Bolt Set-up

In order to apply an evenly distributed load to a subsea bolted joint, it is accepted that a 100% tensioner to bolt ratio is required. I.e if 8 bolts are on the flange to tension, 8 bolt tensioning tools are required. All bolts are simultaneously tensioned.

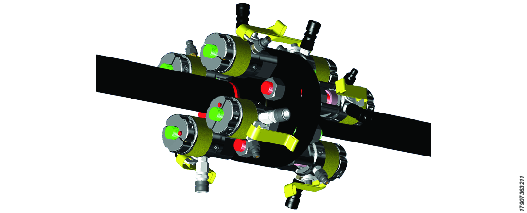

The correct bolt set up for a 8 bolt flange.

Examples:

6 bolt flange requires 6 bolt tensioning tools.

8 bolt flange requires 8 bolt tensioning tools.

Pay attention on how each bolt is set up with the long stud protrusion on every alternate bolt. The long stud protrusion side is the side where the bolt tensioning tool is fitted.

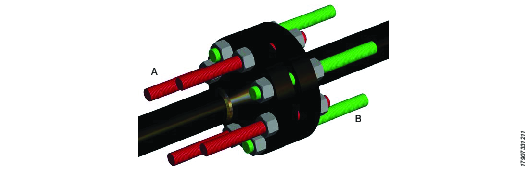

In this case, the 4 alternate red bolts will have tensioners fitted to the left side of the flange, and the 4 alternate green bolts will have tensioners fitted to the right hand side of the flange.

A | 4 Tensioning tools are fitted to the left side of the flange. | B | 4 Tensioning tools are fitted to the right side of the flange. |

Technical Specification

The technical specification of your particular bolt tensioning tools can be found hard stamped on the tensioner body.

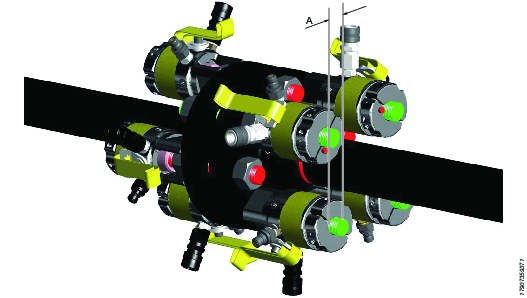

Bolt Set-up Procedure

Ensure the flanges are fully engaged and that the bolts and nuts are tightened. Assemble 50% of the bolt tensioning tools over the ‘long’ bolt extensions on one side of the flange.

Ensure at least three threads protrudes above the top face of the reaction nut after fitting.

A

At least three full threads should protrude from the reaction nut after fitting

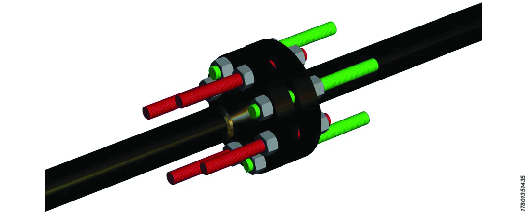

Ensure the flanges are fully pulled together and that the bolts and nuts are tightened down. Assemble the other 50% of the bolt tensioning tools over the ‘long’ bolt extensions on the other side of the flange.

Ensure at least three threads protrudes above the top face of the reaction nut after fitting.

A

At least three full threads should protrude from the reaction nut after fitting

Examine the circumference of the tensioner base to ensure it is sitting fully flat against the tensioning surface.