Introduction

In this section, you can find the basic information about the product and also the formatting conventions used in the topics.

General Description

ToolsTalk 2, the new generation software in controller programming, is ready to take your line management to the next level. The client-server based software solution is geared to provide quick and easy configuration, as well as complete visibility and traceability to your entire line structure. Built on a state-of-the-art user experience and with an extended amount of unique features. Tailored to fit your needs and optimized to get the job done. It allows you to delegate additional features at any time to respective stations, through the embedded simple Functionality Management System (FMS). With 100% customizable user rights, you maintain quality control in complex production systems and increase uptime in production critical operations.

Features

Configuration master of PowerFocus6000, PF6 FlexSystem, accessories, multistep, Fieldbus and Soft plc

Traces analysis and export

Line structure management

Active directory and user administration

Embedded Functionality Management System

Programs library containing full history

Offline and Global programming

Line software visibility and management

Benefits

Reduced training needed due to simple and user friendly interface

Reduced defects with global programs and error notifications

Efficient new product introduction through quick and easy line configuration

Improved productivity due to visibility and traceability on program changes

Increased uptime due to live results analysis and line software management

Full line control thanks to 100% customizable user access permissions

General Data Protection Regulation (GDPR)

This product offers the possibility to process personal identifiable information such as system user name, role and IP-address. The purpose of this processing capability could be to enhance quality control through traceability and proper access management.

If you decide to process personal data you need to be aware of and comply with relevant personal data protection rules, including, in the EU the GDPR as well as other applicable laws, directives and regulations. Atlas Copco can in no way be held liable for any use made by you of the product.

Liabilities and Warnings

Liability

Many events in the operating environment may affect the tightening process and shall require a validation of results. In compliance with applicable standards and/or regulations, we hereby require you to check the installed torque and rotational direction after any event that can influence the tightening result. Examples of such events include but are not limited to:

initial installation of the tooling system

change of part batch, bolt, screw batch, tool, software, configuration or environment

change of air- or electrical connections

change in line ergonomics, process, quality procedures or practices

changing of operator

any other change that influences the result of the tightening process

The check should:

Ensure that the joint conditions have not changed due to events of influence.

Be done after initial installation, maintenance or repair of the equipment.

Occur at least once per shift or at another suitable frequency.

Revision History

Document revision | ToolsTalk 2 Software revision | Changes |

|---|---|---|

12.0 | 2.14 |

|

11.0 | 2.13.4 |

|

10.0 | 2.13 |

|

9.0 | 2.12 |

|

8.0 | 2.11 | N/A |

7.0 | 2.9 | N/A |

6.0 | 2.8 | N/A |

5.1 | 2.7.1 | N/A |

5.0 | 2.7 | N/A |

4.0 | 2.6 | N/A |

3.0 | 2.5 | N/A |

2.0 | 2.4 | N/A |

1.0 | 2.3 | First edition |

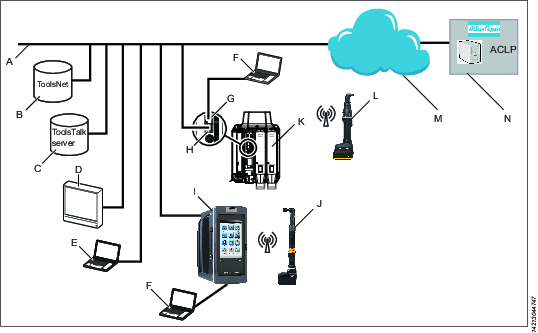

System Overview

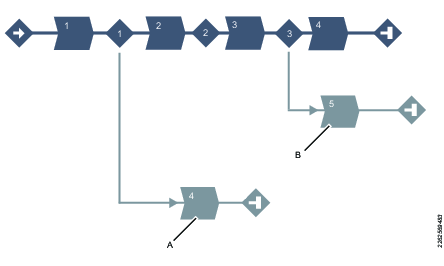

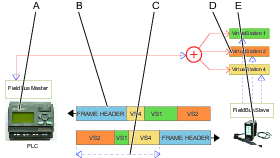

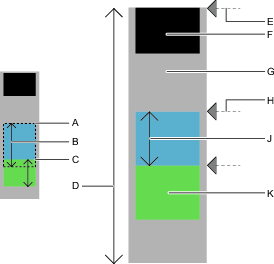

A manufacturing system may consist of the functional blocks in the figure:

A | Factory network. | H | Controller factory port: connected to the factory network. |

B | ToolsNet server: for storing tightening results and for statistical analysis. | I | Power Focus 6000 controller: used with handheld tools. |

C | ToolsTalk 2 server: for configuration and parameter settings for controllers and IXB tools. | J | Handheld battery tool: uses a wireless connection to the controller. |

D | Industrial PC (IPC): can be used as client terminal to the ToolsTalk 2 and ToolsNet servers. | K | PF6 Flex controller: used with fixtured tools. |

E | Portable computer connected to the factory network: can be used as client terminal to the ToolsTalk 2 and ToolsNet servers. | L | IXB handheld battery tool: uses a wireless connection to the factory network. |

F | Service computer: can be connected to the service port of a controller or an IXB tool. | M | The internet cloud. |

G | Controller service port: can be used to connect a service computer. | N | Atlas Copco Licensing Portal (ACLP): located at Atlas Copco and provides support to licensed functionality in the Functional Management System (FMS). |

Software Structure

Icon | Description |

|---|---|

| The ToolsTalk 2 system user administration. Selection of language, temperature and torque units. |

| The Help icon shows the following:

|

| Plant structure Within the plant structure workspace, individual controllers are selected. The workspace is divided into several icons. The menus under each icon are used for configuration of data and parameter settings. The icons differ from the controller interface and the web interface but are very similar in the partitioning and the configurations that can be made under each. |

| Tightening program When selected, the workspace shows a list of existing tightening programs. Selecting an individual program opens the different menus to configure and set parameters for the selected tightening program. |

| Batch sequence When selected, the workspace shows a list of existing batch sequences. Selecting an individual batch sequence opens the different menus to configure and set parameters for the selected batch sequence. |

| Sync Mode The icon is only available on controllers with parallel multistep capabilities. The workspace is used to configure and set parameters for all the synchronized multistep tightening programs. |

| Configurations When selected, the workspace shows a list of existing configurations. The menus where to configure and set parameters vary depending on selected type of device:

|

| Tools The workspace is used to display which tools are connected to the controller and to see and set tool maintenance intervals and calibration data. |

| Virtual stations When selected, the workspace shows a list of existing virtual stations. Selecting an individual virtual station opens the different menus to configure and set parameters for the following:

|

| Controller information Controller hardware and software modules included in the controller. |

| Fieldbus & SoftPLC The workspace is used to configure the fieldbus, acyclic data and SoftPLC settings. |

| Settings

|

| Results Displays the latest tightening results of a selected controller. Results can be shown in a table format or in graphical trace format. |

| Events Displays the latest tightening events for a selected controller. Define what events to display in the event configurations in settings |

| Libraries Includes submenus for managing library templates that can be reused among controllers. |

| Controller library A library of controller configurations. It is very useful in station setup mode which provides a ToolsTalk 2 functionality on a single laptop computer without the need of a server installation. |

| Program Templates library This library contains multistep programs saved as templates to use when creating a new multistep program. Editing a multistep program template will not affect multistep programs based on that template. |

| Tightening Program library A library of tightening programs. It is possible to copy an existing tightening program to the library. Editing a tightening program in the library will affect all controllers that subscribe to the tightening program. |

| Configurations library A library of configurations for virtual stations, devices and accessories. It is possible to copy an existing configuration to the library. Editing a library configuration will affect all controllers that subscribe to the configuration. |

| Fieldbus library A library of fieldbus configurations. It is possible to copy an existing fieldbus configuration to the library. Editing a fieldbus configuration will affect all controllers that subscribe to the fieldbus configuration. |

| Settings library A library for Event configurations that can be distributed to other controllers. The events can be created here or in settings |

| System administration Includes functions for software update, import/export of configuration parameters, task scheduling and the functionality management system. |

| Controller software and data management Manages controller software through the ToolsTalk 2 server. |

| Scheduled export and import Schedules repetitive tasks that affect one or many controllers and that are executed by the ToolsTalk 2 server. |

| Compare configuration Select configuration files to compare. |

| User groups Manages different user groups and the user group rights to folders, controllers and configurations. |

| Functionality Management System (FMS) Manages licensed controller functionality through the ToolsTalk 2 server. |

| Program Approval Manages approvals for tightening and loosening programs. |

| Push The push indicator is shown when configurations have been made to any controller in ToolsTalk 2. Configurations and parameter changes are copied to the controller via the Push function. |

The controller icons differ from the controller GUI and the web GUI but are very similar in the partitioning and the configurations that can be made under each icon.

