Parameters for Four Step Tightening - Rundown Stage

The Rundown step is from thread engagement until the screw head reaches the snug level. During rundown; time, torque and angle are monitored. The target value for the step is when the Rundown complete torque level is reached.

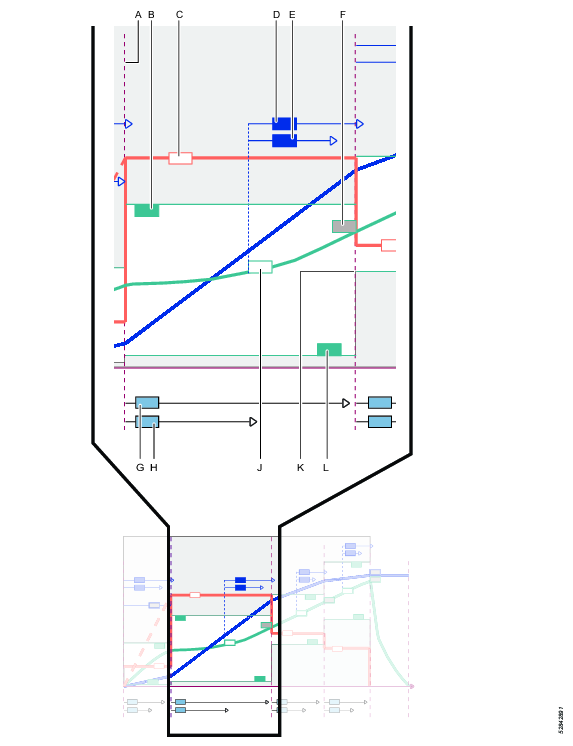

The graphical representation is used in the documentation to describe the configuration setting and the interpretation of the parameter values. The graphs are not used in any GUI.

A | Start of Rundown step |

B | Maximum torque level (monitor) |

C | Speed curve |

D | Minimum angle (monitor); Measured from Rundown angle monitoring torque |

E | Maximum angle (monitor); Measured from Rundown angle monitoring torque |

F | Rundown complete torque value |

G | Time max (monitor) |

H | Time min (monitor) |

J | Torque curve and Rundown angle monitoring torque reference point |

K | End of rundown step, when target value is reached |

L | Minimum torque level (monitor) |

Parameter | Description | Default value |

|---|---|---|

Rundown | Switch with On or Off position. If the switch is in the Off position, the step is not executed and all other parameters are invisible and are ignored. If both the start step and the rundown step are switched off, a final tightening can be performed as a separate task. | On |

Parameter | Description | Default value |

|---|---|---|

Rundown speed | If Max position, the speed is the set to full tool capability. If Manual position, the speed is set manually. | Max |

Rundown speed (parameter entry box) | This parameter entry box is only visible when Manual speed setting is selected. The spindle rotation speed during the step. | 690 rpm |

Torque min (monitor) | Minimum torque value during the step. | 0 Nm |

Torque max (monitor) | Maximum torque value during the step. | 6 Nm |

Rundown angle monitoring torque | A specified torque value. From this point in time the angle monitoring starts. | 0 Nm |

Angle min (monitor) | Minimum spindle rotation for the step. Measured from Rundown angle monitoring torque. | 100 degree |

Angle max (monitor) | Maximum spindle rotation for the step. Measured from Rundown angle monitoring torque. | 5000 degree |

Time min (monitor) | Minimum time for the step. Measured from the start of the step. | 10 ms |

Time max (monitor) | Maximum time for the step. Measured from the start of the step. | 5000 ms |

Rundown complete torque | Defines the target torque for the rundown step. End of step is defined at this point, when the target value is reached. | 5 Nm |