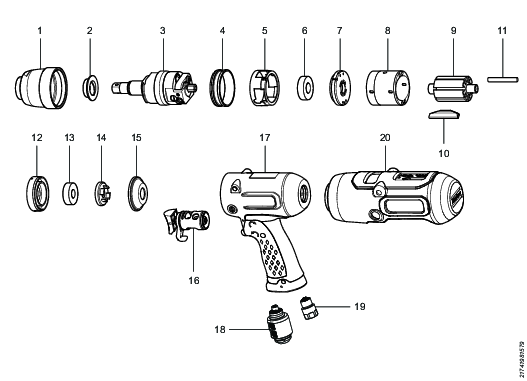

Pos | Part | Remarks | Recycle as |

|---|---|---|---|

1 | Pulse unit casing | Metal, aluminum/steel | |

2 | Bushing | Metal, aluminum bronze | |

3 | Pulse unit | Metal, steel | |

4 | Screw ring | Metal, steel | |

5 | Sleeve | Metal, steel | |

6 | Ball bearing | Metal, steel | |

7 | End plate | Metal, aluminum | |

8 | Cylinder | Metal, aluminum | |

9 | Rotor | Metal, steel | |

10 | 7 vanes | Plastics, other, POM | |

11 | 7 plugs | Plastics, other, POM | |

12 | End plate | Metal, aluminum | |

13 | Ball bearing | Metal, steel | |

14 | Support washer | Metal, aluminum | |

15 | Inlet washer | Metal, aluminum | |

16 | Trigger | Metal, steel | |

17 | Motor casing | Metal, aluminum | |

18 | Silencer | Metal, steel | |

19 | Adapter | Metal, aluminum/steel | |

20 | Protective cover | Plastics, other, vinyl |