Configuration Options

The configuration and setting up of a controller can be done in the following ways:

Controller GUI: This is applicable to Power Focus 6000 controllers which have a touchscreen. A controller can be configured regardless whether it is connected to the network or not.

Web GUI: A PC can be directly connected to the controller service port or if the controller is connected to the network and its IP address is known, it can be accessed from a computer anywhere on the network. One controller at a time can be accessed. For a Power Focus 6000, the web-GUI has the same icons as the controller GUI. For a FlexController, the icons are slightly different. All controllers might have icons that could be unique to them.

ToolsTalk 2 GUI: If the controller is connected to a ToolsTalk 2 server, a ToolsTalk 2 client (PC) can access all connected controllers through the ToolsTalk 2 GUI. Both Power Focus 6000 controllers and FlexControllers can be accessed. The GUI uses a full PC screen and has different partitioning and a different icon, but provides the same functionality.

ToolsTalk 2 GUI in Station Setup mode: Provides a ToolsTalk 2 interface on a PC without a server installation. The PC is connected to the controller service port and provides access to one controller at a time.

Conventions

To enhance user understanding, certain formatting conventions are used throughout this document. The formatting conventions used are listed below.

Element | Notation | Description | Output |

|---|---|---|---|

General emphasis | In the Program workspace. | To make certain text elements stand out, or to highlight. | Text in Bold |

Graphical User Interface (GUI) items | Select the Function button. | Any reference to items found on screen in the GUI (for example, command buttons, icon names and field names). | Text in Bold |

Graphical User Interface (GUI) Path > | Generally, on the top of the GUI. | Navigation aid which keeps track of the location in the GUI. | For example: Controller > Program > Edit |

User input | Enter a Description for the program. | Any text input by the user. | Text in Bold |

File names | Enter a File Name for the export. | Files either exported from, or imported into the system. | Text in Bold Italic |

Variable and parameter names | Enter a Name for the export. | Variable and parameter names (not values). | Text in Italic |

Variable and parameter values | Enter a VALUE for the export. | Variable and parameter values. | Text in BOLD CAPS |

System output | Client.Domain.Models.ExportImportConfiguration | Any text output by the system. | Text in Monospace |

External links | Links to external sites that have information connected to the document or subject content. These could include:

| Selectable text to external sites | |

Internal documentation links |

If available, these links will be presented below the text. | Selectable text to internal content |

License Levels

Line Licenser, Line Configurator and Line Manager

These three versions are all client-server based installations of ToolsTalk 2, but with different feature sets. Line Licenser is the smallest package in which ToolsTalk 2 enters on a clean installation, when neither of the other licenses have been installed. When ToolsTalk 2 has the status Line Licenser, all Line Manager and Line Configurator functionality will be visible, but a warning message will appear every time the user tries to use the included features.

ToolsTalk 2 will only remove, unlink, or delete data created in Line Manager, if a downgrade is initiated. This could happen for example when downgrading to a Line Configurator license, or if the trial period of the Line Manager license has expired.

Station Setup

This is a version of ToolsTalk 2 where all the components are located locally on the computer, giving a one-to-one connection. Station Setup runs without an SQL server database connection and has a built-in limit that enables only one connected controller at a time. Note, a valid license is required to use Station Setup, otherwise a warning message will be displayed.

An unlicensed Station Setup can have one virtual station and this will be validated against the License Server.

License Functionality

Symbol | Description |

|---|---|

X | Full functionality. |

X¹ | Connect, disconnect, and restart enabled. |

X² | Push is enabled if changes are made. |

X³ | Custom sections, restart, and right-click functionality enabled. |

X⁴ | Only Database maintenance enabled. |

X⁵ | Read access only, program export enabled. |

Line Licenser | Line Configurator | Station Setup Licensed | Line Manager | |

|---|---|---|---|---|

Plant Structure | ||||

Right-click - Add new controller | X | X | X | X |

Right-click functionality | X¹ | X | X | X |

History on program configuration | X | |||

Tightening Program | X⁵ | X | X | X |

Batch Sequence | X⁵ | X | X | X |

Sources | X⁵ | X | X | X |

Configurations | X⁵ | X | X | X |

Tools | X⁵ | X | X | X |

Virtual Stations | X⁵ | X | X | X |

Controller | X⁵ | X | X | X |

Settings | X⁵ | X | X | X |

Fieldbus | X² | X | X | X |

SoftPLC | X | X | X | |

Results | X | X | X | |

Events | X | X | X | X |

Library | ||||

Tightening Program | X | |||

Configurations | X | |||

Fieldbus | X | |||

Settings | X | |||

Program Templates | X | |||

Controller Configuration | X | X | X | |

System Administration | ||||

Controller Software & Data Management | X³ | X³ | X | |

Scheduled Task | X⁴ | X⁴ | X⁴ | X |

Functionality Management System (FMS) | X | X | X | X |

User Groups | X | |||

Program Approval | X |

Installation and Upgrade

In this section, you can find information to help with the initial installation of the product, or upgrading from one version to another.

Installation Restrictions

Compatibility Matrix

All versions of ToolsTalk 2 software are backwards compatible unless stated otherwise

ToolsTalk2 | PF6 FlexSystem | PF6000 | PF6000 StepSync | Atlas Copco Data Communication Version | IXB | PF8 | PF8 StepSync |

|---|---|---|---|---|---|---|---|

2.3 | N/A | 2.0, 2.1, 2.1.1, 2.3 | N/A | N/A | N/A | N/A | N/A |

2.4 | N/A | 2.4 | N/A | N/A | N/A | N/A | N/A |

2.5 | 1.2 | 2.4 | N/A | N/A | N/A | N/A | N/A |

2.6 | 1.2 | 2.5 | N/A | N/A | N/A | N/A | N/A |

2.7 | 1.3 | 2.6 | N/A | N/A | N/A | N/A | N/A |

2.7.1 | 1.3.1 | 2.6 | N/A | N/A | N/A | N/A | N/A |

2.8 | 1.3.1 | 2.7 | N/A | N/A | N/A | N/A | N/A |

2.9 | 2.0 | 2.7 | N/A | N/A | N/A | N/A | N/A |

2.11 | 2.1 | 2.8 | N/A | N/A | N/A | N/A | N/A |

2.12 | 3.0 | 3.0 | 3.0 | N/A | N/A | N/A | N/A |

2.13 | 3.1 | 3.1.1 | 3.1.1 | 1.7 | N/A | N/A | N/A |

2.14 | 3.3 | 3.3 | 3.3 | 1.9 | 3.3 | N/A | N/A |

ToolsTalk 2 can run with higher versions of Atlas Copco Data Communication. The Atlas Copco Data Communication version mentioned in the matrix is to be considered as the lowest version the ToolsTalk 2 software is compatible with.

Before Installing or Upgrading

It is not recommended to have both a Station Setup and a Client-Server installation on the same computer. Make sure to uninstall and clear the computer from the components of the unwanted installation.

Server Installation

The Microsoft SQL database, the ToolsTalk 2 server application and the ToolsTalk 2 client application, can all be installed on the same computer.

Before starting the installation, make sure the following is available:

Administrator rights to the computer upon which the server application is to be installed.

Administrator rights to the computer upon which the client application is to be installed.

Computers and programs according to the listed prerequisites.

