Before Connecting the Air Supply

It is strongly recommended that the pump is regulated in order to stall at the required tensioning pressure. This is achieved by adjustment of the air regulator valve.

Before connecting an air supply, it is important to check the following,

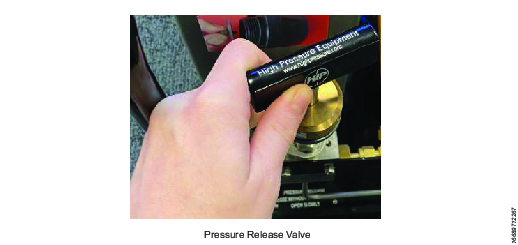

The pressure release valve is fully open (rotated fully anti-clockwise).

The On /Off valve is off (In the horizontal position). The On/OFF valve is by default closed until manually operated and held.

The oil Tank has sufficient oil (Grade ISO 10, 32, 68).

Check that the cap seal plug has been removed.

The oil tank on this pump unit is fitted with a cap seal plug to prevent oil spillage during transit. Remove the M6 cap screw and seal from tank cap prior to use.The oil tank on this pump unit is fitted with a cap seal plug to prevent oil spillage during transit. Remove the M6 cap screw and seal from tank cap prior to use.

In the event of the pump being used at sub-zero temperatures, add deicer additives to the oil to prevent the oil from freezing.

Setting pump stall pressure

Atlas Copco supply all pump units with the air pressure regulator set to stall the pump at its maximum working pressure. Connect the main air supply to the pump unit. Slowly activate the safety On/Off valve by holding the control down, the pump will begin to operate, no pressure can be generated because the pressure release valve is open, so the oil is simply circulated through the system back to the tank.

Before adjusting the pressure on the air filter/regulator, it is necessary for the ‘Snap Action Lock’ to be in the up position. By turning the adjustment knob anticlockwise on the regulator, reduce the air pressure to zero PSI, the pump will slow down considerably and may even stop.

Fully close the pressure release valve by rotating clockwise to stop. As this is done, a slight pressure will be generated on the pressure gauge and the pump will finally stall.

Slowly increase the air supply pressure by turning the adjustment knob clockwise, the oil pressure gauge will indicate a higher pressure as more and more air is allowed into the pump unit. Stop the air adjustment when the oil pressure gauge indicates the desired tensioning pressure.

Stop the pump by releasing the On/Off valve and release the pressure by slowly opening the pressure return valve, the pump gauge will fall to zero. Lock the air regulator by pushing down on to the ‘Snap Action Lock’.

Operate the pump again and allow it to stall, check the pressure and further adjust if necessary. When satisfied that the pump stall pressure is correct the pump unit is now ready for the tensioning operation.