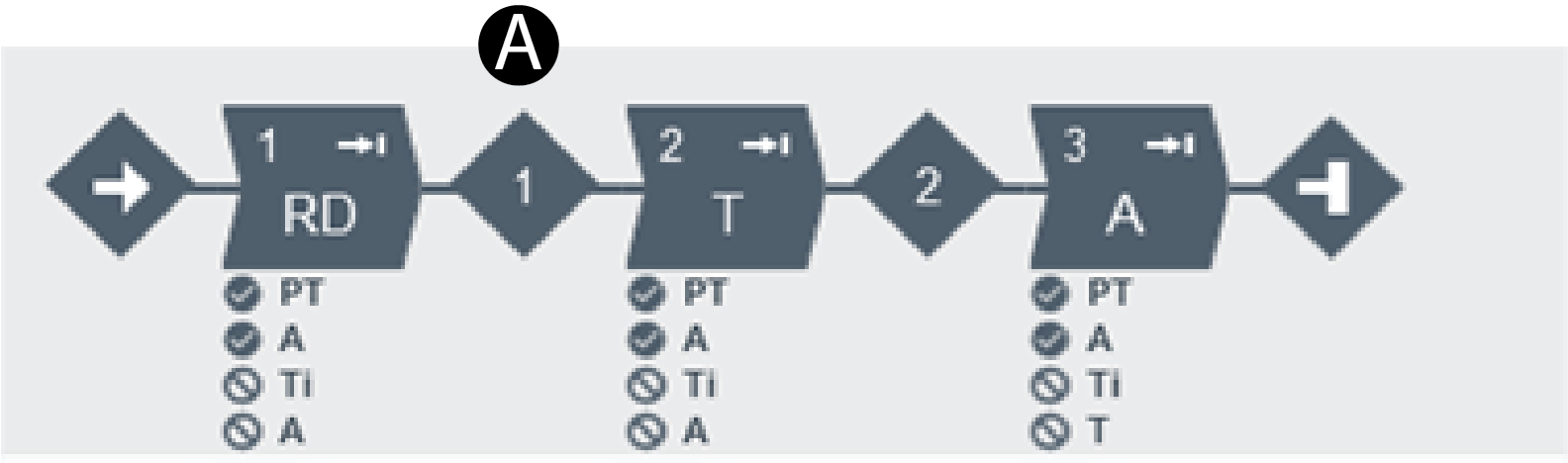

Synchronized Tightenings

It is only possible to use Multistep tightening programs for Synchronized tightening. Synchronization points are used to synchronize the tools in a set-up. At these points, the tools will wait for each other before continuing with the next step in the multistep tightening program.

It is only possible to assign tightening programs to different tools in ToolsTalk2.

A | Synchronization point |

A tightening program can consist of a maximum of 25 steps (Synchronization points not included).

Available steps

Tighten to Angle

Tighten to Torque

Tighten to Torque plus Angle

Tighten to DynaTork

Wait

Socket Release

Tighten to Torque or Angle

Loosen to Angle

Loosen to Torque

Rundown

Tighten to Yield M2

Tighten to Yield

Tighten to Torque and Angle

Thread cutting to torque

Engage

Available Monitors

Angle

Peak Torque

Shut Off Torque

Torque rate and deviation

Torque in angle window

Post view torque high

Post view torque los

Angle from Yield

Prevailing Torque

Shut Off Current

Post Thread cut angle

Post Thread cut peak torque

Stick Slip Detection

Time

Available Step Restrictions

Maximum Torque

Maximum Angle

Cross Thread

Rescinding Torque

Torque Gradient

Torque in Angle View

Torque vs Current Deviation

Reject Management

When switch to Off:

Action if failure | Description |

End all |

|

Continue OK |

|

When switch to On:

Parameter | Description |

|---|---|

Max number of failing steps | Specifies the maximum number of different steps that can fail during the whole tightening. It does not matter if the same step fail more than once, it still only counts as one failing step. |

Action if exceeded | Specifies the action if Maximum number of failing steps is exceeded. |

Action if NOK during repair | Specifies the action if a new error (NOK) is detected while a repair is ongoing. |