A completed installation of the 64-bit Microsoft SQL database according to the listed prerequisites.

An executable file for the server application.

An executable file for the client application.

Atlas Copco Data Communication (ACDC) is installed and running and is compatible with the current version of the ToolsTalk 2 (only for versions of ToolsTalk 2 from 2.13 onwards). Please see the Atlas Copco Data Communication Installation Manual.

Station Setup

Before starting the installation, make sure the following is available:

Administrator rights to the computer upon which the application is to be installed.

Computers and programs according to the listed prerequisites.

An executable file for the Station Setup application.

Database Requirements

All controller data and configurations are stored in the database catalog. The database is a standard 64-bit Microsoft SQL database.

The installation of a Microsoft SQL database is not described in this document. It is recommended to follow a standard installation.

The Microsoft SQL database may be located on the same server or the same network as the ToolsTalk 2 application.

If the database is located elsewhere, firewall needs to be properly configured between the database and the ToolsTalk 2 application server.

The IP address of the Atlas Copco Data Communication server must be known and entered into every controller that is connected to ToolsTalk 2

The server address that hosts the ToolsTalk 2 application must be known by the client PC if a remote connection is being used.

Mandatory when installing the Microsoft SQL database

64-bit Microsoft SQL.

Select both Microsoft SQL server authentication and windows authentication.

Recommended when installing the Microsoft SQL database

Include the management studio in the installation.

Enable the default instances.

Computer Requirements

The ToolsTalk 2 ecosystem requires the following functions to be in place:

64-bit is required for client, server, Station Setup and ClickOnce.

Area | Category | Minimum Requirement | ToolsTalk 2 Release Version | Comments |

|---|---|---|---|---|

Server software requirements | Database | SQL Server 2014 R2, or later version SQL express 2014 R2, or later version (Compatible but not recommended) | The database can be located locally on the same machine, or installed on a remote database server. | |

Java | Version 8 or later | ≥2.3 | 64-bit version | |

.NET Framework | Version 4.6 | 2.3 - 2.4 | ||

Version 4.6.2 | 2.5 - 2.12 | |||

Version 4.8 | 2.13 - current version | |||

Server hardware requirements | Processor | Dual Core 2.70 GHz Intel Xenon or higher | This specification is only meant to give an indication of the performance needed. | |

Memory (RAM) | 4 GB | This specification is only meant to give an indication of the performance needed. | ||

Disk space | 50 GB | Note that the database will grow over time. Configurations and configuration changes are stored to the database. More controllers will also add more info to the database. | ||

Disk speed | 5400 rpm or higher | |||

PC client requirements | Operating system | Windows 10 Windows 7 | 2.14 2.3 - 2.13 | ToolsTalk 2 version 2.14 does not support Windows 7! |

.NET Framework | Version 4.6 | 2.3 - 2.4 | ||

Version 4.6.2 | ≥2.5 - 2.12 | |||

Version 4.8 | 2.13 - current version | |||

User rights | Database access | System administrator access or similar | Users performing the installation, must also have admin rights to create users in the database. | |

Windows access | Administrator account | Needed in order to install the application and its dependencies. |

License Requirements

An Atlas Copco license server is needed when the Functional Management System (FMS) is being used for licensed Feature items.

The license server is included in the server installation file. For correct installation the JAVA_HOME system variable must have a correct path and point at the 64-bit Java installation.

The FMS can only be used in a client-server installation and is not applicable in a Station Setup installation.

Installation Sequence

The installation sequence for any of the ToolsTalk 2 applications should be as follows:

Make sure all the computer and database requirements are met before installation.

Install the Microsoft SQL server.

Refer to https://docs.microsoft.com/en-us/sql/database-engine/install-windows/install-sql-server?view=sql-server-ver15 for the correct installation procedures.

Install Atlas Copco Data Communication if applicable.

Refer to the Atlas Copco Data Communication Installation guide for further information.

Install the required ToolsTalk 2 application.

Deploy the ToolsTalk 2 application if installing the ToolsTalk 2 client application or run the application from the start menu and create shortcuts if required.

License the ToolsTalk 2 application so you get the right features you subscribed to.

Software Installation

ToolsTalk2 Configuration Window

With the ToolsTalk 2 configuration, it is possible to finish the installation of the ToolsTalk 2 software first and then configure the different installation parameters. The ToolsTalk 2 configuration for each installation type is available as a shortcut in the start menu after the installation and so it can be accessed anytime to make changes to the installation parameters.

Default Installation Locations

Installation | Default Location | Remarks |

|---|---|---|

ToolsTalk 2 Server | C:\Program Files (x86)\Atlas Copco\ToolsTalk Server\ | Can be changed to a desired location by the user |

ToolsTalk 2 ClickOnce | C:\Program Files (x86)\Atlas Copco\ToolsTalk ClickOnce\ | Can be changed to a desired location by the user |

ToolsTalk 2 Client | C:\Program Files (x86)\Atlas Copco\ToolsTalk Client\ | Can be changed to a desired location by the user |

ToolsTalk 2 StationSetup | C:\Program Files (x86)\Atlas Copco\ToolsTalk StationSetup\ | Can be changed to a desired location by the user |

AtlasCopco FMS | C:\ProgramData\AtlasCopcoFMS\ | The default path should not be changed! |

Flexera Logs | C:\Windows\ServiceProfiles\NetworkService\Flexnetls\acopco\logs | The default path should not be changed! |

Installing the ToolsTalk Server Application

Before you begin with the ToolsTalk 2 server installation, make sure all the requirements are met as described in section Before Installing or Upgrading.

Before installing the Server Application, make sure that the Atlas Copco Data Communication (ACDC) installed and running is compatible with the current version of the ToolsTalk 2 (only for versions of ToolsTalk 2 from 2.13 onwards). Please see the Atlas Copco Data Communication Installation Manual.

Place the executable file ToolsTalkServer<xxx>.exe in a desired folder on your computer. The <xxx> represents the version of the file.

Double-click on the executable file.

Select Yes to Do you want to allow this app to make changes to your device?

Select Next in the Atlas Copco Tools Talk Server - InstallShield Wizard window to continue.

Read and then select I accept the terms in the license agreement. Select Next to continue.

Select Print if you would like to print the license agreement.

Select Change... to install the application in a different location. The default location is C:\Program Files (x86)\Atlas Copco\ToolsTalk Server\

Select Next to continue.

Select Install to finish the installation.

Select Finish to complete the installation and the ToolsTalk 2 Configuration window opens up or the User Access Control dialog from Windows may be prompted.

If Windows prompts the User Access Control dialog requesting permission, Select Yes to Do you want to allow this app to make changes to your device?

When the installation is completed, the ToolsTalk 2 Configuration window opens up.

If you select No, then the ToolsTalk2 Configuration window does not open automatically and you need to access it from the Windows Start Menu. If the ToolsTalk 2 configurator is opened from the Windows Start menu, select Force Initialize at the bottom of the ToolsTalk 2 Configuration window to complete the installation procedure.

If an error occurs during installation, a step is unclear, or a parameter name or value is unclear, look for more information in the Troubleshooting section.

Enter the parameters in the Server Settings.

Selecting Save will save the Server Settings and will try to restart the service.

if you select Save before entering and completing the Database Installation Settings, an error Changes accepted, but failed to control dependent Windows service appears.

Go to Database Installation Settings and enter the User name and Password and select Test Connection to test the database connection.

The User name and Password should be the same as used for the Microsoft SQL Server installation.

Select Install Database.

Upon successful installation of the database, the message Database creation succeed is displayed.

Select Save and Close.

If you receive a notification about Dependent service not started, restart the FNLS-acopco service and restart the ToolsTalk 2 configuration again. When both the services are up and running, continue with the installation.

