Tightening using the TensorPulse Program

The principle below is applicable for direct driven electrical tool. It is applicable to the Atlas Copco SRB series of tools.

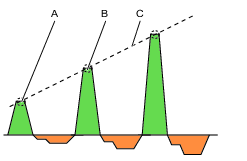

After each pulse period the resulting torque in the screw is increased. After a series of pulses, the final torque target is reached.

A | Maximum positive energy in pulse N |

B | Maximum positive energy in pulse N+1 |

C | Increase in energy (torque) |

The energy level in the action phase and reaction phase are user configurable parameters. The combination of these two parameters creates an efficient tightening combined with operator comfort. It is possible to set the amount of energy in the two phases as a percentage of the maximum energy that can be delivered in each period:

Pulse energy; The amount of energy that is applied to each positive pulse as a percentage of the maximum energy that can be applied in the pulse period. The value is between 10-100%.

Reaction force retention factor; The amount of energy that is applied to each reactive pulse as a percentage of the maximum energy that can be applied in the pulse period. The value is between 0-75%.

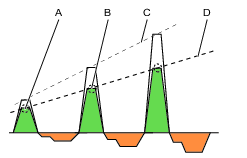

A | Reduced positive energy in pulse N |

B | Reduced positive energy in pulse N+1 |

C | Resulting curve for torque build up using maximum pulse energy. |

D | Resulting curve for torque build up using reduced pulse energy. |

A small Pulse energy (reduced energy) requires more pulses to reach the target torque as the torque is increased in smaller steps. Smaller steps provides better accuracy to terminate the tightening when the target is reached. Smaller pulses decrease tool movement and increases operator comfort.

A correctly tuned Reaction force retention factor will create the desired operator comfort. If the factor is too high the operator feels a clockwise rotation of the tool. If the factor is too low, the operator feels a counter clockwise rotation of the tool.

In an ideal configuration, the reaction energy does not create any loosening force. If the amount of pulses to reach the target value increases, the value is set too high and a small loosening occurs at each pulse.

The optimum values for the Pulse energy and the Reaction force retention factor need to be tuned for optimum performance of the tool and for best operator comfort.