Operating the Flange Spreader

Before operating the tool for flange joint, check the minimum access gap should be 5 mm.

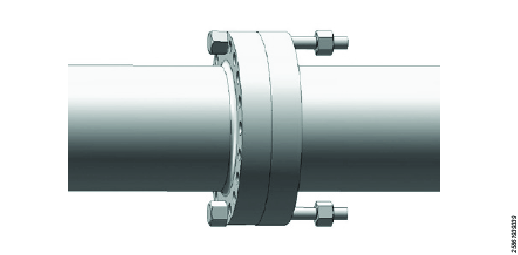

Insert the first flange spreader into the flange Joint access gap.

Insert the second flange spreader into the flange joint access gap.

Make sure the tool is fully inserted.

Operate the pump handle to pressurize the system. Refer to Operating the Pump.

Once the required gap is formed into the flange joint, insert the safety block.

Insert the safety blocks on both sides of the flange joint.

Release the pressure and depressurize the system. Refer to Operating the Pump.

The operator may perform the flange work now.

Close the flange joint after the work is finished.

Depressurize the system after the work is finished.