Server Settings Parameters

Parameters | Description |

|---|---|

SQL Server Address | IP or Hostname of the SQL Server The Microsoft Windows Defender Firewall will prevent connections through the network to SQL Server. Therefore, it is required to configure SQL Server to accept connections by using TCP/IP. This setting can be modified in section SQL Server Configuration Manager in Windows Computer Management. Computer Management -> SQL Server Configuration Manager -> SQL Server Network Configuration -> Protocols for MSSQLSERVER -> TCP/IP -> Enabled |

Database Name | The Database/Catalog used by ToolsTalk 2. The database will be created during database installation if not already existing. |

Parameters | Description |

|---|---|

Authentication Mode | The authentication mode used to verify user authority. Select Windows (Active directory) or None. |

Active Directory Group | Only visible if the Authentication Mode selected is Windows. Specifies what active directory group a user must be member of. Example: DOMAIN\GROUP |

Server Address | IP or Hostname of the ToolsTalk 2 Server. |

Web Application Port | Communication port for ToolsTalk 2. |

Controller Port | Port 9016 is used as the default controller port. If using the port 9016, make sure this port is open and you can connect to it, else the application will not work. Port 80 is used when the function Connect/disconnect/add controller is used from ToolsTalk 2 to interact with a controller. |

Make sure that the controller port you enter is open and is possible to connect to!

Parameters | Description |

|---|---|

Controller Backup Folder | Specifies a folder where the backup for the controllers will be located. |

Parameters | Description |

|---|---|

Server Address | IP or Hostname of the Atlas Copco Data Communication server |

Web API Port | Port for Web API |

SignalR Port | Port for SignalR |

Database Installation Settings

Parameters | Description |

|---|---|

User name | The username of a database user with the credentials to create databases/catalogs. Usually the system administrator credential. |

Password | Enter the password. Usually the system administrator credential |

Parameters | Description |

|---|---|

Manual Script | Specifies whether or not the database has been manually created. If this box is checked, ToolsTalk 2 expects that you have already created the SQL catalogue and the default user manually. The entered User Name and Password will be the default credentials that connects to the SQL server and are stored in clear text in the configuration files. This setting should be only used if you have created the database catalogue and user yourself. |

The ToolsTalk 2 application is available in the start menu.

Installing the Client Application

Before you begin with the ToolsTalk 2 client installation, make sure all the requirements are met as described in section Before Installing or Upgrading.

Place the executable file ToolsTalkClientxxx>.exe in a desired folder on your computer. The <xxx> represents the version of the file.

Double-click on the executable file.

Select Yes to Do you want to allow this app to make changes to your device?

Select Yes in the Atlas Copco Tools Talk Server - InstallShield Wizard window to continue.

Read and then select I accept the terms in the license agreement. Select Next to continue.

Select Print if you would like to print the license agreement.

Select Change... to install the application in a different location. The default location is C:\Program Files (x86)\Atlas Copco\ToolsTalk Client\

Select Next to continue.

Select Install to finish the installation.

Select Finish to complete the installation.

If an error occurs during installation, a step is unclear, or a parameter name or value is unclear, look for more information in the Troubleshooting section.

When the installation is completed, the ToolsTalk 2 Configuration window opens up.

Enter the parameters in the Client Settings and select Save.

Server Settings Parameters

Description

Authentication Mode

The authentication mode used to verify user authority. Select Windows (Active directory) or None.

Server Address

IP or Hostname of the ToolsTalk 2 Server.

Web Application Port

Communication port for ToolsTalk 2.

Convert Service URL to IP Address

On or Off. When On is selected, if a hostname is used in the address, it is converted to an IP address.

The ToolsTalk 2 application is installed and a shortcut available on the desktop.

Installing the Client by Using ClickOnce

Place the executable file ToolsTalkServerClickOnce<xxx>.exe in a desired folder on your computer. The <xxx> represents the version of the file.

Double-click on the executable file.

Select Yes to Do you want to allow this app to make changes to your device?

Select Next in the Atlas Copco Tools Talk Server ClickOnce - InstallShield Wizard window to continue.

Read and then select I accept the terms in the license agreement. Select Next to continue.

Select Print if you would like to print the license agreement.

Select Change... to install the application in a different location. The default location is C:\Program Files (x86)\Atlas Copco\ToolsTalk ClickOnce\

Select Next to continue.

Select Install to finish the installation.

Select Finish to complete the installation and the ToolsTalk 2 Configuration window opens up or the User Access Control dialog from Windows may be prompted.

If Windows prompts the User Access Control dialog requesting permission, Select Yes to Do you want to allow this app to make changes to your device?

When the installation is completed, the ToolsTalk 2 Configuration window opens up.

If you select No, then the ToolsTalk 2 Configuration window does not open automatically and you need to access it from the Windows Start Menu. If the ToolsTalk 2 configurator is opened from the Windows Start menu, select Force Initialize at the bottom of the ToolsTalk 2 Configuration window to complete the installation procedure.

If an error occurs during installation, a step is unclear, or a parameter name or value is unclear, look for more information in the Troubleshooting section.

Enter the parameters in the Server Settings.

Selecting Save will save the Server Settings and will try to restart the service.

if you select Save before entering and completing the Database Installation Settings, an error Changes accepted, but failed to control dependent Windows service appears.

Go to Database Installation Settings and enter the User name and Password and select Test Connection to test the database connection.

The User name and Password should be the same as used for the Microsoft SQL Server installation.

Select Install Database.

Upon successful installation of the database, the message Database creation succeed is displayed.

Select Save and Close.

If you receive a notification about Dependent service not started, restart the FNLS-acopco service and restart theToolsTalk 2 configuration again. When both the services are up and running, continue with the installation.

Server Settings Parameters

Parameters | Description |

|---|---|

SQL Server Address | IP or Hostname of the SQL Server The Microsoft Windows Defender Firewall will prevent connections through the network to SQL Server. Therefore, it is required to configure SQL Server to accept connections by using TCP/IP. This setting can be modified in section SQL Server Configuration Manager in Windows Computer Management. Computer Management -> SQL Server Configuration Manager -> SQL Server Network Configuration -> Protocols for MSSQLSERVER -> TCP/IP -> Enabled |

Database Name | The Database/Catalog used by ToolsTalk 2. The database will be created during database installation if not already existing. |

Parameters | Description |

|---|---|

Authentication Mode | The authentication mode used to verify user authority. Select Windows (Active directory) or None. |

Active Directory Group | Only visible if the Authentication Mode selected is Windows. Specifies what active directory group a user must be member of. Example: DOMAIN\GROUP |

Server Address | IP or Hostname of the ToolsTalk 2 Server. |

Web Application Port | Communication port for ToolsTalk 2. |

Controller Port | Port 9016 is used as the default controller port. If using the port 9016, make sure this port is open and you can connect to it, else the application will not work. Port 80 is used when the function Connect/disconnect/add controller is used from ToolsTalk 2 to interact with a controller. |

Convert Service URL to IP Address | On or Off. When On is selected, if a hostname is used in the address, it is converted to an IP address. |

Make sure that the controller port you enter is open and is possible to connect to!

Parameters | Description |

|---|---|

Controller Backup Folder | Specifies a folder where the backup for the controllers will be located. |

The Active Directory Group and Controller Backup Folder are empty by default.

Parameters | Description |

|---|---|

Server Address | IP or Hostname of the Atlas Copco Data Communication server |

Web API Port | Port for Web API |

SignaIR Port | Port for SignaIR |

Database Installation Settings

Parameters | Description |

|---|---|

User name | The username of a database user with the credentials to create databases/catalogs. Usually the system administrator credential. |

Password | Enter the password. Usually the system administrator credential |

Parameters | Description |

|---|---|

Manual Script | Specifies whether or not the database has been manually created. If this box is checked, ToolsTalk 2 expects that you have already created the SQL catalogue and the default user manually. The entered User Name and Password will be the default credentials that connects to the SQL server and are stored in clear text in the configuration files. This setting should be only used if you have created the database catalogue and user yourself. |

Deploying the Client On a Remote Machine

Browse to the server, via web browser, by using the link:

http://<FULL COMPUTER NAME>:<PORT NUMBER>/deploym

Replace <FULL COMPUTER NAME> and <PORT NUMBER>.

