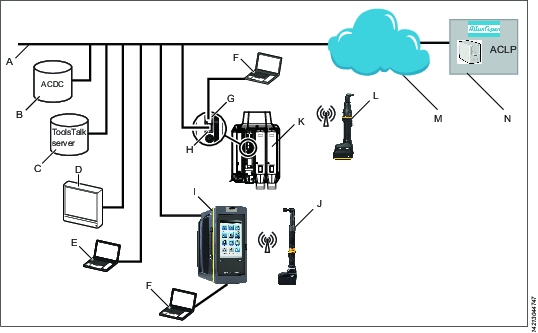

System Overview

A manufacturing system may consist of the functional blocks in the figure:

A | Factory network. | H | Controller factory port: connected to the factory network. |

B | ACDC: for storing tightening results and for statistical analysis. | I | Power Focus 6000 controller: used with handheld tools. |

C | ToolsTalk 2 server: for configuration and parameter settings for controllers and IxB tools. | J | Handheld battery tool: uses a wireless connection to the controller. |

D | Industrial PC (IPC): can be used as client terminal to the ToolsTalk 2 and ToolsNet servers. | K | PF6 Flex controller: used with fixtured tools. |

E | Portable computer connected to the factory network: can be used as client terminal to the ToolsTalk 2 and ToolsNet servers. | L | IxB handheld battery tool: uses a wireless connection to the factory network. |

F | Service computer: can be connected to the service port of a controller or an IxB tool. | M | The internet cloud. |

G | Controller service port: can be used to connect a service computer. | N | Atlas Copco Licensing Portal (ACLP): located at Atlas Copco and provides support to licensed functionality in the Functional Management System (FMS). |