Minimum Torque

This strategy verifies that the minimum torque value is reached within a specified angle value.

Parameter | Description |

|---|---|

Inspection Name | Name of the inspection. |

Cycle start | Torque value from which the test operation starts. |

Minimum torque limit | Minimum torque value that must be reached within the Target angle value in order to get an OK result. |

Maximum torque limit | Upper torque limit value. |

Change screw | If the torque applied reaches this limit, the message Change screw is shown on the wrench display. The Change screw must be equal or higher than the Maximum limit torque. |

Final angle monitoring torque | Torque value from which the angle measurement starts (usually set to 50% of the Target torque). |

Angle limit | Angle value within which the Minimum torque limit value must be reached in order to get an OK result. |

Maximum angle limit | Upper angle limit value. |

Torque units | Measurement unit set for the joint linked to the inspection. |

Torque correction coefficient | When extensions are used, the wrench measurement must be compensated to show a more accurate torque value. To calculate the correction coefficient, please refer toHow to calculate the Torque Correction Coefficient. When extensions are not used, Torque correction coefficient = 1. |

Angle correction coefficient | When extensions cause additional wrench bending, the wrench angle measurement must be compensated to show a more accurate angle value. When extensions are not used, Angle correction coefficient = 0. |

Number of sample | Number of tests to run inside the inspection. |

Ratchet time | Starts when the torque goes below the Cycle start without reaching the 3rd percentage value. This allows the operator to release the torque for a while and recharge during the tightening operation. |

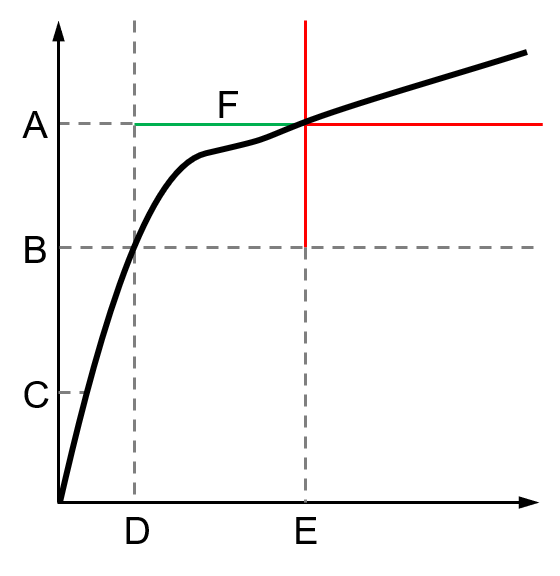

A | Minimum torque limit | D | Angle measurement start |

B | Final angle monitoring torque | E | Angle limit |

C | Cycle start | F | Angle range for OK results |

Define the values of the following parameters to get an OK result:

Final angle monitoring torque

Minimum torque limit

Angle limit

Results:

If the Minimum torque limit value is reached within the Angle limit value (measured from Final angle monitoring torque), the result is OK.

If the Minimum torque limit value is not reached within the Angle limit value (measured from Final angle monitoring torque), the result is not OK.

During the test operation, LEDs, buzzer and vibration are activated as follows:

LED:

White LED: activated when the Cycle start is reached.

Buzzer:

The beep starts when the torque goes over the Cycle start value; the signal increases when the minimum torque is reached / the tightening process has been completed.

Vibration:

Starts when the residual torque is detected.

At the end of the test operation, LEDs, buzzer and vibration are activated as follows:

LEDs:

Green LEDs: Minimum torque detected within the Target angle value (measured from Final angle monitoring torque).

Red LEDs: measured torque is lower or higher than Minimum torque and / or angle value is higher than Target angle (measured from Final angle monitoring torque).

Buzzer

Two beeps indicate the end of the operation; if the final result is in the red area, the signal in continuous.

To stop the buzzer, start a new tightening operation or press a button on the tool controller.

Vibration:

Stays active until the torque applied is released.