Make sure that the <FULL COMPUTER NAME> is exactly the same as on which the server and database are located. If Full Computer Name [TOOLSE277256.ATLASCOPCO.COM] or Computer Name [TOOLSE277256] is set, then a DNS server must exist and be set in the controller, otherwise it is not possible to add controllers to the ToolsTalk 2 environment.

Save the executable file ToolsTalk.Client.WPF.Desktop.application on your computer.

Double-click on the executable file, or select Open if prompted.

ToolsTalk 2 client opens with the latest version installed.

The ToolsTalk 2 client will always open with the latest server version by using ClickOnce.

Deploying the Client on Local Machine

If ClickOnce was installed in the default folder, navigate to “C:\Program Files (x86)\Atlas Copco\ToolsTalk ClickOnce\ClientDeploy” and double click on ToolsTalk.Client.WPF.Desktop Application manifest file to deploy the client.

Once the installation is completed, the ToolsTalk 2 icon is created on the desktop.

Installing the Station Setup Application

The condensed Station Setup installation has full controller configuration functionality, but also some limitations:

The entire installation has a smaller footprint and is installed on a portable computer.

Only one physical controller can be managed at a time.

The computer is connected to the service port of the controller to avoid interruption of normal activity.

Applications

The typical application for this mode of operation can be the following:

A controller can be accessed using ToolsTalk 2 without connecting to the customer network but instead using the service port of the controller.

Offline configuration of controllers using the controller library features. The configuration file can later be transferred to a real controller for verification.

An easy export of a controller configuration that is very helpful in debugging tasks.

Before you begin with the ToolsTalk 2 Station Setup installation, make sure all the requirements are met as described in section Before installing or Upgrading.

Place the executable file ToolsTalkStationSetup<xxx>.exe in a desired folder on your computer. The <xxx> represents the version of the file.

Double-click on the executable file.

Select Yes to Do you want to allow this app to make changes to your device?

Select Next in the Atlas Copco Tools Talk Server - InstallShield Wizard window to continue.

Read and then select I accept the terms in the license agreement. Select Next to continue.

Select Print if you would like to print the license agreement.

Select Change... to install the application in a different location. The default location is C:\Program Files (x86)\Atlas Copco\ToolsTalk StationSetup\

Select Next to continue.

Select Install to finish the installation.

Select Finish to complete the installation.

If an error occurs during installation, a step is unclear, or a parameter name or value is unclear, look for more information in the Troubleshooting section.

When the installation is completed, the ToolsTalk 2 Configuration window opens up.

Enter the parameters in the Server Settings tab and select Save.

Parameters | Description |

|---|---|

ToolsTalk User Name | Username of the user that is local to the application. |

Server Address | IP or Hostname of the ToolsTalk 2 Server. |

Web Application Port | Communication port for ToolsTalk 2. |

Parameters | Description |

|---|---|

Web API | Web API port |

SignalR | SignalR port |

Controller Port | Port 9016 is used as the default controller port. If using the port 9016, make sure this port is open and you can connect to it, else the application will not work. Port 80 is used when the function Connect/disconnect/add controller is used from ToolsTalk 2 to interact with a controller. |

Make sure that the controller port you enter is open and is possible to connect to!

The ToolsTalk 2 application is available in the start menu.

Station Setup Connection

A computer with a Station Setup of ToolsTalk 2 can be connected to a controller through the network or directly to the service port.

Network Connection

The ToolsTalk 2 server connection address in the controller must be directed to this computer. This is done via the controller GUI or the controller web GUI.

Only one controller at a time can be connected to a computer with a ToolsTalk 2 Station Setup. If an online controller is connected to the ToolsTalk 2 Station Setup computer, subsequent connection attempts from other controllers will be ignored.

Controller Service Port Connection

The controller service port can be used to connect a controller to ToolsTalk 2 when the PC with ToolsTalk 2 is not allowed to be connected to the network. For example, an Atlas Copco - or external - service technician visits a factory and the external computer is not allowed to be connected to the factory network.

If a computer is connected to the service port of the controller, the controller acts as a DHCP server and provides an IP address to the computer. This address must be entered in the controller server connection address field for the ToolsTalk 2 connection.

File Comparison

The configurator stores a copy of all configuration settings as an .xml file called Storage. The file helps in identifying manual changes in the product configuration .xml files. If the product configuration .xml files have been modified, then when you start the configurator, the File Comparison window opens, where you can choose between options Use Storage Files or Use Configuration Files.

SoftPLC Configurator Installation

To be able to use the SoftPLC functionality in a controller, the SoftPLC Configurator must be installed on the computer where a ToolsTalk 2 Client is installed.

Insert a USB device or similar, containing the MultiProg551_Atlas_Installation.

Double-click on Installation.bat in MultiProg551_Atlas_Installation, the installation starts.

Open the ToolsTalk client when the installation is completed (no restart required).

In the ToolsTalk 2 client, go to the Fieldbus and SoftPLC

tab. Select the SoftPLC configuration section and in the General SoftPLC Settings, set SoftPLC to On.

tab. Select the SoftPLC configuration section and in the General SoftPLC Settings, set SoftPLC to On.

Uninstalling the Software

Each one of the modules (Client, Server, Station Setup) can be uninstalled as follows:

Using the windows control panel / Programs and features to select and uninstall the desired programs and modules.

For some modules it may be necessary to restart the computer for the changes to take effect.

Installation Validation

Validating Windows System Services

To verify that background programs and services have started correctly, perform the following check:

Select the Windows Search button.

Type services in the Search windows entry box.

Scroll down and verify that the Atlas Copco Industrial Technique Host for ToolsTalk has started.

This indicates that the ToolsTalk 2 server application is running.

Scroll down and verify that the FlexNet License server - acopco has started.

This indicates that the license server application for the functional management system is running.

Validating the Client-Server Installation

After successful installation of the client-server version of the ToolsTalk 2 application, a controller is needed for a complete system test.

The server computer must be connected to the network.

The client computer must be connected to the network.

The controller must be connected to the network and configured to communicate with the server computer.

Check that Atlas Copco Data Communication service is started.

The server and client may be installed on the same computer.

For configuration and starting the controller please refer to the controller user guide.

For configuration, starting and navigating in the ToolsTalk 2 GUI, please refer to the ToolsTalk 2 user guide.

If the ToolsTalk 2 client is installed, the application can be started in the following way:

Select the Windows Start menu and locate the ToolsTalk 2 folder.

Select the ToolsTalk 2 icon

to launch the application.

to launch the application.

Validating the Station Setup Installation

If the ToolsTalk 2 Station Setup is installed, the application can be started in the following way:

Select the Windows Start menu and locate the ToolsTalk 2 folder.

Select the ToolsTalk 2 icon

to launch the application.

to launch the application.

The ToolsTalk 2 Station Setup application cannot execute if a ToolsTalk 2 client application or a ToolsTalk 2 server application is installed. They can easily be removed by executing their respective installation programs and choose the Remove option in the Program maintenance window.

The Getting started section in the ToolsTalk 2 user guide describes the windows and the window navigation.

The GUI for a ToolsTalk 2 Station Setup application is slightly different if there is no controller connected. Please refer to the information under the library  icon and the controller library

icon and the controller library  icon in the configuration manual.

icon in the configuration manual.

Validating the License Service

This validation process is only applicable for Client, Server and ClickOnce application installations and is not valid for a Station Setup installation.

When the ToolsTalk 2 installation is complete, you will need to check that the license service is ready upon startup.

Open a web browser, browse to the following two pages and complete the steps:

http://”ip-address:port"/api/1.0/health - This page should have the “connectionCheck” : “success”, if not you will need to restart the Flexera service. In some cases more than one restart may be required.

http://”ip-address:port"/api/1.0/hostids - If this page is empty you will need to restart the Flexera service. In some cases more than one restart may be required.

This validation process is not applicable for a Station Setup installation

Upgrading ToolsTalk 2

Please make sure that the ToolsTalk2 server is running before starting the upgrade.

When upgrading ToolsTalk 2 from 2.12 or earlier versions and Atlas Copco Data Communication (ACDC) is already installed, make sure that the controller port is pointing to the same port that ACDC was installed on. If you are installing ACDC for the first time and want to use another port than your current controller port in your ToolsTalk 2 version, then please change the controller port as described in the following procedure.

In the configuration files, controller port is named as HubPort.

In ToolsTalk.Server.SelfHostService.exe.config(ClickOnce/Client/Server) or ToolsTalk.Standalone.exe.config(Station Setup), change the controller port to the correct port number <add key="HubPort" value="XXXX" />

Troubleshooting

Troubleshooting During Installation

Restart the ToolsTalk Industrial Technique Host service after upgrading ToolsTalk 2.

Error | Solution |

|---|---|

Error code 1920 Failed to start. Verify you have correct permission | Database authentication error. For the SQL database mixed mode authentication must be configured. Use the SQL management studio to correct the authentication. A restart of the computer is most likely needed before another installation attempt can be made. |

The InstallShield Wizard detects if installations have already been made, when using an installation file. If older installations are present on the computer, they may not be detected.

It is therefore recommended to remove old instances of the program and of the database catalog before starting a new installation.

Configuration

In this section, you can find detailed information about how to create, modify, and verify product settings.

- Getting started

- Working with the Hardware Configuration Tab

- Working with the Tightening Program Tab

- Working with the Sync Mode Tab

- Working with the Batch Sequence Tab

- Working with the Sources Tab

- Working with the Configurations Tab

- Working with the Tools Tab

- Working with the Virtual Station Tab

- Working with the Controller Information Tab

- Working with the Settings Tab

- Working with Fieldbus, SoftPLC and Acyclic Data Tab

- Working with the Libraries Tab

- Working with the System Administration Tab

- Working with Push Configuration Changes

Getting started

Starting

If the ToolsTalk 2 client is installed, the application can be started:

Select the Windows Start menu, open All programs and scroll down to ToolsTalk 2.

Open the folder and select ToolsTalk 2

to launch the application.

to launch the application.

User Interface Start View

After a successful start of ToolsTalk 2 this view below is displayed, containing the icons described above:

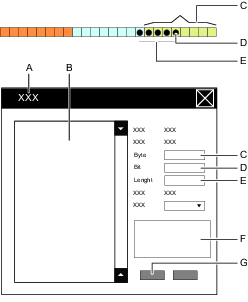

A | Left-side menu bar | C | System menu bar |

B | Plant structure workspace | D | Controller workspace |

The controller workspace area displays different content, depending on the selected icon or menu.

At start the default icon selection is the Plant structure icon  . This is indicated by changing the icon color to light blue. The workspace is divided into two parts:

. This is indicated by changing the icon color to light blue. The workspace is divided into two parts:

The structure workspace is used to organize controllers and to select an individual controller.

The controller workspace shows all the controller icons and is used to view and set all parameters and configurations for one selected controller.

Left menu bar | Function |

|---|---|

Plant structure | ThePlant structure icon |

System administration | The System administration icon |

Libraries | Under the Libraries icon |

System menu bar | Function |

|---|---|

Push changes | Push icon |

User settings | User settings icon |

Help | The Help |

The plant structure view is empty if no controllers are connected to ToolsTalk 2, or if user rights do not allow access to folders or controllers.

Controllers

Controller Types

Apart from the controllers that are supported and configurable using ToolsTalk 2, there is the capability to show other controller types in the Controller List and some limited information about these. The controllers which aren't configurable can launch the relevant software through ToolsTalk 2, where they can be further configured.

The different controller types are represented with an icon in the All Controllers list.

Controller Icon | Controller Type | Compatible Software |

|---|---|---|

| Power Focus 6000 | ToolsTalk 2 |

| PF6 Flex System | ToolsTalk 2 |

| Power Focus 6000 StepSync | ToolsTalk 2 |

| Power Focus 4000 | ToolsTalkPF |

| Power Macs 4000 | ToolsTalkPM |

| Unsupported Controller - A Controller with a higher version and not compatible with the current ToolsTalk 2 release | N/A |

| IXB | ToolsTalk 2 |

Controller Information

The following is an example of the information that a Power Focus 4000, or a Power Macs 4000 controller can display. An Unsupported Controller will not display this information..

Application Boot Software Version

Controller Serial Number

Protocol Version

RBU Serial Number

RBU Type

Software version

Tool Information

The information below is displayed under Tools in ToolsTalk 2. What will be shown here is configured in the respective controller software.

Identifier

Serial Number

Model Type

Service Date

Calibration Date

Tightening Count

Tool Type

Tightenings Since Service

Application Code Version

Boot Code Version

To receive tool information, the controllers will need to be connected to ACDC. For further information please see the ToolsTalk 2 documentation.

Adding Controllers

Controllers connected to ToolsTalk 2 may be visible in the Plant structure

.

.

The plant structure view is empty if no controllers are connected to ToolsTalk 2, or if user rights do not allow access to folders or controllers.

Select Plant structure and then right-click anywhere in the upper area of the controller list. Alternatively, select System administration, then in the Controller software & data management tab right-click in the left-side menu workspace area. Choose Add new controller. The Connect controller dialog window opens.

Enter the IP address, or the DNS name of the controller. The IP address of the ToolsTalk 2 server will be pre-populated.

Select Connect and select Close once the Controller online message is displayed.

Connection Status

If you enter the IP address of an already connected controller in the Connect controller window, the message Controller already connected and online is displayed.

The message Waiting for controller to come online is displayed while the connection is being established.

The message Controller online is displayed when the connection to the controller is established.

The message ToolsTalk failed to connect to controller. Please verify IP address/DNS name is displayed if the connection failed.

A controller can also be connected to the ToolsTalk 2 application via the web GUI or controller GUI.

This procedure is described in the controller specific documentation.

Managing the Controller List

The Plant structure workspace  default view displays All controllers. The All controllers view contains all the controllers currently connected to the ToolsTalk 2 server, regardless of whether they are online or offline. Custom Sections is a subsection of All Controllers ordered into folders.

default view displays All controllers. The All controllers view contains all the controllers currently connected to the ToolsTalk 2 server, regardless of whether they are online or offline. Custom Sections is a subsection of All Controllers ordered into folders.

Selecting a Custom Sections folder

On the top of the controller list, click the options button,  and select Custom Sections and then select the appropriate folder.

and select Custom Sections and then select the appropriate folder.

Selecting a Controller

In the left side menu bar, select Plant structure

.

.Scroll down to the relevant controller and select it by clicking on the name field

.

. The selected controller is highlighted. A controller with an online status constantly updates the ToolsTalk 2 application.

Offline controller names are struck-through.

A controller in offline status may display old and outdated information if changes have been made through another controller interface other than ToolsTalk 2.

It is possible for several ToolsTalk 2 users to access the same controller. If an attempt is made to select a controller, which is already selected by another ToolsTalk 2 user, a modal dialog box is displayed with the following warning message:

Other users are currently active in the system. Parameter values may be changed without notice.

Select OK to close the dialog box and to continue.

Searching for Controllers

In the Plant structure workspace there is a field for searching for controllers in the controller list.

In the search field, enter at least two letters of the controller name.

It is possible to search for the controller name or type.

Remote Controller Restart

In certain circumstances it may be required to make a complete power on reset (POR) of the controller.

The following describes how to make a remote POR from ToolsTalk 2:

In the left side menu bar, select Plant structure

.

.Right-click on the selected controller and select Restart in the shortcut menu

Confirm or cancel the controller restart operation in the modal window dialog. The controller will first go offline before it gets back online.

This operation may take a few minutes.

While this is in progress, it is possible to perform other tasks in ToolsTalk 2.

It is only possible to make a remote restart on a controller that is online and connected to the ToolsTalk 2 application server. Offline controller names are struck-through.

Saving Changes in Parameters and Configurations

When a controller has a status of On-line, it automatically updates ToolsTalk 2 if any changes are made in the web GUI or in the controller GUI.

Any changes made in ToolsTalk 2 are automatically saved but are not copied to the controller. A Push copies changes to the controller and is executed by an active command.

A push indicator  is displayed beside the controller name in the plant structure

is displayed beside the controller name in the plant structure  workspace to indicate that configuration changes have been made in ToolsTalk 2 but not yet copied to the controller.

workspace to indicate that configuration changes have been made in ToolsTalk 2 but not yet copied to the controller.

A push can be made in several ways:

Select the Push indicator icon

next to the controller name in the controller list.

next to the controller name in the controller list.Click the Push command button

in the system menu bar to start copying changes from ToolsTalk 2 to one or more controllers. A shortcut menu opens to select affected controllers

in the system menu bar to start copying changes from ToolsTalk 2 to one or more controllers. A shortcut menu opens to select affected controllersRight click on a controller name in the plant structure

workspace and select the Push command button in the shortcut menu. Changes are copied from ToolsTalk 2 to the one selected controller.

workspace and select the Push command button in the shortcut menu. Changes are copied from ToolsTalk 2 to the one selected controller.

It is not possible to make a Push to a controller which has a status of Off-line.

Managing the Workspace Windows

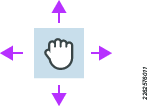

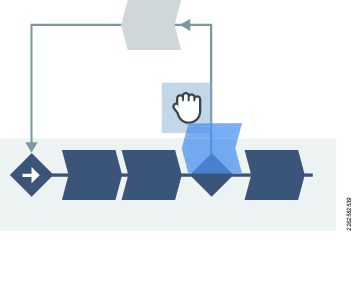

The workspace for plant structure and reports both involve the selection of a single controller for further work. The workspace can be minimized or maximized to increase the space for the controller workspace by either, dragging as described and shown in the image below, or by selecting the Plant structure icon  .

.

Minimizing and Maximizing the Workspace View

Place the cursor on the line between the two workspace areas. The cursor shape changes from a white arrow to the shape of a horizontal double sided arrow.

Click-hold-drag and the border line between the two workspace area can be moved. The workspace can be maximized by moving the window border all the way to the left-side menu, or maximized by moving the window border to the right-side menu.

Filtering and Sorting the Data Grid

The data grid columns in the workspace windows can be sorted and filtered.

Select a column header to access the sort and filter function.

To sort the list, select Sort list to arrange the list into ascending, descending, or default order.

To filter the list, select the check boxes to filter what is to be displayed. Select Clear filter to return to the default view.

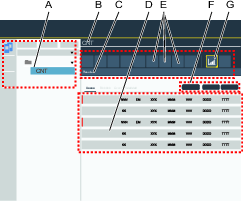

User Interface - Workspace With Controller Overview

After selecting a controller and selecting a controller menu icon, the controller workspace can show the following information.

A | A selected controller in the Plant structure workspace |

B | Controller name in the controller workspace. The name is identical to the selected controller name in the Plant structure |

C | Name of the selected controller menu icon |

D | List of configurations with overview information in the controller workspace |

E | Controller menu icons |

F | A row of command buttons in the controller workspace. The type of command buttons vary depending on the controller menu icon selected |

G | Selected controller menu icon. Highlighted with a yellow border |

The workspace overview shows either a list of configurations or shows menus with parameter values. If a list of configurations is shown, the next level, the Menu level is accessed by a double-click on a configuration name.

Working with the Hardware Configuration Tab

Offline programming of a Hardware Layout Configuration is made in the Controller Template Library.

Configuration Area

In the configuration area, you can either create a layout from scratch or update the existing layout extracted from your controller.

Extract | Updates the hardware layout configuration according to the hardware connected to the controller. |

Zoom in | Zooms in on the layout. (Ctrl + mouse wheel forward) |

Zoom out | Zooms out on the layout. (Ctrl + mouse wheel backward) |

Fit to screen | Reverts the layout back to a default size. |

Delete | Deletes the selected item. |

Tool box

The toolbox contains all valid products for the controller version.

Creating Hardware Layout

A new installation of a PF6 System does not have any hardware layout.

To create a hardware layout, always start with a carrier (3-slot or 6-slot) from Tool Box. For the sequence of the channel number, it is recommended to use 6-slot carriers first. For any system with more than two FlexCarriers, start hardware configuration with a 6-slot FlexCarrier.

Drag FlexCarrier to the Drop here area and drop it. Indicators are displayed. You can point to a symbol to get a tooltip .

Drag other products from Tool Box to a target place. When pointing to a target place with a product, the target place will change color:

Red: invalid drop

Blue: valid drop

You can move, copy and remove a single product or a carrier with all its products.

To move, click and drag the product.

To copy, press Ctrl and drag the product.

To delete, choose the product and press Delete. The FlexCarrier containing the FlexController can only be deleted when it is the single remaining carrier.

Extracting a hardware layout configuration

If the Hardware Layout Configuration is empty, a current controller setup can be extracted by using the Extract button.

Select Extract, the Extract Hardware Configuration dialog box opens.

Select OK to extract the current configuration.

After extracting, push the changes to the controller in order to receive status and health. The hardware deployment status will change after validation.

Status

When the controller is connected and online, and the hardware layout configuration is in sync with the controller, ToolsTalk 2 will start to receive notifications of changes in the hardware deployment status. Once notified, ToolsTalk 2 will ask the controller for the Hardware measurement data.

To see detailed deployment status and measurement data:

Select the product in the configuration area. Multiple products can be selected by pressing Ctrl and select.

Click on the Status bar to expand the window.

Tips:

The height of panel can be increased by dragging the top border.

To get the latest measurement data, click Refresh.

The details of Health status can be expanded. Select Show only NOK to only view the data with NOK result.

Tool configuration

For each tool, it is possible to select a tool configuration from a list containing all available tool configurations. By default, no mapping of Tool Configuration is made. It is possible to run tools that are not mapped to a tool configuration. In this case, the controller will use an internally created default Tool Configuration without any of the dual transducer functionality enabled.

Inhibit mode

If there is something wrong with the channel (Drive or tool), inhibit mode can be set to continue using your hardware:

False: Channel is running OK.

Report OK: Channel is disabled and reports OK in result.

Report NOK: Channel is disabled and reports NOK in result.

Report No Result: Channel is disabled and do not show up in the result.

Carrier

There are two types of carriers:

3-slot

6-slot

You can have maximum 11 carriers in your configuration. The carrier with controller is always the first carrier. All the carriers need to be dropped after the first carrier.

Controller

The controller can only be added to the first slot of the first carrier. It is not possible to add the Controller product to any other slots in the system.

Drive

The drive can be placed in all free slots except the first carrier’s first slot or slot with channel number 65. See section on channel numbering for further information.

You can have maximum 64 drives in your configuration.

Blank

The blank can be placed in all free slots except the first slot of any carrier.

Fan

The fan product can only be dropped at the top of a carrier. A 3-carrier has one fan module and a 6-carrier has two fan modules.

E-Stop

There are three different types of E-Stop:

E-Stop ASM

E-Stop Entry

E-Stop ByPass

The first two E-Stops can only be dropped in the configuration’s first carrier. All other carriers can only have an E-Stop ByPass.

Tool

The Flex system can only add QST tools. The tool can only be dropped on a Drive that does not have a tool connected.

Symbols

Symbols indicate status of each product. You can always point to each indicator to get a tooltip.

| Warning |

| Not expected |

| OK |

| Empty |

| Wrong type |

| Missing |

Channel Numbering

When a system is powered up a channel number (also named drive index) will be assigned to each FlexDrive. The drive index is dependent of which FlexCarrier and where in the FlexCarrier the FlexDrive is mounted.

Example: Channel numbering

Carrier 1 | Slot 1 | Slot 2 | Slot 3 | Slot 4 | Slot 5 | Slot 6 |

Controller | Drive | Drive | Drive | Drive | Drive | |

Drive index | - | 2 | 3 | 4 | 5 | 6 |

Carrier 2 | Slot 1 | Slot 2 | Slot 3 |

|

|

|

Drive | Drive | Drive | ||||

Drive index | 7 | 8 | 9 |

Working with the Tightening Program Tab

Select a controller in the Plant structure workspace

.

.On the toolbar, select Tightening program

.

.The Tightening program overview shows a list of tightening programs.

The list has the following columns:

Column | Description |

|---|---|

Check box | Select a tightening program by marking a check box. |

Name | Name of the tightening program. A Push indicator |

Strategy | The tightening strategy selected for the tightening program. |

Library Link | Indicates if the program is linked to a Global tightening program in the tightening program library. |

Target | The final tightening target is either expressed as a torque value or as an angle value. |

Last change | Last changes made, expressed in ToolsTalk 2 time. |

Changed by | Indicates which user made the last changes. |

Controller updated | Last changes pushed to a controller, expressed in controller time. |

Controller updated by | Indicates which user made the last push to the controller. |

Approval status | Approval status of the tightening or loosening program |

The field Changed by can be a registered ToolsTalk 2 user, as it is done via the ToolsTalk 2 GUI.

The field Controller updated by can be a registered ToolsTalk 2 user, via the web-GUI or via the controller-GUI.

Command | Description |

|---|---|

Add | Creates a new tightening program. |

Add to library | Converts a Local tightening program into a Global tightening program. |

Unlink | Converts a Global tightening program into a Local tightening program. |

Compare | Compares two selected tightening programs. These must have the same strategy. |

Delete | Removes selected tightening program(s) from the list. |

Tightening Program Menu

Each row in the list represents one multistep tightening program.

Header | Description |

|---|---|

Check box | Used for selecting a specific tightening program. |

Name | A user-defined name. |

Strategy | Selected strategy for the tightening program. |

Library link | Linked to global library Yes/No. |

Target |

|

Last changed | Time expressed in ToolsTalk 2 time. |

Changed by | Tightening program changed by <user> |

Controller updated | Controller updated, expressed in controller time. |

Controller updated by | Controller updated by <user> |

Approval status | Approval status of the tightening or loosening program |

Command | Description |

|---|---|

Add |

|

Manage |

|

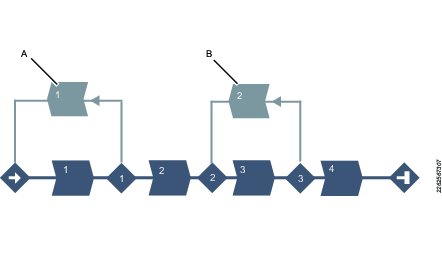

Multistep Tightening Introduction

A multistep tightening is a tightening done in several steps. The number of steps and the type of the steps vary depending on the tightening to be done.

Often a multistep tightening is run with many tools in parallel, for example, to tighten the five bolts holding a wheel on a car. To make sure the tightening is done properly all the tools must run synchronized so they reach the same torque at roughly the same time.

To make sure this synchronization happens, the multistep program uses synchronization points. At a synchronization points each tool stop. When all of the tools have reached the synchronization point the tools continue with the next step until they reach the next synchronization point.

The number of steps between the synchronization points is flexible and could vary from 1 to 10. It is not necessary for the multistep programs running on different tools to have the same number of steps between the synchronization points. A multistep tightening program is highly configurable and the actual layout of different multistep programs can vary wildly.

Example: Multistep tightening program

Pos |

|

A | Step 1 and 2 engage the tool on the bolt. |

B | A fast rundown is made with step 3. |

C | Step 4 and 5 run the actual tightening |

D | Step 6 is used to release the socket from the bolt. |

Restrictions

Restrictions are used to make sure the tightening stops if something unexpected occurs. These restrictions could, for example, test that a maximum set torque is not reached or that a part of the multistep tightening does not take too long to run. Every step can have up to four restrictions each.

Monitors

Monitors are used to verify that the tightening was made according to the specification. This can be, for example, angle limits or torque limits. Every step can have up to four monitors each.

Sync mode

With sync mode it is possible to run different tightening programs on different tools at the same time. The main function of the sync mode is to define the tools that shall be included in a synchronized tightening and specify the tightening program each tool shall run.

Reject management

If something goes wrong in a tightening program the program can either do a repair or the program is terminated.

The reject management works like this, when all tools have reached a synchronization point the status of each tool and the total status is evaluated. If all channels at the synchronization point are OK the program continues with the next step. If something is NOK the program will repair or terminate according the set action.

Adding a Multistep Program

Select the Add button. The Create new Tightening program dialog window opens.

Enter tightening program name, index number (only valid for tightenings), and select tightening strategy Multistep. The tightening program will be issued with the next sequential number in the list of programs, if no active selection of the index is made.

Select the Add button.

Copying and Pasting a Tightening Program

Existing tightening programs can be copied as a template and then pasted on another controller.

Copy and Paste are only possible if they are performed on the same controller, or different controllers running the same software version and controller type.

In the Plant structure

area, select a controller.

area, select a controller.Go to Tightening Program

.

.The workspace area displays all the tightening programs available.

Right-click on a single row to be copied, or to copy many, select the check box

on each of the programs you want to copy, and then right-click.

on each of the programs you want to copy, and then right-click.Select Copy.

Right-click anywhere in the empty workspace area, and then select Paste to add the tightening program to the first available position in the list. Alternatively, right-click and choose Paste with index to choose the position in the program list. Double-click to open the tightening program and modify.

It is also possible to paste the tightening program template into the Program Templates library workspace.

Importing a Multistep Program

Select the Add button. The Create new Tightening program dialog window opens.

Select the Import tab.

Select Open file and select the file from the desired location. The file must have the format <template_name>.json. Select Open.

Deleting a Multistep Program

For each Multistep program to be deleted, mark the check box in the leftmost column in the workspace area.

Select the Manage command button, then Delete from the drop-down list.

The selected Multistep program(s) are removed and the list is updated.

Comparing Multistep Tightening Programs

In Tightening Programs, two different Multistep Programs can be compared.

Go to the Tightening Program tab

, in the list of programs select the corresponding check boxes of the Tightening Programs to be compared.

, in the list of programs select the corresponding check boxes of the Tightening Programs to be compared.

Only Multistep Programs with the same operation mode can be compared, Tightenings with Tightenings and Loosenings with Loosenings.

Select the Manage command button, and then select Compare.

The workspace displays graphical images of the actual Multistep Program Steps, and in the Compare area, the parameters for the two selected tightening programs are shown.

In the Compare window, the specific parameter values that differ will be displayed in red. Select the check box Show only differences to display only the parameter values that differ. The Properties and Steps sections which include parameters that differ will be marked with a blue indicator.

It is not possible to edit the two Multistep Programs that are being compared and configuration errors or warnings will not be shown.

Global Tightening Program

A tightening program can be either Local or Global. If a tightening program is global, it is indicated with a Yes in the Library link column in the list of tightening programs.

A Local tightening program is valid for a single controller.

Select a controller in the Plant structure workspace

.

.On the toolbar, select Tightening program

.

.The Tightening program overview shows a list of tightening programs.

A Local tightening program can only be edited via the Tightening program  tab.

tab.

A Local tightening program is not visible in the Tightening program library  .

.

A Global tightening program is valid for multiple controllers subscribing to the tightening program. The Global tightening programs are located in the tightening program library.

Select Library

in the left-side menu bar.

in the left-side menu bar. Select Tightening program library

in the top menu bar.

in the top menu bar. The Tightening program library shows a list of global tightening programs.

If a controller subscribes to a Global tightening program, it is visible in Tightening program  , but editing is prohibited.

, but editing is prohibited.

A Global tightening program can only be edited via the Tightening program library  .

.

Tightening Editor

Buttons

Name | Description |

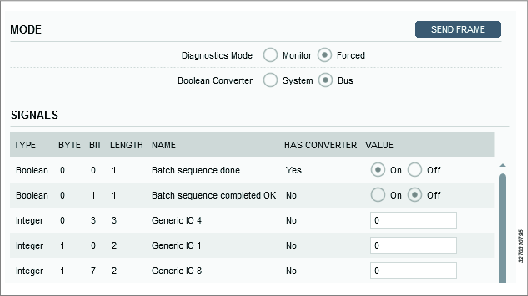

|---|---|